Metal rotor flowmeter with rectification function

A technology of metal rotor and flowmeter, which is applied in volume/mass flow generated by mechanical effects, volume measurement, liquid/fluid solid measurement, etc., and can solve the influence of measurement stability, impact bending of lower stop, length of rib force arm, etc. problems, to achieve the effect of improving measurement stability, reliability, and small rotation fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

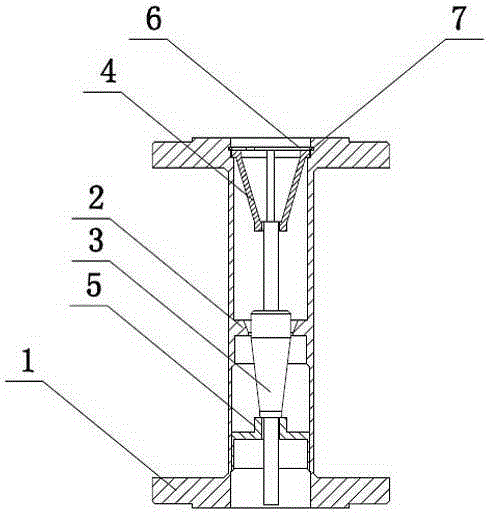

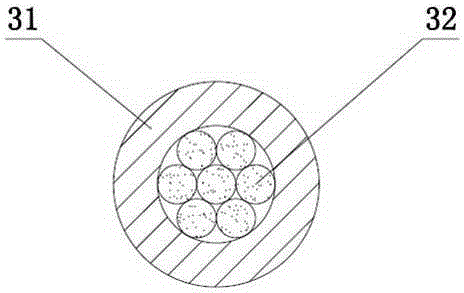

[0031] Embodiment 1: as figure 1 and figure 2 As shown, a metal rotameter with rectification function includes a pipe body 1, a rotor sleeve 2, a rotor 3, an upper stop 4 and a lower stop 5, wherein the rotor sleeve is an orifice. The rotor 3 is installed in the rotor sleeve 2, the rotor sleeve 2 is installed in the pipe body 1, the upper stop 4 and the lower stop 5 are respectively arranged at the upper port and the lower port of the pipe body, and the lower stop 5 is connected with the pipe body 1. Integral structure (it can be welded or integrally cast, inseparable), the upper stop 4 and the pipe body 1 are split structures (the two are independent parts, detachable), the upper stop 4 can be separated by a circlip 6 It is disassembled and installed in the tube body 1, and the inner edge of the tube body 1 is provided with a groove 7 that allows the snap spring 6 to snap in.

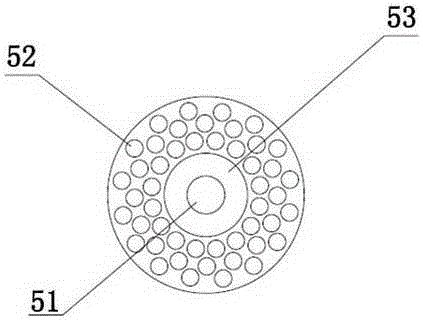

[0032] The center of the lower stopper 5 is provided with a guide hole 51 that allows the rotor ...

Embodiment 2

[0034] Embodiment 2: The rotor sleeve is a tapered tube. All the other are with embodiment 1.

[0035] Practical: When the fluid passes through the throttling parts in the pipeline (such as elbows, valves, and reducing pipes), the unstable flow field passes through the bottom stop from bottom to top, and the fluid passes through evenly distributed holes for rectification. Outflow, the larger foreign matter is blocked under the lower stop, and the rectified fluid impacts the metal rotor again, and generates a force on the metal rotor (the magnitude of this force varies with the flow rate); when the flow rate is large enough, The resulting force lifts the rotor up and raises it. When the rotor is in a balanced state, it stays at a certain height.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com