Feeding mechanism of biomass combustion furnace

A biomass combustion furnace and feeder technology, which is applied in the combustion method, combustion equipment, fuel supply and other directions, can solve the problems of hidden danger of silo combustion and blockage of biomass fuel, so as to ensure safe use, simple structure, and increased use. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

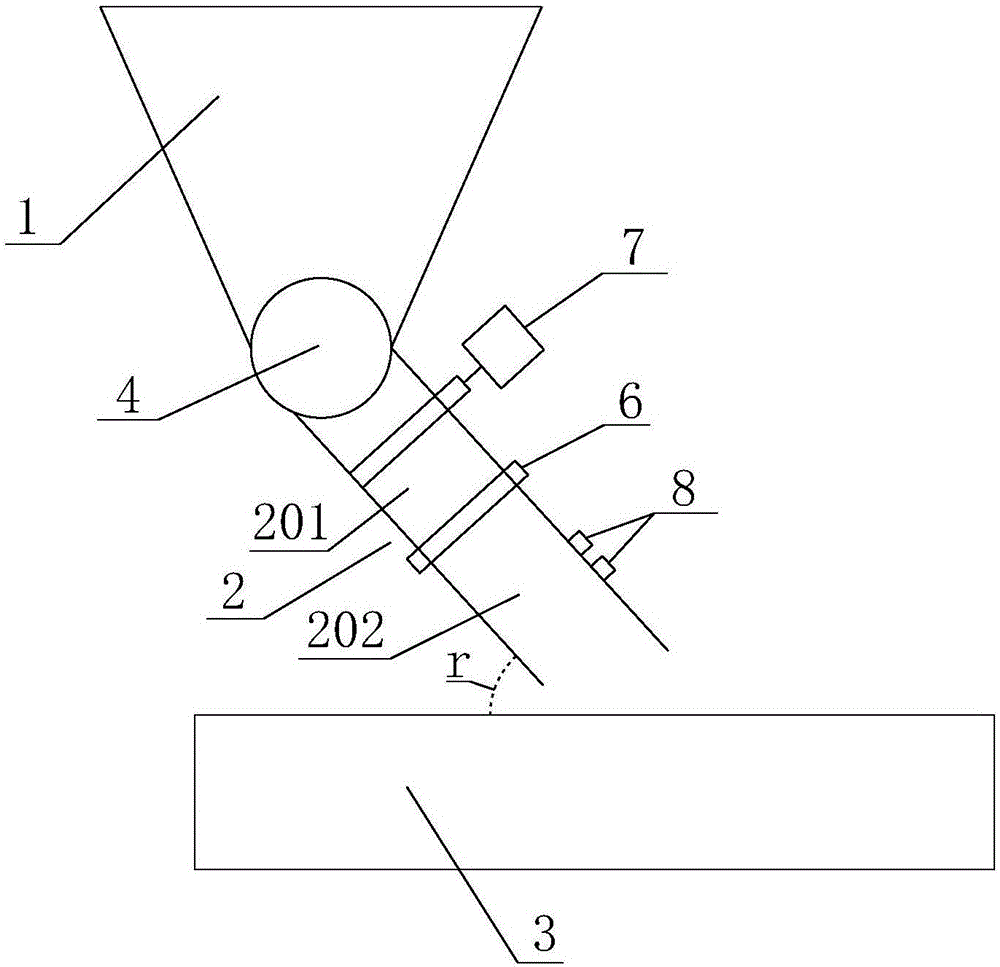

[0015] Such as Figure 1 to Figure 2 As shown, a biomass combustion furnace feeding mechanism provided by the present invention is suitable for use in a biomass combustion furnace, and the biomass combustion furnace is also called a biomass boiler. The feeding mechanism of the biomass burning furnace includes a feed bin 1, a feed channel 2 and a chain grate 3, and the biomass fuel in the feed bin 1 is discharged onto the chain grate 3 through the feed channel 2, and the chain grate 3 The biomass fuel is fed into the furnace for full combustion.

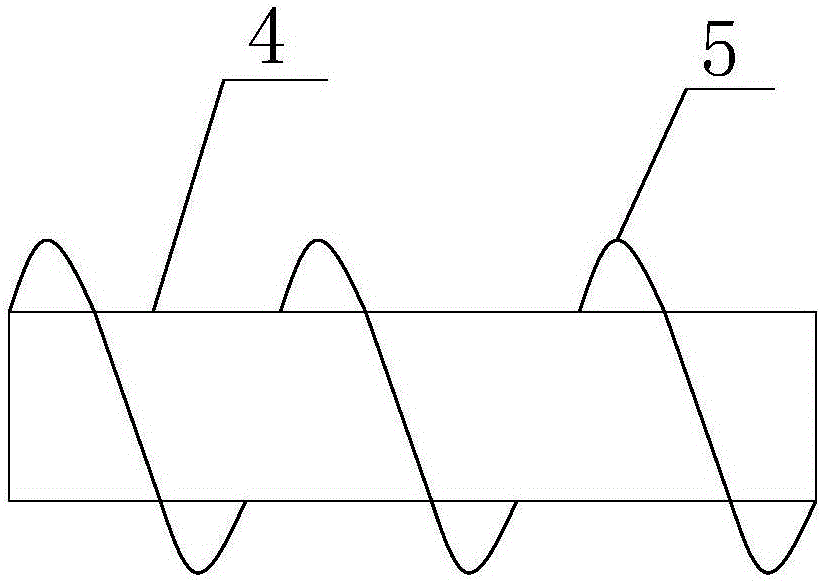

[0016] A feeding drum 4 is arranged between the silo 1 and the feeding passage 2, and the feeding drum 4 is driven to rotate by a feeder, and the feeder is not shown in the figure, and the feeder is preferably The forward and reverse frequency conversion motor is adopted, that is, the rotation of the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com