Refractive displacement sensor and measuring method thereof

A technology of displacement sensor and refracting mirror, which is applied in the field of measurement, can solve the problems of sensor magnification influence, PSD measurement accuracy decline, etc., and achieve the effect of increasing magnification, reducing requirements, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

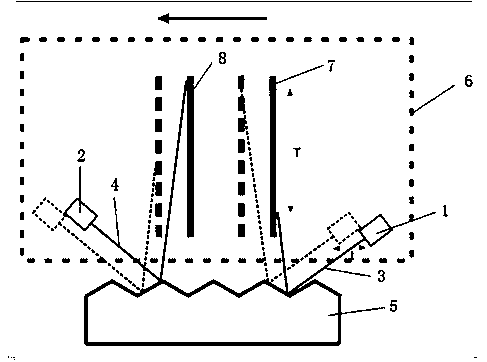

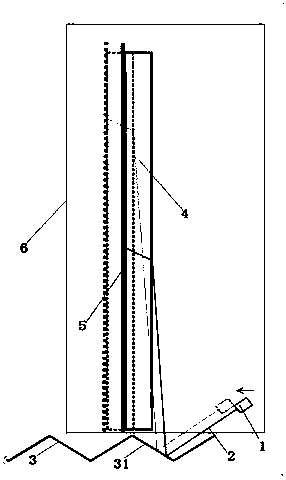

[0035] see figure 2 In this embodiment, a refraction displacement sensor is provided, including a laser source 1, a laser beam 2, a triangular wave reflector 3, and the triangular wave reflector 3 includes a reflective surface 31, a refractor 4, a photodetector 5, and a housing 6 .

[0036] In this refraction displacement sensor:

[0037] The laser source 1 emits the laser beam 2, and makes the laser beam 2 shoot to the reflective surface 31 of the triangular wave reflector 3; the refractor 4 is used to receive the laser beam 2 reflected by the first reflective surface 31 of the triangular wave reflector 3, and The laser beam is refracted; the photodetector 5 is used to receive the laser beam refracted by the refracting mirror 4 and measure its incident position; the processing system is used to change the incident position of the laser beam 2 received by the photodetector 5 Calculate the displacement change value of the measured object.

[0038] Such as figure 2 As show...

Embodiment 2

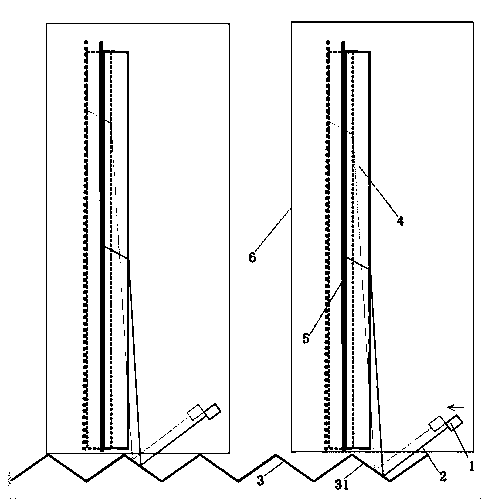

[0054] can refer to image 3 Compared with the refraction displacement sensor described in Embodiment 1, the refraction displacement sensor in this embodiment differs in that: the refraction displacement sensor provided in this embodiment includes two reading heads, and the structure of the two reading heads consistent, and the positional relationship between the two reading heads satisfies: during the measurement process, at least one reading head can read the incident position variation of the laser beam on the photodetector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com