Single-handle magnetic control built-in hollow shutter glass

A venetian hollow glass and single-handle technology, which is applied to door/window protection devices, windows/doors, building components, etc., can solve the problem of difficulty in maintaining the level of the venetian blind, difficulty in tightening the turning line of the venetian blind, and inconvenient operation of the venetian blind and other problems, to achieve the effect of good tension, large elasticity and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

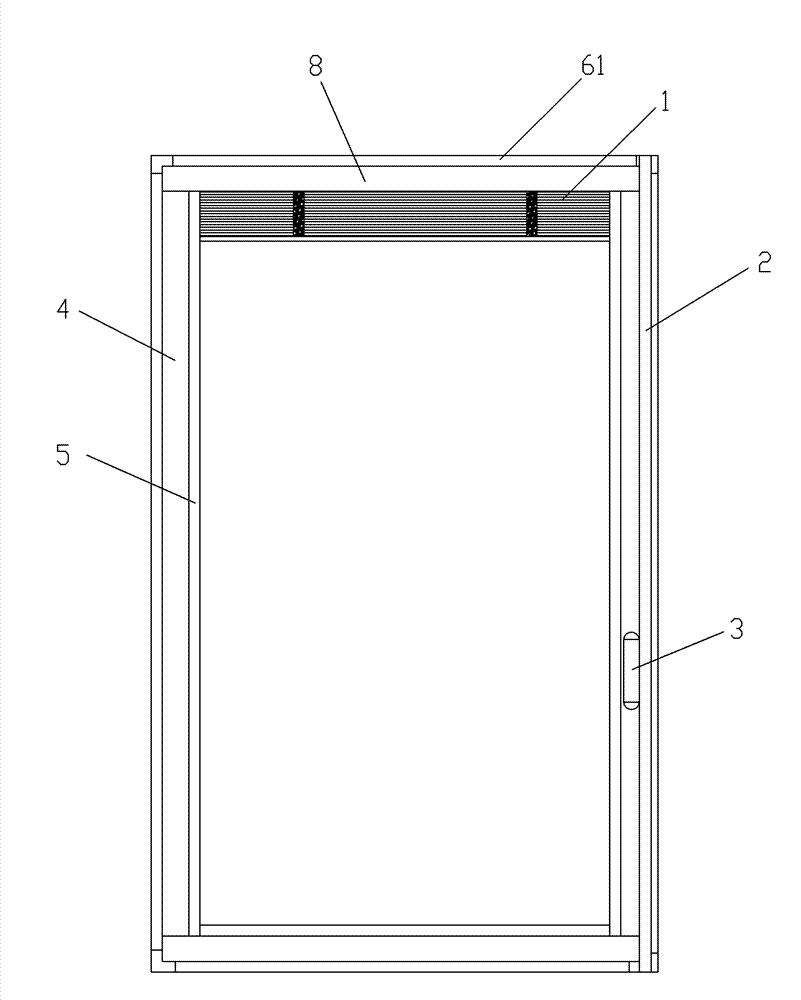

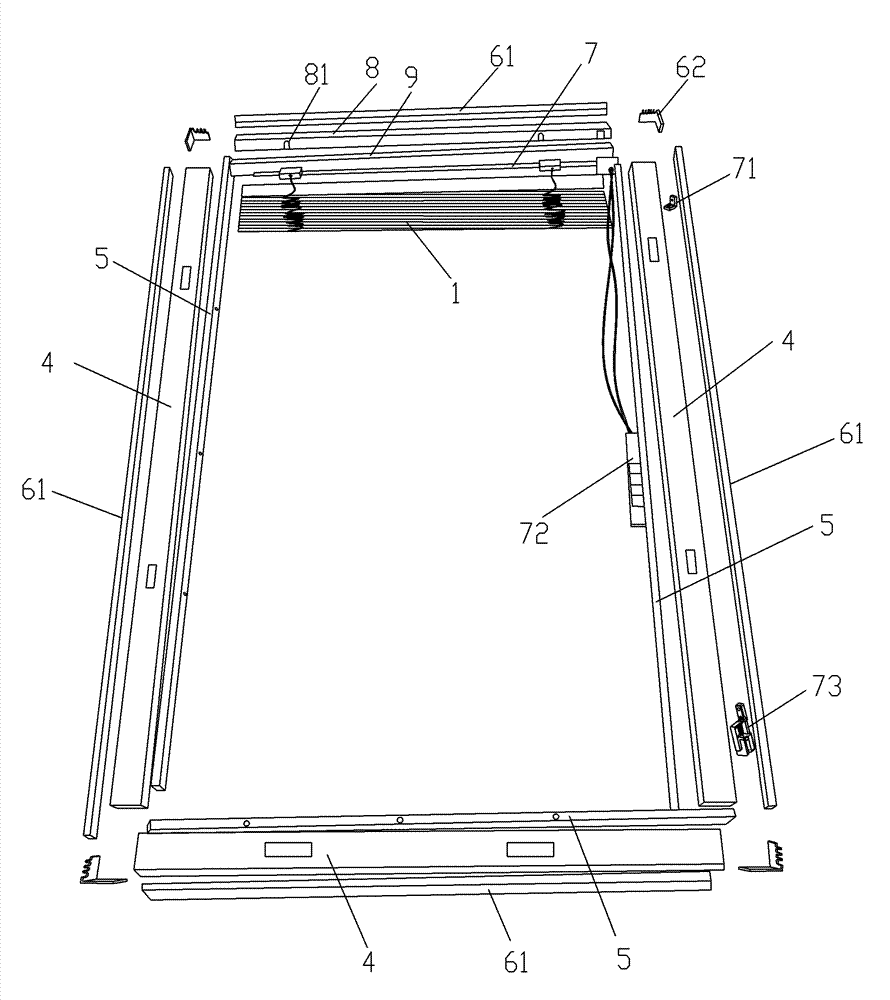

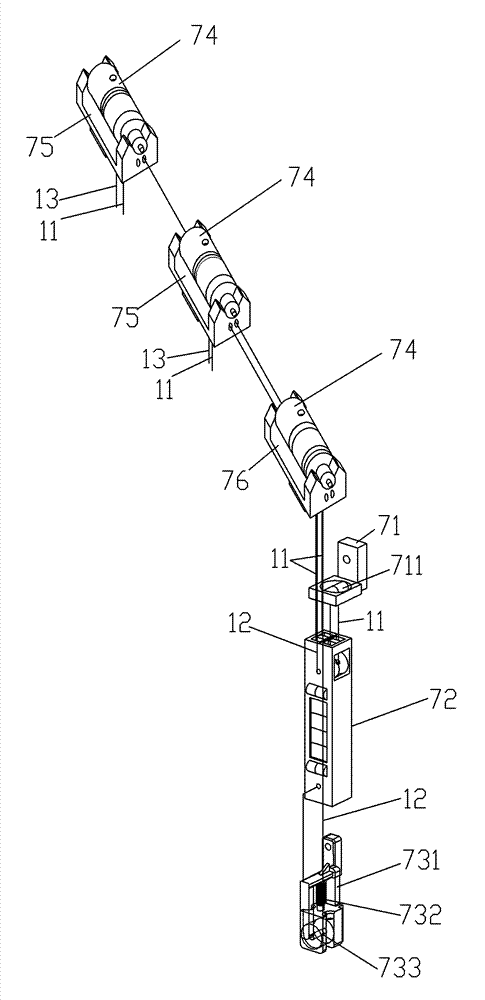

[0023] Examples, see Figure 1-Figure 3 As shown, a single-handle magnetically controlled built-in louver insulating glass of the present invention includes an upper glass, a lower glass, a venetian blind 1 and a louver pulling and turning mechanism 7; the venetian blind 1 and the louver pulling and turning mechanism 7 are respectively arranged on the upper glass and the lower Between the glass, there is a frame around the venetian blind 1, which includes four frame bars 61 (such as aluminum bars), a tube 4, a sunshade 5, a front suspension 8 and a rear suspension 9. The pins 62 are connected to each other, and the tube 4, the sunshade 5, the front suspension 8, and the rear suspension 9 are respectively arranged on the inner side of the frame bar 61; Slidingly fitted with an outer magnet slider 3; the louver pulling and turning mechanism 7 includes three coaxial runners 74, a first runner seat 76, two second runner seats 75, and a louver located on the upper end of the veneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com