Patents

Literature

46results about How to "Eliminate transmission errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

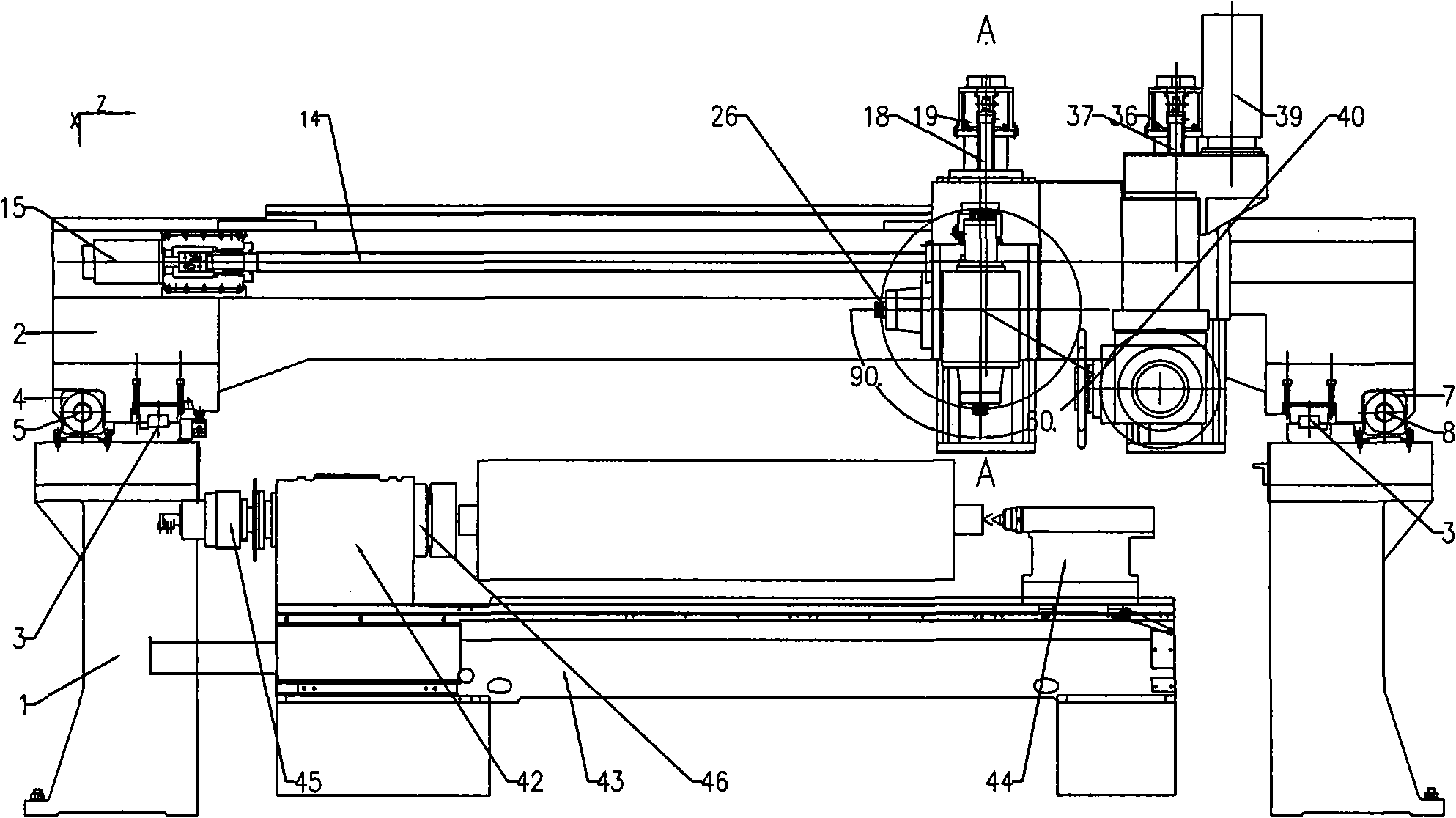

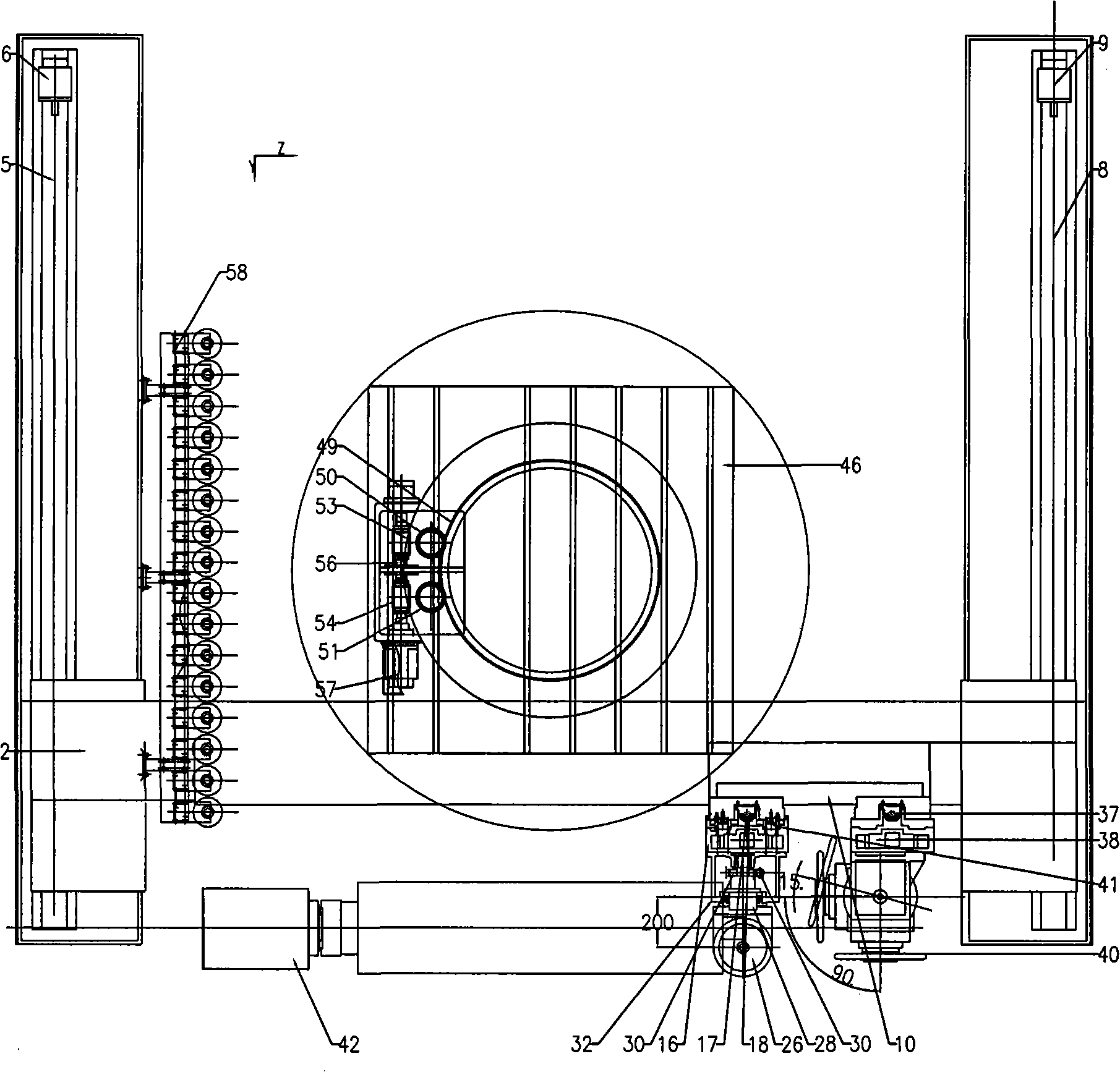

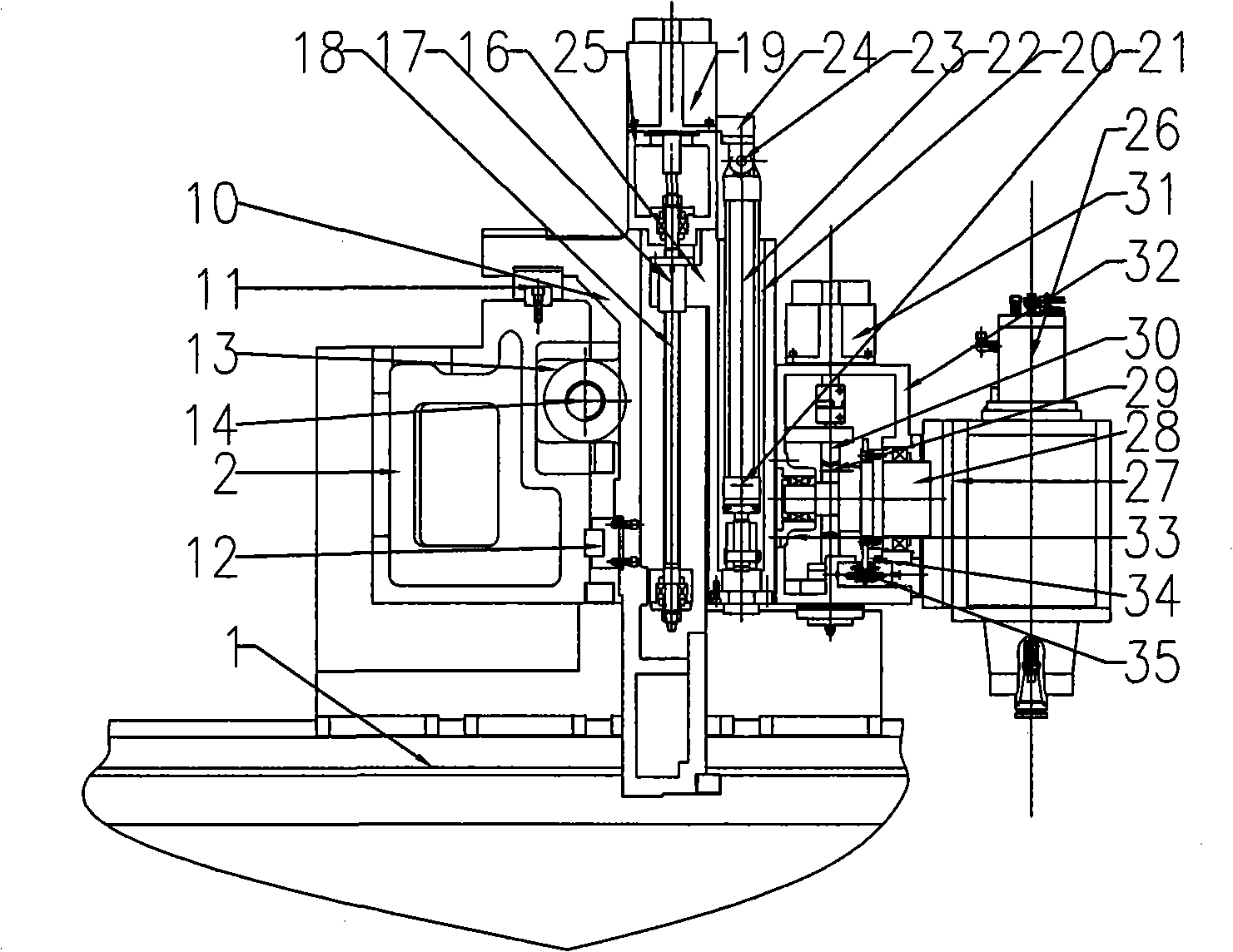

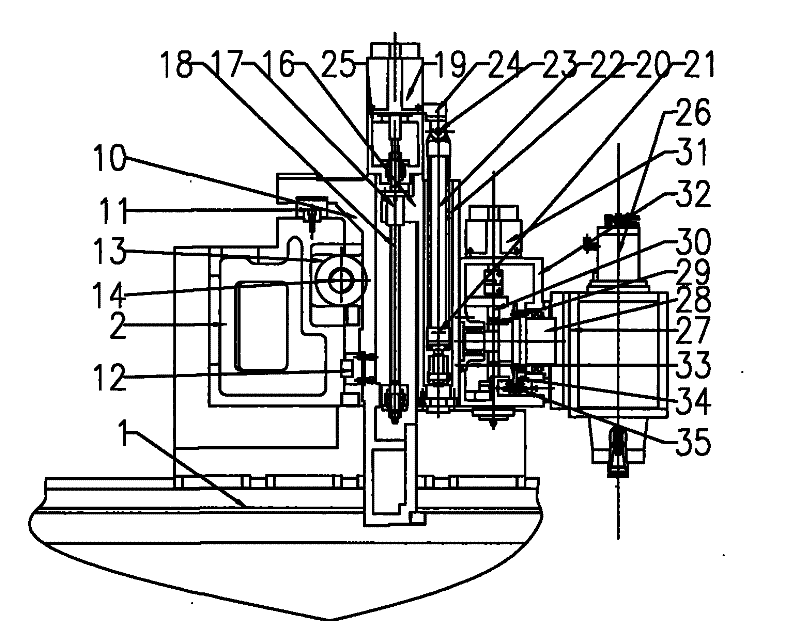

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490AEngraving and milling realizationAchieve turningGrinding machinesStone-like material working toolsEngineeringMechanical engineering

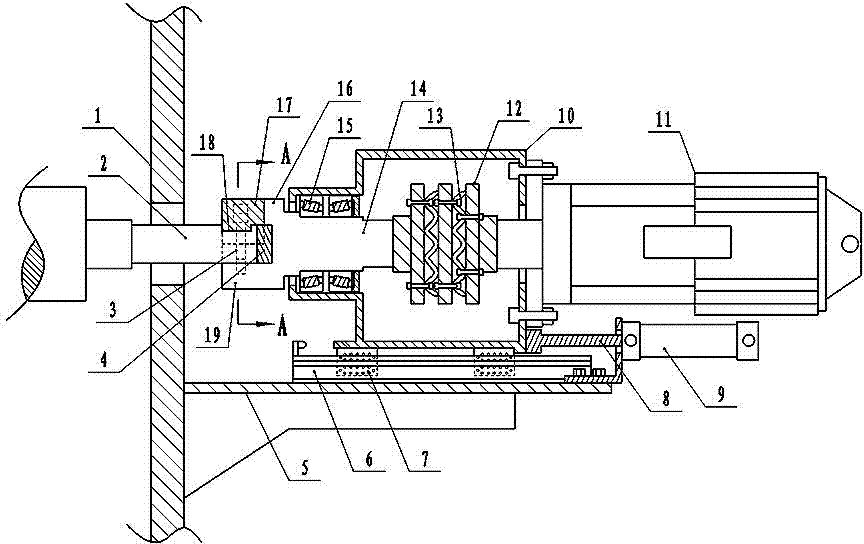

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division around the axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

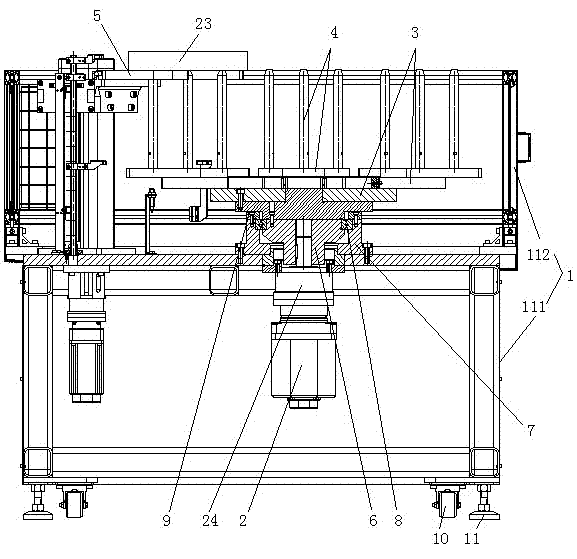

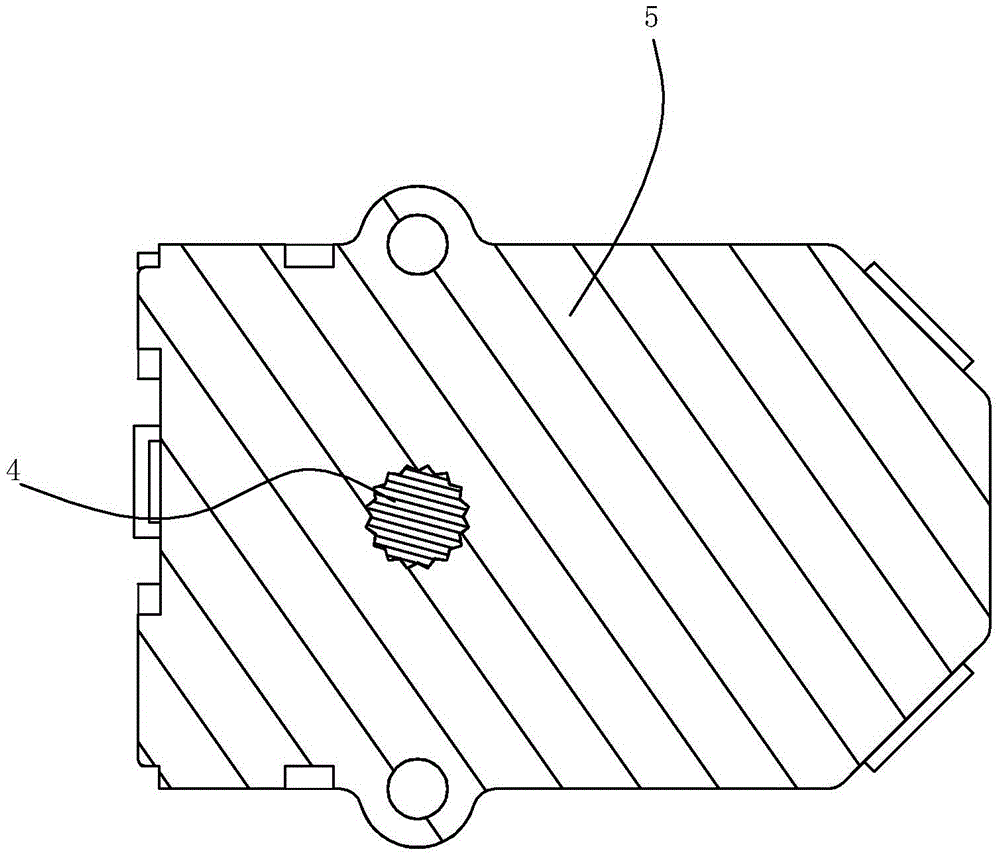

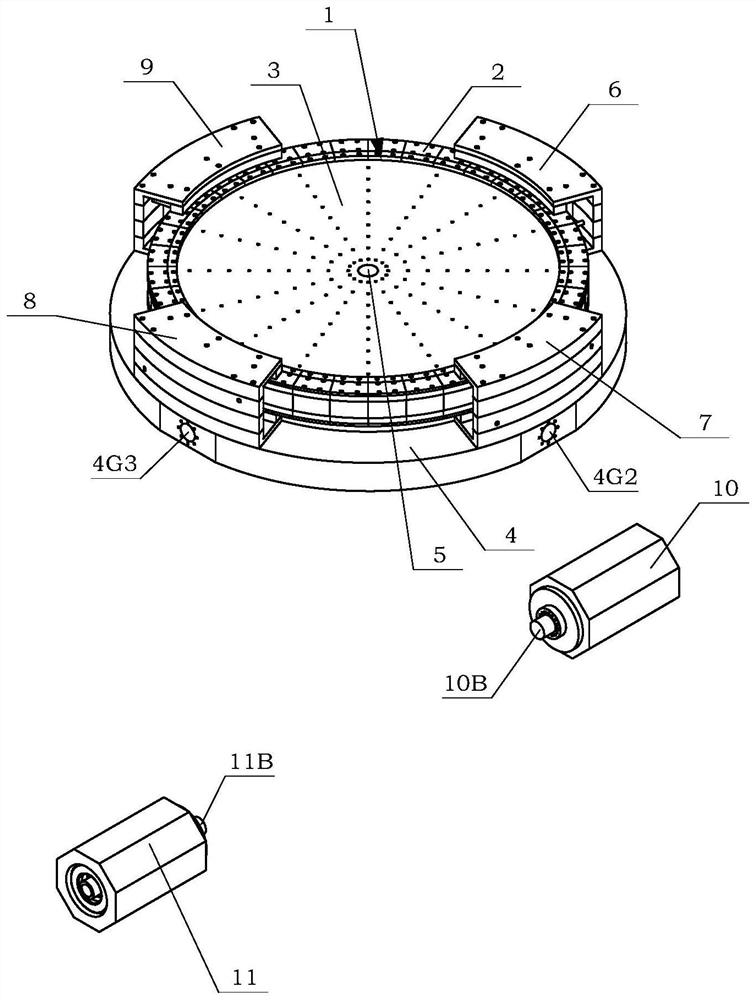

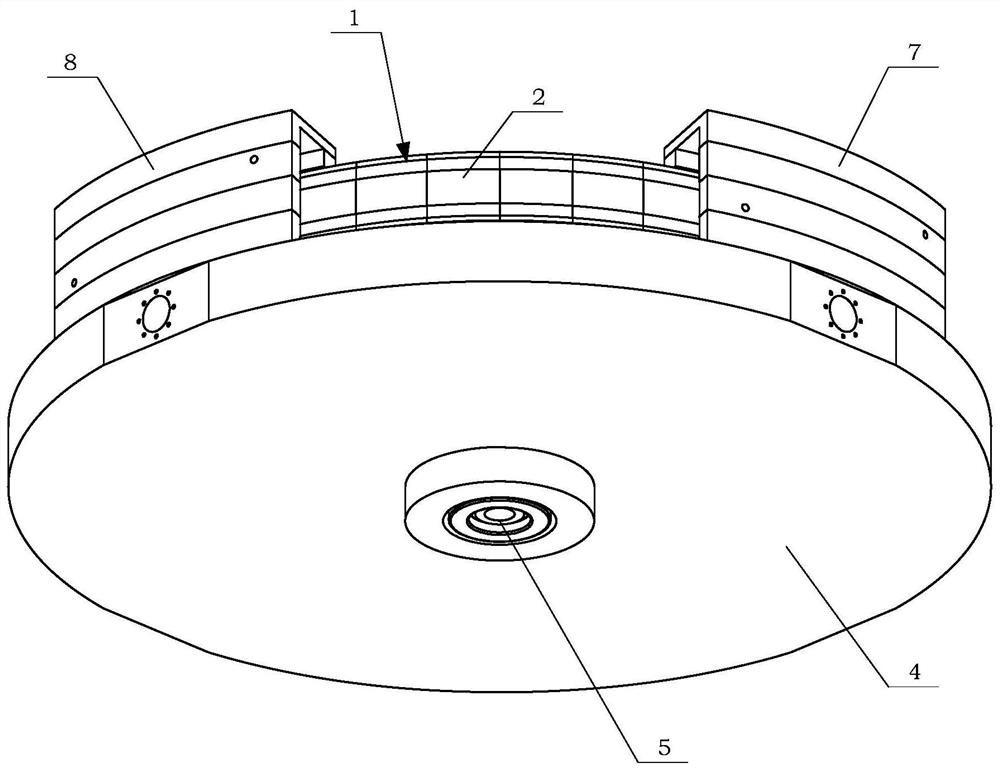

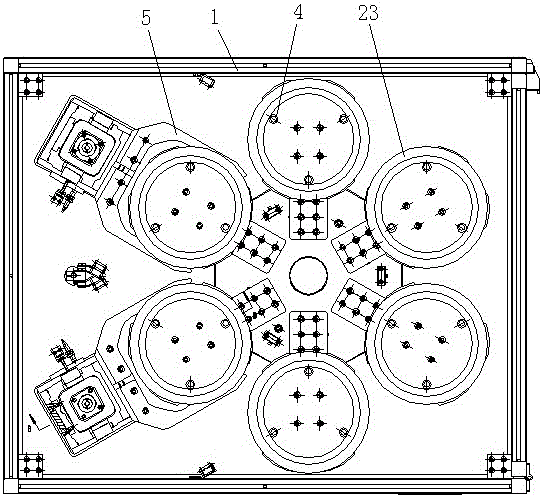

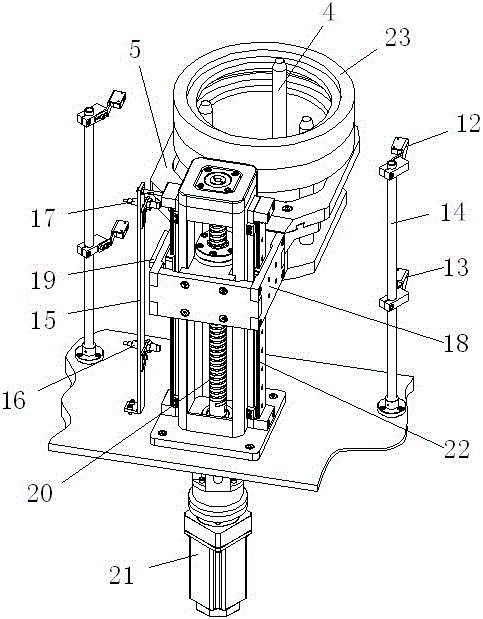

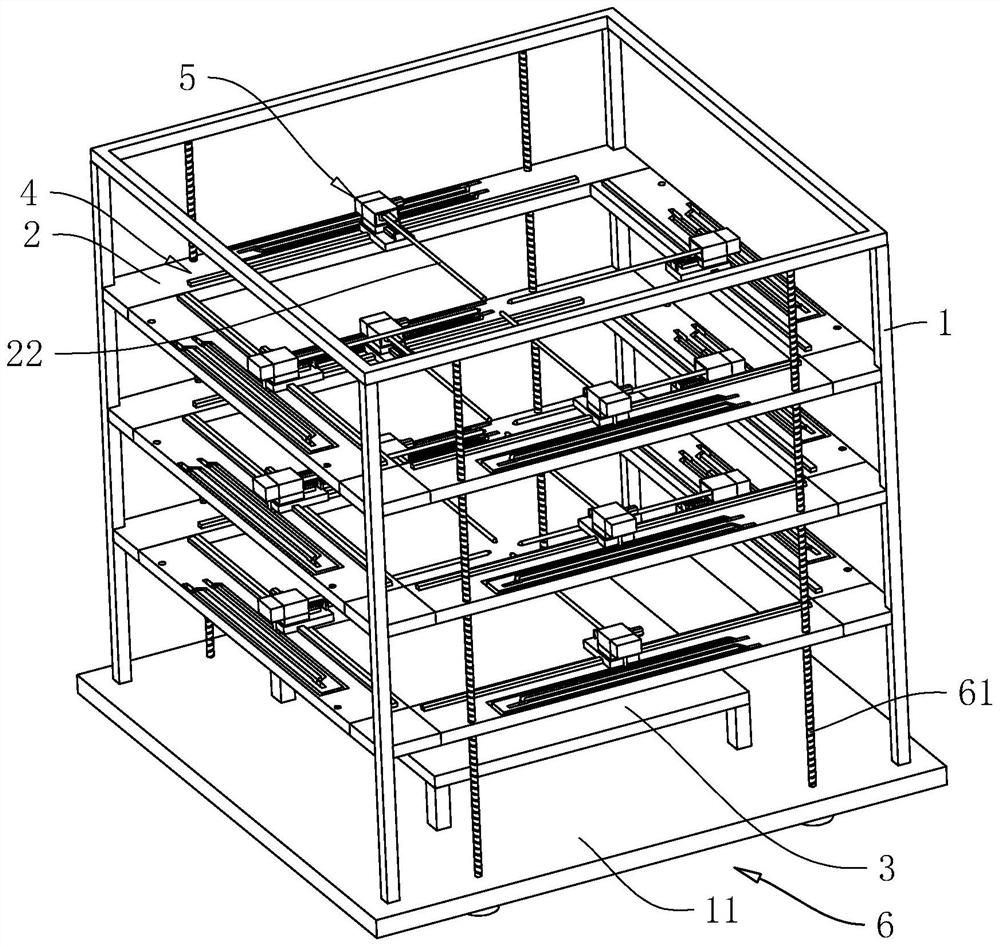

Accurate positioning storage bin

ActiveCN103028998AIncrease loading capacitySmall footprintMetal working apparatusMotor driveSmall footprint

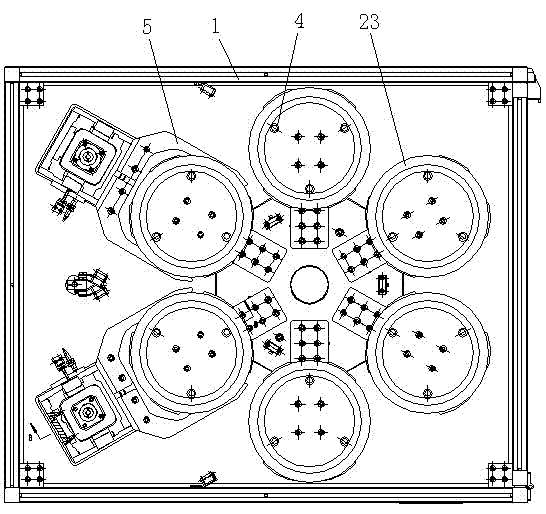

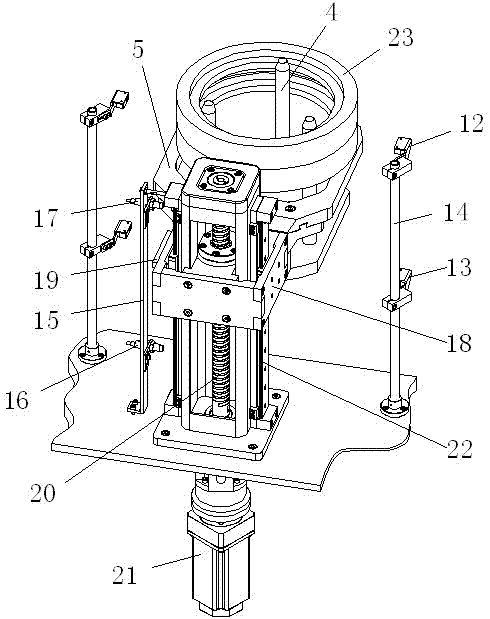

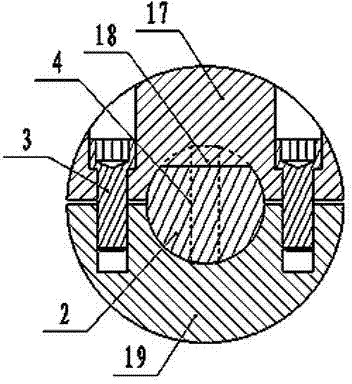

The invention discloses an accurate positioning storage bin. The accurate positioning storage bin comprises a storage bin frame, workpiece lifting mechanisms and a workpiece horizontal rotary conveying mechanism; the workpiece horizontal rotary conveying mechanism comprises a first motor which is arranged on the storage bin frame, a rotary disc which is connected with a first motor rotor and workpiece loading mechanisms which are arranged along the peripheral direction of the rotary disc at equal intervals; and two sets of workpiece lifting mechanisms are arranged and are distributed opposite to the two sets of workpiece loading mechanisms, and each workpiece lifting mechanism comprises a clamping jaw for conveying workpieces on the workpiece loading mechanisms and a drive device for driving the clamping jaw to lift and descend. According to the accurate positioning storage bin, the first motor drives the rotary disc so as to drive the workpiece loading mechanisms to rotate horizontally, so that the transmission error existing in conventional storage bin chain wheel and chain transmission is eliminated, the repeat positioning precision along the horizontal direction is high, and a manipulator of processing equipment can accurately take and store materials; and moreover, a plurality of workpiece loading mechanisms can be arranged on the same rotary disc, the loading capacity of the storage bin is large and the storage bin occupies a small area.

Owner:CHONGQING MACHINE TOOL GROUP

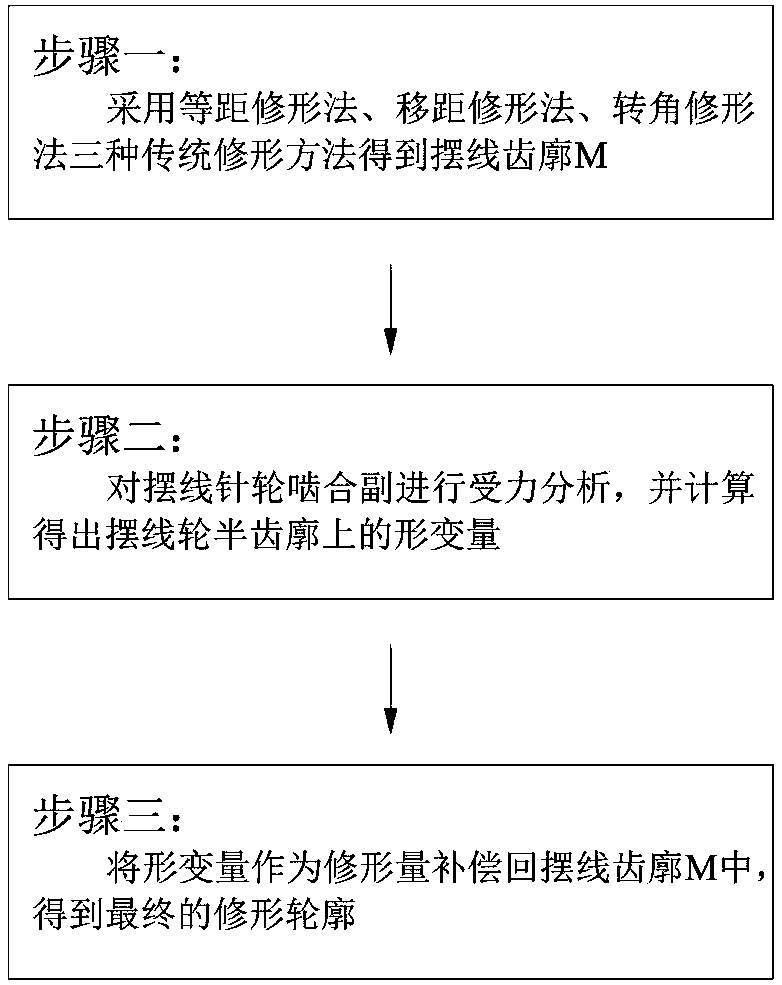

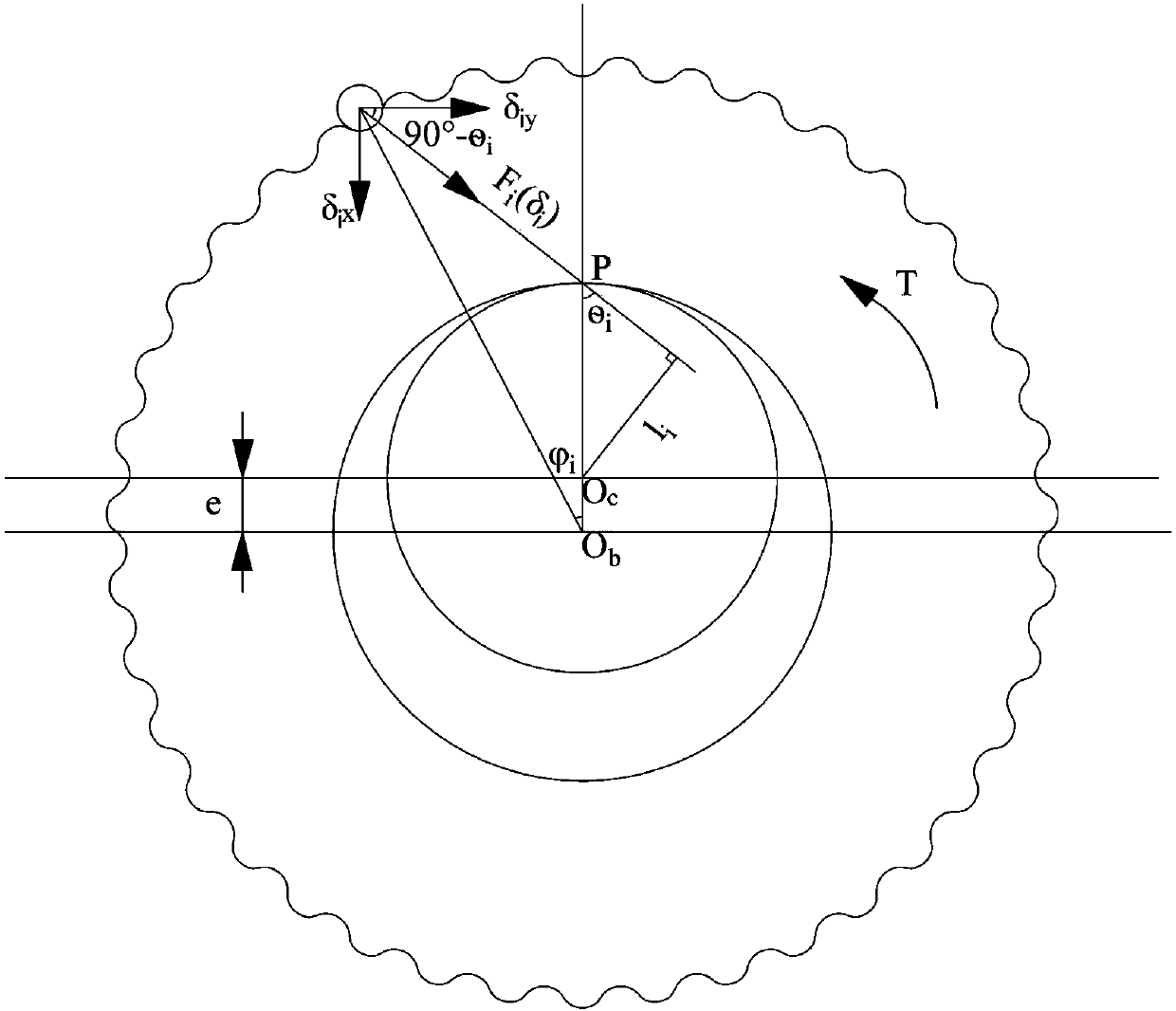

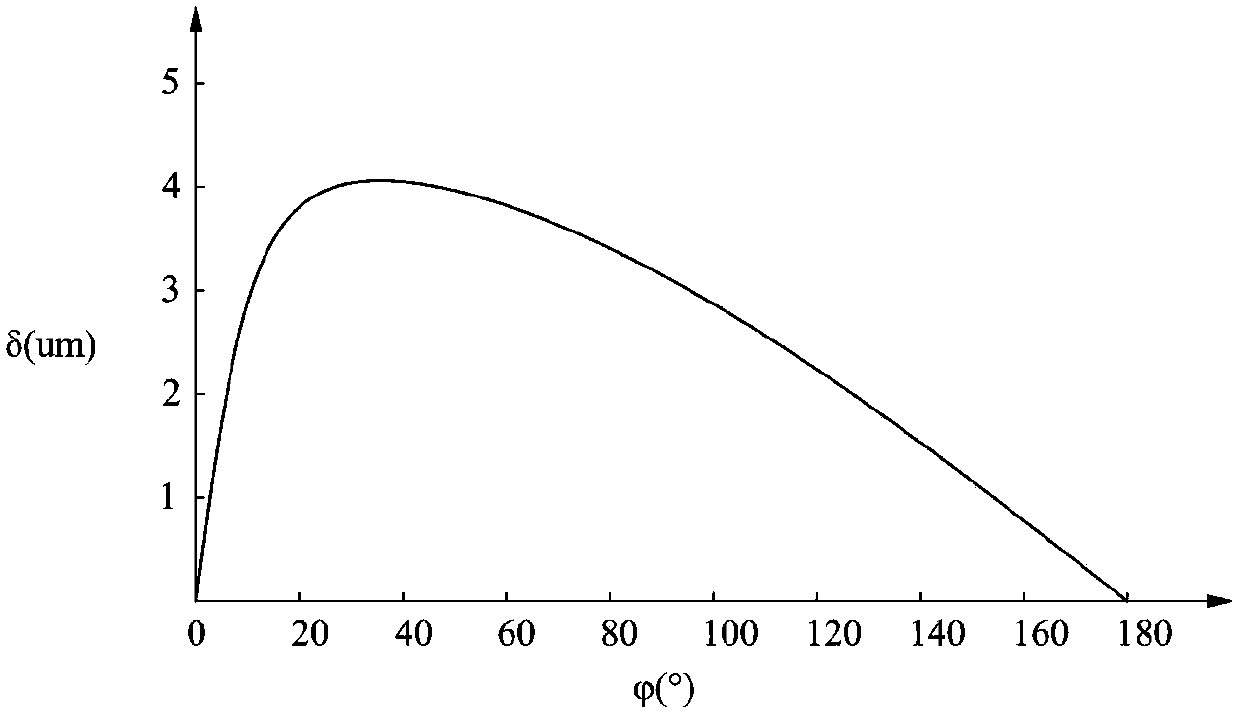

RV speed reducer cycloidal gear contour profiling method based on deformation quantity compensation

InactiveCN107256282AEliminate transmission errorsIncrease stiffnessGeometric CADSpecial data processing applicationsEngineeringExtrusion

The invention discloses an RV speed reducer cycloidal gear contour profiling method based on deformation quantity compensation, and relates to the field of design and manufacturing of an RV speed reducer cycloidal gear. On the basis of the profiling gear contour determined by three conventional gear contour profiling methods, the extrusion deformation quantity of the cycloidal gear contour in the practical operation process is used as the profiling quantity to be compensated back into the gear contour of the cycloidal gear; the condition better conforms to the cycloidal gear contour profiling of an RV speed reducer applied to high-precision and high-load conditions; the transmission error of the RV speed reducer under the high-load condition can be further eliminated; and the rigidity of the speed reducer is improved. The method provided by the invention comprises the following steps of 1, obtaining the cycloidal gear contour M by using the three conventional profiling methods; 2, performing stress analysis on a cycloid pin gear engagement pair; and obtaining the cycloidal gear contour deformation quantity through calculation; and 3, using the deformation quantity as the profiling quantity to be compensated back into the cycloidal gear contour M for obtaining the final profiling contour.

Owner:SOUTH CHINA UNIV OF TECH +1

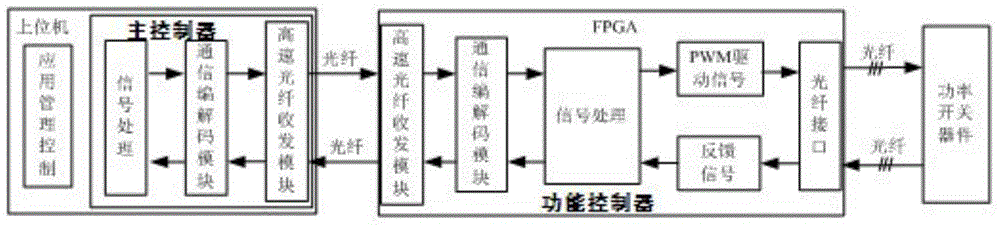

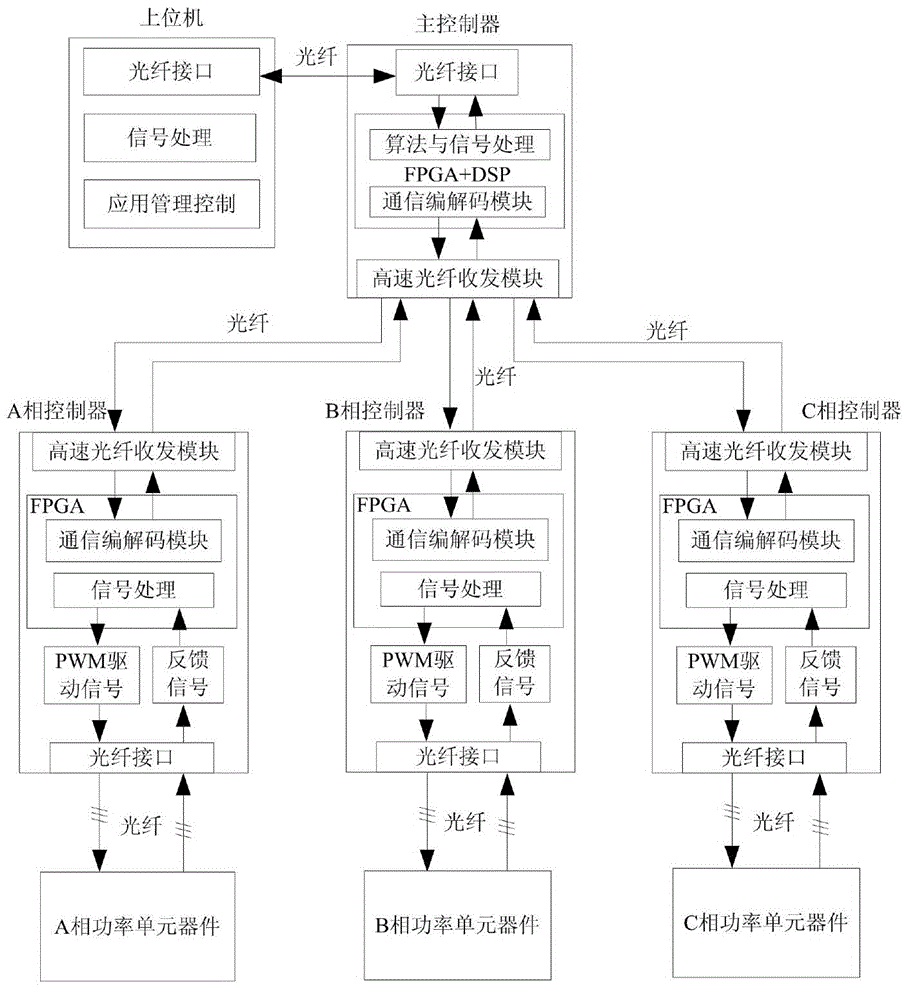

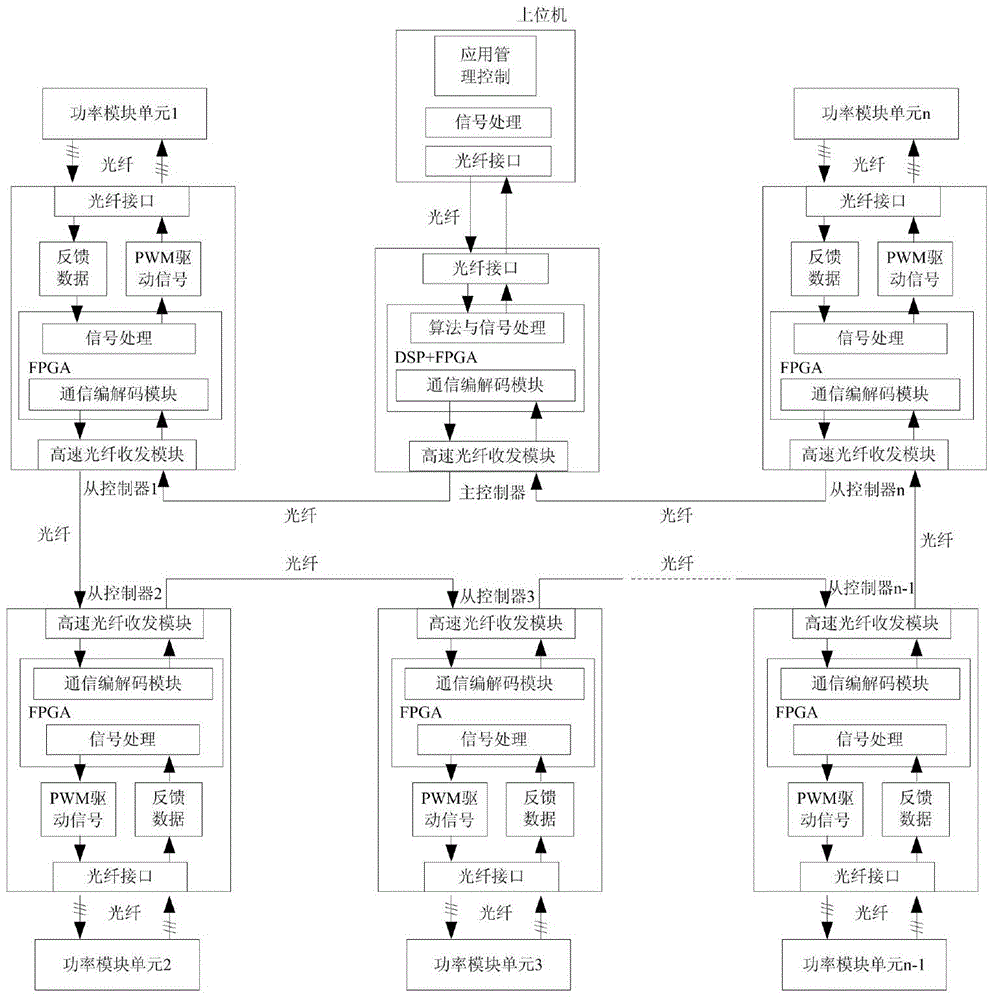

Manchester-code-based power electronic conversion system communication control framework

InactiveCN104158853ASatisfy communication controlFulfil requirementsError preventionManchester codeComputer module

The invention belongs to the field of power electronic conversion system communication control, and particularly relates to a Manchester-code-based power electronic conversion system communication control framework. According to the invention, the Manchester code with self-synchronizing communication characteristic is adopted as the communication platform; a high-power current transformer centralization control framework and a parallel networking thereof, and distributed control frameworks such as a three-phase distributed chain and a multiphase multilevel modularized structure are adopted; the communication modes are directly applied to power electronic module communication control such as a digital IGBT driver. The Manchester-code-based power electronic variable current system communication control framework has the characteristic of self-synchronizing communication, is simple in realization method, is high in communication rate, is good in reliability, is convenient to make communication protocol, and can satisfy the requirement of communication application on the high-power power electronic conversion system and other power electronic modules.

Owner:NAVAL UNIV OF ENG PLA

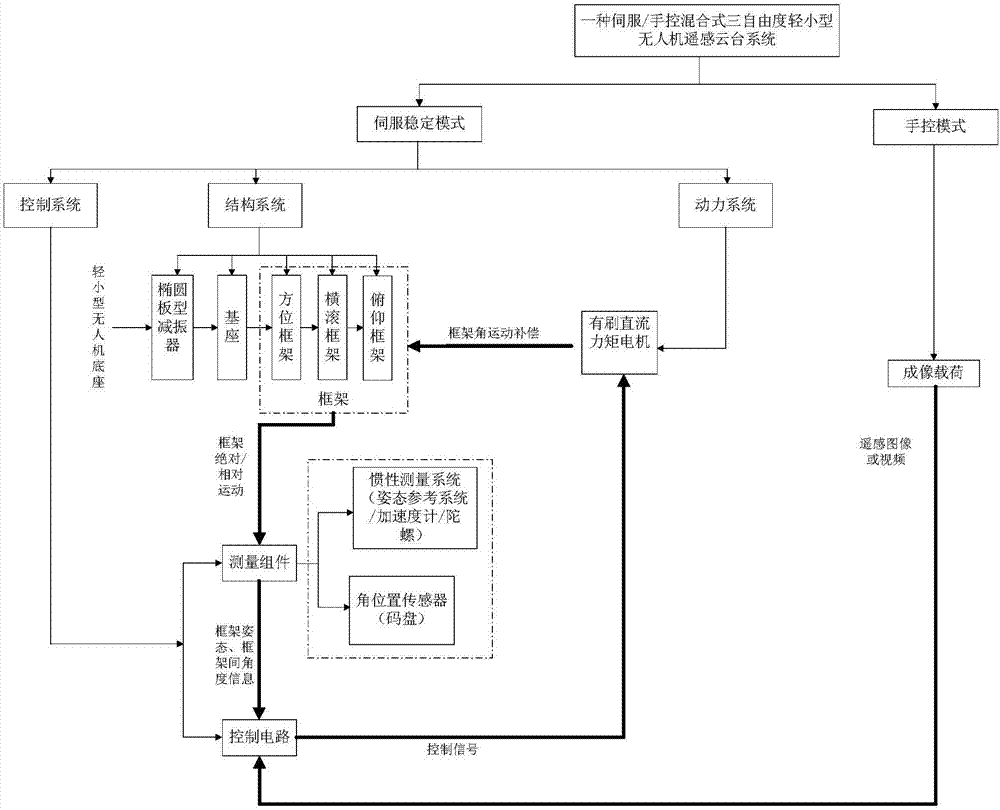

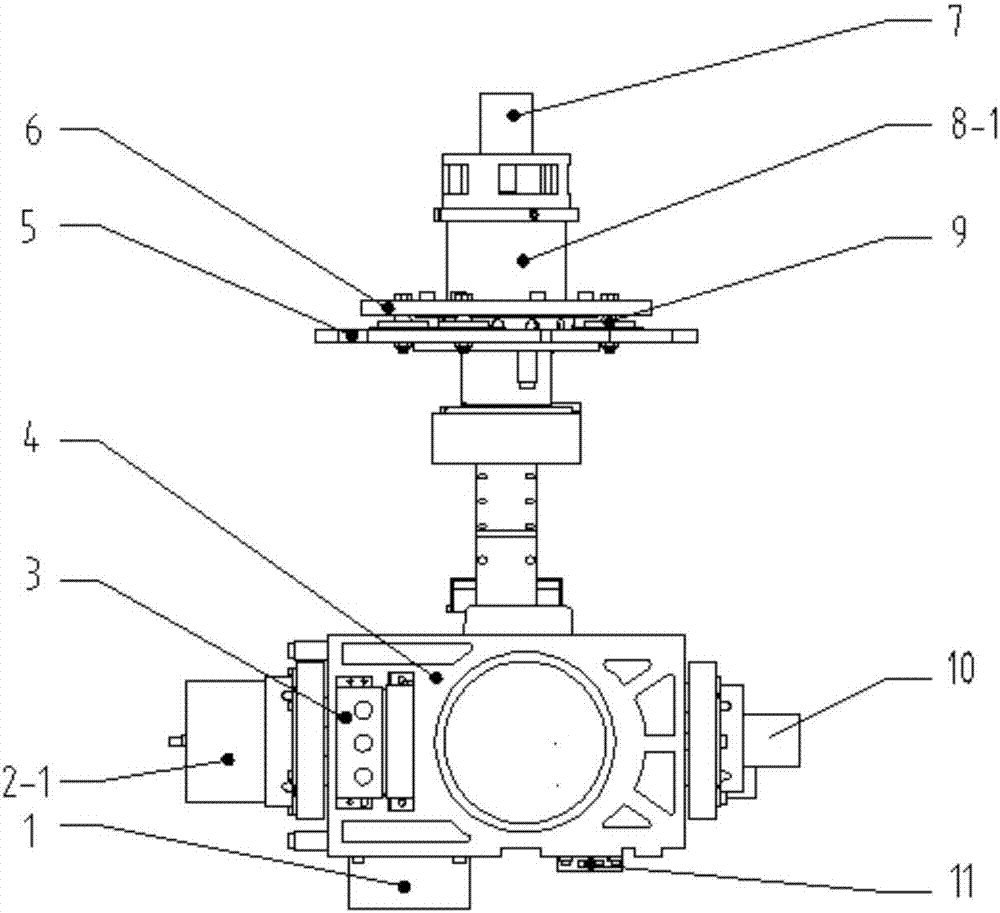

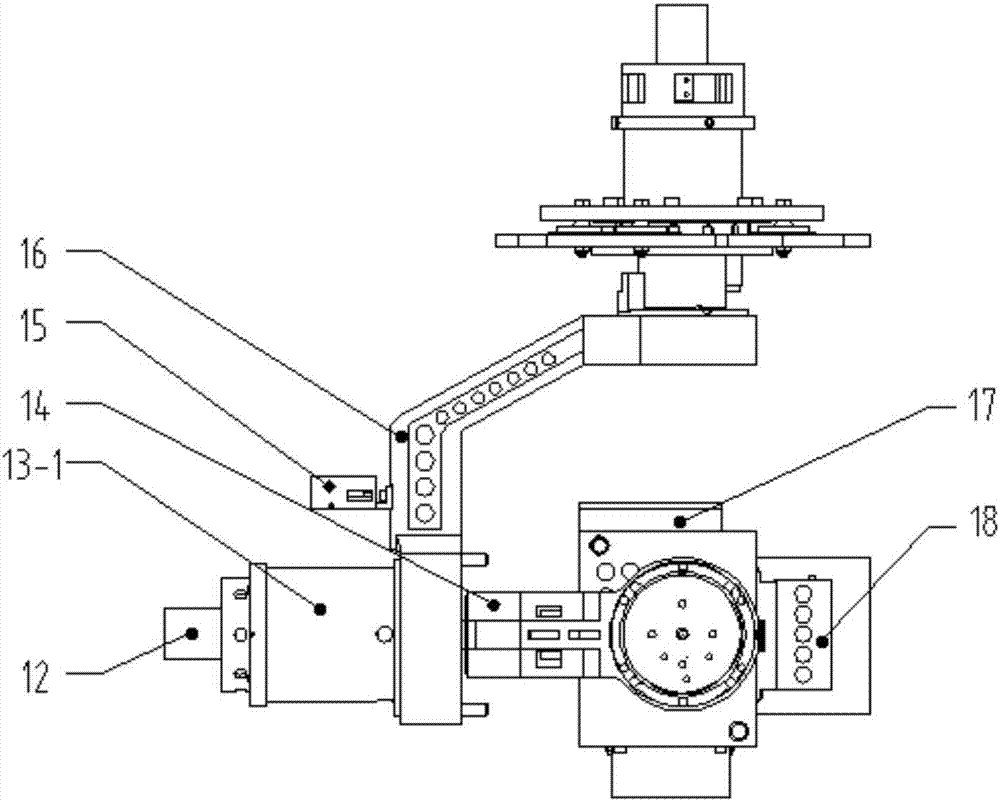

Servo/manual control mixing-type three-degree-of-freedom light-small unmanned aerial vehicle remote sensing holder system

The present invention discloses a servo / manual control mixing-type three-degree-of-freedom light-small unmanned aerial vehicle remote sensing holder system. The system comprises two work modes of servo stabilization and manual control. The system comprises a structure system, a power system and a control system. The pedestal of the structure system is connected with an airplane through a vibration damper to isolated from the vibration of an aircraft wire; an orientation framework is supported by the pedestal to realize revolution in the range of +_130 degrees; a roll framework is supported by the orientation framework to realize revolution in the range of +_30 degrees; and a pitching framework is supported by the roll framework to realize revolution in the range of -90 to 30 degrees. The control system generates an instruction according to framework angular position and angular rate information provided by an attitude reference system, and the power system is configured to perform compensation of attitude errors and rate disturbance to realize stabilization of an imaging load visual axis and real-time tracking of an object; when a tracking angle is large, the manual remote operation is employed to realize large-angle rapid tracking; and the system is small in size, light in weight, fast in response and wide in tracking range, and can be suitable for systems with light and small unmanned aerial vehicle remote control, target tracking and monitoring, etc.

Owner:BEIHANG UNIV

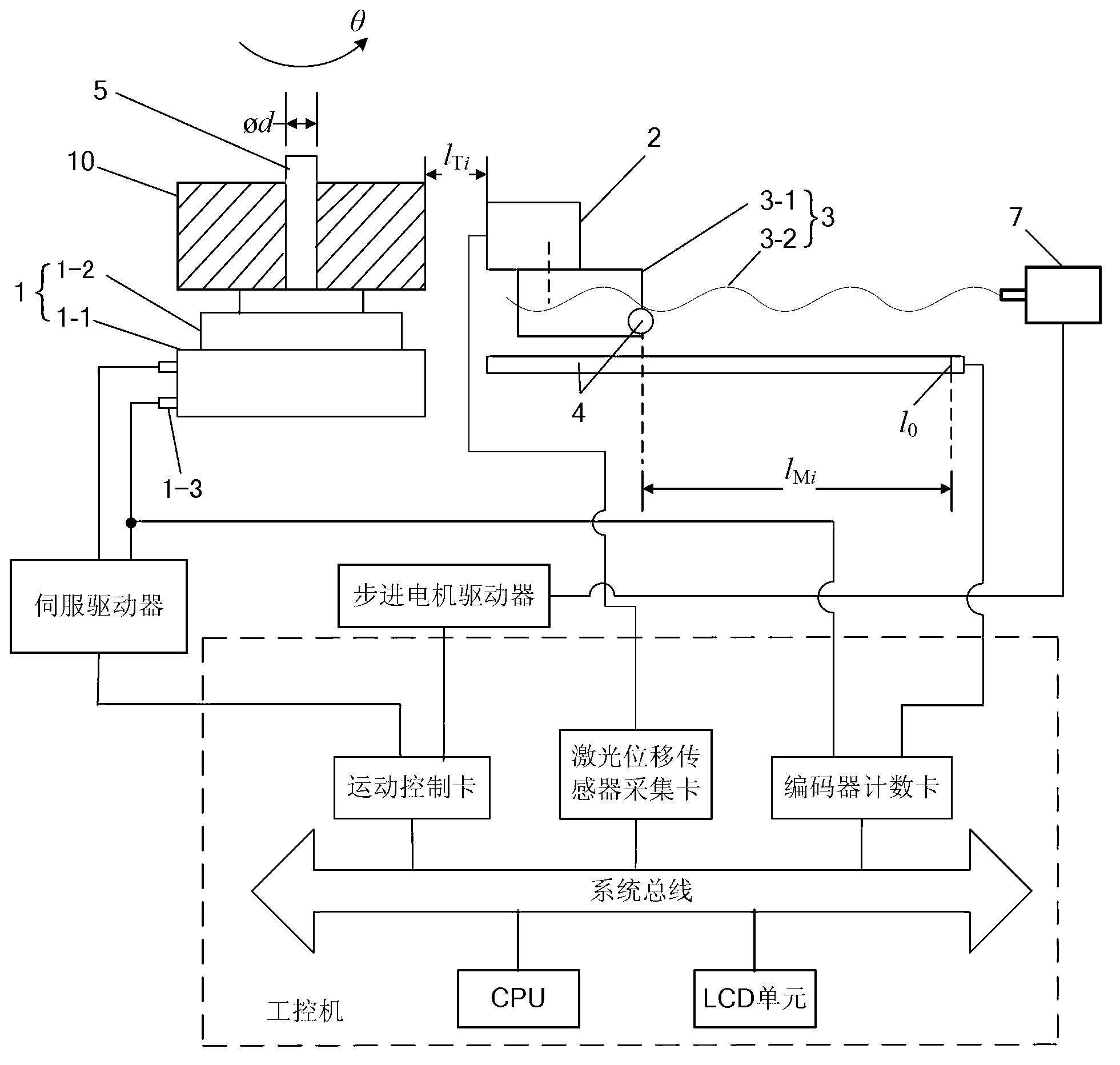

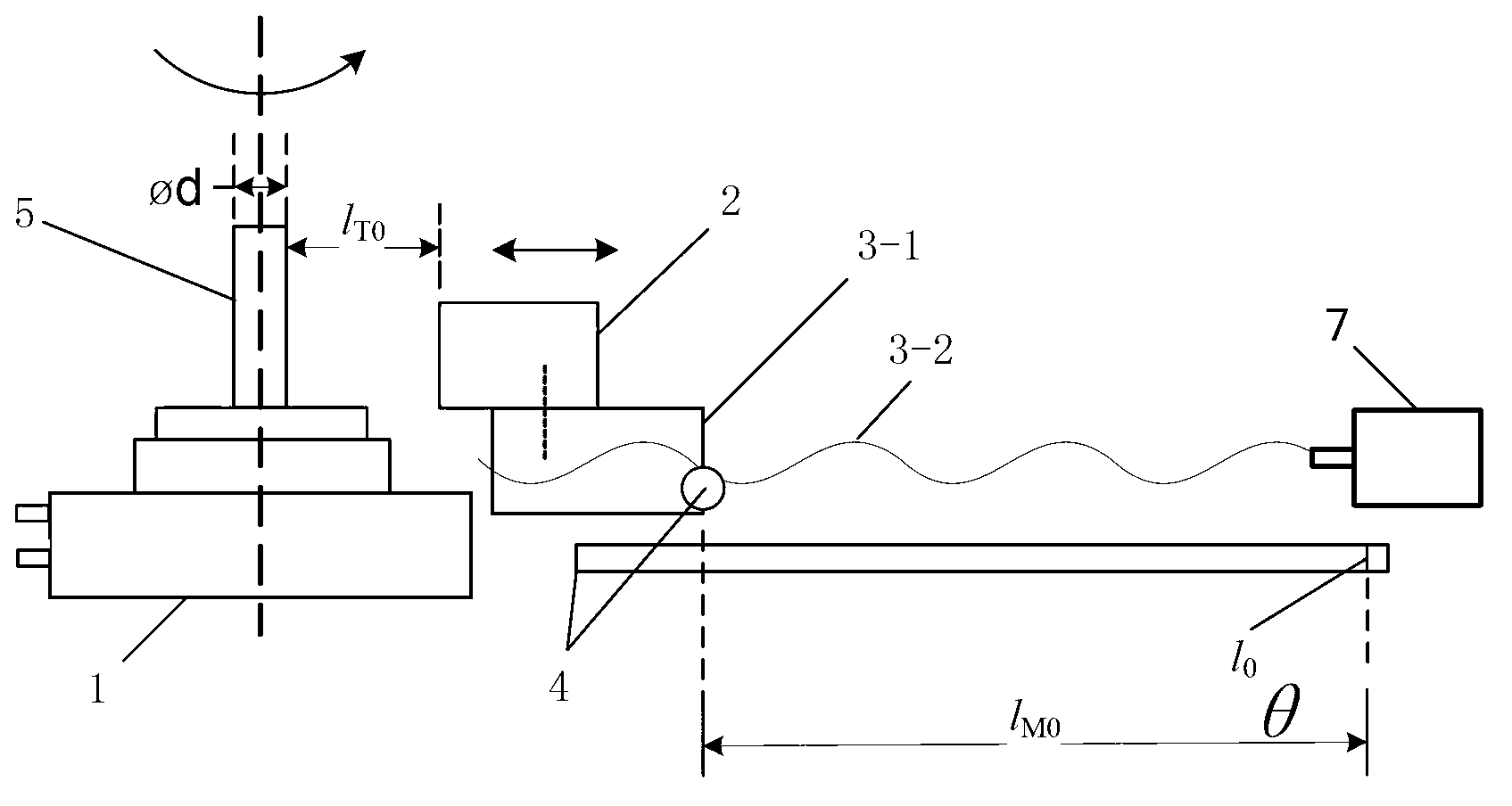

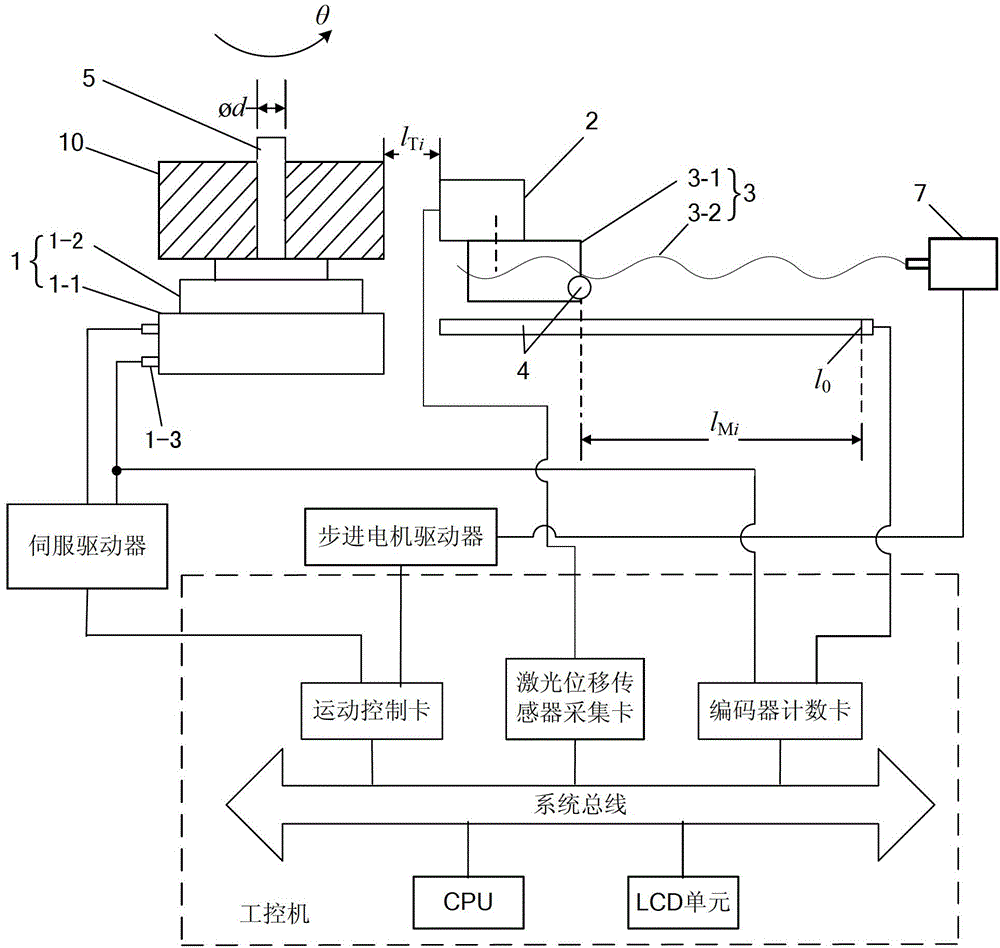

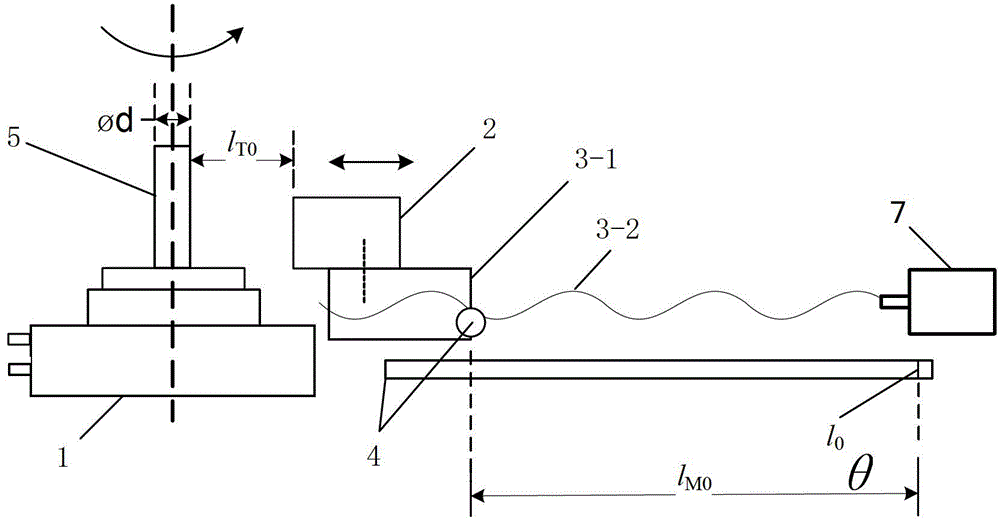

Cam profile detection system

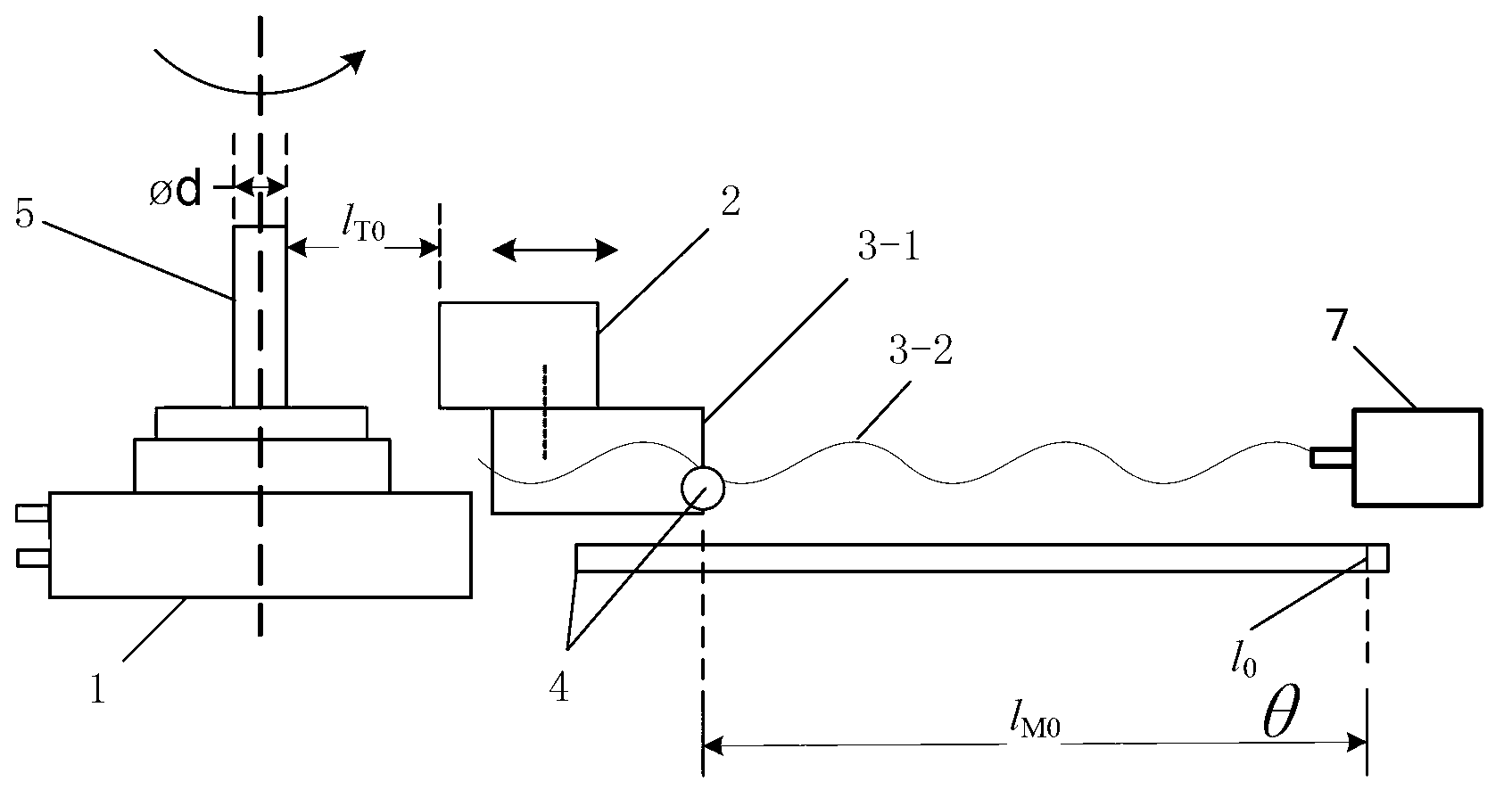

The invention provides a cam profile detection system based on a direct driving motor, and the system is simple in structure and high in detection precision and efficiency. The system comprises the direct driving motor, a mandrel, a feed screw nut pair, a laser measurement head, a grating ruler displacement sensor, a circular grating and an industrial personal computer, wherein the mandrel is coaxially fixedly arranged on the rotor of the direct driving motor and is used for driving a cam to coaxially rotate synchronously; the feed screw nut pair is horizontally arranged at one side of the cam; the laser measurement head is arranged on the movable nut of the feed screw nut pair; the grating ruler displacement sensor is used for measuring the horizontal displacement amount of the movable nut; the circular grating is arranged in the fixed seat of the direct driving motor and is used for detecting the rotation angle of the rotor; and the industrial personal computer is used for controlling the actions of the direct driving motor and the feed screw nut pair, and obtaining outer profile data of the cam according to data obtained by the laser measurement head, the grating ruler displacement sensor and the circular grating.

Owner:CHANGZHOU INST OF TECH

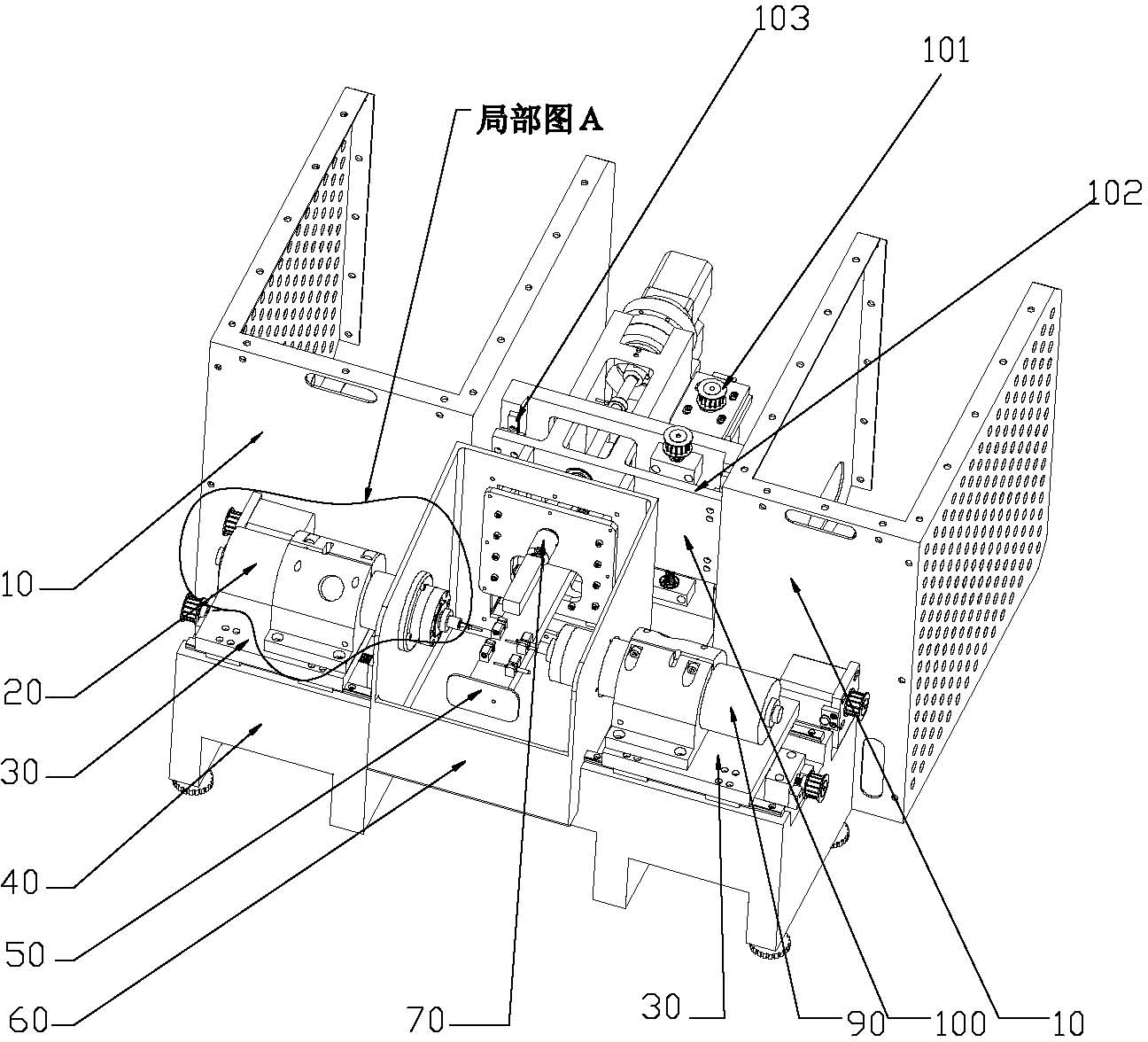

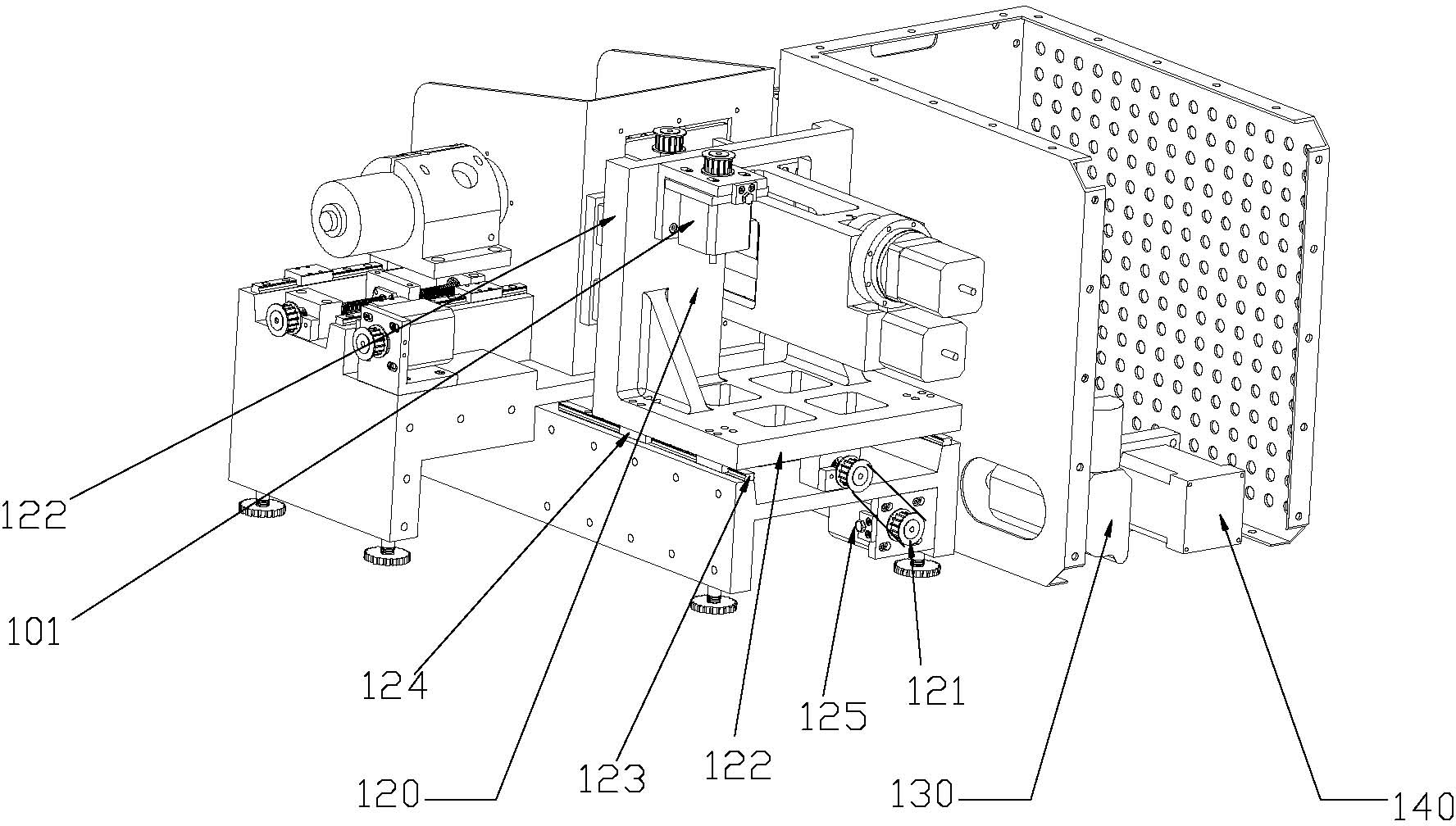

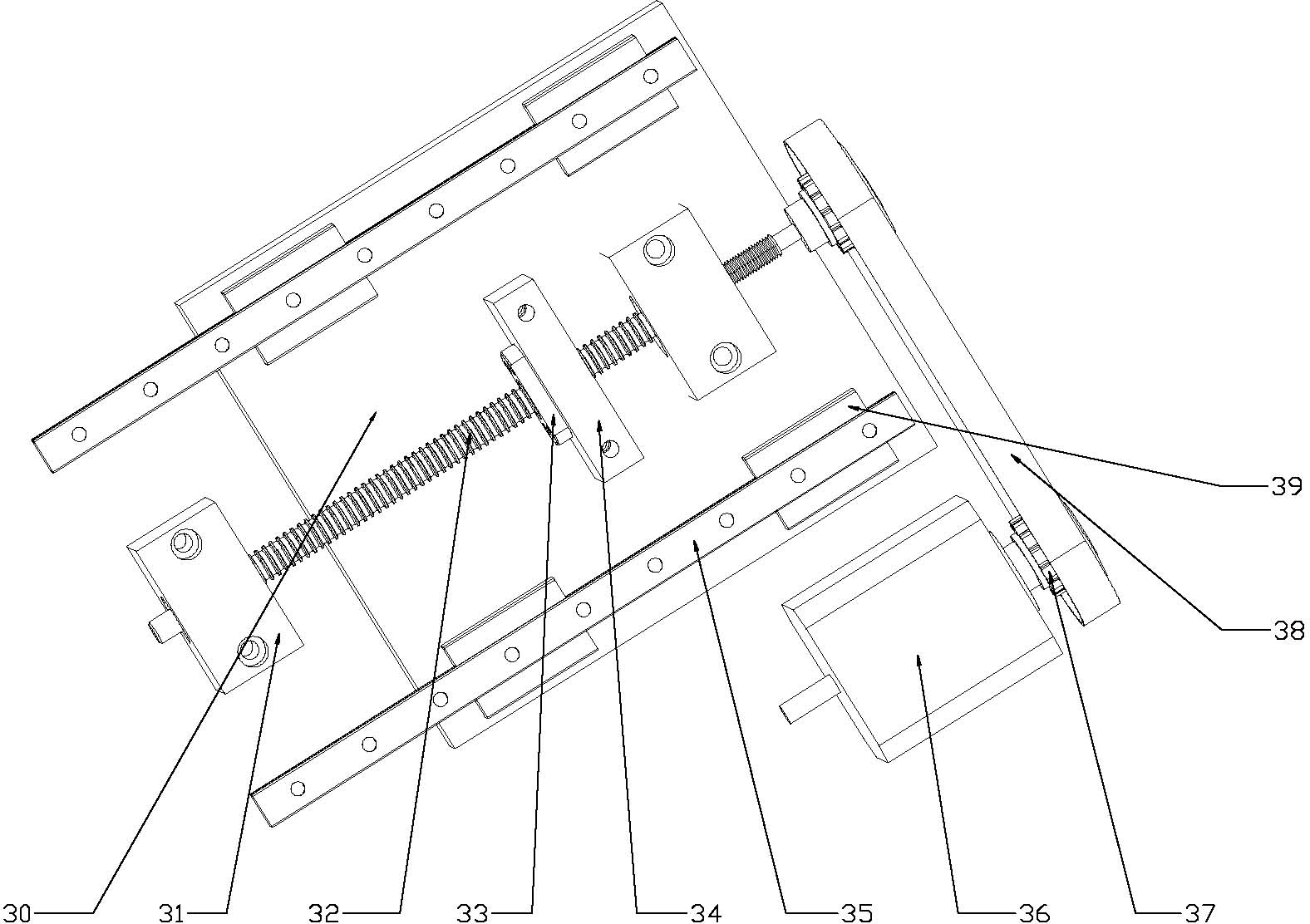

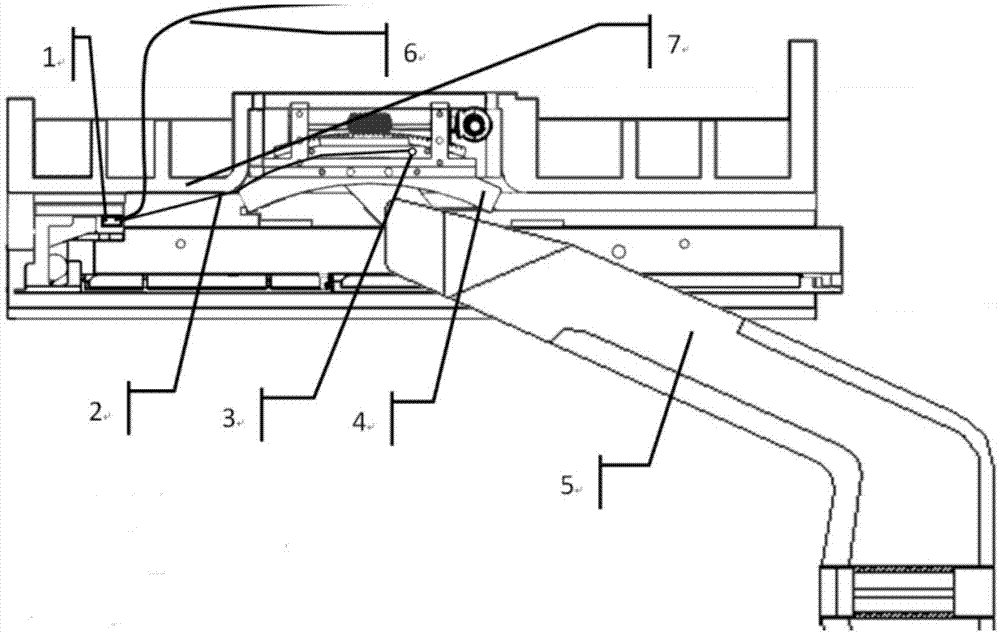

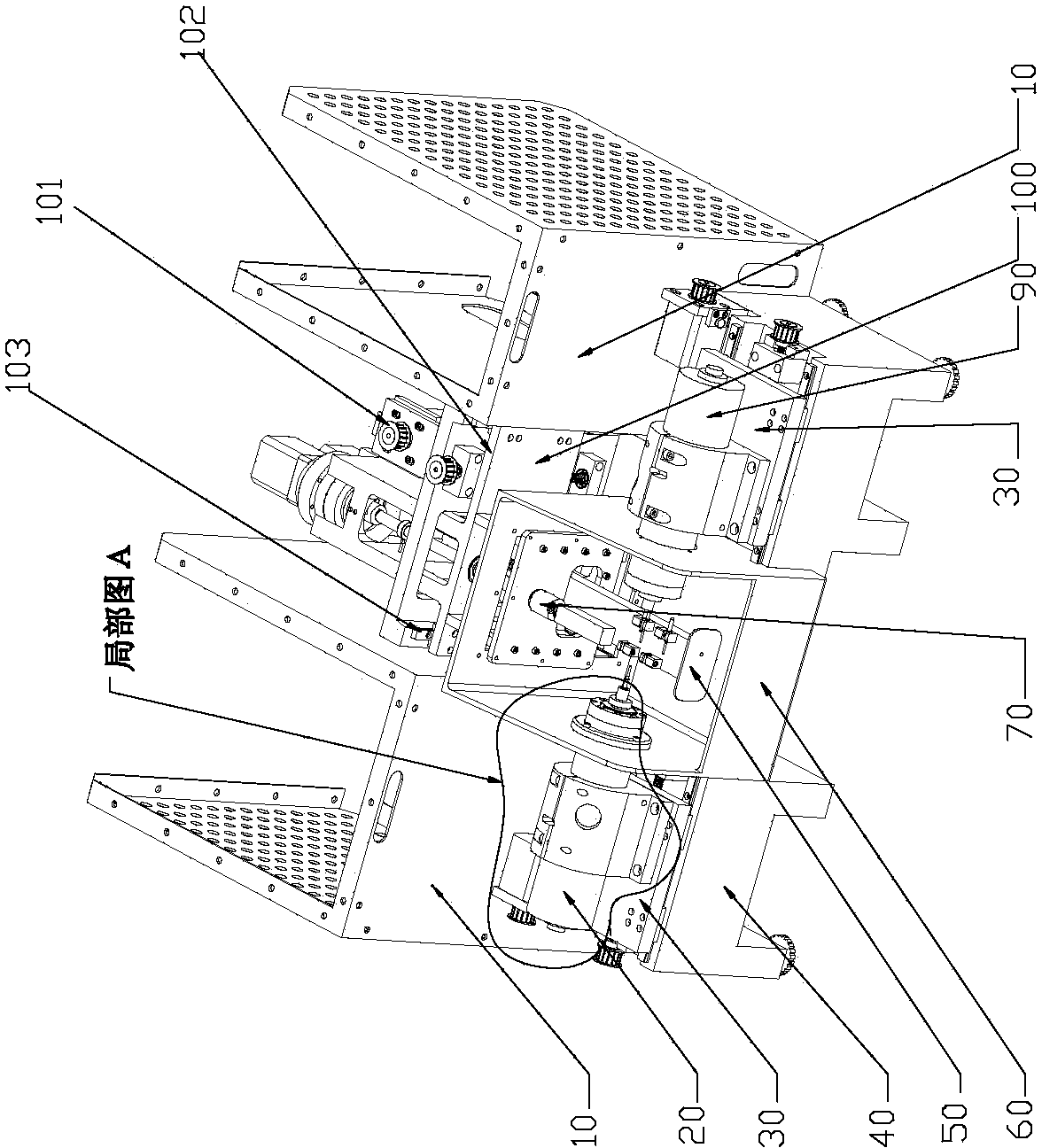

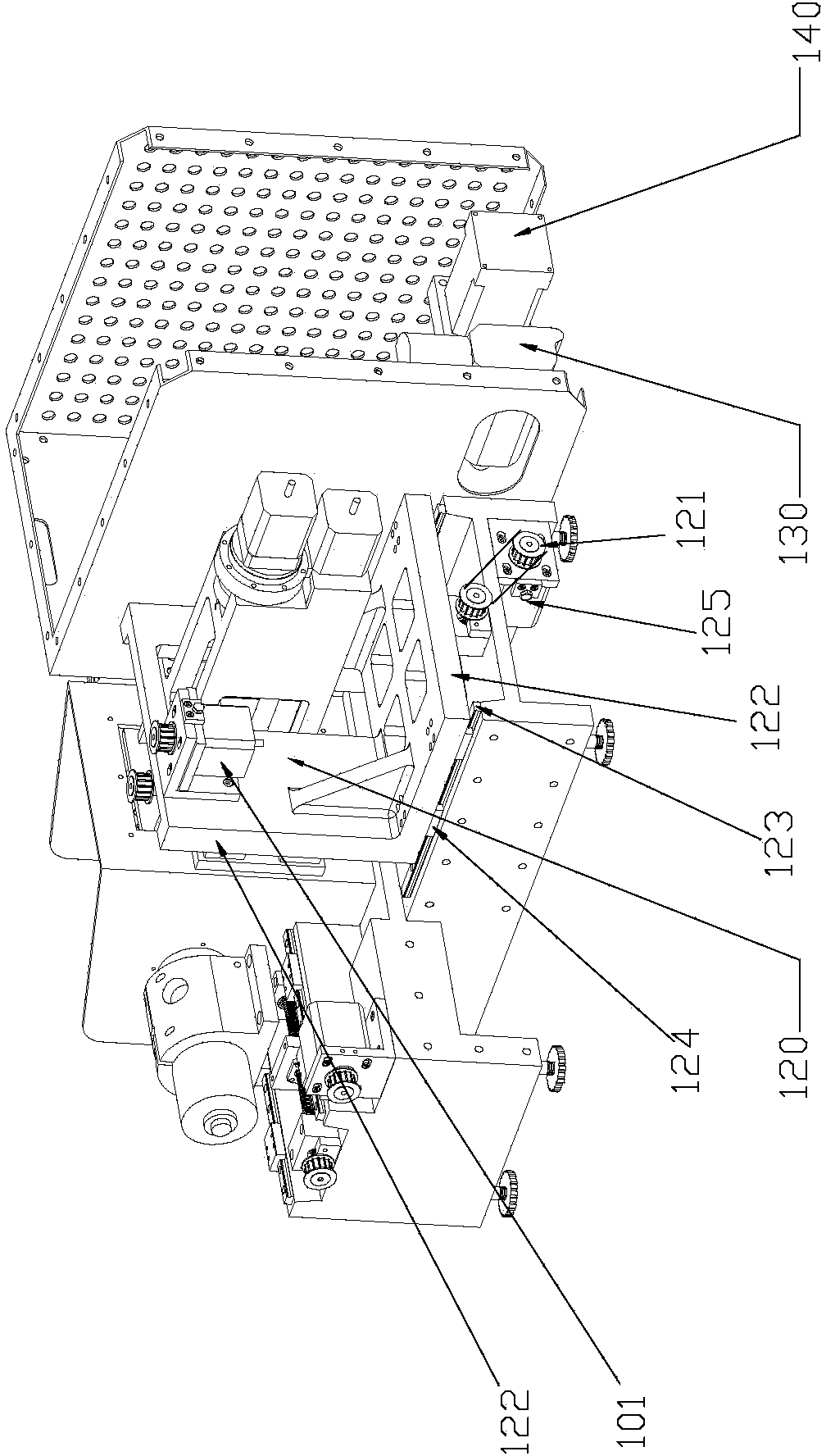

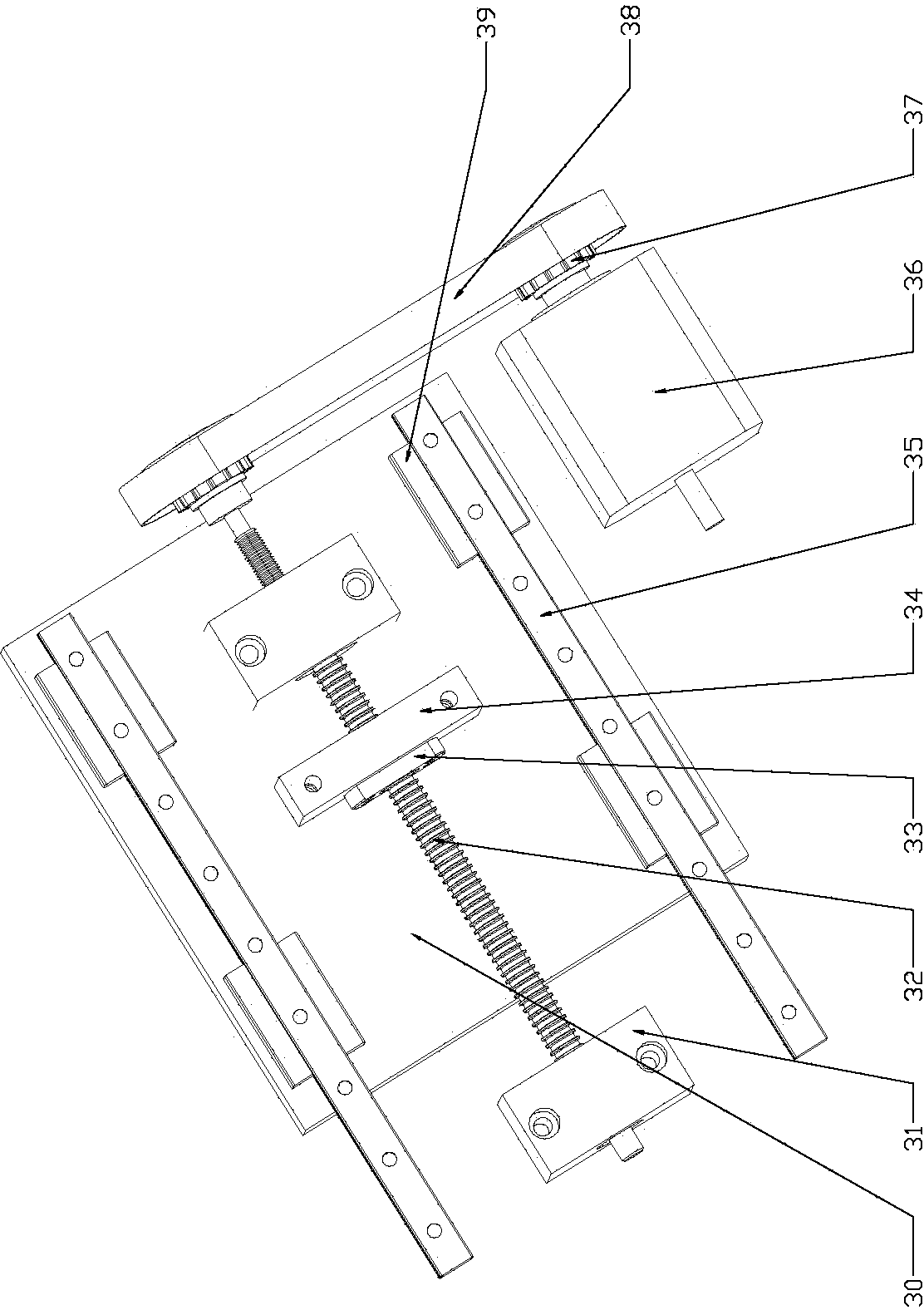

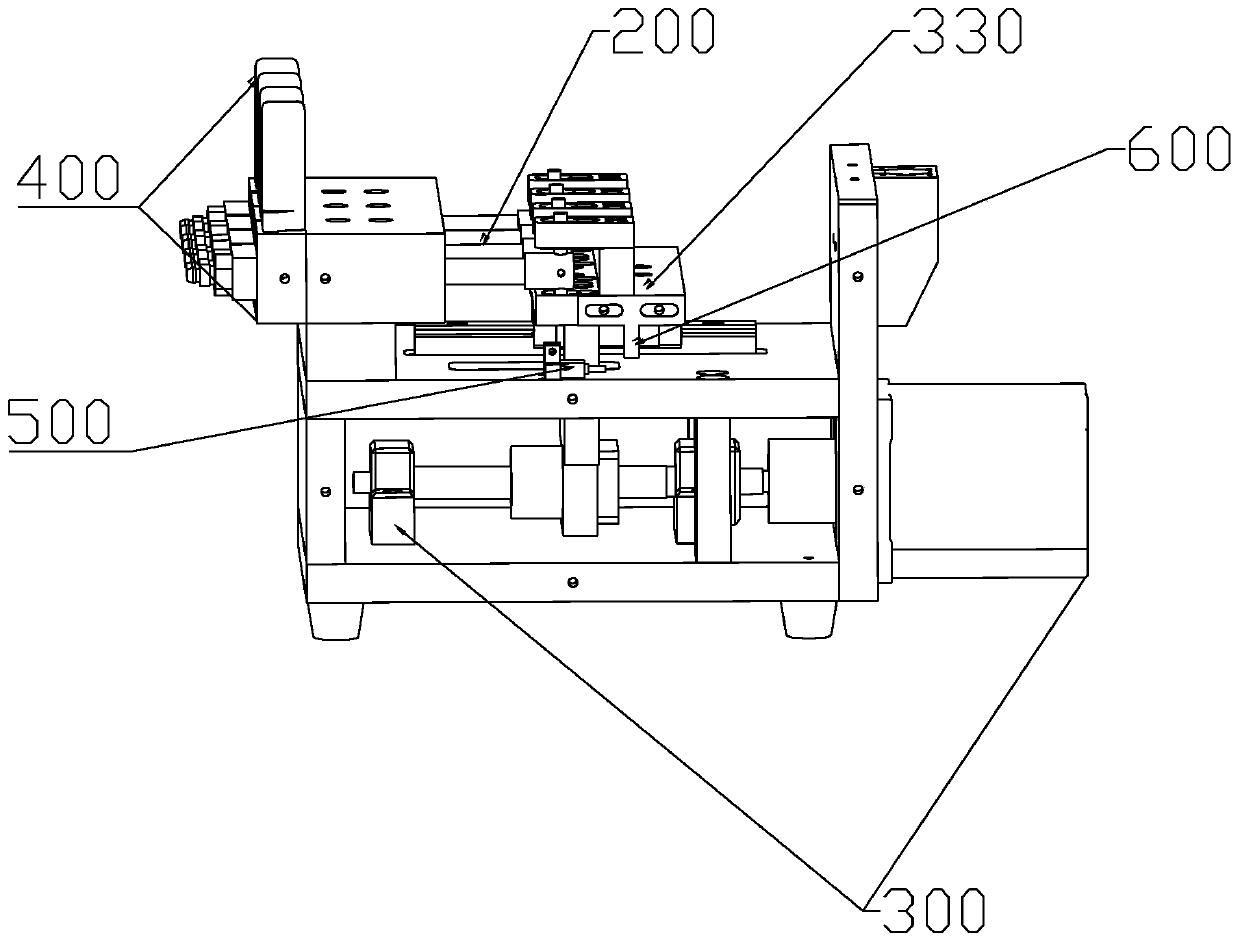

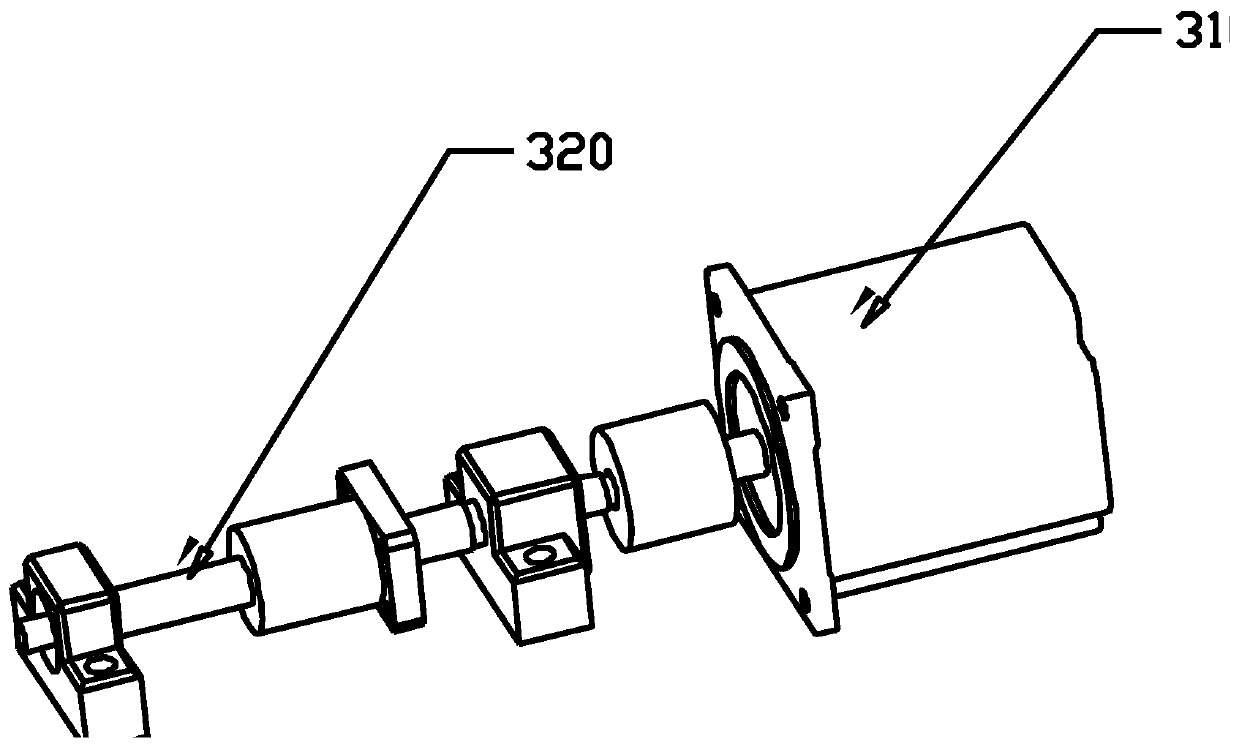

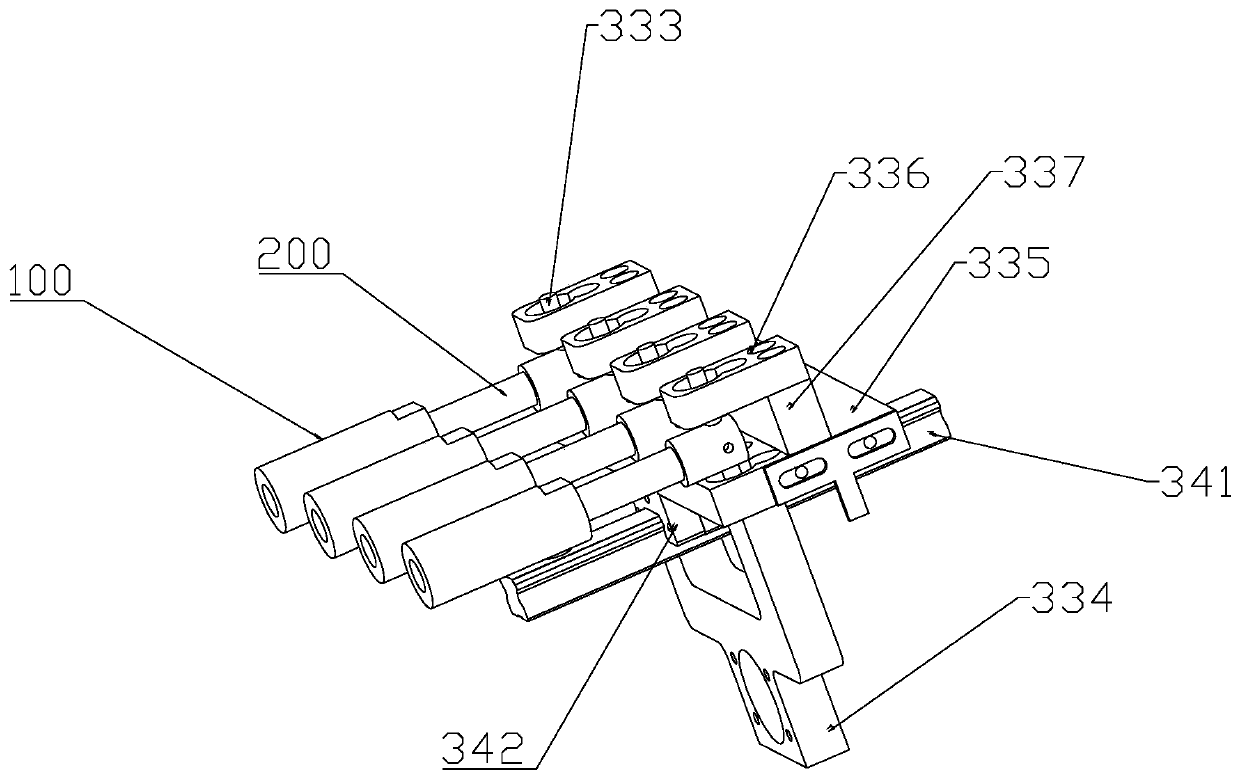

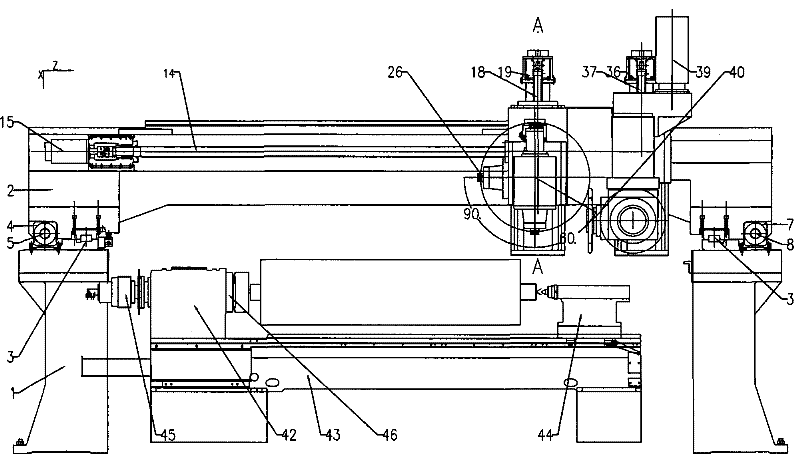

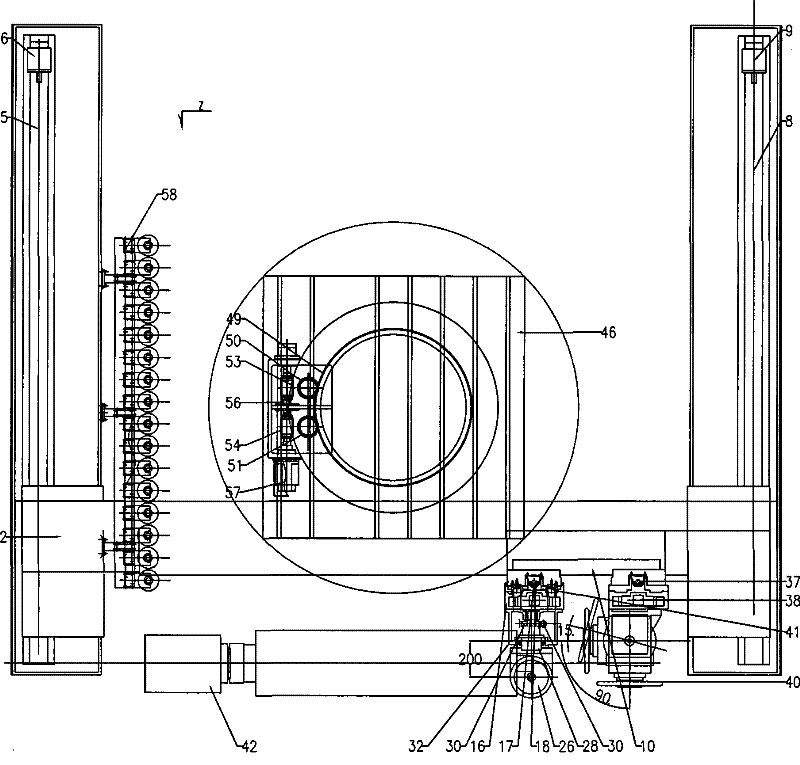

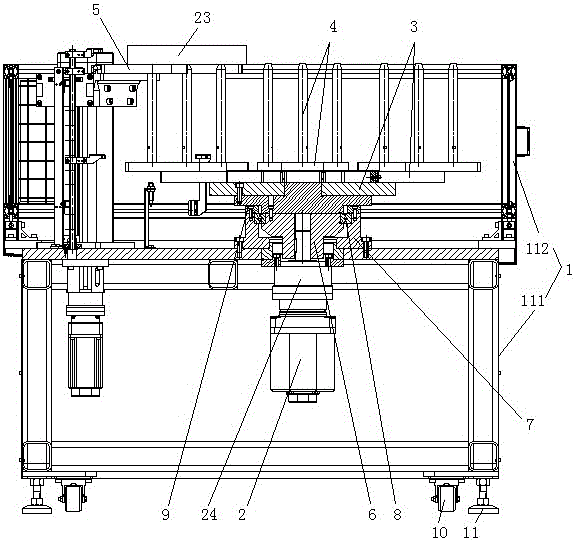

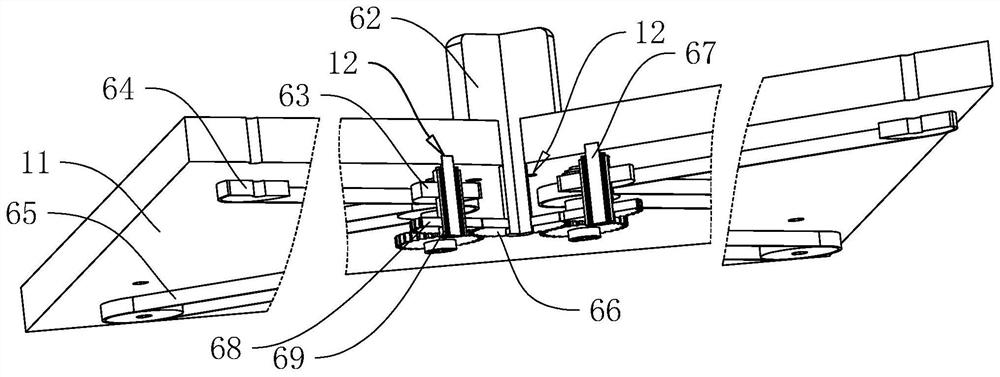

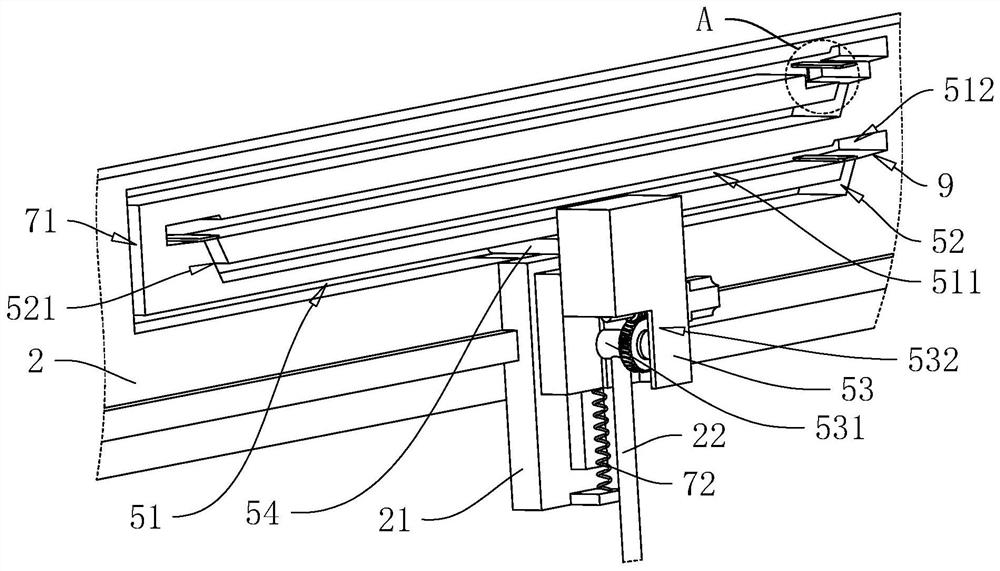

Micro double-spindle false tooth repair machine

ActiveCN102525677ASimplified volumeGuaranteed machining accuracyArtificial teethEngineeringMachining

The invention discloses a micro double-spindle false tooth repair machine. The false tooth repair machine comprises a base (40) and a first electric spindle system (20), a second electric spindle system (90), electric cabinets (10) and a workpiece rotating mechanism (70) which are arranged on the base (40). The false tooth repair machine is characterized in that: the first electric spindle system (20) and the second electric spindle system (90) are arranged coaxially, and cutters arranged on the first electric spindle system (20) and the second electric spindle system (90) and a workpiece arranged on the workpiece rotating mechanism (70) extend into a machining space (60) and are arranged vertically in a horizontal plane; the first electric spindle system (20) and the second electric spindle system (90) are arranged on respective X-axial feeding mechanisms (30); the workpiece rotating mechanism (70) is arranged on a Y-axis feeding mechanism (100), the Y-axis feeding mechanism (100) is arranged on a Z-axis feeding mechanism (120), and the Z-axis feeding mechanism (120) is arranged on the base (40); and a tool magazine system (50) is also arranged on the Y-axis feeding mechanism (100). The false tooth repair machine has the advantages of simple structure, small volume, high machining precision and convenience in operation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

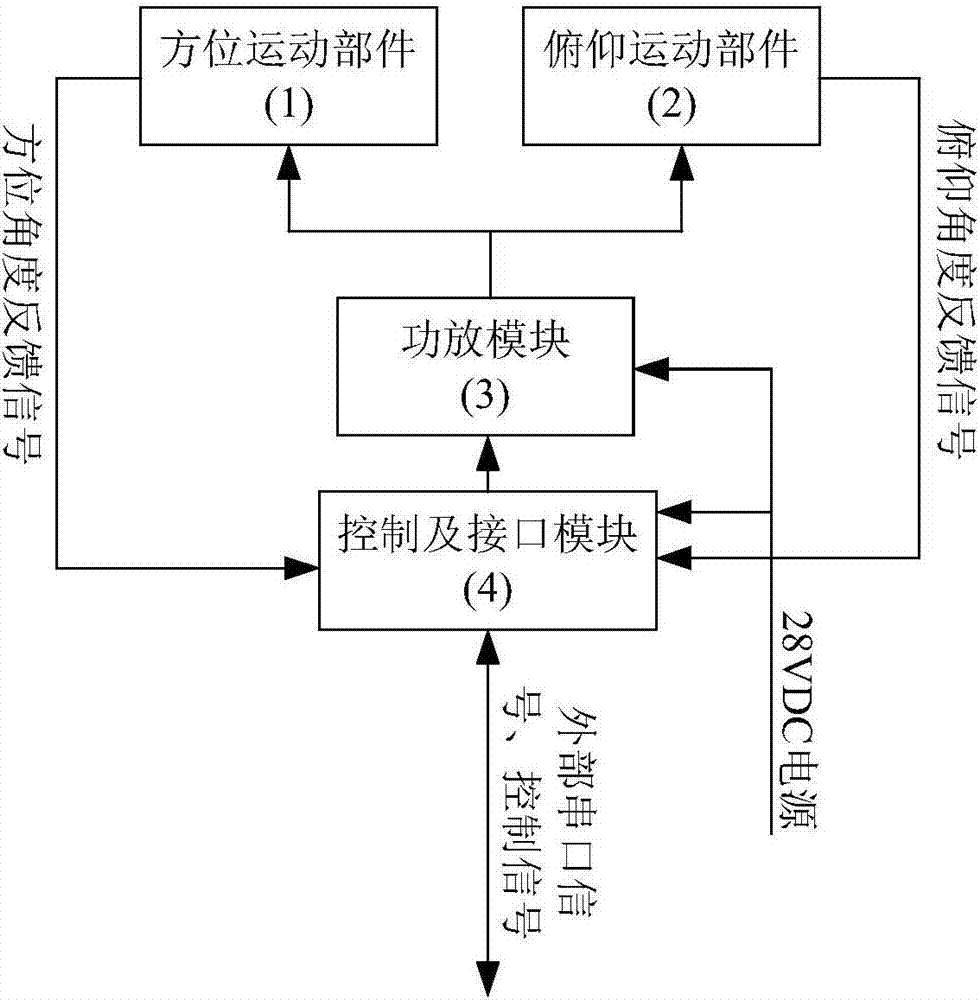

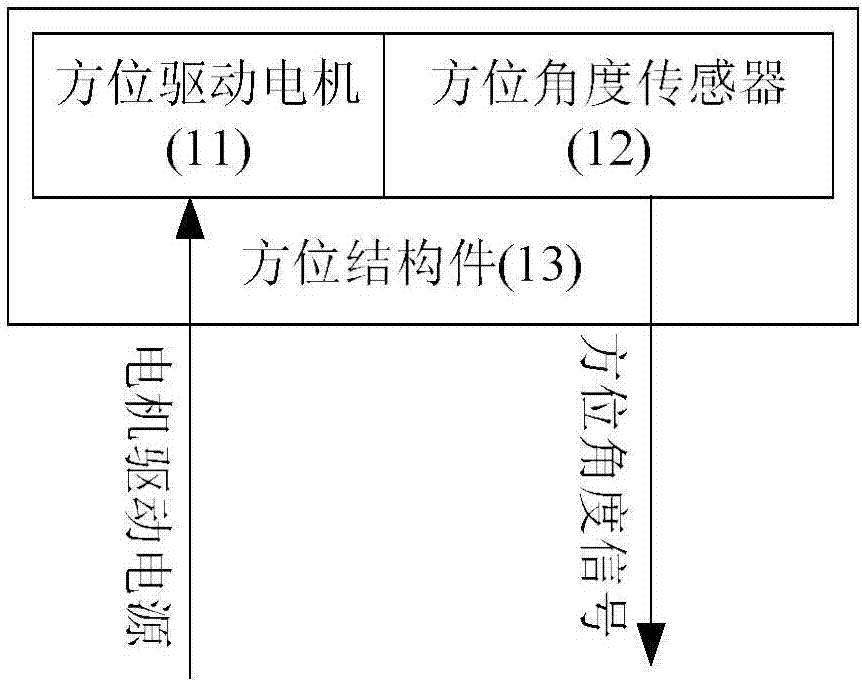

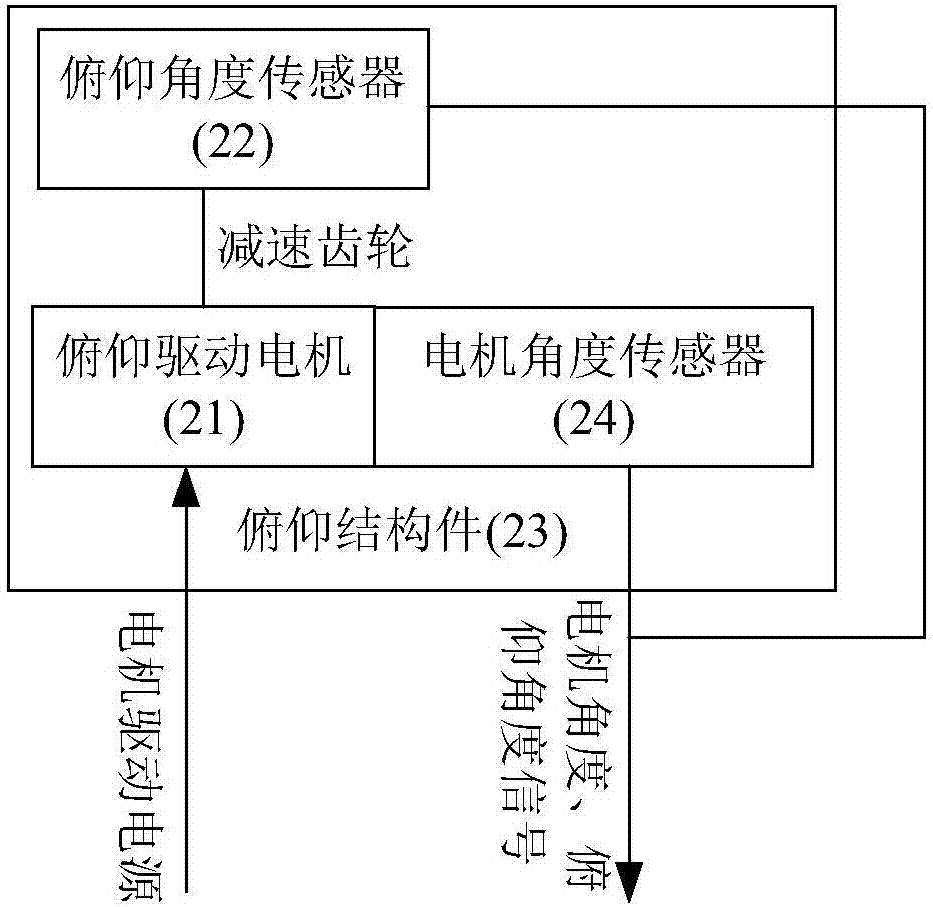

Airborne-antenna high speed servo motion platform

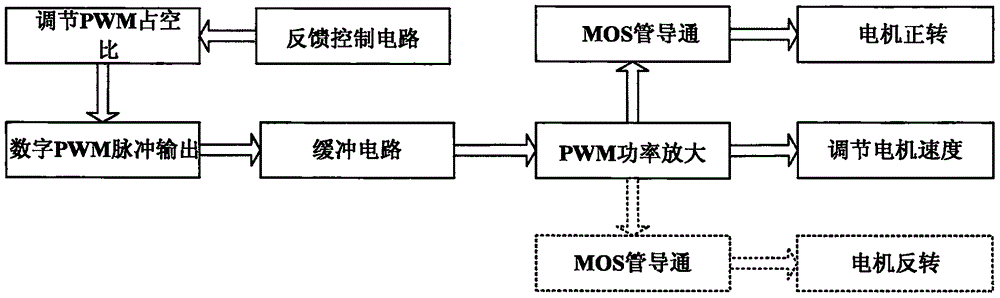

PendingCN107193292AImprove response speedHigh control precisionControl using feedbackControl signalFlight vehicle

The invention discloses an airborne-antenna high speed servo motion platform. By using an existing airborne-antenna servo motion platform, an antenna can not be driven to carry out high-speed and high-precision scanning motion. By using platform of the invention, the above problem is solved. The platform comprises an orientation motion component (1), a pitching motion component (2), a power amplifier module (3) and a control and interface module (4). The control and interface module (4) generates a pulse width modulation signal which is used to control a motor and outputs to the power amplifier module (3) according to a received control instruction, aerial carrier attitude data and feedback signals of orientation and a pitch angle. The power amplifier module generates a motor driving power supply according to a received pulse width modulation control signal, outputs to the orientation motion component (1) and the pitching motion component (2) so as to drive the two components to carry out orientation and pitching motion, and simultaneously feeds back the orientation and the pitch angle to the control and interface module (4) in real time. The platform possesses advantages that a response speed is fast and control precision is high and can be used in various aircrafts which need the antenna to carry out mechanical scanning motion.

Owner:SHAANXI CHANGLING ELECTRONICS TECH

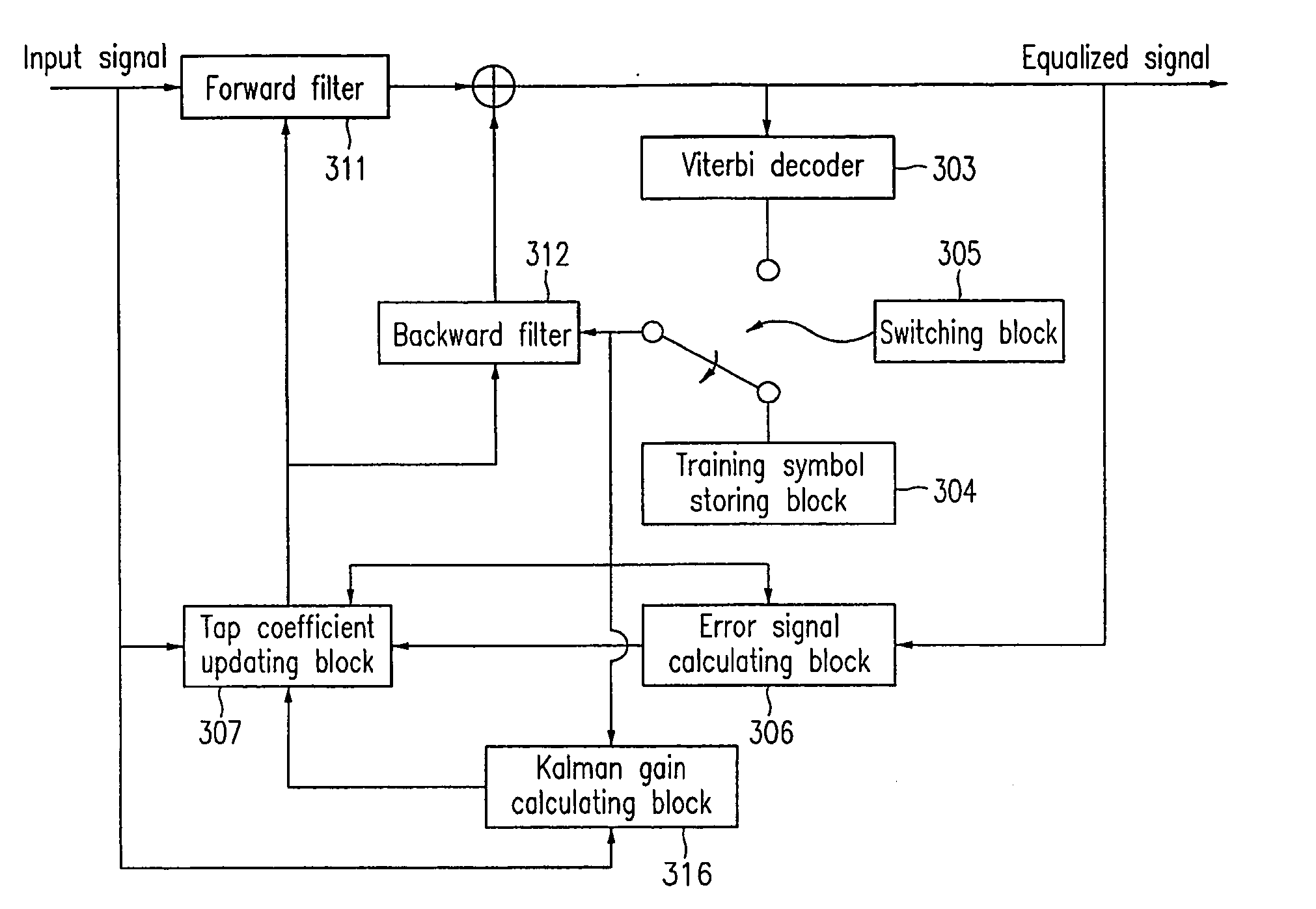

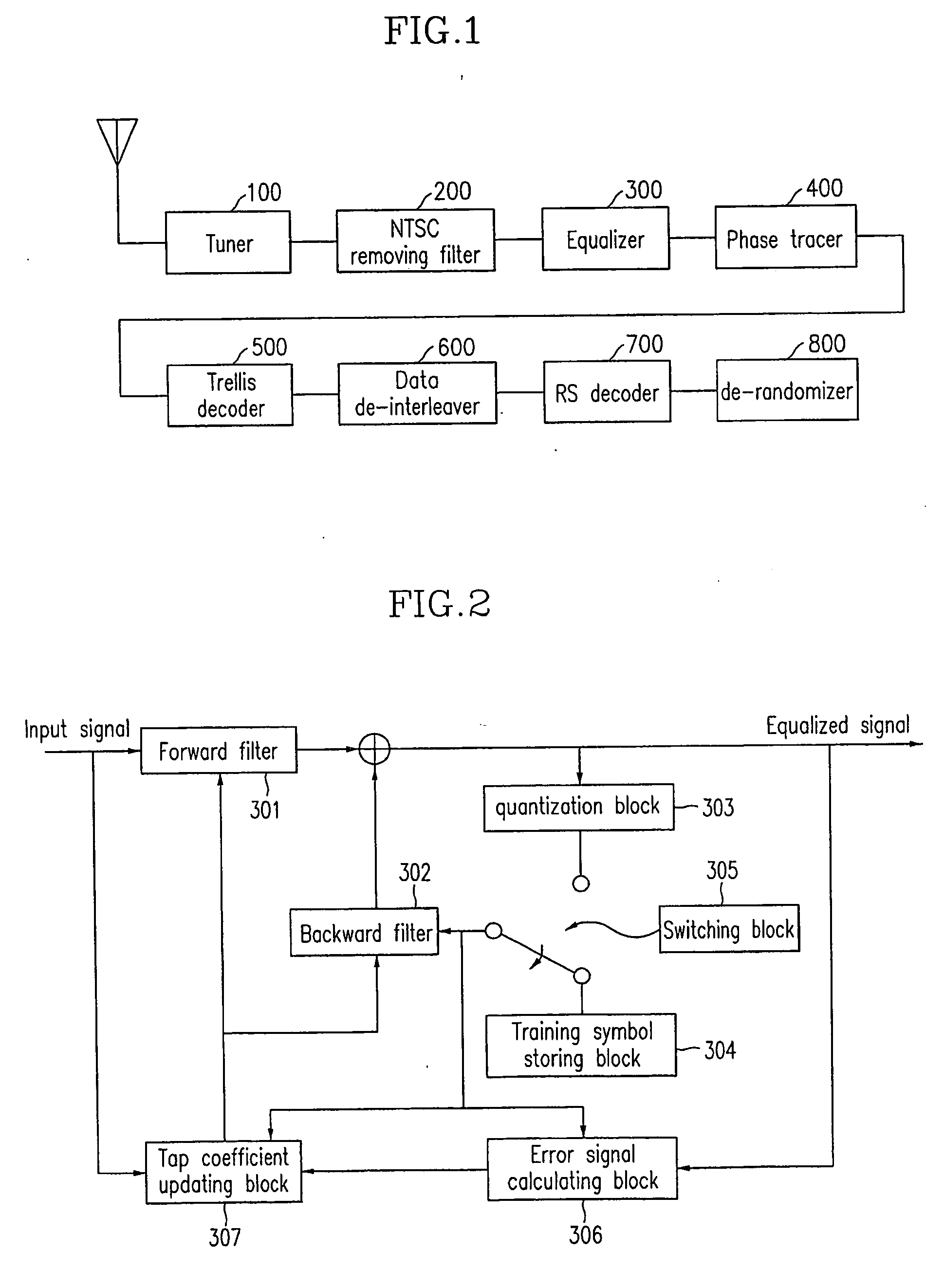

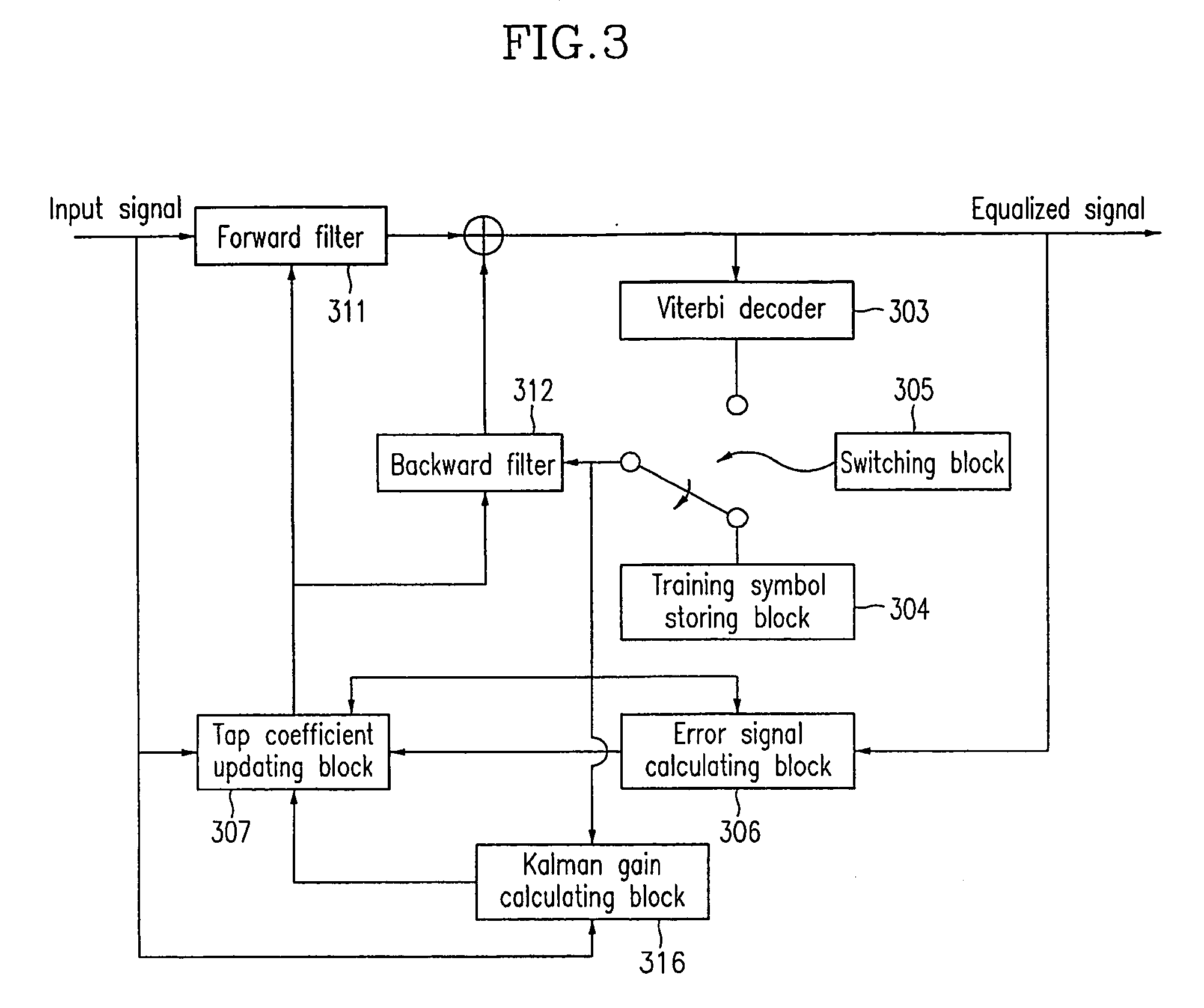

Kalman-viterbi joint channel equalizer

InactiveUS20050286622A1Easy to solve distortionEliminate transmission errorsMultiple-port networksTelevision system detailsViterbi decoderDTV receiver

In a channel equalizer applicable to a digital television receiver, a forward filter and a backward filter perform filtering to an input signal and a predetermined signal. A Viterbi decoder corrects errors during a transmission procedure in a blind mode. A training symbol storing block stores training symbols. An output signal of the Viterbi decoder and symbols are provided to the backward filter in accordance with a blind mode or a training mode. A Kalman gain is calculated in a Kalman gain calculating block and an error signal is calculated by comparing an equalized signal, symbols, and the output signal of the Viterbi decoder with one another. A tap coefficient is updated by using the calculated error signal and the Kalman gain.

Owner:ELECTRONICS & TELECOMM RES INST

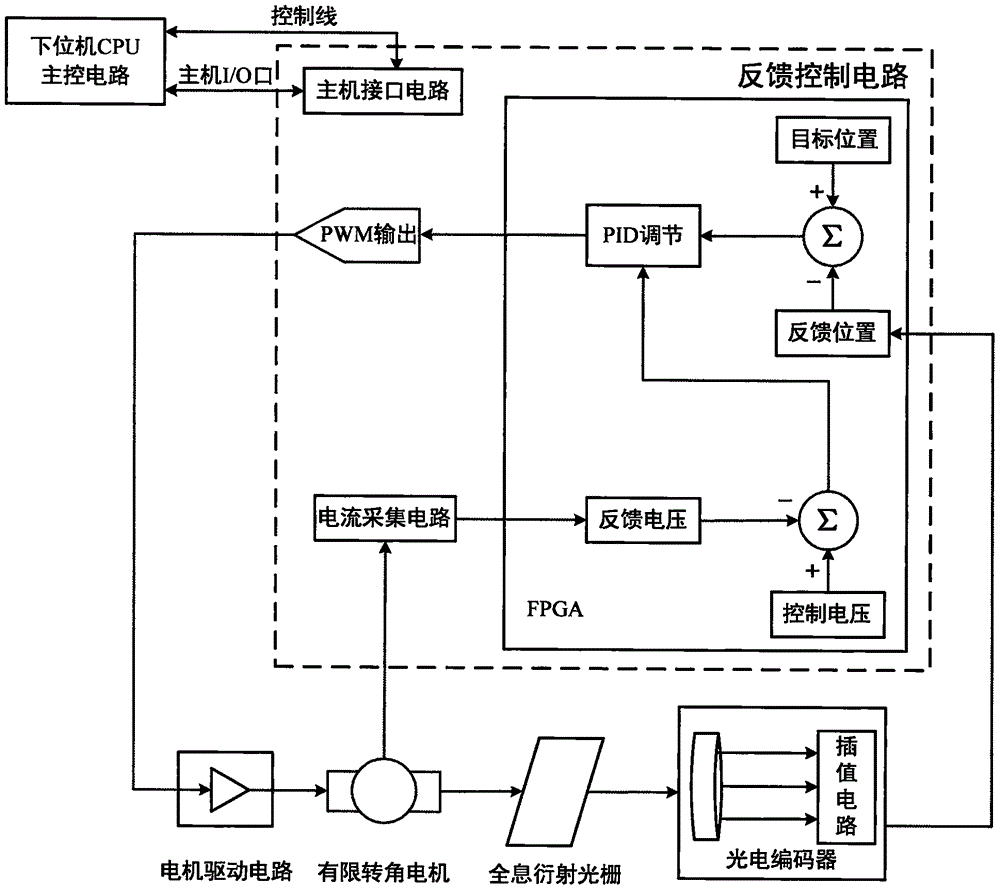

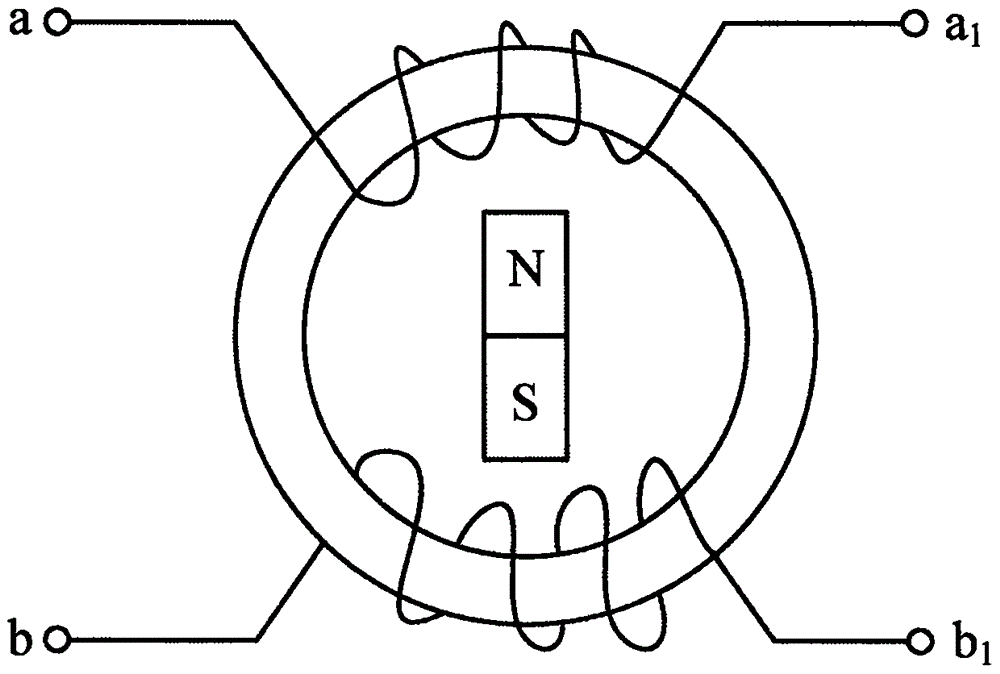

High-precision grating positioning device directly driven by a limited angle motor

InactiveCN106352980AEliminate transmission errorsEliminate transmission lossesSpectrum investigationStructural associationClosed loopOpto electronic

The invention provides a high-precision grating positioning device directly driven by a limited angle motor, which comprises a motor drive circuit, a limited angle motor, a holographic diffraction grating, a photoelectric encoder, an interpolation circuit and a feedback control circuit. The rotor on one side of the limited angle motor passes directly through the bottom of the diffraction grating, while ensuring the center of the grating is located on the shaft, the stator is fixed on the outer heat dissipation frame, the motor is connected with the load through rigid coupling and directly drives the grating to rotate; the photoelectric encoder detects the angular position of the diffraction grating, and the output terminal of the photoelectric encoder is connected with the interpolation circuit. The interpolation circuit amplifies the sine and cosine signals outputted by the photoelectric encoder, doubles the frequency and interpolates after conversion, and connects the feedback control circuit through the interpolated output signal; the feedback control circuit achieves double closed-loop control of current feedback and position feedback, and the motor drives the circuit to generate the drive voltage to control the motor rotation. The high-precision grating positioning device has strong anti-interference ability, high resolution precision, and strong practicability and versatility.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Angle control device for tunnel attack-angle mechanism

ActiveCN105444980AEliminate transmission errorsEliminate errorsAerodynamic testingElectricityControl system

The invention discloses an angle control device for a tunnel attack-angle mechanism, and solves a problem that there is no angle control device which can eliminate the mechanical wear of the attack-angle mechanism and an error caused by mechanical transmission. The device comprises a stay cord sensor which is disposed in an upper column room of a tunnel, wherein a cord pulling end of the stay cord sensor is fixed on a sliding block of the attack-angle mechanism, and the sliding block is fixedly connected with a bent knife of the attack-angle mechanism; and a measurement and control system which is electrically connected with the stay cord sensor. A driving mechanism of the attack-angle mechanism drives the sliding block to slide. When the sliding block slides, a stay cord of the stay cord sensor is enabled to extend or withdraw. The stay cord sensor outputs voltage data to the measurement and control system, and the measurement and control system obtains an attack angle value according to the received voltage data and a fitting attack angle voltage formula. A control device of the attack-angle mechanism controls the attack angle of the attack-angle mechanism according to the attack angle value.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

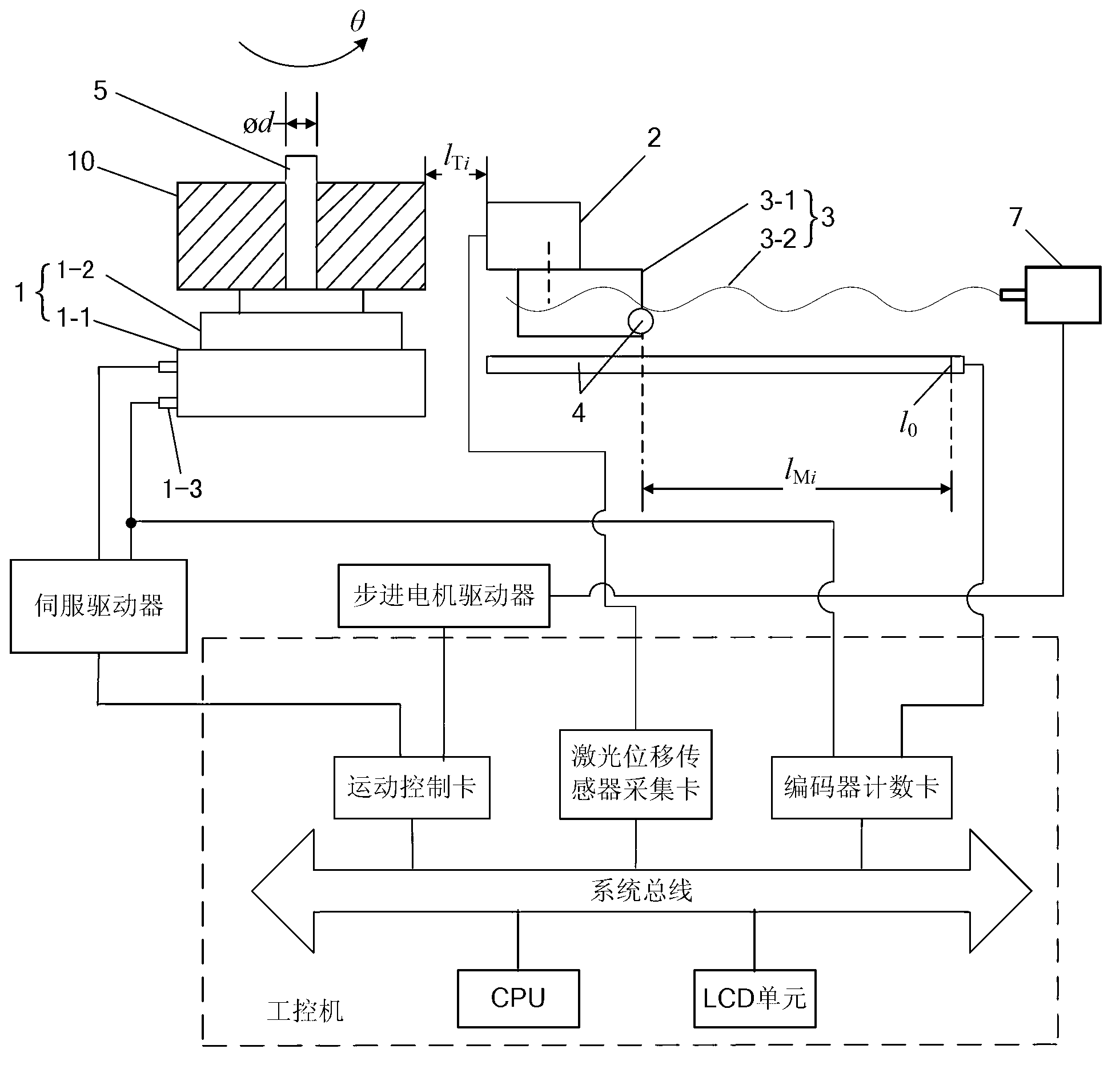

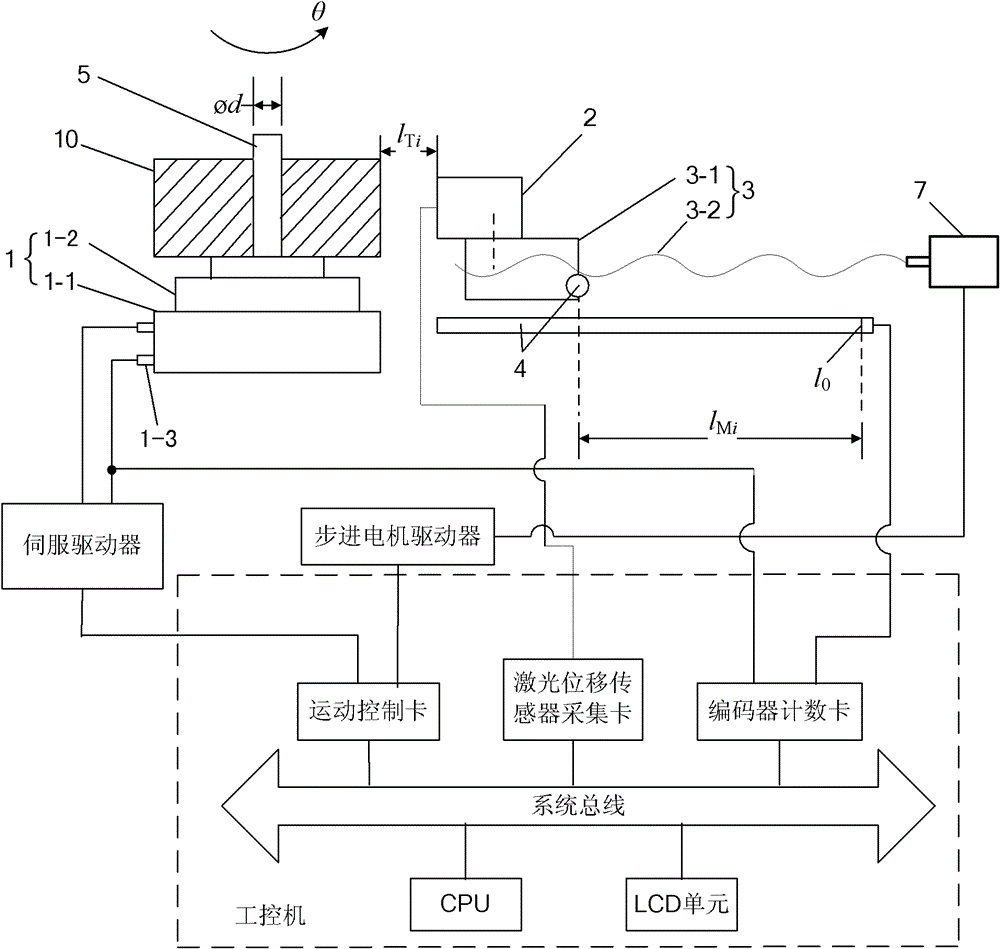

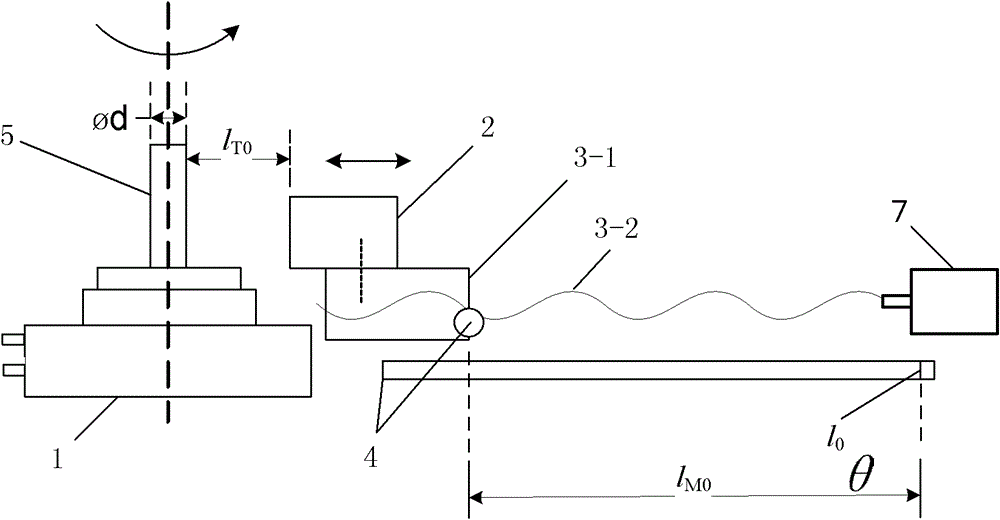

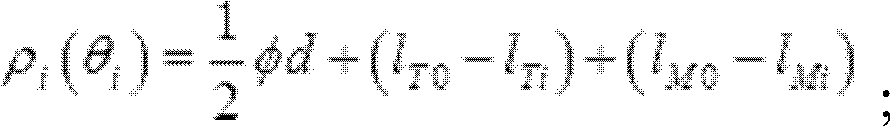

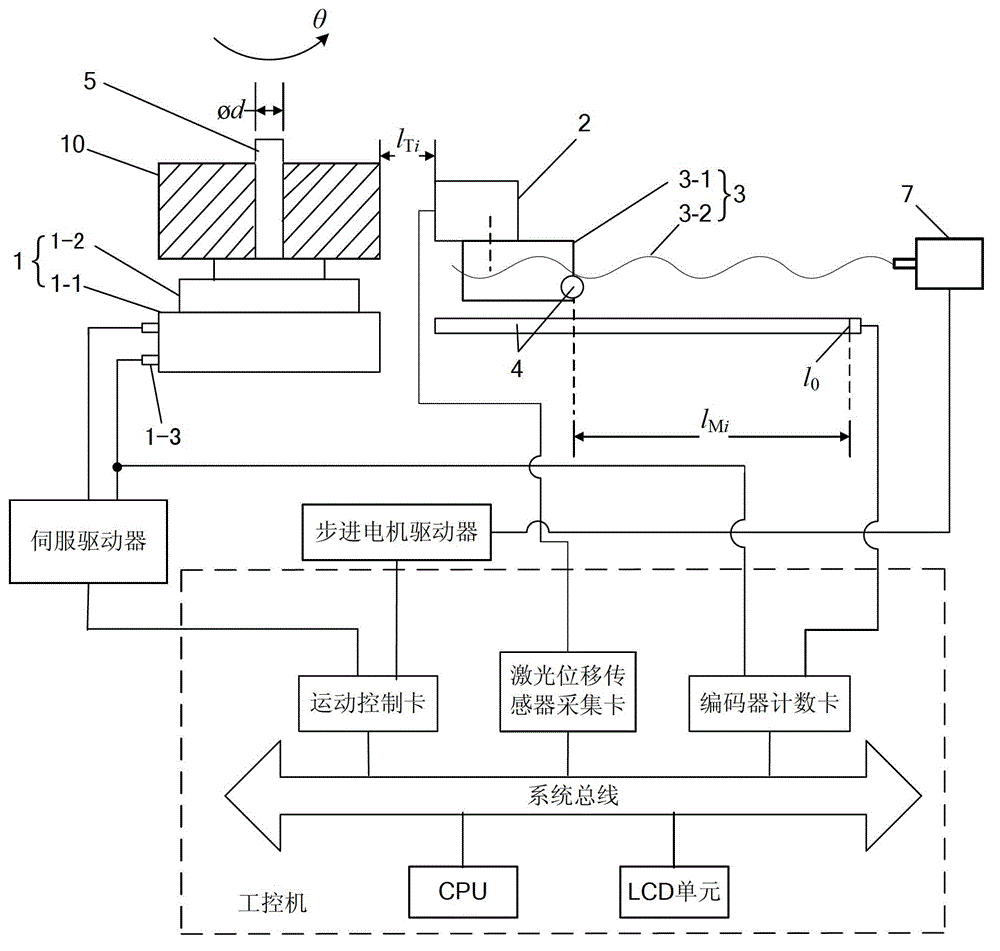

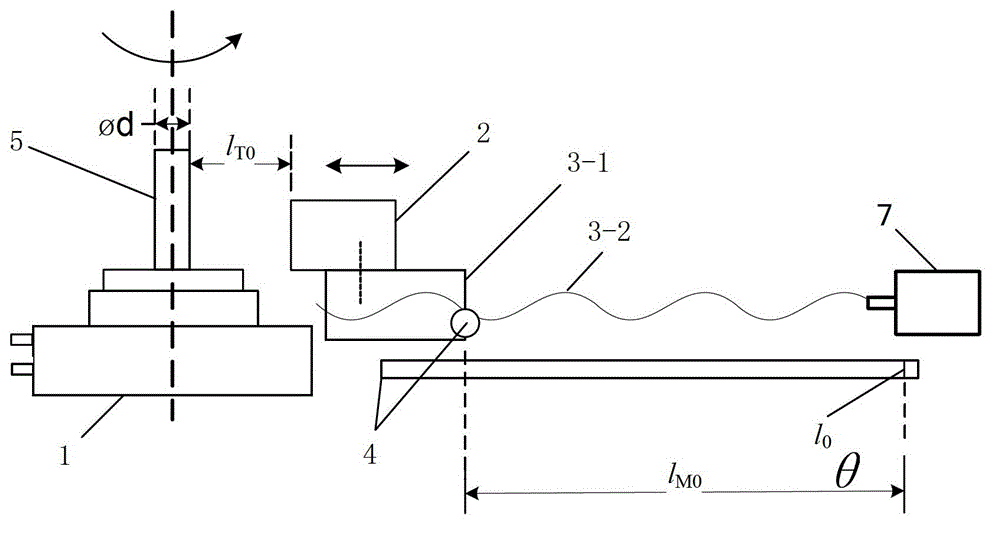

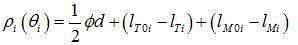

Cam profile detection system based on direct driving motor

The invention provides a cam profile detection system based on a direct driving motor, and the cam profile detection system is simple in structure and high in detection precision and efficiency. The system comprises the direct driving motor, a mandrel, a feed screw nut pair, a laser measurement head, a grating ruler displacement sensor, a circular grating and an industrial personal computer, wherein the mandrel is coaxially and fixedly arranged on the rotor of the direct driving motor and is used for driving a cam to coaxially rotate synchronously; the feed screw nut pair is horizontally arranged at one side of the cam; the laser measurement head is arranged on the movable nut of the feed screw nut pair; the grating ruler displacement sensor is used for measuring the horizontal displacement amount of the movable nut; the circular grating is arranged in the fixed seat of the direct driving motor and is used for detecting the rotation angle of the rotor; and the industrial personal computer controls actions of the direct driving motor and the feed screw nut pair, and obtains outer profile data of the cam according to data obtained by the laser measurement head, the grating ruler displacement sensor and the circular grating.

Owner:CHANGZHOU INST OF TECH

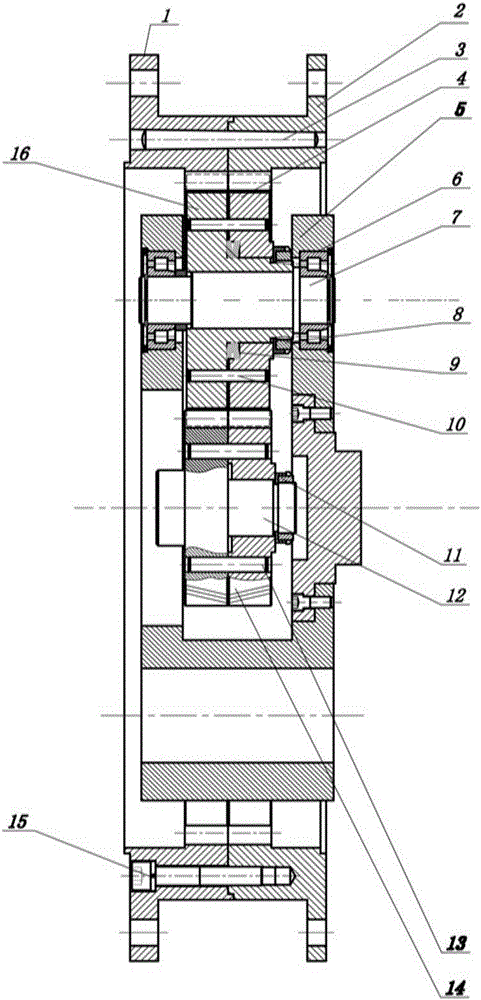

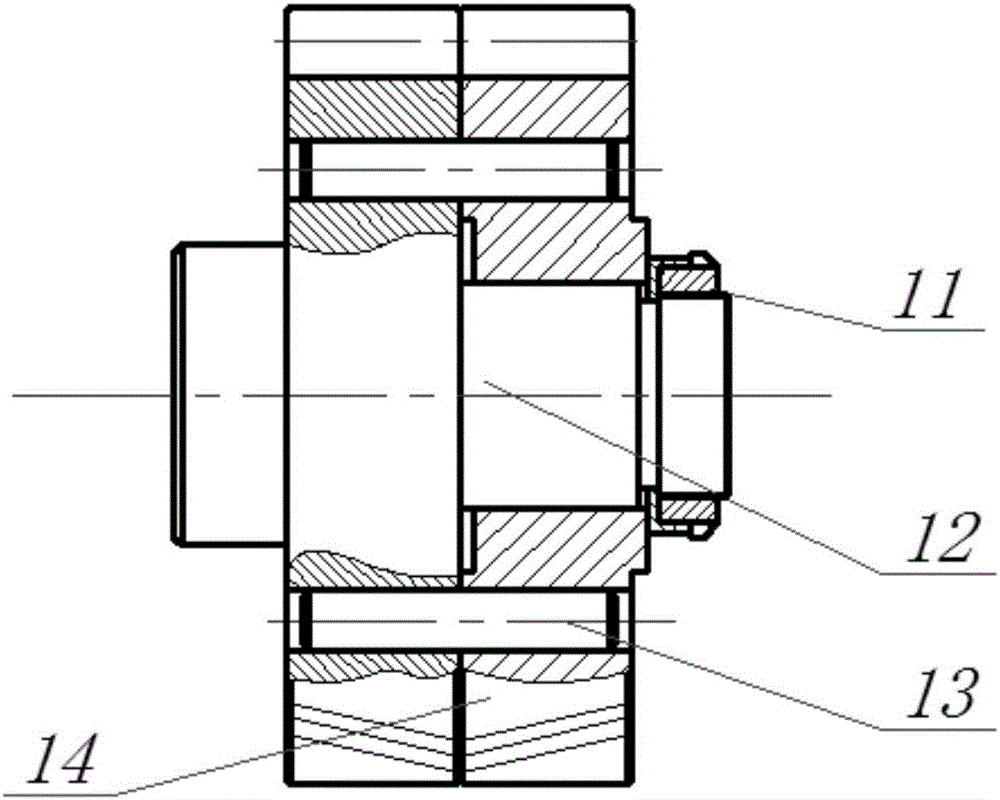

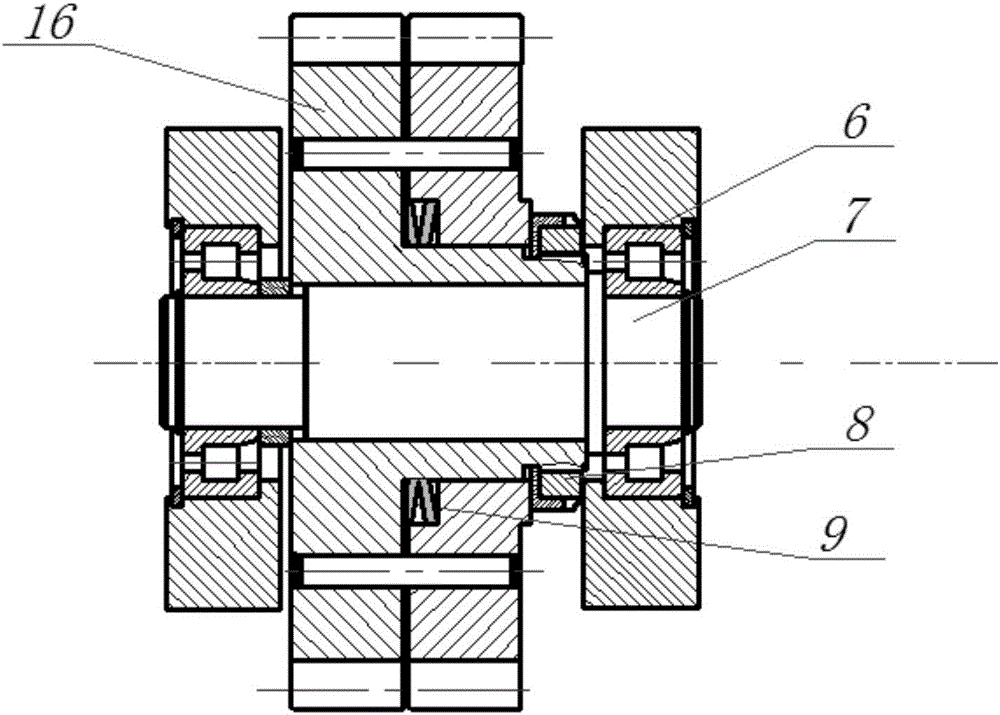

Combined type herringbone gear planet transmission device with adjustable backlashes

InactiveCN106286718AHigh transmission precisionAchieve engagement backlashToothed gearingsGearing detailsGear wheelHerringbone gear

The invention belongs to the field of gear transmission and provides a combined type herringbone gear planet transmission device with adjustable backlashes. The device comprises an inner gear ring, sun gears, planet gears, planet carriers, planet gear bearings, a planet gear shaft and elastic pieces. According to the combined type herringbone gear planet transmission device with the adjustable backlashes, symmetrical bevel gears are combined to form a herringbone gear, machining with high difficulty of an integrated herringbone gear is brought down into machining with low difficulty of the common bevel gears, a new form of herringbone gear combined installation is provided, machining and assembling are simple, and manufacturing cost is reduced; the axial elastic pieces are installed between a main planet gear and an assistant planet gear, the main planet gear, the assistant planet gear and the elastic pieces are pre-tightened through nuts, meshing backlashes between the planet gears and the sun gears as well as between the planet gears and the inner gear ring are achieved, transmission errors caused by positive and negative rotation of the gears are eliminated, and transmission precision of the planet gears is improved.

Owner:DALIAN UNIV OF TECH

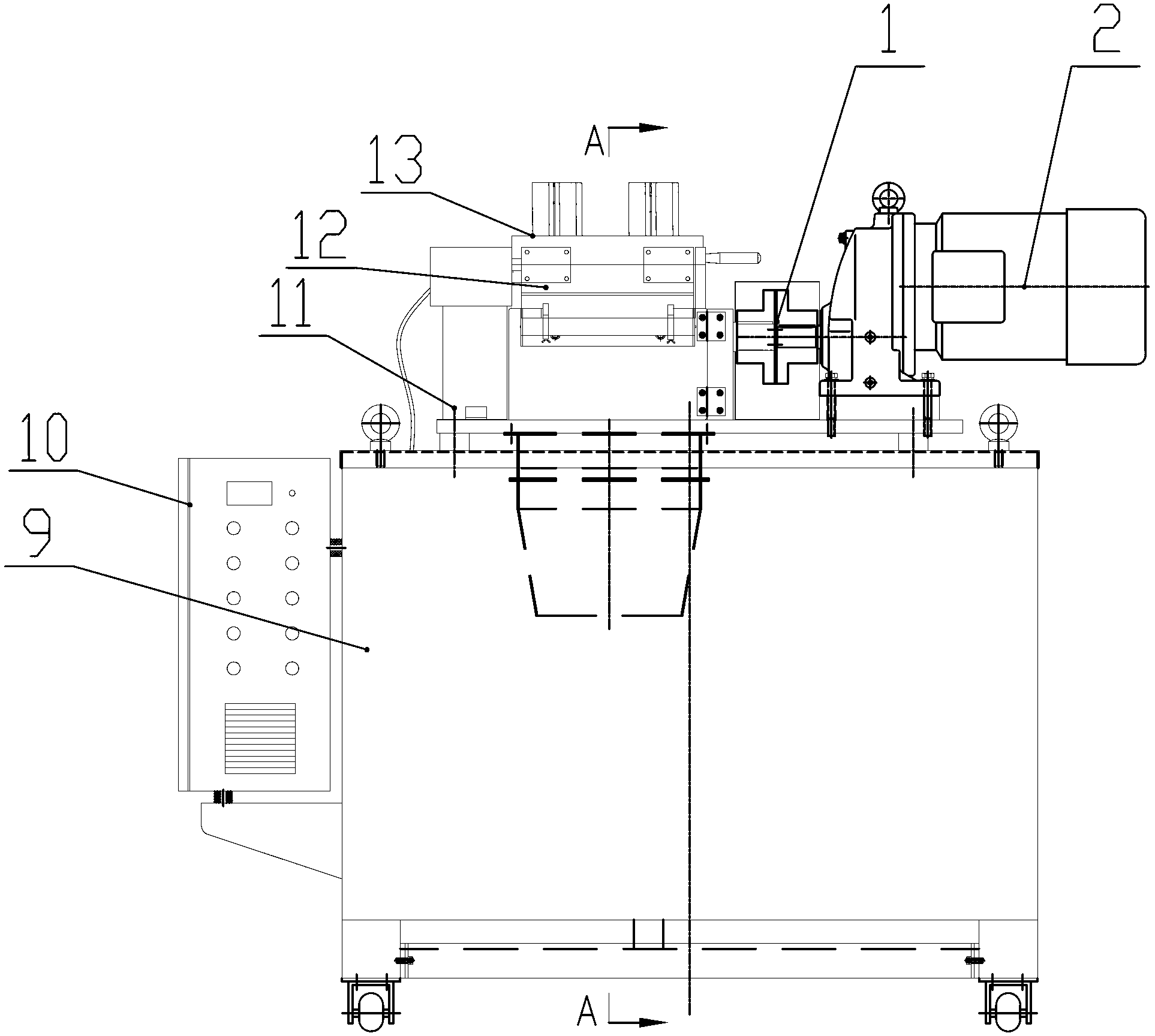

Gear-type granulator

InactiveCN103317614AEliminate transmission errorsSmooth and safe transmissionMetal working apparatusEngineeringTransmission ratio

The invention relates to a plastic granulating device, and in particular relates to a gear-type granulator. The gear-type granulator comprises a stander and an electric cabinet which is arranged on the end part side surface of the stander. The gear-type granulator is characterized in that a motor is installed on one end of the top of the stander, a granulating device and a conveying device are installed on the other end of the top of the stander, a housing on the top of the stander wraps the granulating device and the conveying device, the top of the housing is provided with an upper cover, a discharging port is formed in the bottom of the housing, an output shaft of the motor is connected with a hob shaft of the granulating device through an elastic coupler, and a hob is installed on the hob shaft. By adopting the granulator, the precise transmission ratio can be realized, the transmission efficiency is high, and the service life is long.

Owner:WUXI LINGOOD MACHINERY TECH

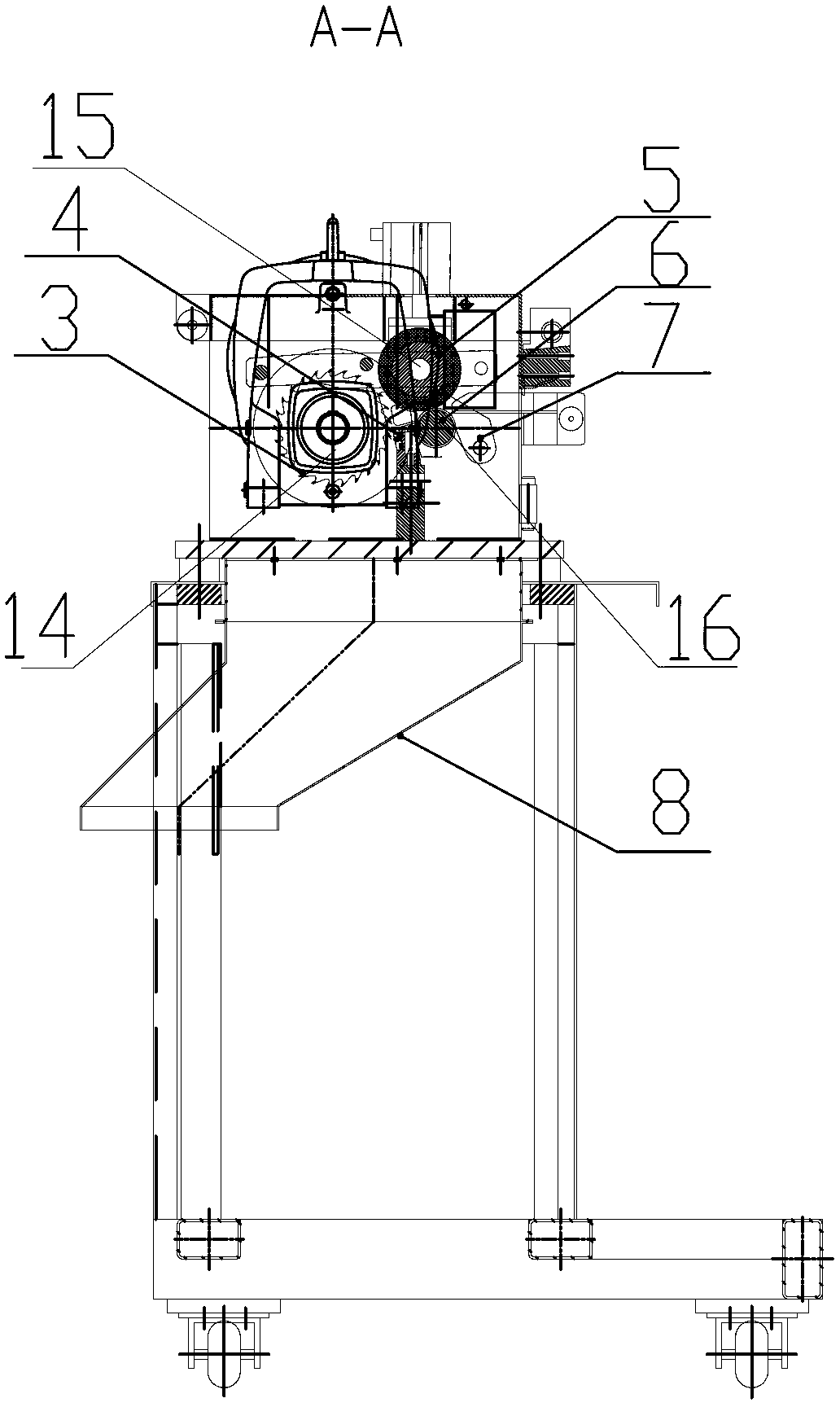

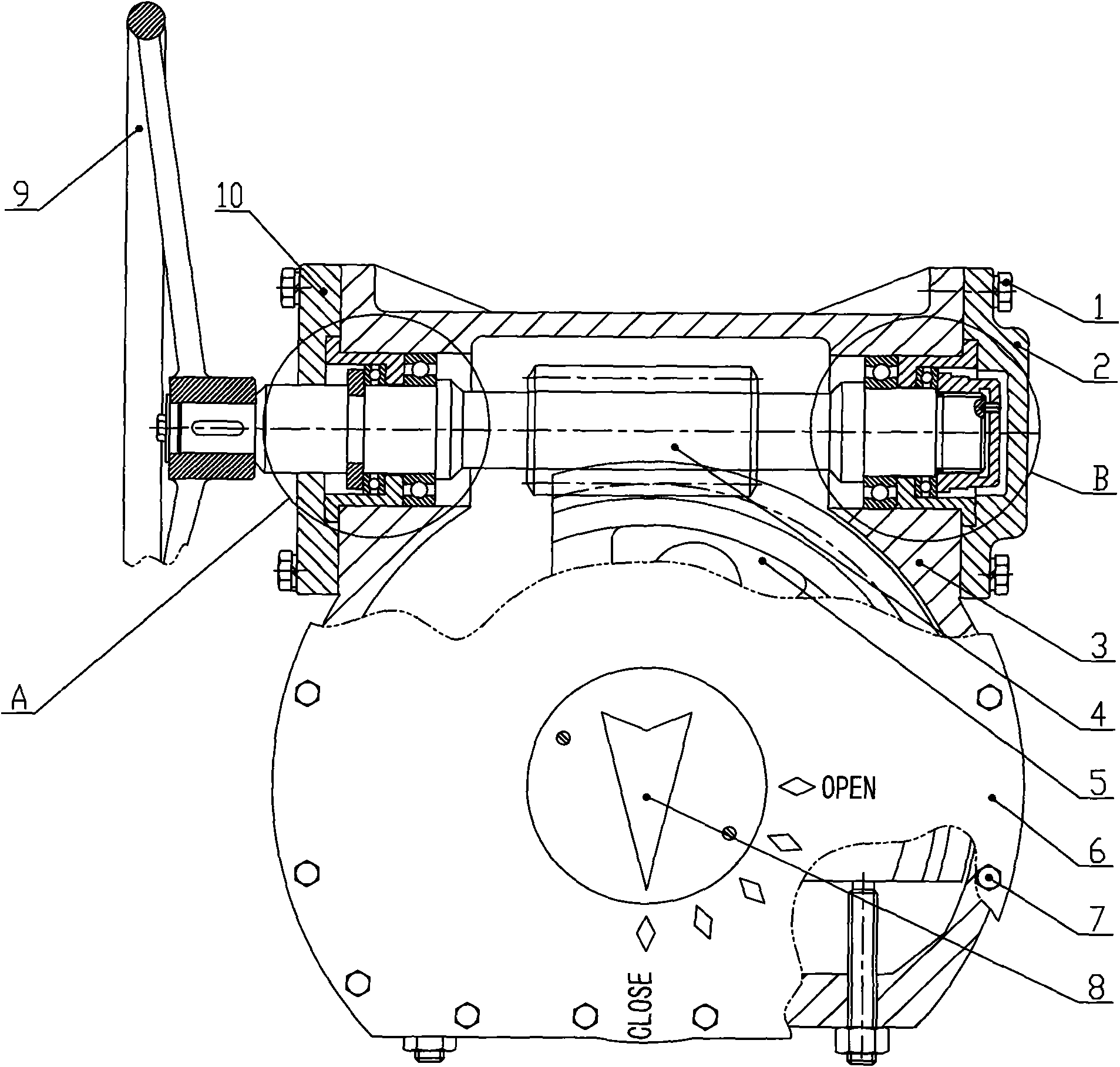

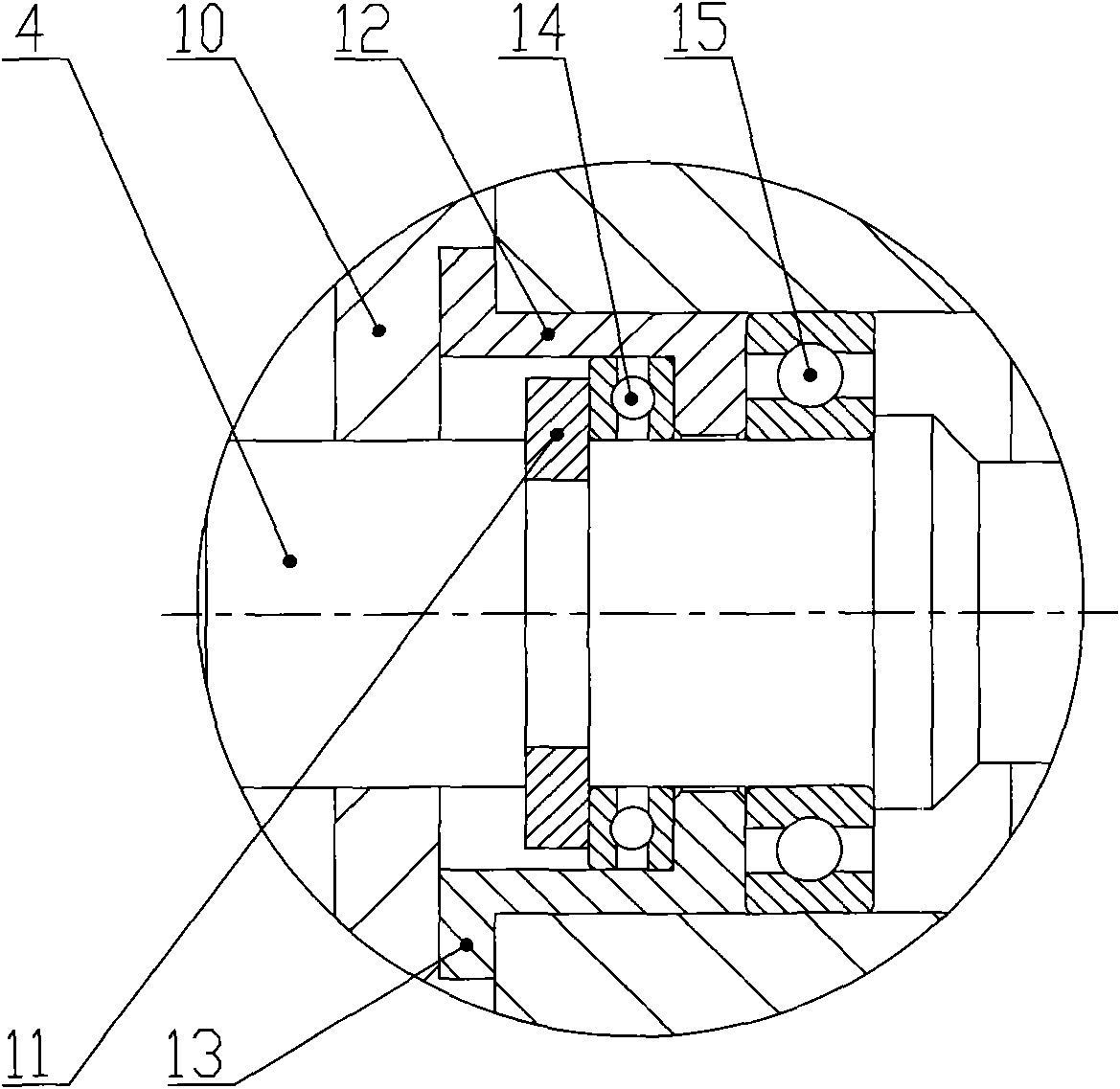

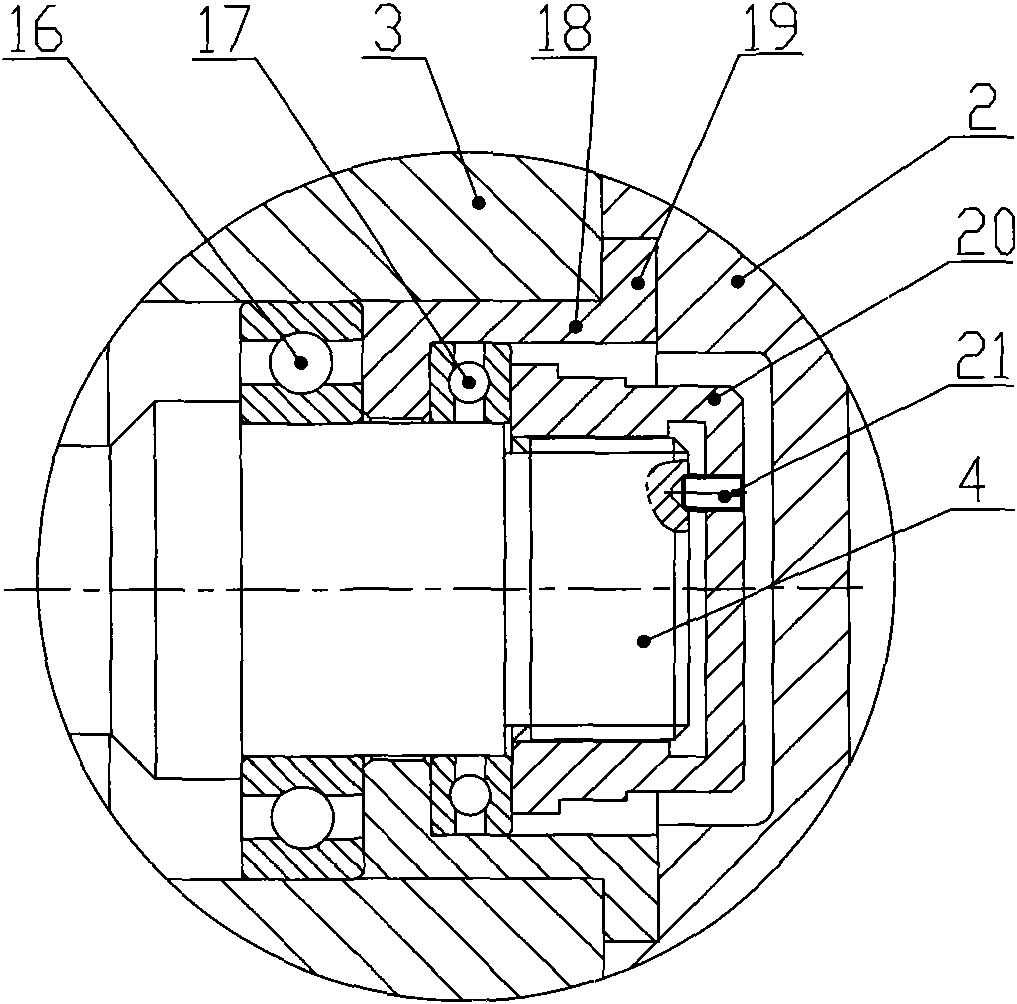

Driving device capable of accurately controlling valve

InactiveCN101956863AEliminate transmission errorsLimit movementOperating means/releasing devices for valvesControl valvesScrew thread

The invention discloses a driving device capable of accurately controlling a valve, comprising a worm wheel, a worm and a hand wheel, wherein both ends of the worm are fixedly arranged on a box body by a bearing and an end cover, the worm wheel is arranged on the box body, the hand wheel is fixed on one end of the worm, a clamp ring groove is arranged at the outer end of the bearing on the worm of one side of the hand wheel, a limiting clamp ring is arranged in the clamp ring groove, a locking screw cap is arranged at the outer end of the bearing at the other end of the worm, the locking screw cap is connected with the worm by screw threads and is used for locking the bearing, and a positioning pin which is used for positioning the shaft end of the worm is arranged in the locking screw cap. In the invention, both ends of the worm are axially and respectively positioned by the clamp ring and the locking screw cap to limit the leap of the worm, eliminate driving errors and ensure that the driving device can accurately control the valve.

Owner:铜陵市江南阀门机械有限公司

Forme roller gap-free transmission connection device

A forme roller gap-free transmission connection device is installed on a machine frame of a printing machine and at the position corresponding to a forme roller shaft head and consists of a support plate, a sliding rail, a bearing slide block, a fixing box, a servo motor, a coupler, a connecting shaft and an air cylinder. The support plate is installed on the lateral side of the machine frame of the printing machine and is perpendicular to the machine frame, the sliding rail is installed on the support plate, the fixing box is installed on the sliding rail, and the bottom of the fixing box is connected with the sliding rail through the bearing slide block. The servo motor is installed at one end of the coupler, a bearing penetrates through the middle of the connecting shaft, and a fixing sleeve of the forme roller shaft head is designed on an end head of the connecting shaft. A connecting notch is processed on the forme roller shaft head of the printing machine and is sleeved in the fixing sleeve. The air cylinder is installed at one end of the support plate, and an air cylinder shaft of the air cylinder is installed on the lateral side of the lower end of the fixing box. After adopting the forme roller gap-free transmission connection device, the transmission accuracy of a forme roller of the printing machine is improved, and the overprinting quality of products is improved greatly.

Owner:玉溪环球彩印纸盒有限公司

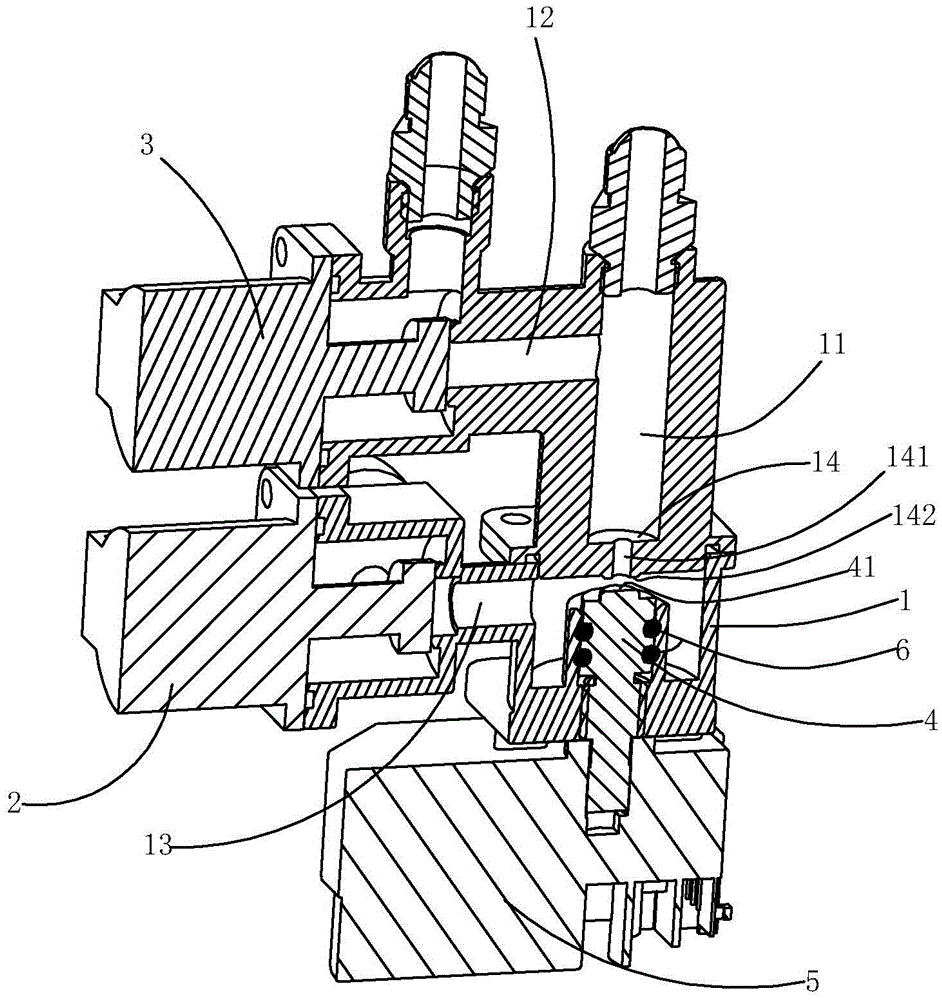

Flow control valve for gas stove

InactiveCN105485401APlay a loose phenomenonEliminate loosenessOperating means/releasing devices for valvesEqualizing valvesLinear relationshipEngineering

The invention relates to a flow control valve for a gas stove. The flow control valve comprises a valve body, wherein an inner ring gas outlet passage communicated with an inner ring combustor and an outer ring gas outlet passage communicated with an outer ring combustor are formed in the valve body; the outer ring gas outlet passage is communicated with the inner ring gas outlet passage; a gas inlet passage communicated with a gas source is also formed in the valve body. The flow control valve is characterized in that a partition board is arranged in the valve body, so as to divide the interior of the valve body into two spaces; one space, on one side of the partition board, in the valve body is communicated with the gas inlet passage; the other space, on the other side of the partition board, in the valve body is communicated with the inner ring gas outlet passage; a through hole is formed in the partition board; an adjusting rod opposite to the through hole in the partition board is arranged in the valve body, and is connected with an electric driving mechanism, so that the clearance between the adjusting rod and the partition board can be changed under the driving of the electric driving mechanism. Compared with the prior art, the flow control valve has the advantages that stepless adjusting of gas flow can be realized; the linear relationship between the adjusting angle and the gas flow can be excellent; the structure is novel; the implementation is convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Micro double-spindle false tooth repair machine

ActiveCN102525677BSimplified volumeGuaranteed machining accuracyArtificial teethEngineeringMachining

The invention discloses a micro double-spindle false tooth repair machine. The false tooth repair machine comprises a base (40) and a first electric spindle system (20), a second electric spindle system (90), electric cabinets (10) and a workpiece rotating mechanism (70) which are arranged on the base (40). The false tooth repair machine is characterized in that: the first electric spindle system (20) and the second electric spindle system (90) are arranged coaxially, and cutters arranged on the first electric spindle system (20) and the second electric spindle system (90) and a workpiece arranged on the workpiece rotating mechanism (70) extend into a machining space (60) and are arranged vertically in a horizontal plane; the first electric spindle system (20) and the second electric spindle system (90) are arranged on respective X-axial feeding mechanisms (30); the workpiece rotating mechanism (70) is arranged on a Y-axis feeding mechanism (100), the Y-axis feeding mechanism (100) is arranged on a Z-axis feeding mechanism (120), and the Z-axis feeding mechanism (120) is arranged on the base (40); and a tool magazine system (50) is also arranged on the Y-axis feeding mechanism (100). The false tooth repair machine has the advantages of simple structure, small volume, high machining precision and convenience in operation.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

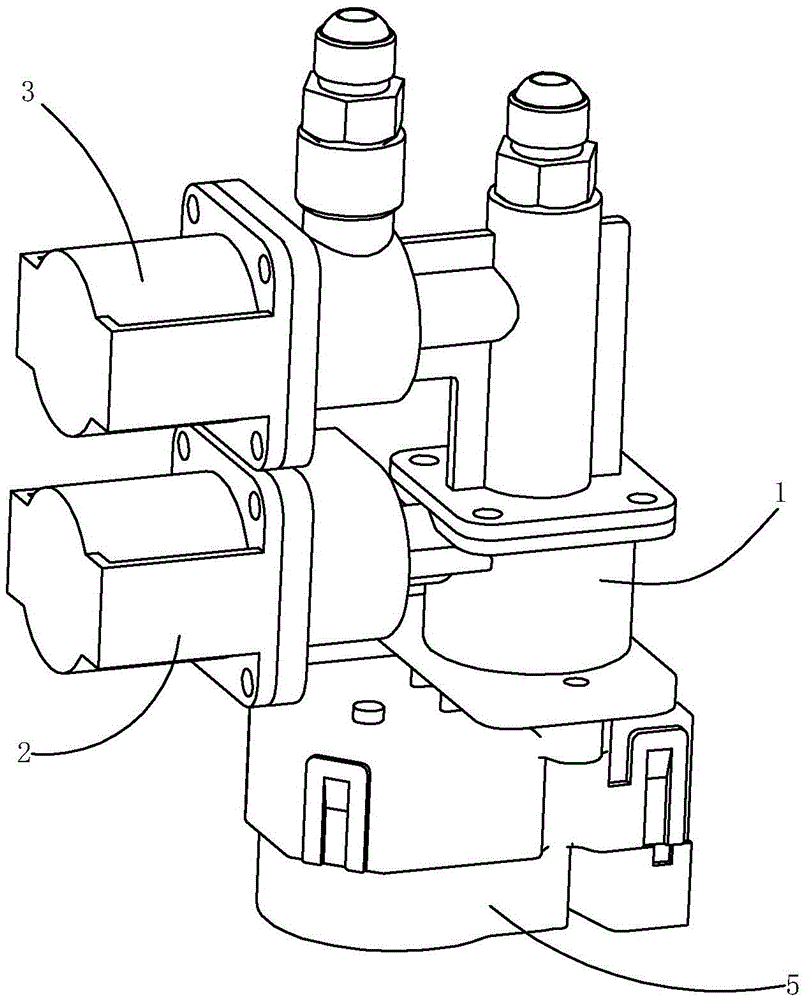

Liquid metering pump, electrolyte filling device and liquid filling method

PendingCN110778477AEliminate transmission errorsGuaranteed accuracyPump controlPumpsPhysicsElectrolytes fluids

The invention provides a liquid metering pump, an electrolyte filling device and a liquid filling method and relates to the technical field of liquid metering pumps. The liquid metering pump comprisesa pump body, a plunger, a driving device and a liquid path control device. The electrolyte filling device comprises the liquid metering pump. The liquid filling method comprises the following steps:cutting off a liquid outlet channel of the pump body and connecting a liquid inlet channel of the pump body; controlling the driving device drive the plunger to move for a first preset distance; cutting off the liquid inlet channel of the pump body and connecting the liquid outlet channel of the pump body; and controlling the driving device drive the plunger to move for a second preset distance. The liquid metering pump, the electrolyte filling device and the liquid filling method can solve the technical problems that the liquid filling quantity of the existing liquid metering pump cannot be rapidly and flexibly changed according to production demands, the adjusting time of the liquid filling quantity is long, and great materials are wasted in the adjusting process.

Owner:深圳市易捷迅自动化设备有限公司

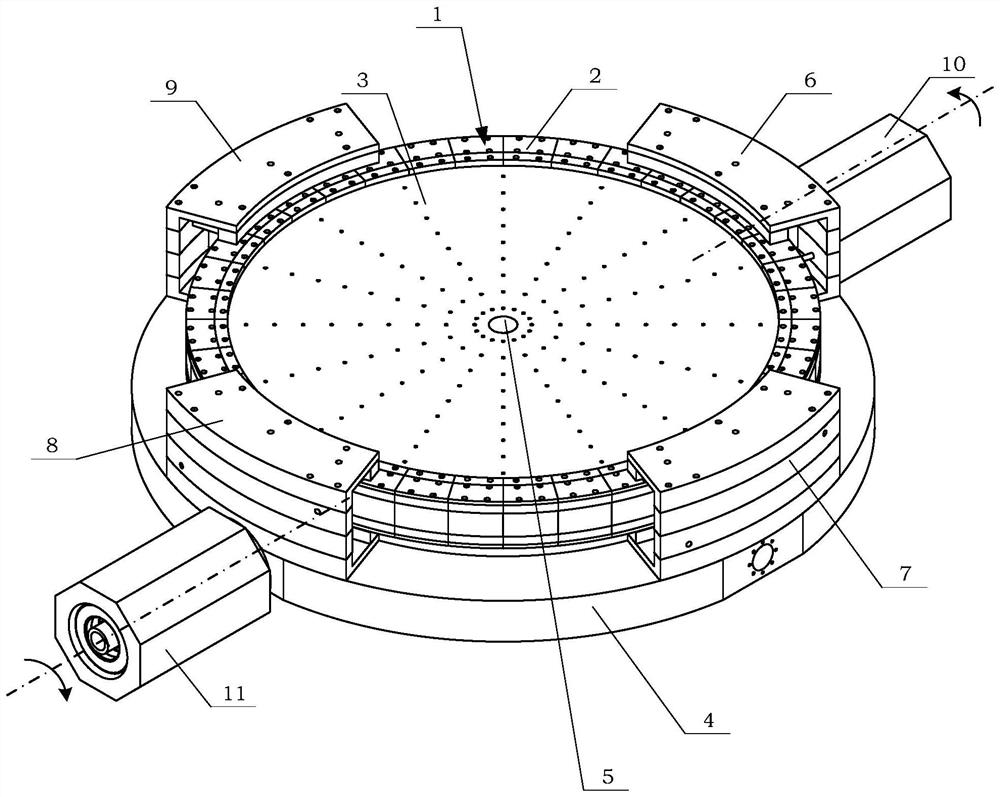

Sight-stabilizing active magnetic suspension rotary table with 10 degrees of freedom

ActiveCN112729250AImprove interchangeabilityImprove general performancePicture taking arrangementsCircular discMagnetic bearing

The invention discloses a sight-stabilizing active magnetic suspension rotary table with 10 degrees of freedom. Driving mechanisms (10 and 11) are symmetrically mounted on the outer circular surface of a base (4). A plurality of radial and axial magnetic bearing integrated rotor assemblies (2) with the same structure are arranged on the circumference of the disc body (3), four radial and axial magnetic bearing integrated stator assemblies (6, 7, 8 and 9) are symmetrically distributed on the outer circumference of the magnetic suspension rotating platform (1), and a single-shaft turntable driving mechanism (5) is arranged in the center of the magnetic suspension rotating platform (1). Under the power-on condition, the radial and axial magnetic bearing integrated stator assemblies (6, 7, 8 and 9) are powered on to suspend the radial and axial magnetic bearing integrated rotor assembly (2), and on one hand, the radial and axial magnetic bearing integrated rotor assembly (2) is driven by the single-shaft turntable driving mechanism (5) to rotate; and on the other hand, the radial and axial magnetic bearing integrated rotor assembly (2) is driven by the driving mechanisms (10, 11) to realize complete suspension motion in clockwise, anticlockwise and vertical directions. An active vibration suppression function of the magnetic suspension bearing is adopted, mechanical isolation is achieved for micro-vibration of the sight-stabilizing active magnetic suspension rotary table, and the purpose of ultra-stability and ultra-quietness is achieved.

Owner:BEIHANG UNIV

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490BEngraving and milling realizationRealize the processing effectGrinding machinesStone-like material working toolsEngineeringMachining

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division aroundthe axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

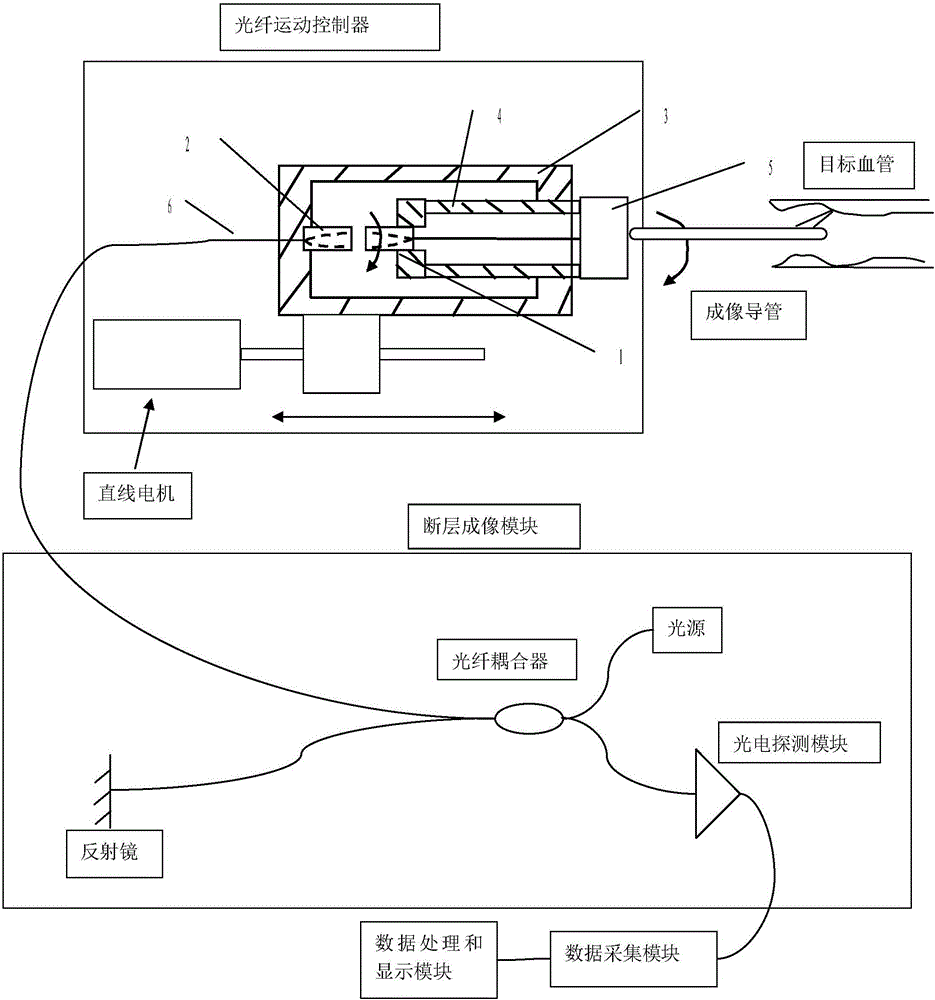

An intravascular tomography system

ActiveCN104856652BSimple structureEasy to detectDiagnostics using lightCatheterEngineeringTomography

The invention discloses a tomography system inside a blood vessel. The tomography system comprises an imaging catheter, an optical fiber movement controller, a tomography module, a data collecting module and a data processing and displaying module which are connected in sequence. The light emitted by the tomography module is transmitted to the imaging catheter through the optical fiber movement controller, the light is concentrated on a target blood vessel wall through the imaging catheter, and the optical fiber movement controller drives the imaging catheter to conduct rectilinear motion inside a target blood vessel at the same time of rotating at a high speed. The reflected light of different layers of the target blood vessel wall is collected and transmitted to the optical fiber movement controller and the tomography module in sequence by the imaging catheter, the tomography module demodulates the received reflected light into intensity information and then converts the intensity information into electrical signals, the data collecting module collects and transmits the electrical signals to the data processing and displaying module, and the data processing and displaying module processes, generates and displays cross-section image information of the blood vessel. By means of the tomography system inside the blood vessel, the high-speed tomography of the blood vessel can be achieved.

Owner:南京沃福曼医疗科技有限公司

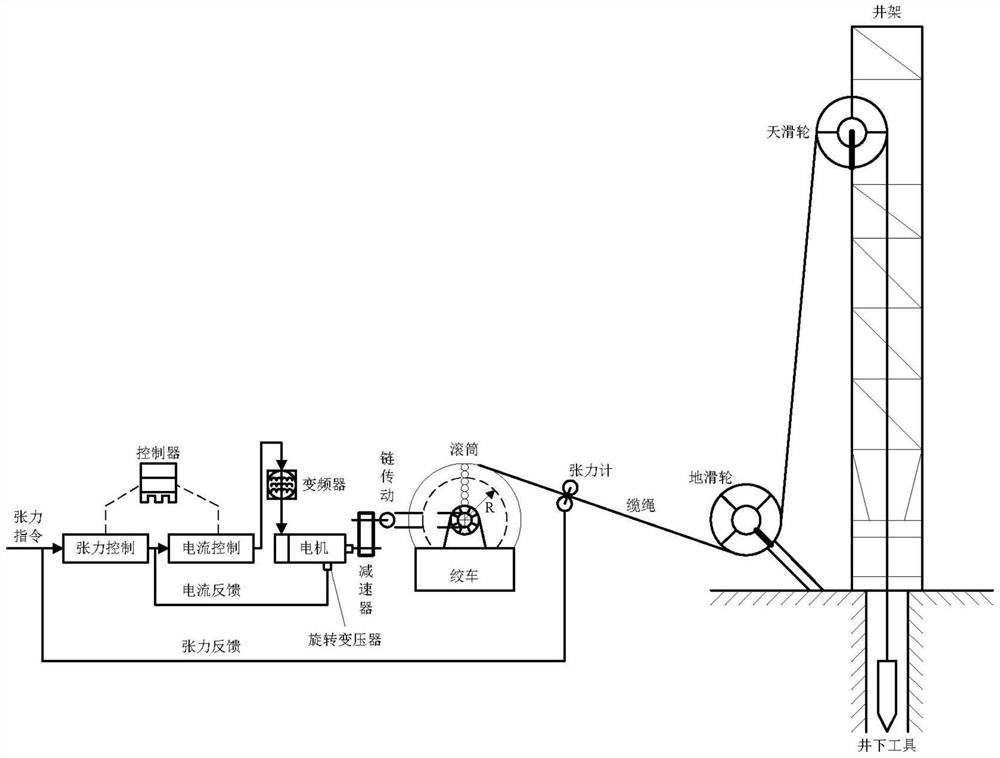

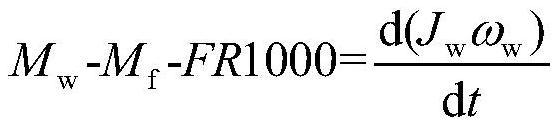

Petroleum machinery winch cable tension intelligent control method

PendingCN114660945AImprove stabilityHigh precision of tension controlWinding mechanismsAdaptive controlFrequency changerControl signal

The invention discloses an intelligent control method for cable tension of a petroleum mechanical winch. A tension feedback signal is directly transmitted to a controller in real time through a tensiometer which is independently and separately arranged between a ground pulley and a roller, the controller outputs a control signal to a driving motor through a frequency converter, the driving motor transmits motion to the roller, the output torque of the driving motor is dynamically adjusted, and a full-closed-loop tension control system is established. The control method comprises the following steps: calculating a layer index of hierarchical control according to the total length of a cable and the size of a roller, optimizing an initial value of a control parameter for each layer by combining analysis modeling and prior experience, and adaptively correcting a PID (Proportion Integration Differentiation) regulation value by using fuzzy control, a neural network or a fuzzy neural network intelligent control algorithm. The method can be used for cable car tension intelligent control of the winch for petroleum drilling, well logging, well repairing and the like, the tension control precision can be improved, the labor amount of operators is reduced, and a foundation is laid for achieving an intelligent winch system.

Owner:SOUTHWEST PETROLEUM UNIV

Cam contour detecting system based on direct drive motor

The invention provides a cam contour detecting system based on a direct drive motor. The cam contour detecting system has the advantages of simple structure, high detection accuracy and higher efficiency and comprises a direct drive motor, a mandrel coaxially and fixedly arranged on a rotor of the direct drive motor and used for driving a cam to rotate synchronously and coaxially, a screwpair horizontally arranged at one side of the cam, a laser measuring head on a traveling nut of the screwpair, a grating ruler displacement sensor for measuring the horizontal displacement of the traveling nut, a circular grating arranged in the direct drive motor fixing seat and used for detecting the rotational angle of the rotor and an industrial control computer; and the industrial control computer isused for controlling the direct drive motor and the screwpair to act, and obtaining the outer contour data of the cam, according to the data measured by the laser measuring head, the grating ruler displacement sensor and the circular grating.

Owner:江苏今越控股集团有限公司

Cam profile detection system

The invention provides a cam profile detection system based on a direct driving motor, and the system is simple in structure and high in detection precision and efficiency. The system comprises the direct driving motor, a mandrel, a feed screw nut pair, a laser measurement head, a grating ruler displacement sensor, a circular grating and an industrial personal computer, wherein the mandrel is coaxially fixedly arranged on the rotor of the direct driving motor and is used for driving a cam to coaxially rotate synchronously; the feed screw nut pair is horizontally arranged at one side of the cam; the laser measurement head is arranged on the movable nut of the feed screw nut pair; the grating ruler displacement sensor is used for measuring the horizontal displacement amount of the movable nut; the circular grating is arranged in the fixed seat of the direct driving motor and is used for detecting the rotation angle of the rotor; and the industrial personal computer is used for controlling the actions of the direct driving motor and the feed screw nut pair, and obtaining outer profile data of the cam according to data obtained by the laser measurement head, the grating ruler displacement sensor and the circular grating.

Owner:CHANGZHOU INST OF TECH

Precisely position the silo

ActiveCN103028998BIncrease loading capacitySmall footprintMetal working apparatusMotor driveSmall footprint

The invention discloses an accurate positioning storage bin. The accurate positioning storage bin comprises a storage bin frame, workpiece lifting mechanisms and a workpiece horizontal rotary conveying mechanism; the workpiece horizontal rotary conveying mechanism comprises a first motor which is arranged on the storage bin frame, a rotary disc which is connected with a first motor rotor and workpiece loading mechanisms which are arranged along the peripheral direction of the rotary disc at equal intervals; and two sets of workpiece lifting mechanisms are arranged and are distributed opposite to the two sets of workpiece loading mechanisms, and each workpiece lifting mechanism comprises a clamping jaw for conveying workpieces on the workpiece loading mechanisms and a drive device for driving the clamping jaw to lift and descend. According to the accurate positioning storage bin, the first motor drives the rotary disc so as to drive the workpiece loading mechanisms to rotate horizontally, so that the transmission error existing in conventional storage bin chain wheel and chain transmission is eliminated, the repeat positioning precision along the horizontal direction is high, and a manipulator of processing equipment can accurately take and store materials; and moreover, a plurality of workpiece loading mechanisms can be arranged on the same rotary disc, the loading capacity of the storage bin is large and the storage bin occupies a small area.

Owner:CHONGQING MACHINE TOOL GROUP

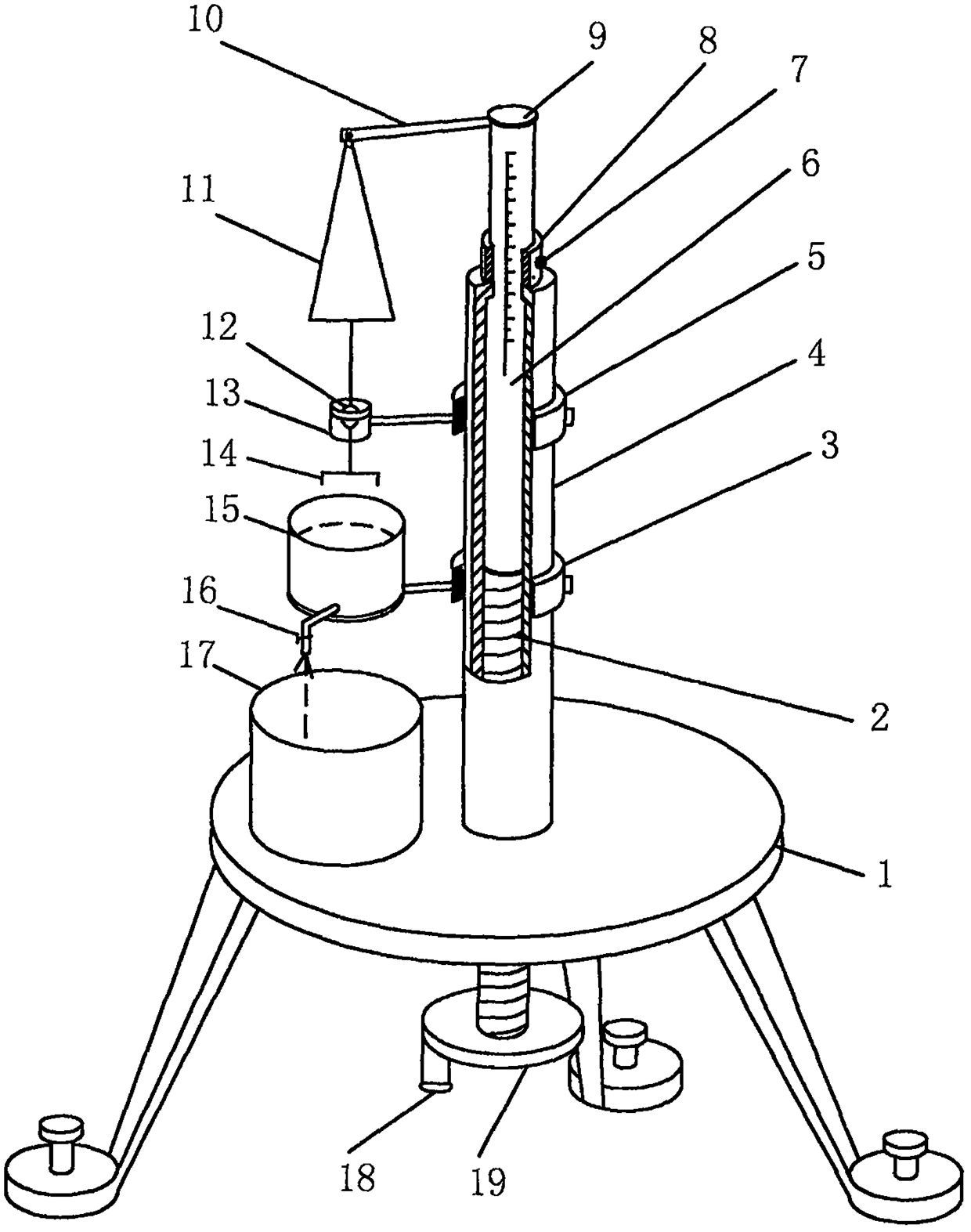

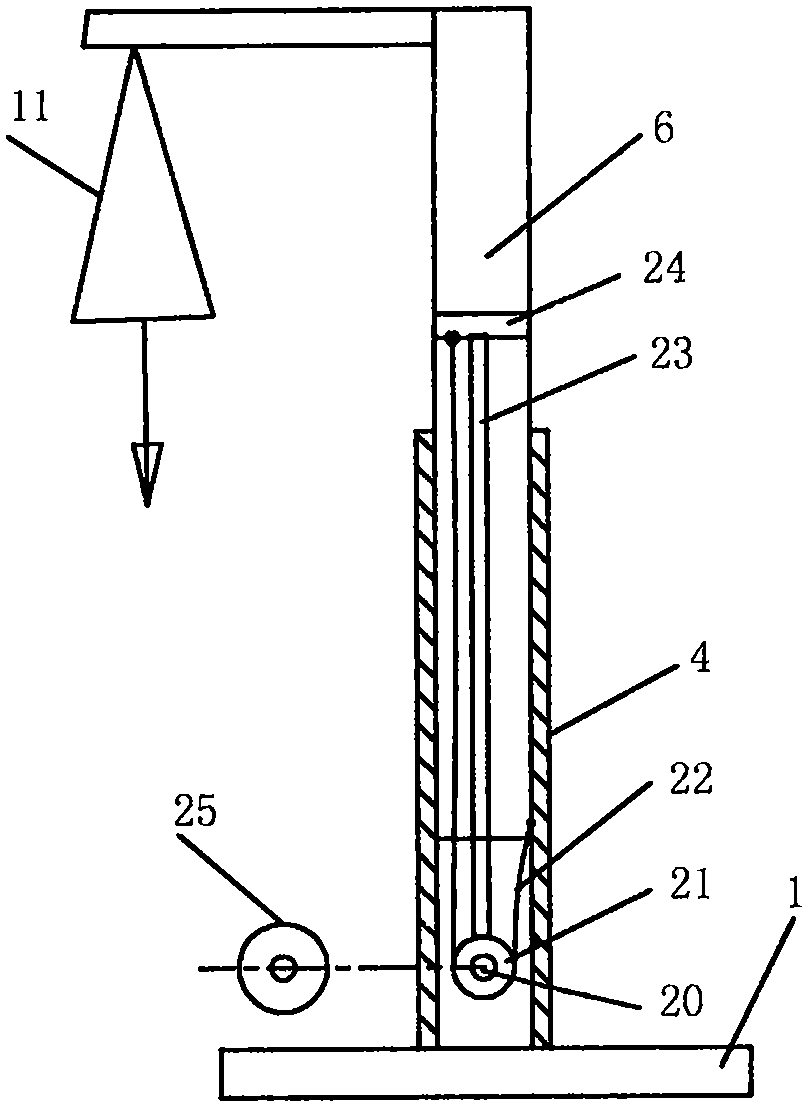

Novel Joly balance

PendingCN109187282ANo more slippageNo longer will it be pulled offEducational modelsSurface tension analysisEngineeringMechanical engineering

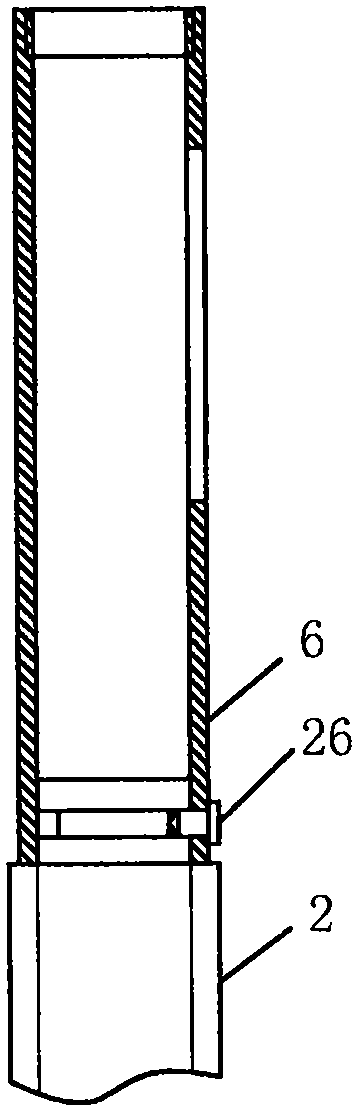

The invention discloses a novel Joly balance, which comprises a stand (1), a screw rod (2), an outer barrel (4), a lifting barrel (6), a rotation stopping screw (7), a vernier (8), a screw (9), a handle (18), a turntable (19), a connecting screw (26) and a measuring part, wherein the inner bottom end of the outer barrel (4) is provided with an internal thread; the outer barrel (4) is perpendicularly fixed at the center position of the stand (1); the screw rod (2) passes through the bottom of the stand (1) and is screwed into the outer barrel (4); the upper end of the screw rod (2) is providedwith a ring slot; after the lifting barrel (6) is inserted into the outer barrel (4) from the upper part, the ring slot in the upper end of the screw rod (2) is inserted into the bottom of the liftingbarrel (6); the connecting screw (26) passes through the lifting barrel (6) and is inserted into the ring slot in the upper end of the screw rod (2); and the screw rod (2) can drive the lifting barrel (6) to move axially, but cannot drive the lifting barrel (6) to rotate. The measuring precision of the novel Joly balance is greatly improved, and the novel Joly balance works reliably and is convenient to operate.

Owner:HUZHOU TEACHERS COLLEGE

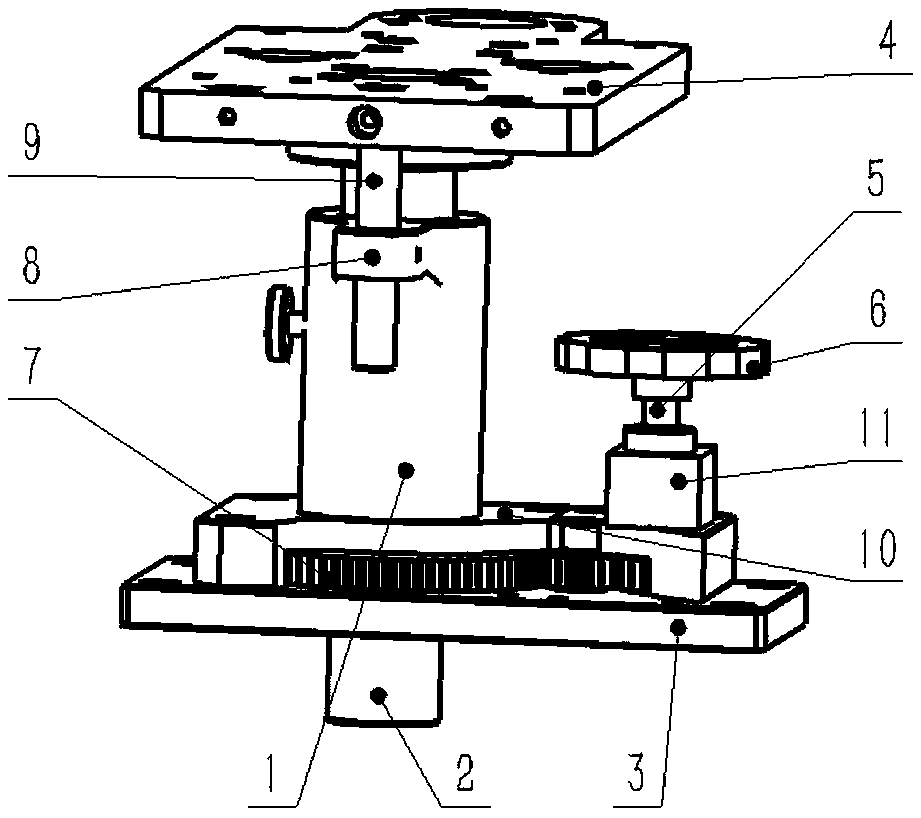

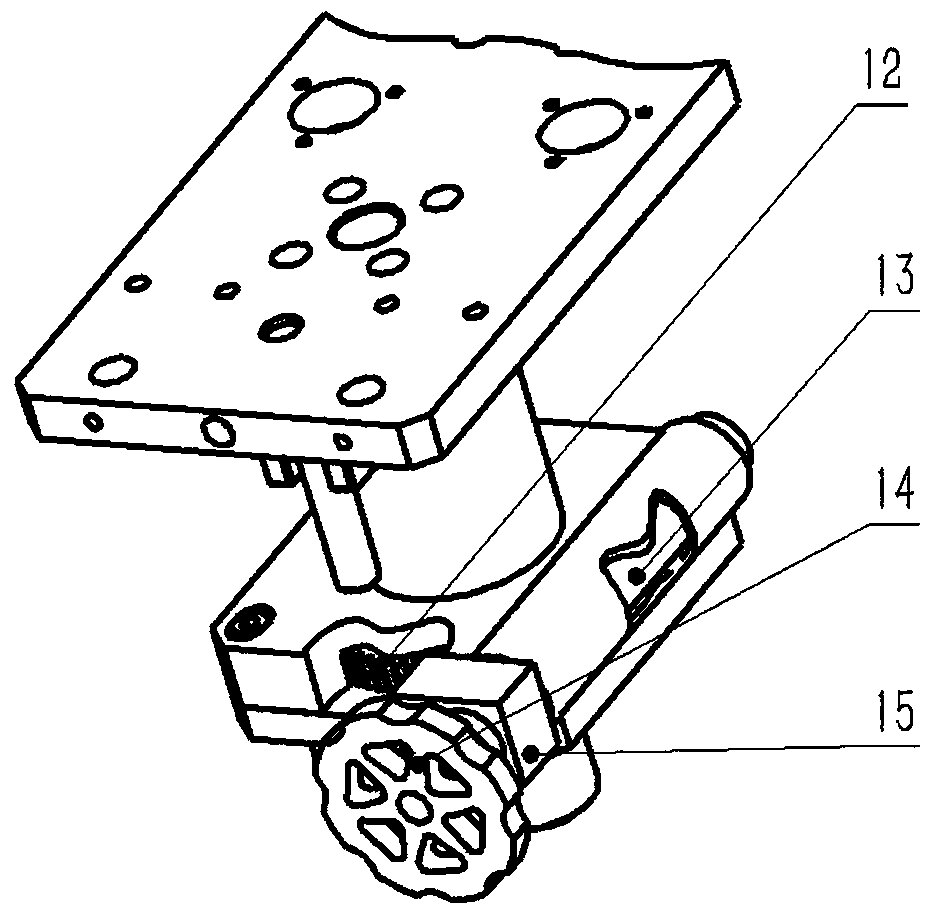

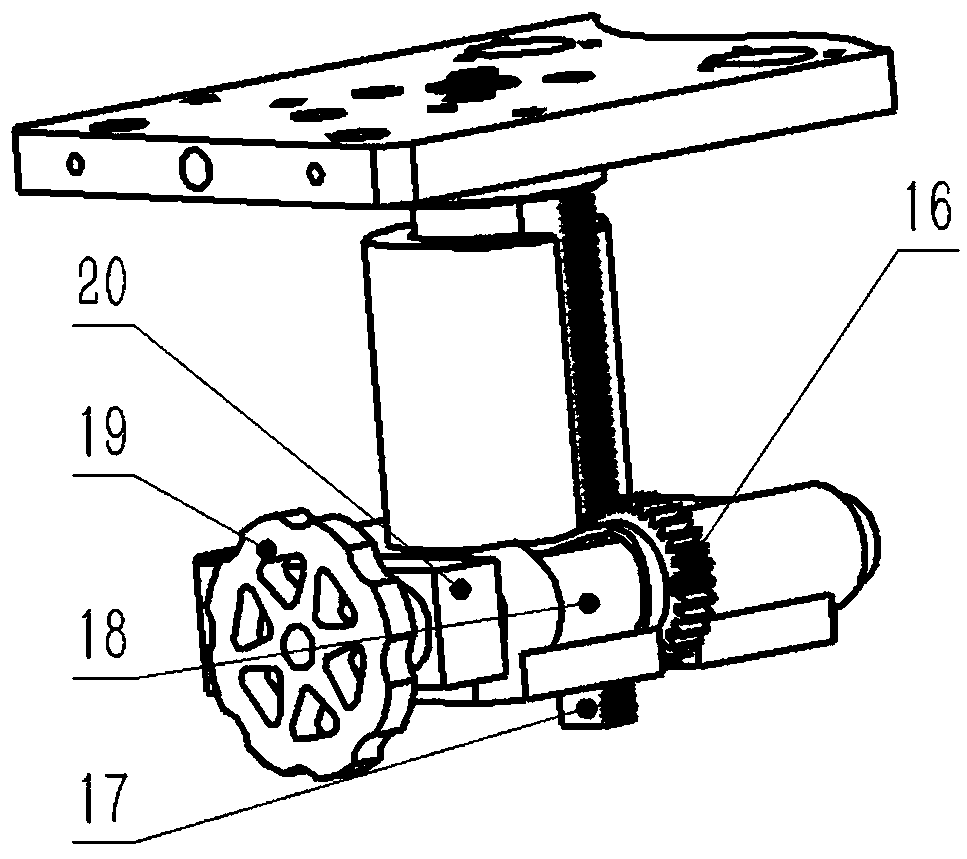

The special lifting and adjusting mechanism for the mouth forming device of the bottle making machine

ActiveCN106116115BPrecise adjustment of displacementImprove positioning accuracyGlass blowing apparatusGlass productionEngineeringBottle

The invention relates to a special lifting adjusting mechanism for a bottle-making machine pressed mouth forming device, wherein the special lifting adjusting mechanism comprises a machine frame, and a driving mechanism for driving a lifting shaft, the lifting shaft and a lifting sleeve which are successively assembled on the machine seat; the top end of the lifting shaft and a base of the pressed mouth forming mechanism are connected into a whole, and output of the driving mechanism is in thread or intertooth meshing connection with the lifting shaft. Through a rotary driving way of thread or intertooth meshing of the driving mechanism, the adjusting mechanism adopts a direct-driving linear adjusting control way for height positioning of the lifting shaft, the displacement amount of the lifting shaft can be accurately adjusted, accurate positioning of the height of the pressed mouth forming device is ensured, and the product qualified rate of pressed mouth forming of a bottle body reaches more than or equal to 98%. The stable and reliable production quality and production efficiency of a bottle-making machine are further improved.

Owner:重庆正川永成医药材料有限公司 +1

Detection method of cam profile detection system based on direct drive motor

The invention provides a detection method of a cam profile detection system based on a direct drive motor, which is simple in structure and higher in detection precision and efficiency. The cam profile detection system comprises the direct drive motor, a mandrel coaxially fixed to a rotor of the direct drive motor and used for driving a cam to synchronously and coaxially rotate, a lead screw nut pair horizontally arranged on one side of the cam, a laser measurement head arranged on a movable nut of the lead screw nut pair, a grating ruler displacement sensor for measuring the horizontal displacement of the movable nut, a round grating arranged in a fixing seat of the direct drive motor and used for detecting a rotation angle of the rotor, and an industrial personal computer, wherein the industrial personal computer is used for controlling the direct drive motor and the lead screw nut pair to act, and obtaining the external profile data of the cam according to the measurement data of the laser measurement head, the grating ruler displacement sensor and the round grating.

Owner:CHANGZHOU INST OF TECH

3D printer

ActiveCN113665111AReduced range of movementIncrease productivityIncreasing energy efficiency3D object support structuresComputer printingEngineering

The invention relates to a 3D printer. The 3D printer comprises a movable frame arranged on a rack, a working platform, a plurality of sliding seats, a nozzle, an X-direction driving piece, a Y-direction driving piece and a Z-direction driving piece. The movable frame is in sliding connection with the rack, the movable frame is in a regular polygon shape matched with the bottom face of a workpiece, and the movable frame is located above the working platform; the sliding seats are connected with the movable frame in a sliding mode, the multiple sliding seats correspond to the multiple edges of the movable frame respectively, and the sliding direction of each sliding seat is parallel to the edge close to the sliding seat. The nozzle is connected with the sliding seat, and the moving direction of the nozzle is perpendicular to the sliding direction of the sliding seat; the X-direction driving piece is arranged on the movable frame so as to enable the sliding seat to move; the Y-direction driving piece is connected with the nozzle so that the nozzle can move in the direction perpendicular to the moving direction of the sliding seat. The Z-direction driving piece is used for enabling the movable frame to get close to or away from the working platform. The 3D printer has the effect that workpieces in the shapes of regular quadrangular prisms, regular hexagonal prisms and the like can be more efficiently manufactured through the 3D printer.

Owner:SHENZHEN MINGDA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com