Assembling and detecting all-in-one machine for vacuum bottle

一种保温瓶、一体机的技术,应用在流体密封性的测试、机器/结构部件的测试、测量装置等方向,能够解决不方便检测瓶盖气密性、影响保温瓶品质、降低生产效率等问题,达到保温效果理想、广配合性、提高效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

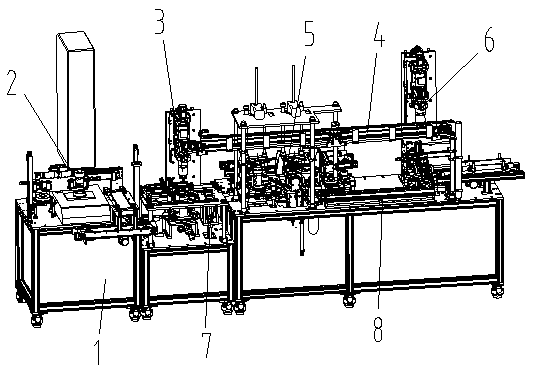

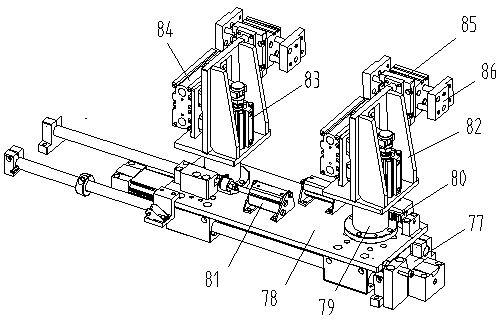

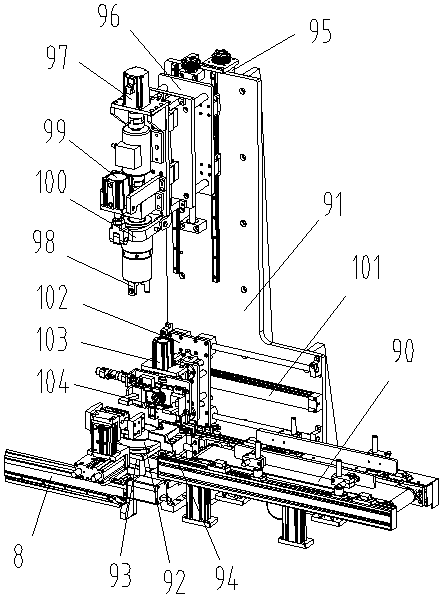

[0045] Such as Figure 1-Figure 13 As shown, the specific structure of the present invention is: a thermos bottle assembly and detection all-in-one machine, which includes a power distribution control box 1, and the power distribution control box 1 is provided with an airtightness detection device 3 from left to right, The cover device 5 and the tightening device 6, the left and right sides of the air tightness detection device 3 are provided with a feeding device 7 that cooperates with it, and the described feeding device 7 includes a feeding lifting cylinder 46 and a feeding lifting seat 47, And the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com