Liquid metering pump, electrolyte filling device and liquid filling method

A liquid metering pump and liquid technology, which is applied in mechanical equipment, liquid variable capacity machinery, pumps, etc., can solve the problems of long adjustment time of liquid injection amount and waste of materials during adjustment process, saving adjustment time, accurately changing, The effect of avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

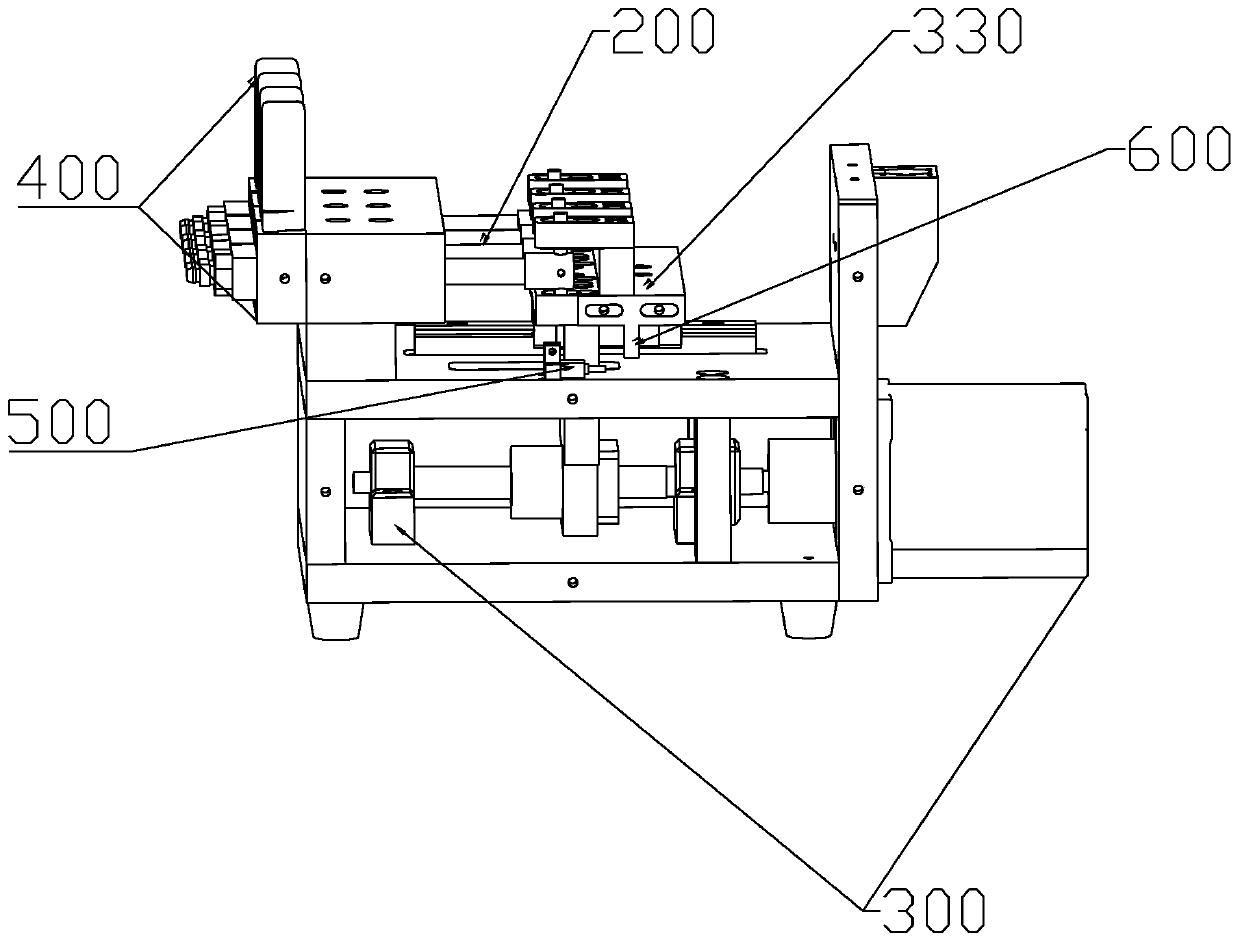

[0034] Such as figure 1As shown, the present embodiment provides a liquid metering pump, the liquid metering pump passes through the driving device 300, the device drives the plunger 200 to move a preset distance relative to the pump body 100 according to the amount of perfusion liquid, and cooperates with the liquid circuit control device The control action of 400, when the plunger 200 moves a preset distance in the direction opposite to the direction of the pump body 100, the liquid circuit control device 400 cuts off the liquid outlet passage of the pump body 100 and connects the liquid inlet passage of the pump body 100 so that A specific amount of liquid to be metered enters the liquid metering pump, and when the plunger 200 moves a preset distance toward the pump body 100, the liquid circuit device cuts off the liquid inlet path of the pump body 100 and connects the liquid outlet path of the pump body 100 so that A specific amount of liquid to be metered is discharged fr...

Embodiment 2

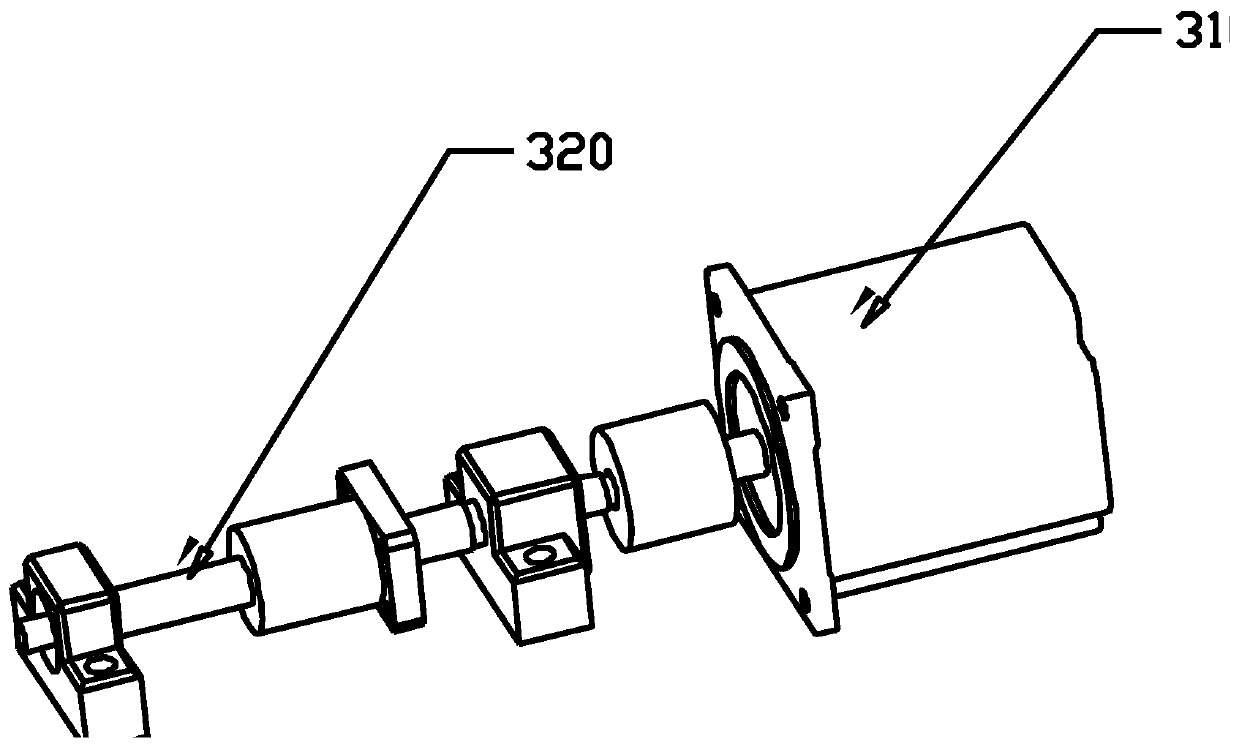

[0047] Such as Figure 2 to Figure 4 As shown, this embodiment is optimized on the basis of Embodiment 1, wherein the driving device 300 includes a motor 310, a ball screw 320 and an output part 330, and the motor 310 is used to drive the ball screw 320 through the output part 330 drives the plunger 200 to perform reciprocating linear motion relative to the pump body 100 . During the working process, the motor 310 is connected with the ball screw by a coupling, and the nut in the ball screw is connected with the output part 330 . The motor 310 drives the screw to rotate, the screw rotates to drive the nut to perform reciprocating linear motion, the nut then drives the output part 330 to perform reciprocating linear motion, and finally the output part 330 drives the plunger 200 to perform reciprocating linear motion. Therefore, controlling the rotation angle of the motor 310 can control the moving distance of the plunger 200 . Due to the accurate transmission of the ball scre...

Embodiment 3

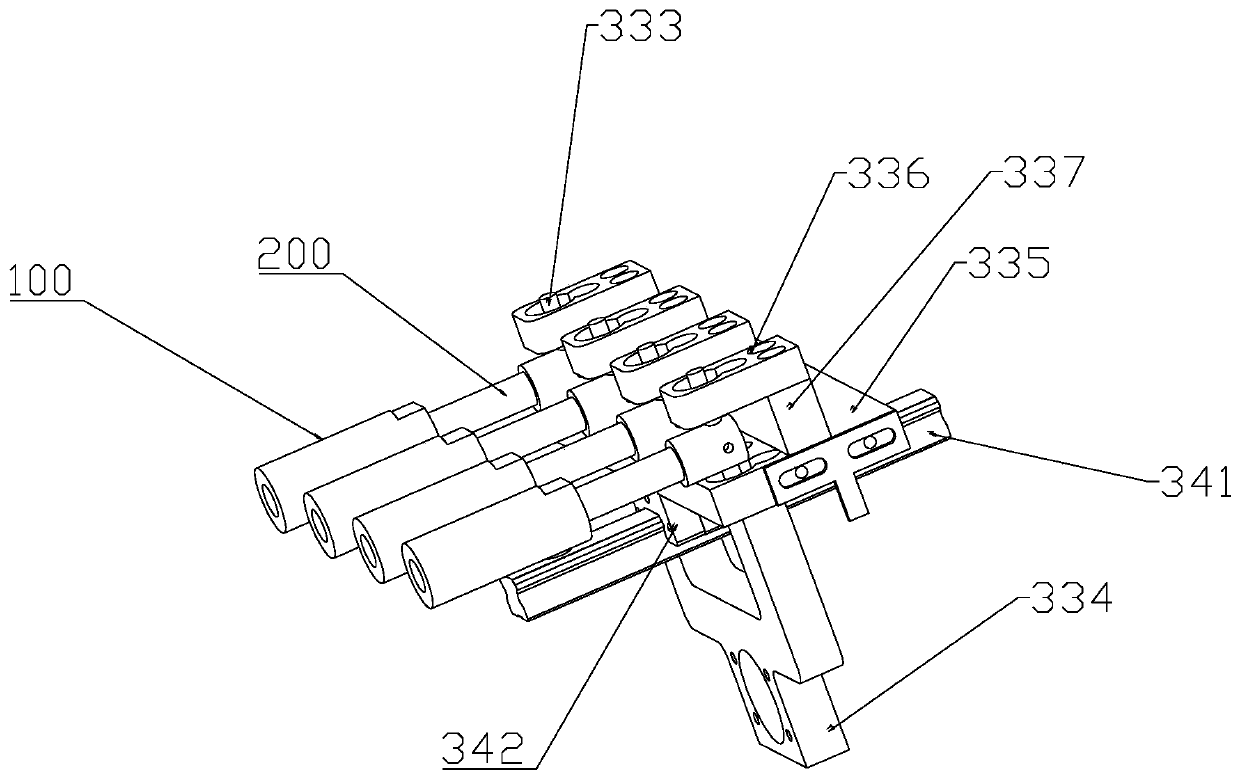

[0054] Such as figure 1 As shown, this embodiment is further optimized on the basis of embodiment 2. In this embodiment, the liquid metering pump includes multiple pairs of pump bodies 100 and plungers 200 arranged side by side in a direction perpendicular to the guiding direction of the guide mechanism, and connecting rods 333 corresponding to each plunger 200 , a first joint bearing 331 and a second joint bearing 332 , and each plunger 200 is connected to its corresponding first joint bearing 331 and second joint bearing 332 through its corresponding connecting rod 333 .

[0055] In order to improve the efficiency of liquid perfusion while ensuring the accuracy of liquid perfusion, this embodiment adopts the scheme of driving multiple metering pumps with the same driving device 300, and the plunger 200 of each metering pump is equipped with a set of first joint bearings 331 and the second joint bearing 332, so that each plunger 200 can automatically find its position during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com