Device for releasing pellets in liquid viscosity coefficient experiment

A viscosity coefficient, liquid technology, applied in the application field of AC electromagnet, can solve problems such as large error and inconvenient operation, and achieve the effect of simplifying operation, reducing experimental error, and increasing experimental success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment.

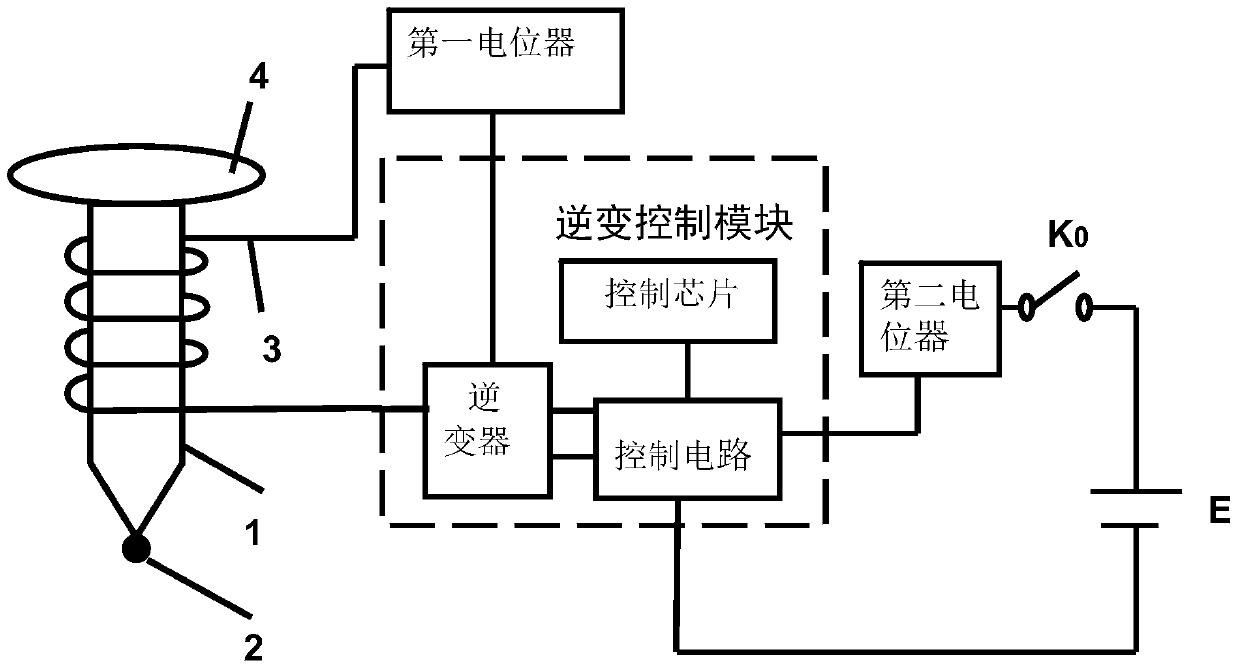

[0021] A device for releasing pellets in liquid viscosity experiments, such as figure 1 As shown, it includes a metal core 1, a small steel ball 2, a metal coil 3, a hanging plate 4, an inverter control module, a first potentiometer, a second potentiometer, a switch K0, and a DC power supply E; wherein the inverter control module includes an inverter Inverter, control chip and control circuit.

[0022] The metal core 1 is arranged vertically, and its lower end has a tip for the adsorption of small steel balls. The small steel ball 2 is adsorbed on the tip of the metal core 1. The upper end of the metal core 1 is provided with a hanging plate 4, wherein the metal core 1 is in the shape of a sword or Conical shape; the metal coil 3 is wound on the outside of the metal core, and the number of turns of the metal coil 3 is 20-50; the metal core and the metal coil form a magnetic force ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com