Mine-used large-range fiber grating passive roof bed separation sensor

A fiber grating and passive top plate technology, applied in the direction of optical devices, instruments, measuring devices, etc., can solve the problems of poor data transmission capability, poor anti-interference ability, mine safety monitoring is not in place, etc., to achieve large range and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] A mine-used large-range optical fiber grating passive roof separation sensor includes a shell, a wire rope roller mechanism, and an optical fiber grating strain mechanism.

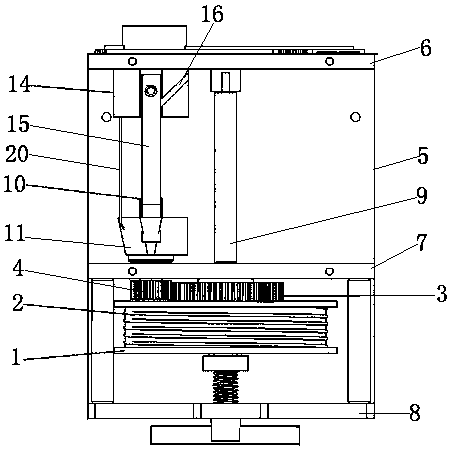

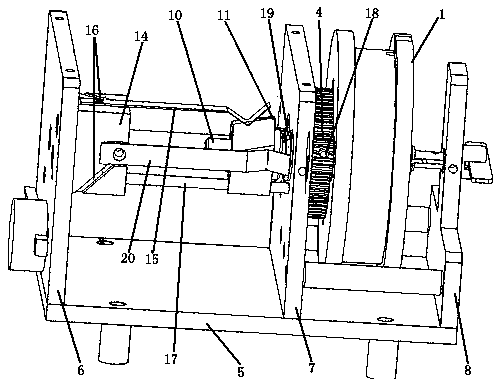

[0030] refer to figure 1 and figure 2 , the housing 5 of the sensor body includes three support frames, a front bearing support frame 6, an intermediate bearing support frame 7, and a rear bearing support frame 8, which are mainly used to fix the internal structure of the sensor.

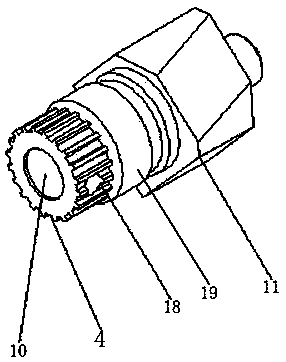

[0031] The wire rope roller mechanism includes a first gear 3, and the fiber grating strain mechanism includes a second gear 4, a precision lead screw 10 that is fixed at one end to the second gear and rotates with the second gear; an inclined-plane slide block 11 is provided with an inclined plane, and the inclined-plane slide block 11 is set on the precision screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com