Laser-oriented control system and method for shield machine

A technology of steering control and shield machine, applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of construction efficiency, construction progress and construction quality, no automatic deviation correction, etc., to save engineering costs, improve The effect of automation and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

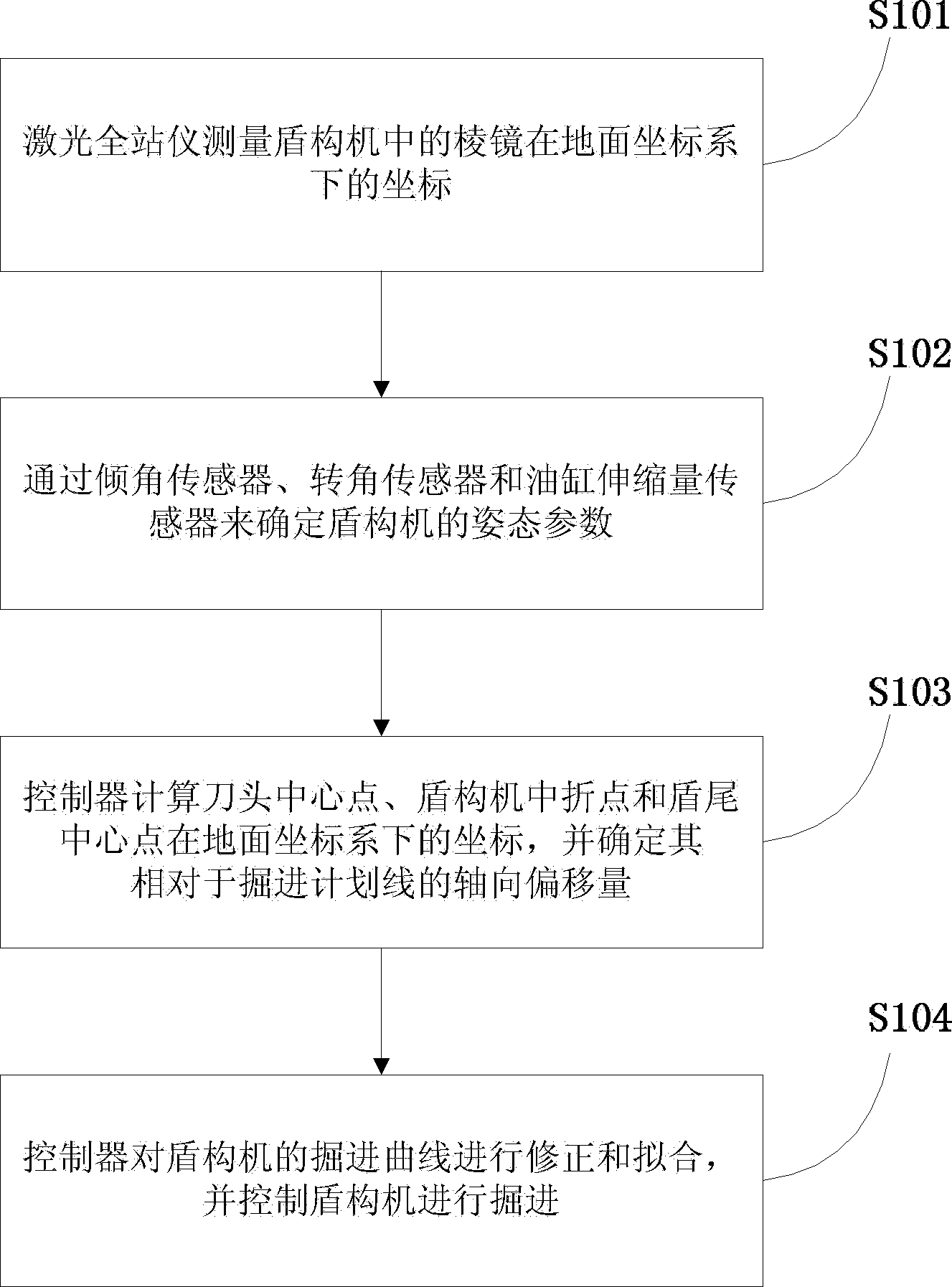

[0036] figure 1 A schematic flow chart of the shield machine laser guidance control method provided for the specific implementation of the present invention, as shown in figure 1 As shown, the process mainly includes the following steps:

[0037] In step S101, the laser total station measures the coordinates of the prism in the shield machine in the ground coordinate system. Although multiple prisms are set in the shield machine, only the coordinates of one prism need to be calculated. The purpose of setting multiple prisms in the shield machine is that the laser total station may not be able to obtain the positions of some prisms during the excavation process of the shield machine.

[0038] The laser total station is installed in the established construction tunnel, and the installation position of the prism in the shield machine is fixed. Before starting the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com