Clamp ring type torque sensor

A torque sensor and clamp ring technology, applied in the field of fast-installed torque sensors, can solve the problems of large measurement error, long waiting time for shutdown, poor stability, etc., achieve measurement accuracy and stability assurance, improve reliability, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

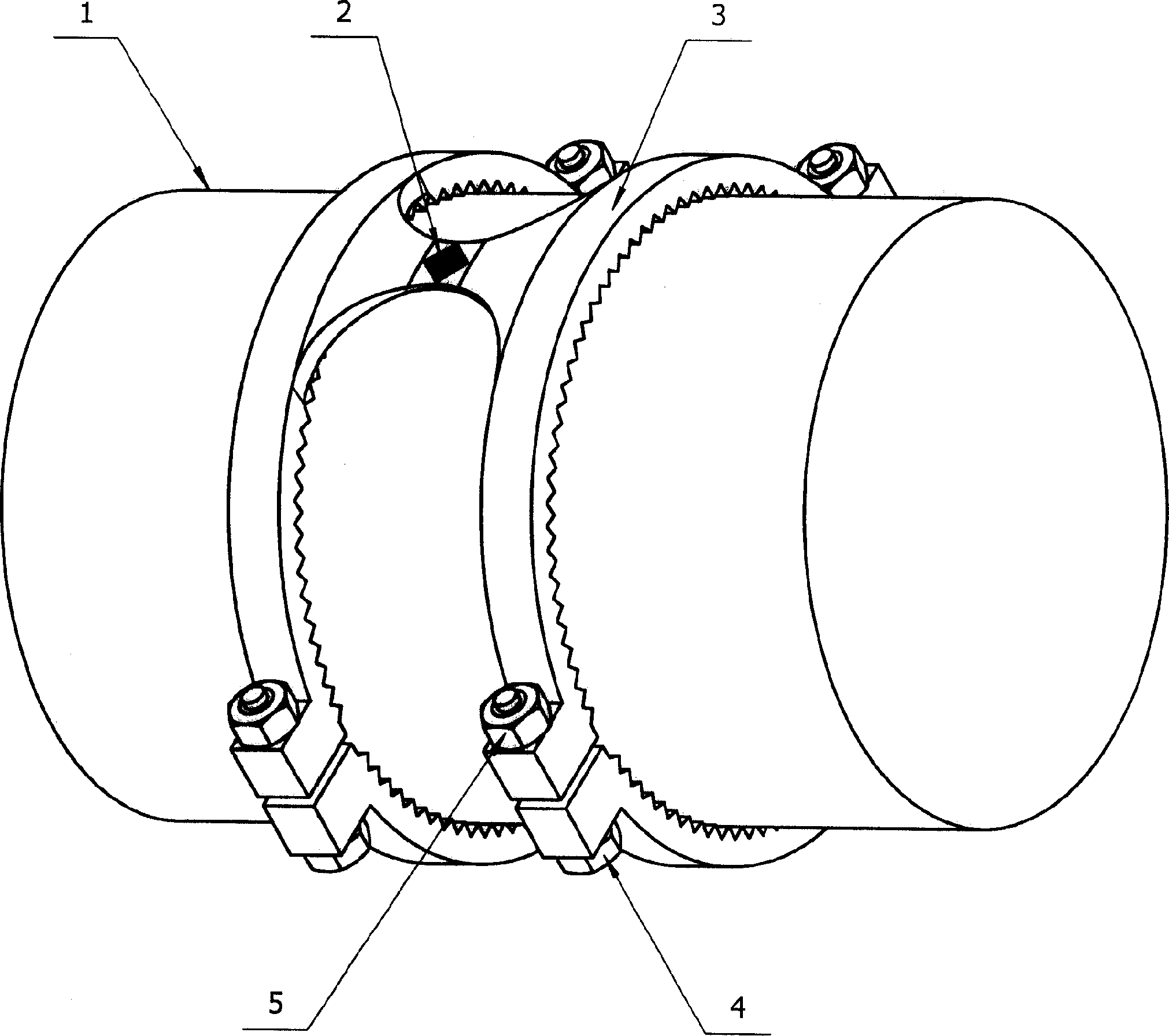

[0009] In the laboratory environment, the resistance strain gauge (2) is pasted on the elastic body (3) of the clamp ring torque sensor, and the necessary bridging, compensation, protection and calibration are carried out to make the clamp ring torque sensor; (4), the nut (5) clamps the clamp ring type torque sensor on the transmission shaft (1), and exerts a clamping force as large as possible. In order to prevent the bolts and nuts from loosening during long-term use, the nut (5) adopts anti- Loose nuts, which can be welded firmly with the bolts if necessary; the sharp-toothed contact surfaces at both ends of the sensor, under the action of clamping force, "mesh" with the surface of the drive shaft. When a torque acts on the drive shaft, the torque makes the sensor The cross-section of the transmission shaft corresponding to both ends produces a relative torsion angle, and the "meshing" surface of the transmission shaft / sensor transmits this relative torsion angle to the sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com