Methane sensor based on single heating element, preparation method and application

A methane sensor and heating element technology, applied in the direction of material resistance, can solve the problems of high price, short calibration time and poisoning of infrared methane sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

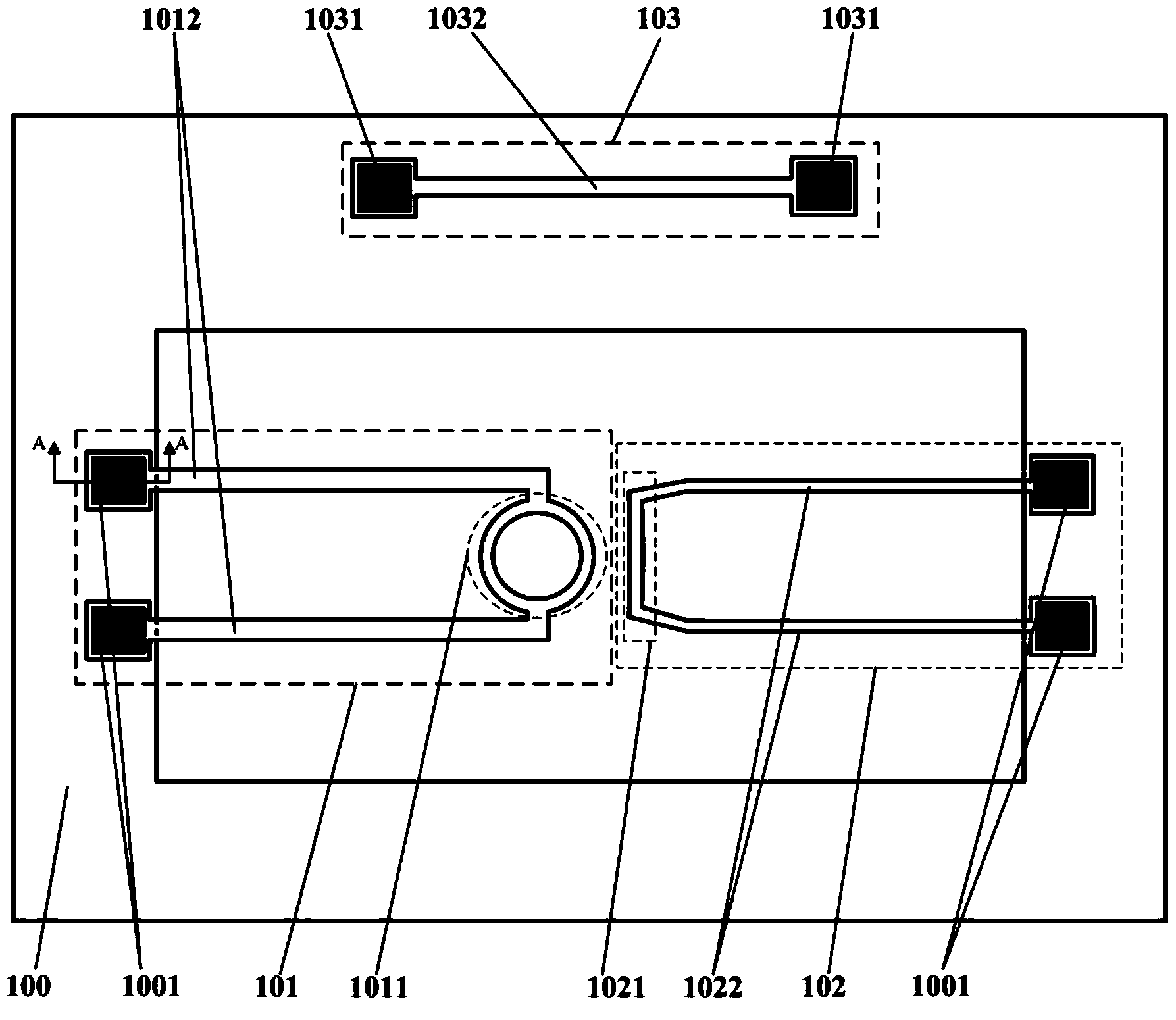

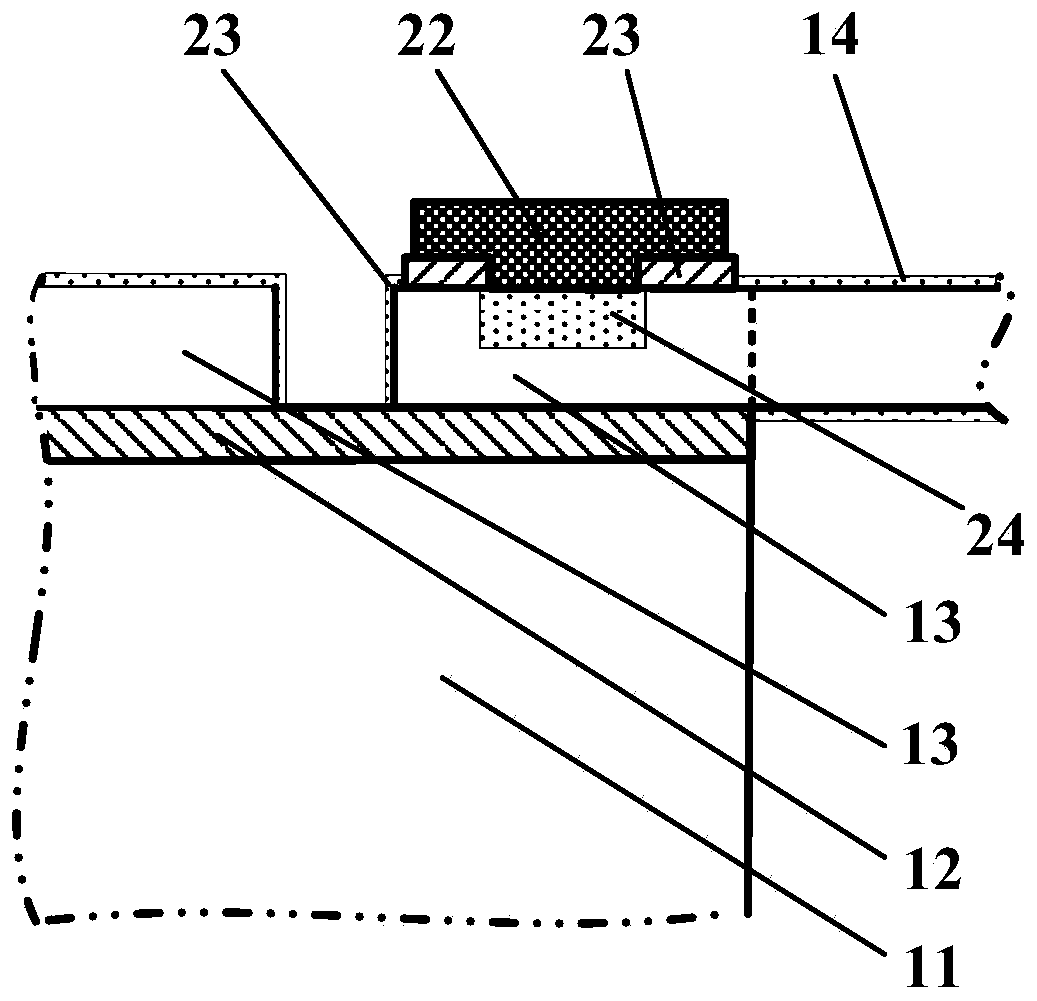

[0065] Example 1: As in figure 1 , figure 2 Among them, the methane sensor includes a heating element 101, a measuring element 102 and an ambient temperature measuring element 103; the ambient temperature measuring element 103 is arranged on the support 100;

[0066] The heating element 101 is composed of two fixed ends 1001, two side-by-side support arms A1012 and a heater 1011, and the two ends of the two support arms A1012 are respectively connected with the fixed ends 1001 and the heater 1011 to form a two-terminal device The length of each support arm A1012 is at least 300um; the measurement element 102 is composed of two fixed ends 1001, a measurement member 1021 and two support arms B1022, and the two support arms B1022 are respectively connected to the two ends of the measurement member 1021 connection, the other ends of the two support arms B1022 are respectively connected to the two fixed ends 1001 to form a two-terminal device; the length of each support cantileve...

Embodiment 2

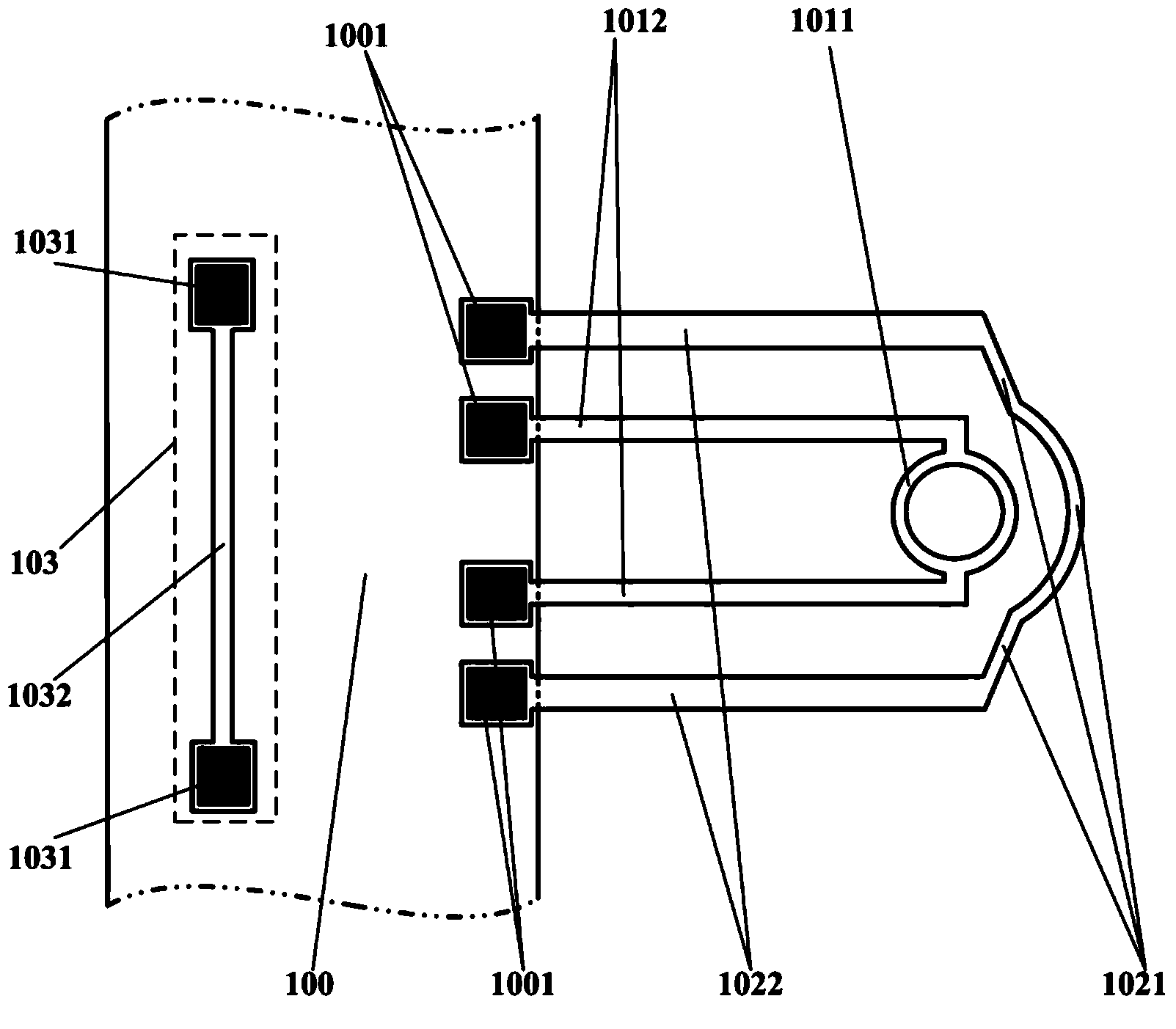

[0109] Embodiment 2: The heating element 101 and the measuring element 102 of the methane sensor based on a single heating element are arranged on the same side, such as image 3 shown. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com