Winding-proof cloth-baffle device for flat knitting machine

A flat knitting machine and anti-rolling technology, which is applied in weft knitting, knitting, textiles and papermaking, etc. It can solve the problems of the transmission mechanism being stuck and affecting the normal operation of the flat knitting machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

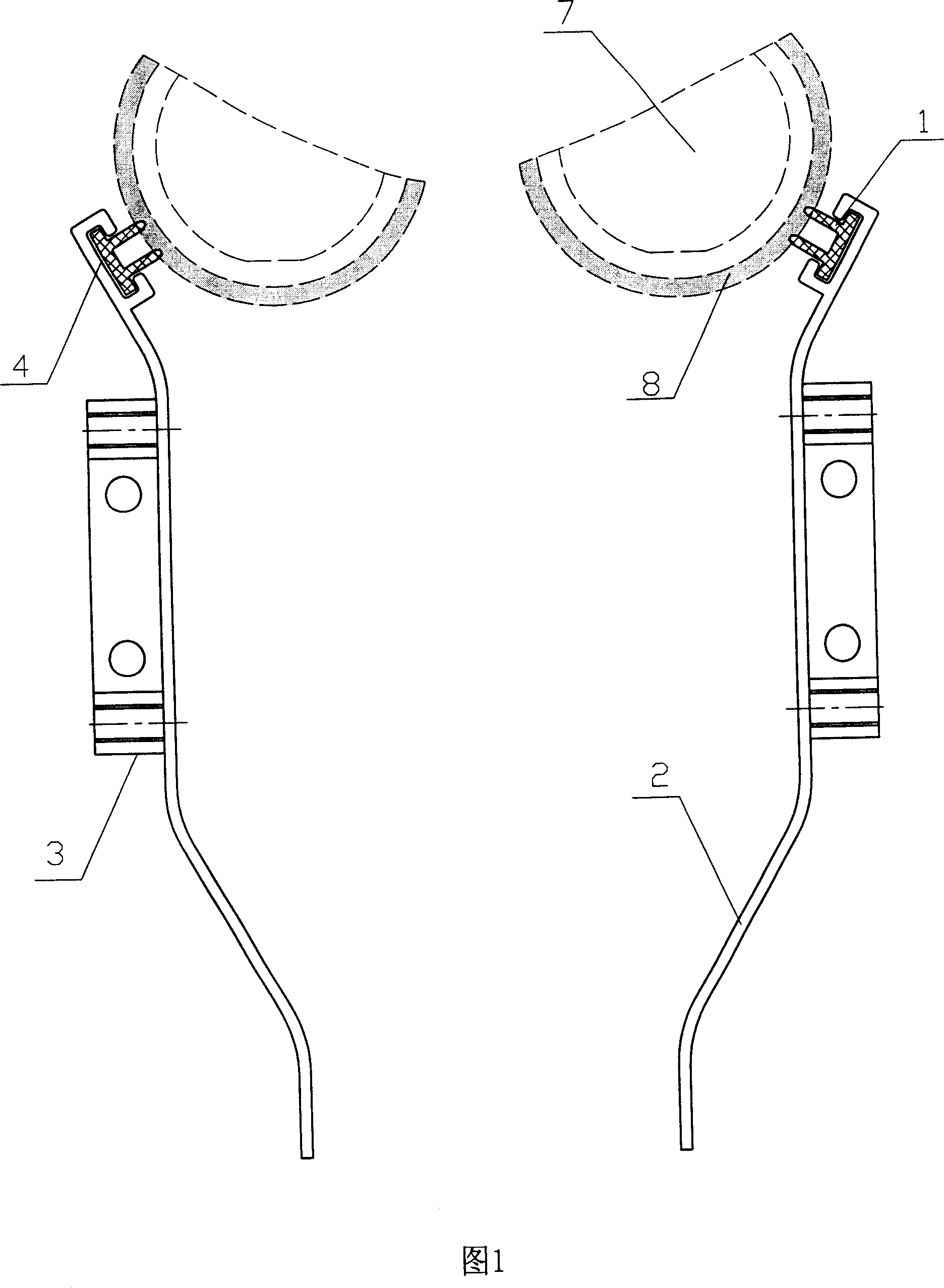

[0015] With reference to Fig. 1, the two baffle plates 2 are placed symmetrically on the lower side of the large roller 7. Its middle outer surface is connected with a mounting block 10, its upper side is bent outwards and upwards, and a slot 4 is provided on the inner side of the upper end of the bent part, and the rubber strip 1 is inserted into the slot.

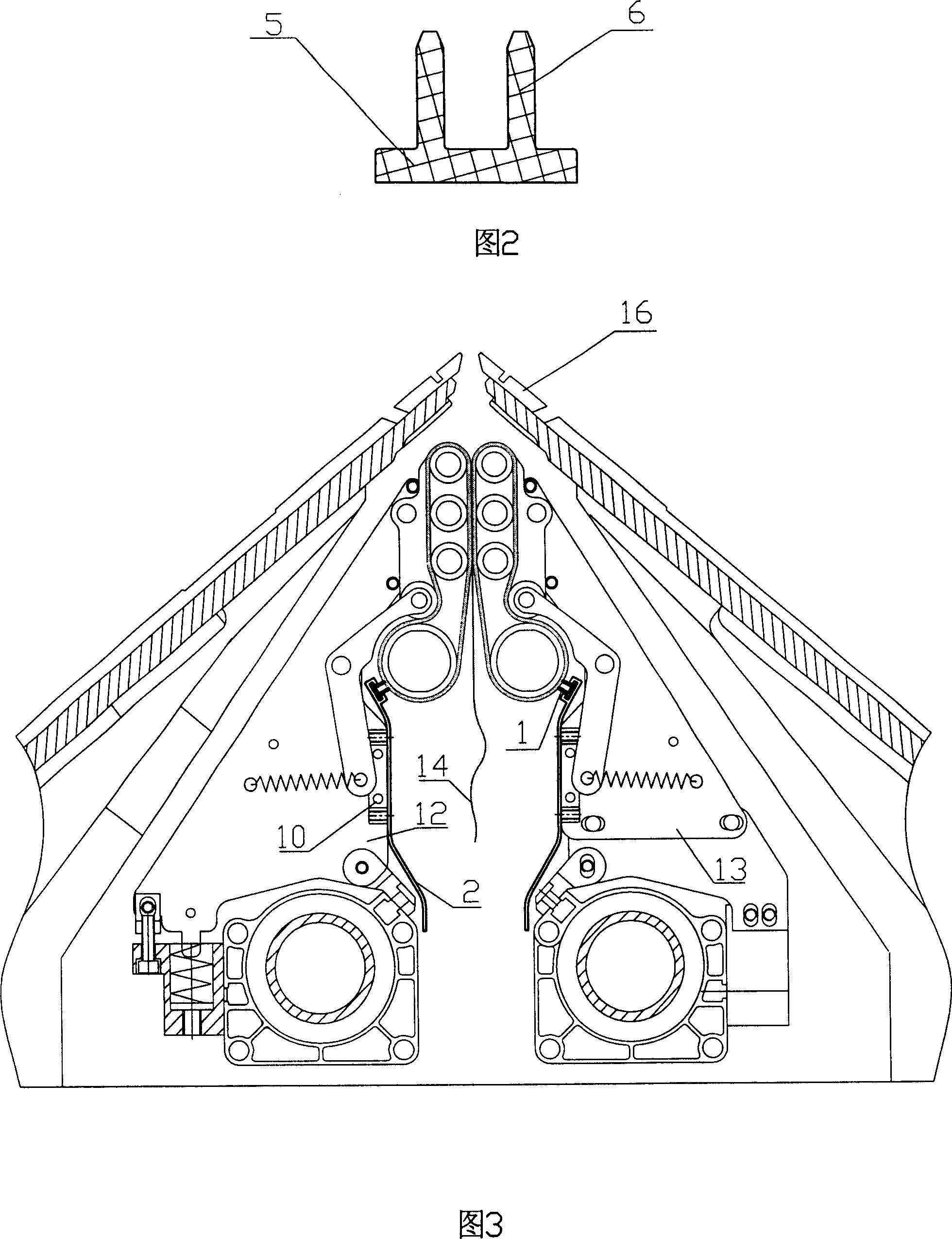

[0016] Please refer to Figure 2 for the structure of the rubber strip 1. It consists of a base 5 and a contact part 6. The contact part 6 is vertically connected to the base 5. Its cross section is π-shaped. Figure 2 just reflects the shape of the cross section of the rubber strip 1. structure.

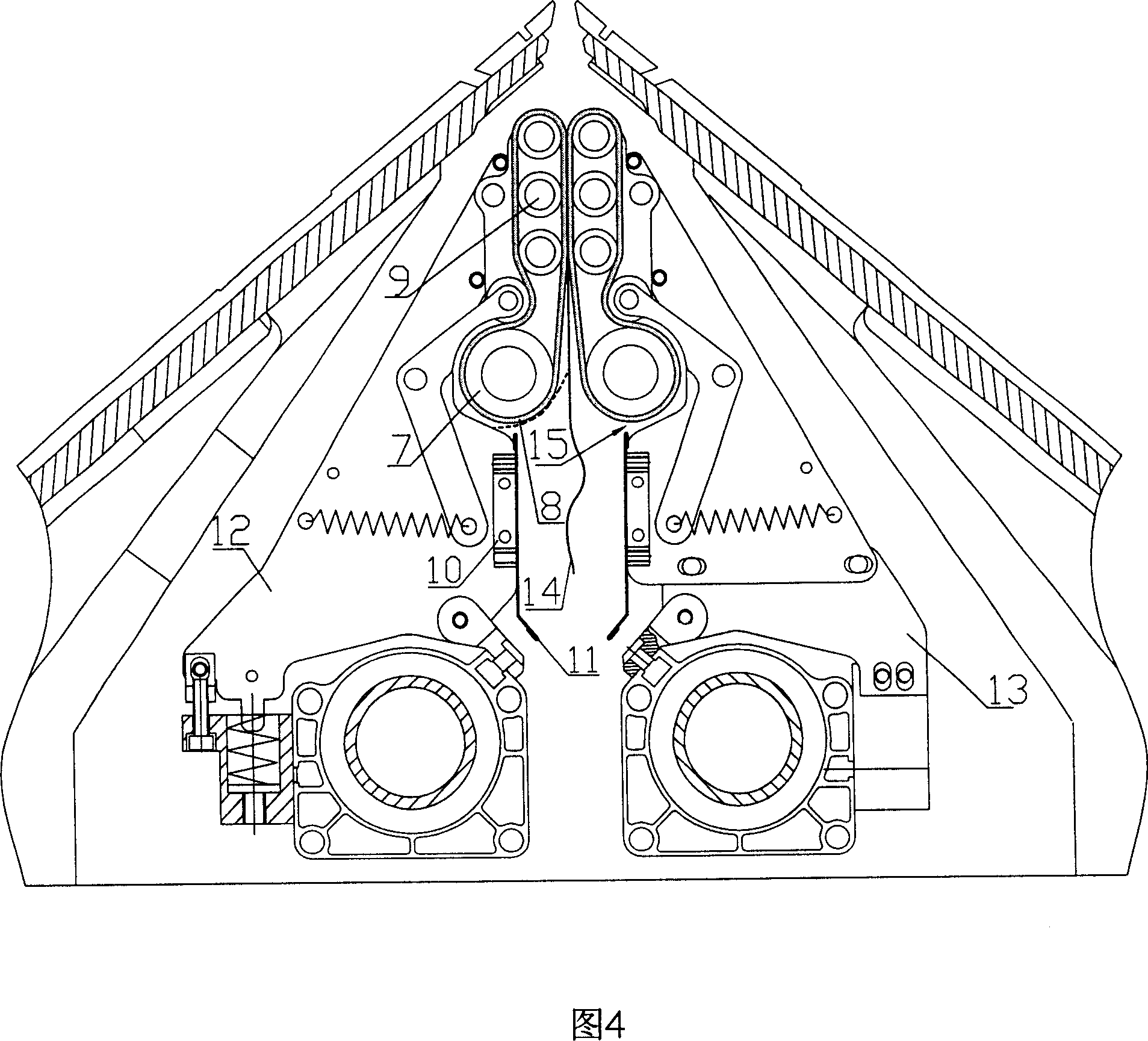

[0017] With reference to Fig. 3, the device of the present invention is installed on the lower side of the coiling device, which is the prior patent application of the applicant of this case (the applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com