Solid mineral sample preparation system

A sample preparation system and mineral technology, applied in sampling devices, grain processing, etc., can solve the problems of uniform, continuous, stable transportation of difficult materials, insufficient representative samples, etc., to reduce labor intensity, ensure continuity and stability , Improve the effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

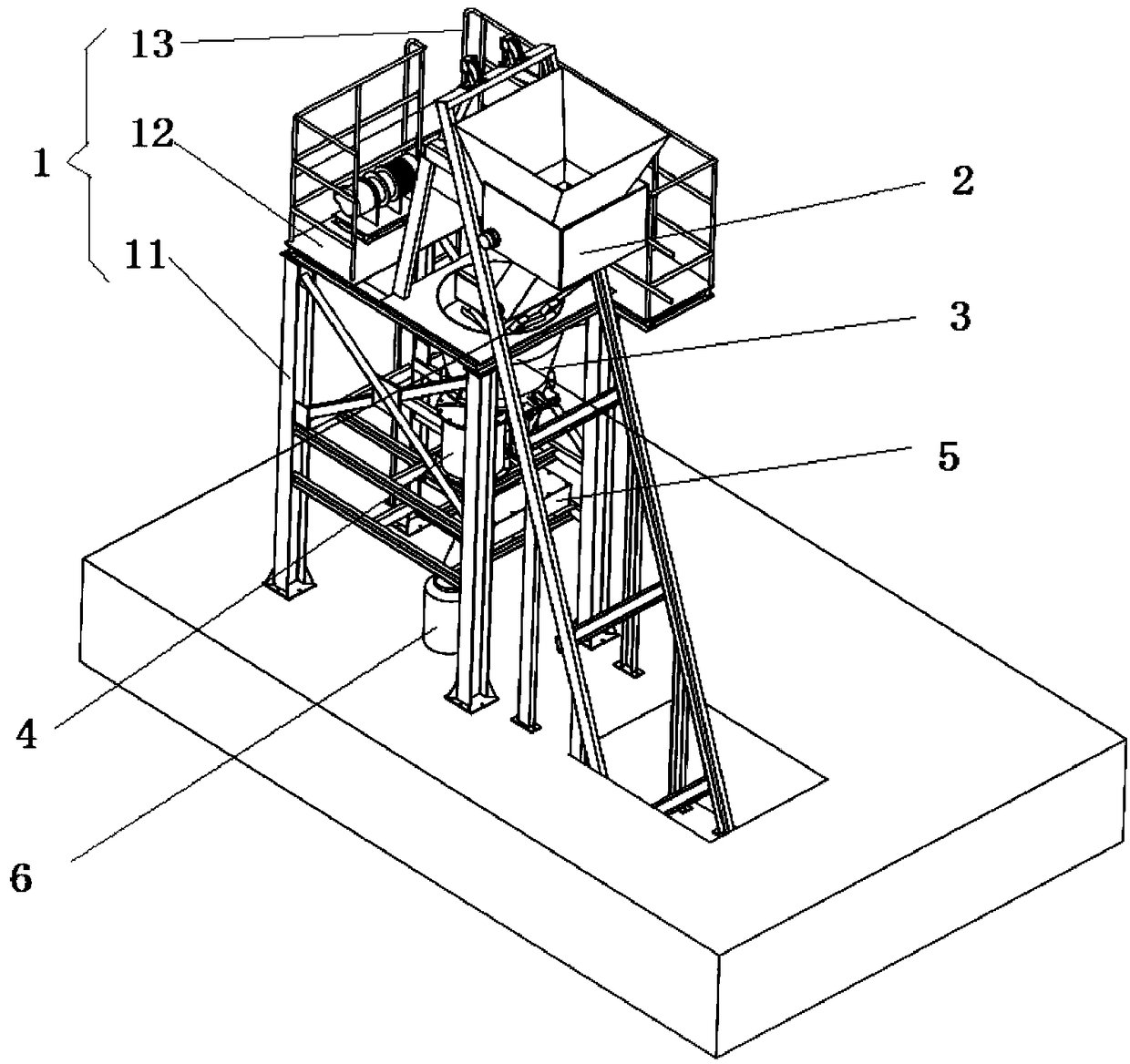

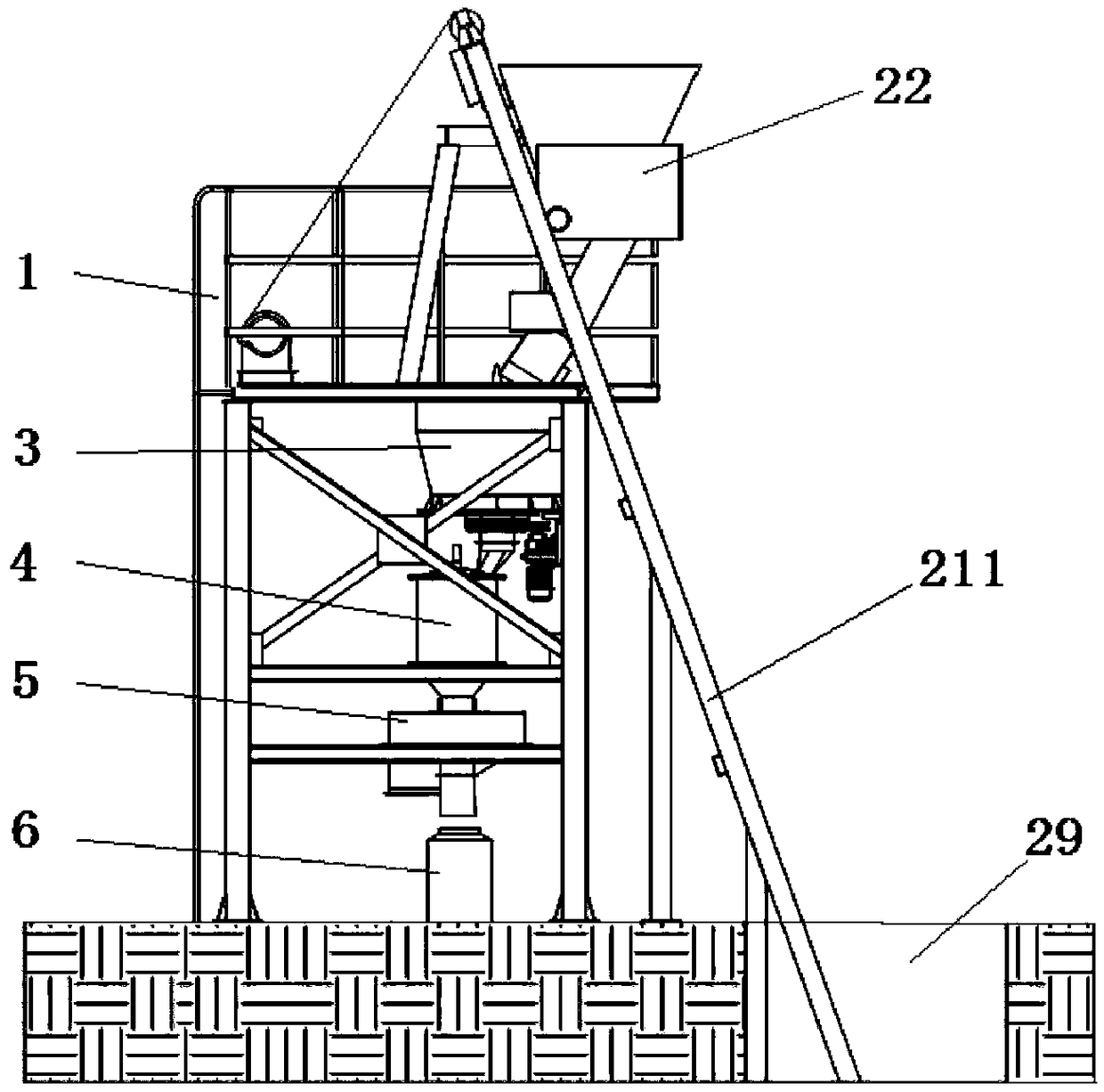

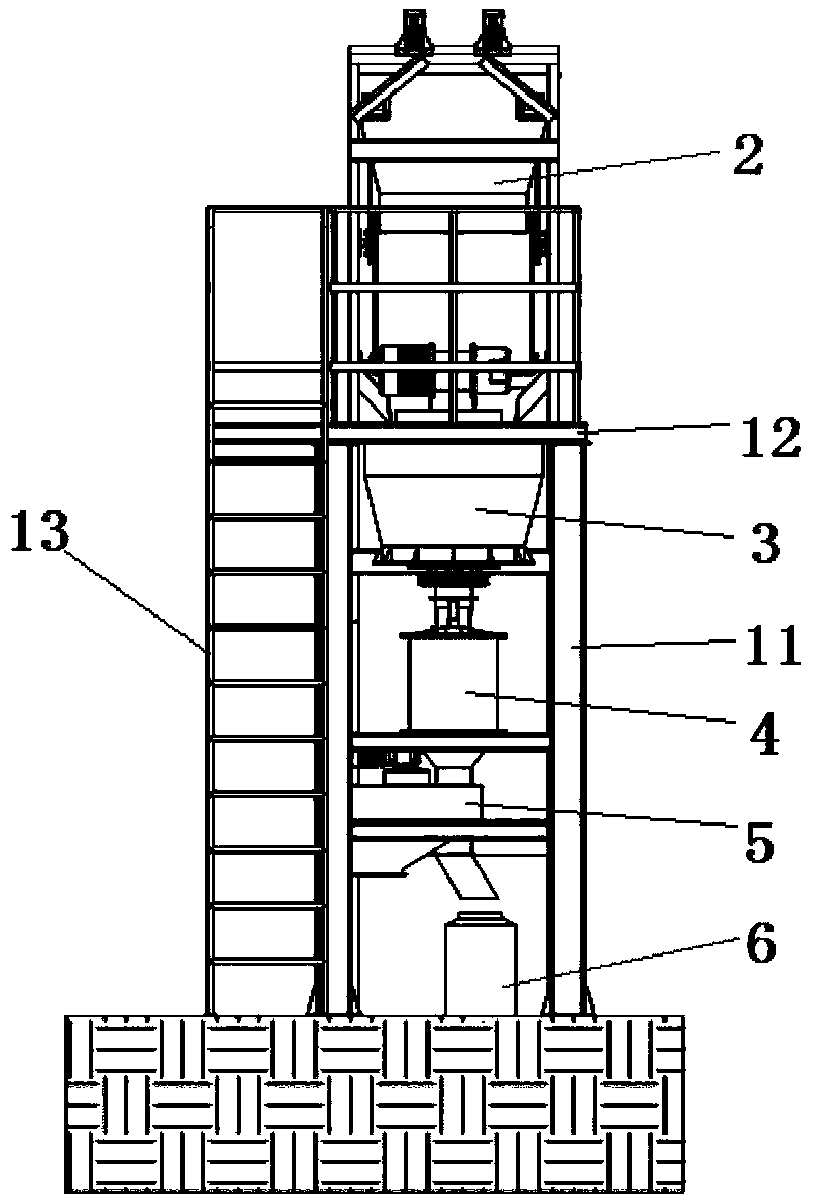

[0073] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a solid mineral sample preparation system, the solid mineral sample preparation system includes a lifting platform 1, a feeding device 2, a feeder 3, a crusher 4, a fixed mass reduction machine 5 and a collection device 6 , the feeder 3, the crusher 4, the constant mass reduction machine 5 and the collection device 6 are arranged vertically from top to bottom, and the feeding device 2 is located on one side of the lifting platform 1 and connected with the lifting platform 1, The feeder 3 is installed on the lifting platform 1, the feeding device 2 can transport the material to the feeder 3, the feeder 3, the crusher 4, the constant mass reduction machine 5 and the collecting device 6 are connected in sequence, and the feeding The machine 3 can evenly and continuously transport the material to the crusher 4. The crusher 4 is used to break the large particle material into small particle material. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com