Convenient-to-clamp winding machine for transformer skeleton

一种变压器骨架、绕线机的技术,应用在电感/变压器/磁铁制造、线圈制造、电气元件等方向,能够解决耗费人力劳作、分布不均、返工等问题,达到避免缠绕打结、确保效率、提高效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

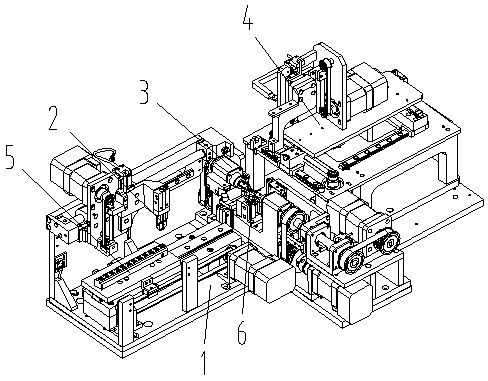

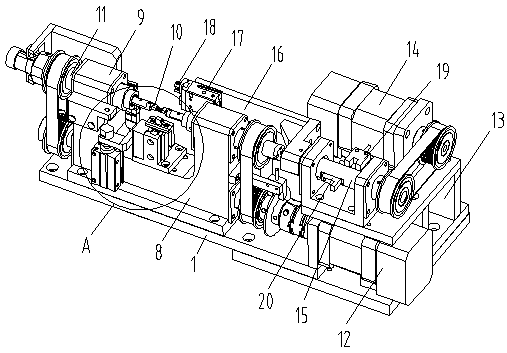

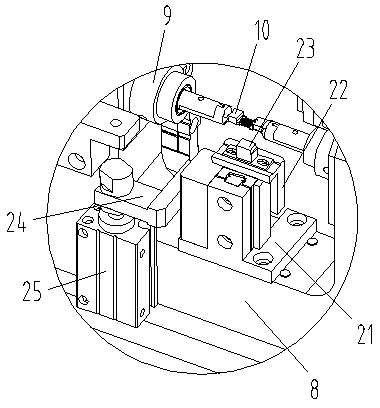

[0039] Such as Figure 1-Figure 8 As shown, the specific structure of the present invention is: a winding machine for a conveniently clamped transformer skeleton, which includes a support plate 1, and the support plate 1 is provided with a winding mechanism 3 and a wire releasing device 4 that cooperate with each other The winding mechanism 3 includes a winding seat 8 arranged on the support plate 1, and the winding seat 8 is provided with a winding shaft 11 whose two ends cooperate with each other, and the outer body of the winding shaft 11 is end is connected to the winding motor 12, the inner end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com