A kind of dynamic drying equipment for powdery plastic particles

A technology of plastic particles and drying equipment, which is applied in the direction of non-progressive dryers, drying solid materials, drying chambers/containers, etc., can solve the problems of low drying efficiency and drying uniformity, and achieve improved drying uniformity and improved drying efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

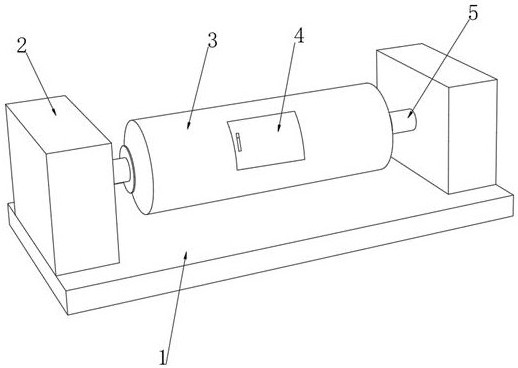

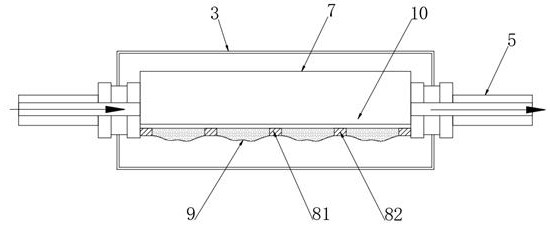

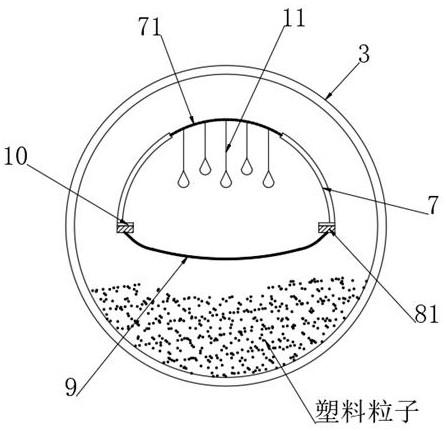

[0041] see figure 1 , a dynamic drying equipment for powder-topping plastic particles, comprising a bottom plate 1, air boxes 2 are fixedly connected to the left and right ends of the bottom plate 1, a blower is installed in one air box 2, and an exhaust fan is connected in the other air box 2, and The air box 2 equipped with a blower communicates with the external hot air source, and the other air box 2 has an air outlet. Through the blower and exhaust fan, the circulation of the hot air in the outer drum 3 is effectively realized, so that the outer drum 3 is taken away in time The water vapor separated from the plastic particles by heating inside makes the drying effect better. The ends of the two air boxes 2 close to each other are fixedly connected with the rotating shaft 5. The rotating shaft 5 is a hollow structure, and the rotating shaft 5 communicates with the air box 2 and the outer drum 3. , and the inner wall of the end of the rotating shaft 5 located in the outer r...

Embodiment 2

[0047] see Figure 9 , the powder-passing layer 71 is a high-toughness structure provided with a plurality of parallel strip-shaped holes. The moving rod 11 is constantly subjected to downward attraction at intervals, and the distances between the plurality of longitudinal moving rods 11 and the traction rod 82 are different, so that the force is different, so that the left and right long edges of the strip-shaped hole are vertically aligned. Offset from each other to make the gap larger and further ensure the falling of plastic particles.

[0048] This embodiment remains the same as that of Embodiment 1 except that the over-powder layer 71 is different from Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com