Preparation method of circular-section steel wire ring for radial tire

A technology for radial tires and circular cross-sections, which is applied in the field of preparation of circular cross-section bead rings for radial tires. It can solve the problems of large radial deformation, large bead ring stress, and easy damage, and achieve stable circular cross-section shape and uniform spacing. , tightly wound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings:

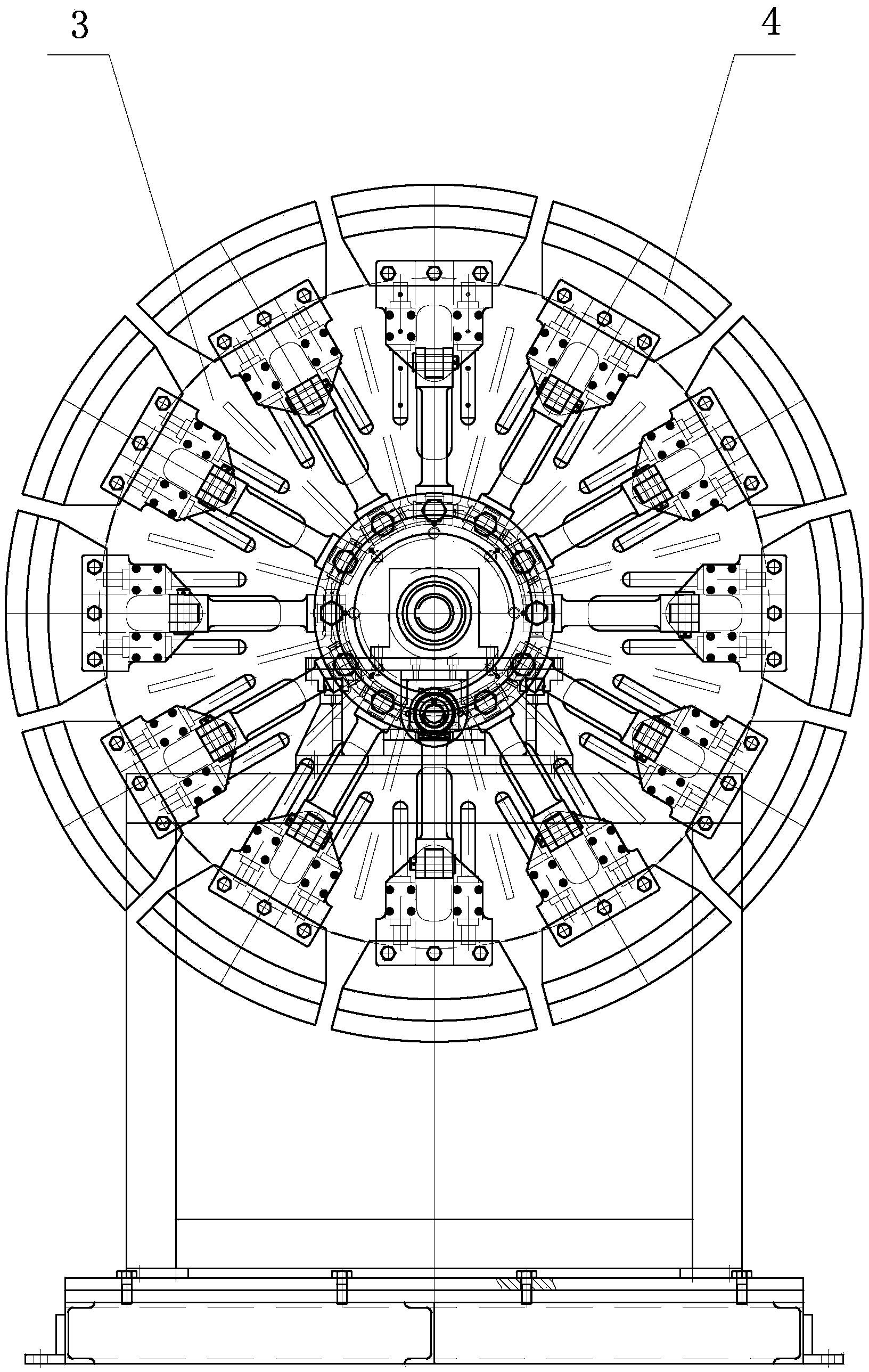

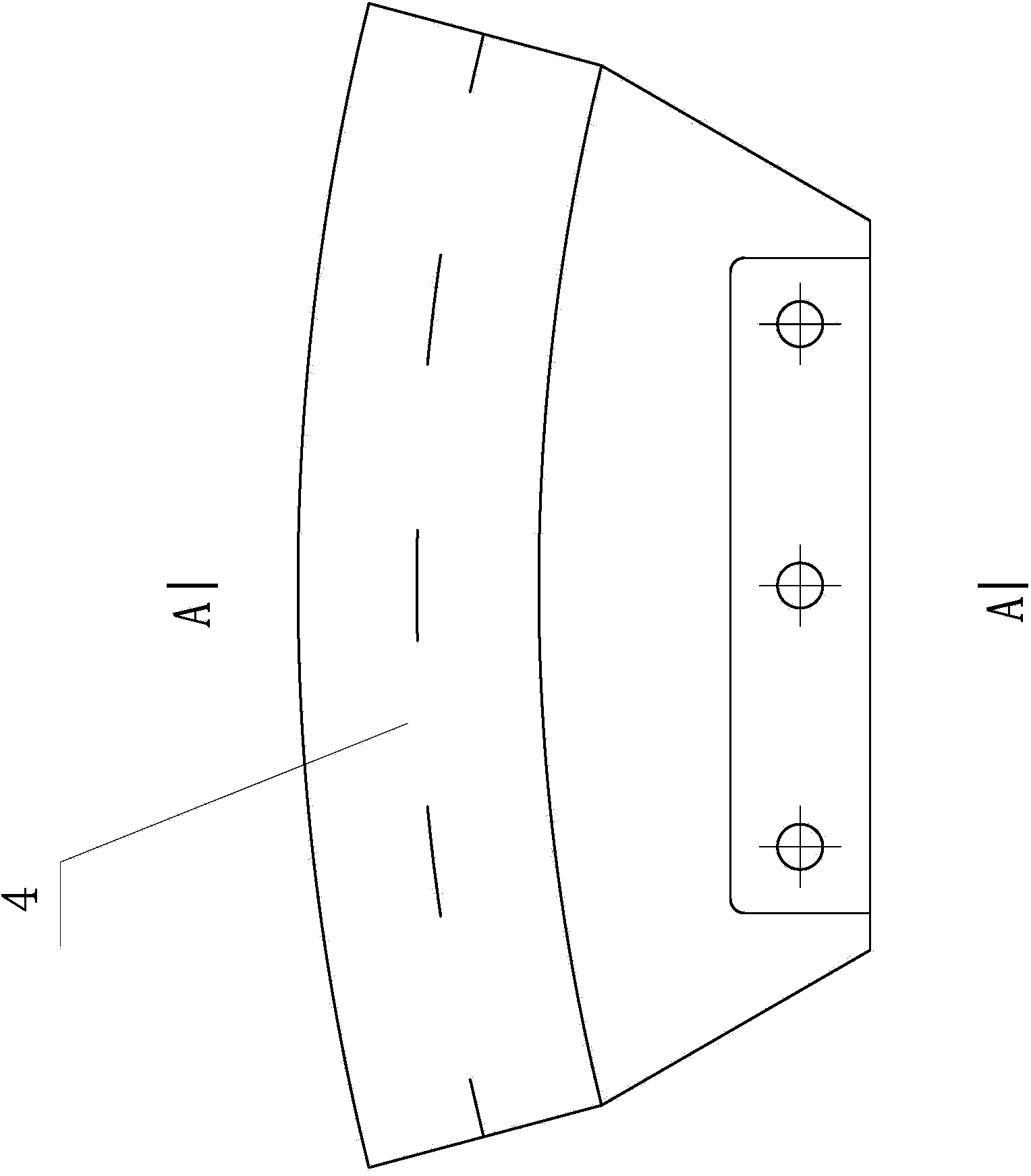

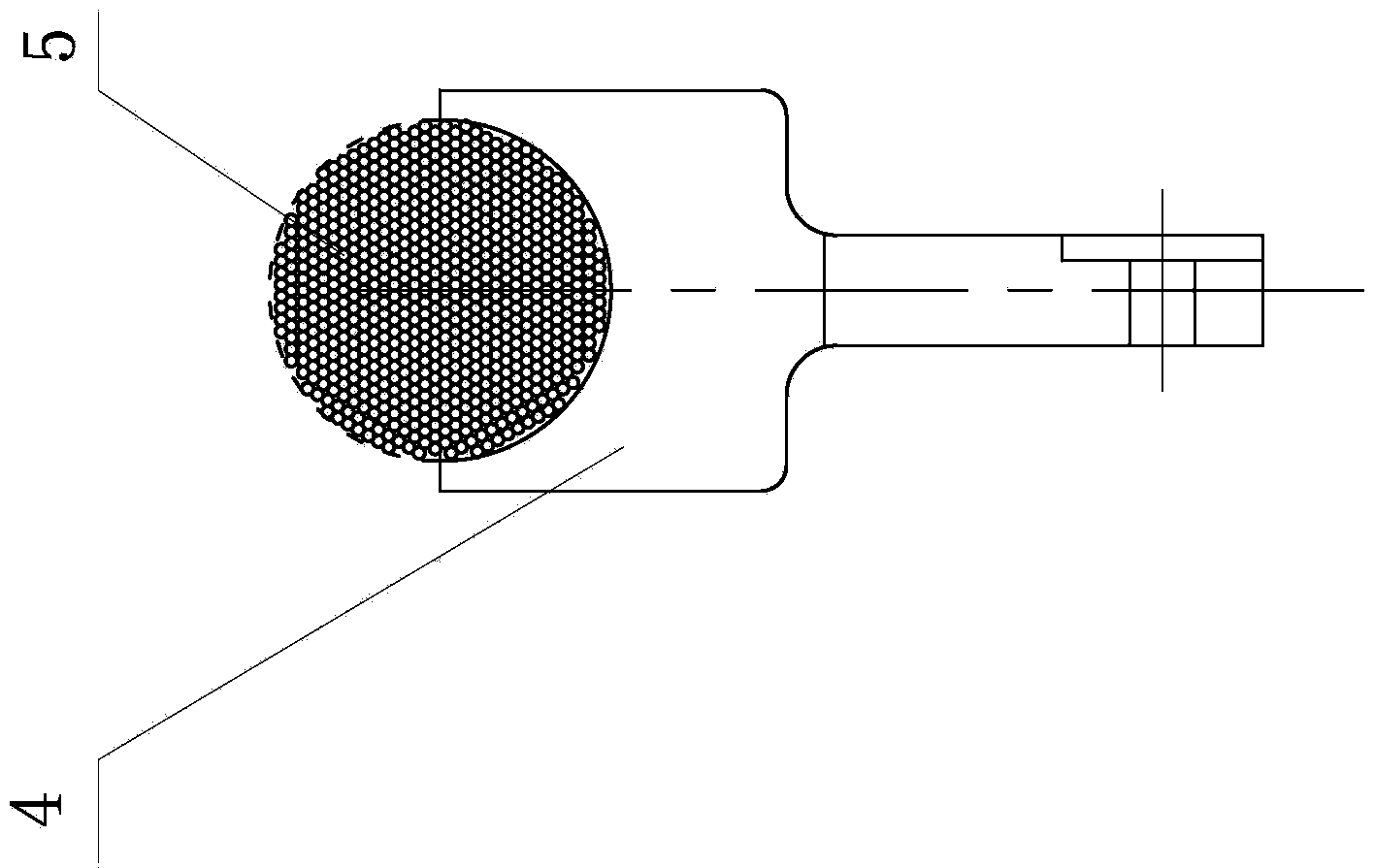

[0021] The method for preparing a circular cross-section steel traveler for a radial tire of the present invention is carried out on a steel wire winding device 1, and the steel wire winding device 1 is provided with a servo system for controlling the coiling of the steel wire 2 and a servo system for controlling the horizontal wire arrangement between the steel wires 2. system, the servo system for controlling the wire jumping up and down between the steel wires 2 and the servo system for controlling the total winding amount of the steel wires 2, each servo system is connected with the PLC controller through a line; They are separately arranged and can be stretched and expanded synchronously in the radial direction. The tiles 4 on the outer circumference of the traveler winding disc 3 are in a concave semicircle, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com