3D printer

A 3D printer and rack technology, which is applied to 3D object support structures, coating devices, manufacturing tools, etc., can solve the problems of low production efficiency of 3D printers, and achieve the effect of improving production accuracy, eliminating transmission errors and reducing errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-4 The application is described in further detail.

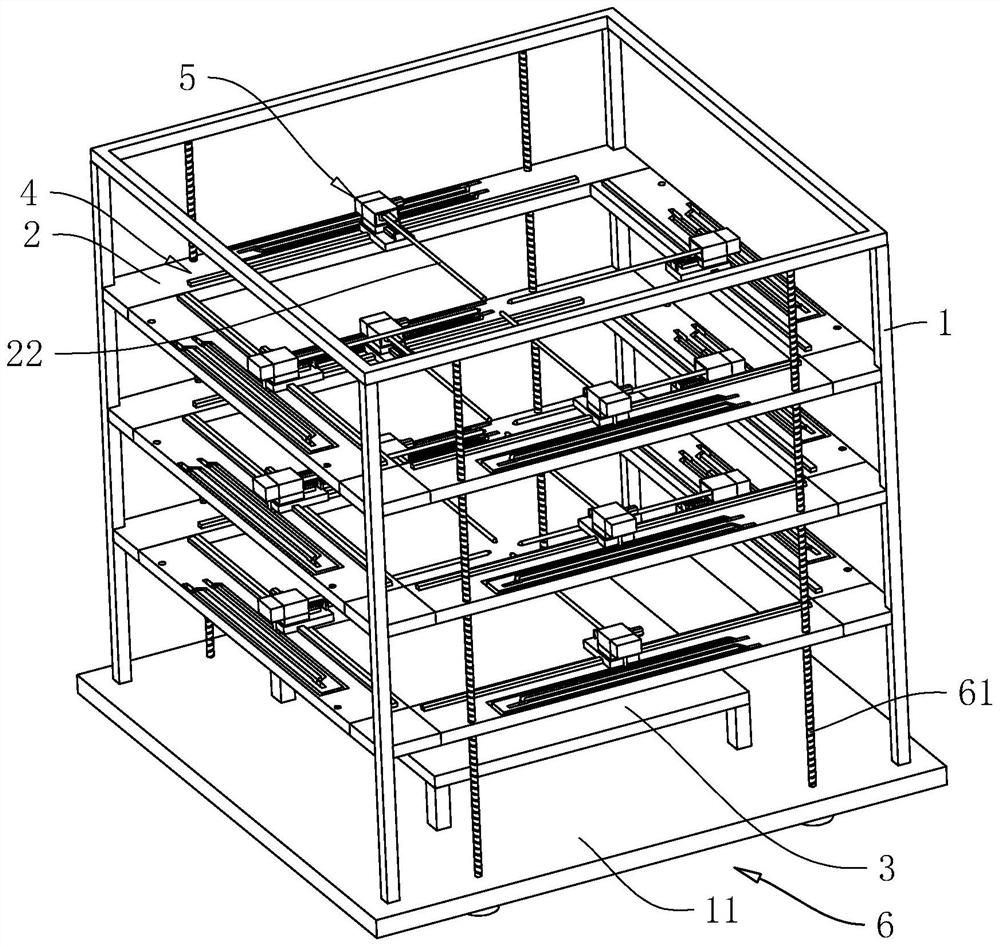

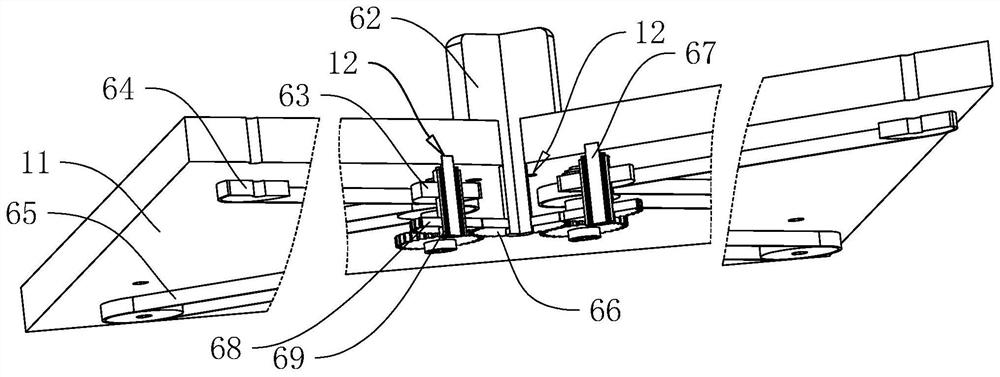

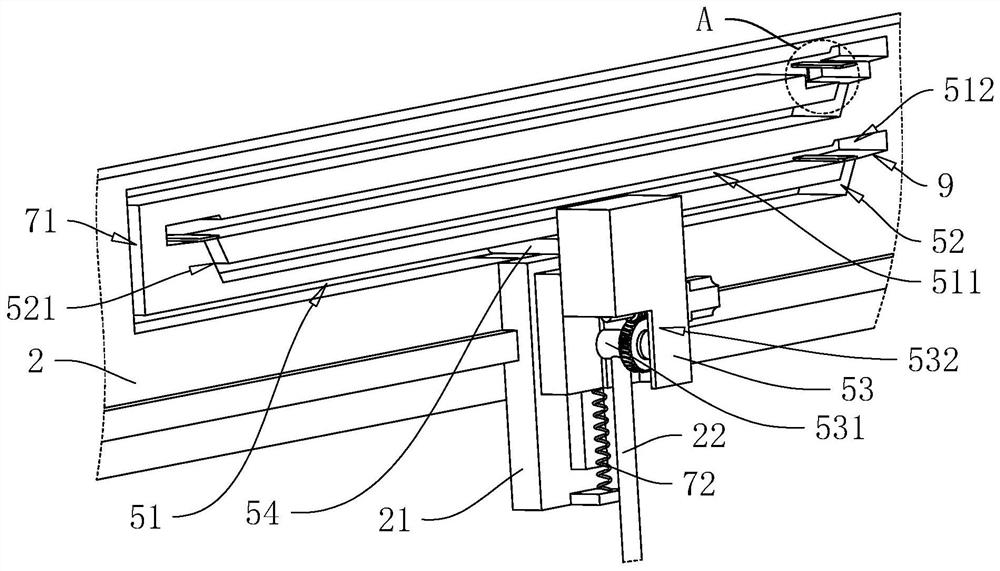

[0037] The embodiment of the present application discloses a 3D printer. refer to figure 1 , the 3D printer includes a movable frame 2, a working platform 3, a nozzle 22, an X-direction driver 4, a Y-direction driver 5, and a Z-direction driver 6 arranged on a frame 1. Specifically, the movable frame 2 is parallel to each other and spaced apart from each other. There are multiple, and the movable frame 2 is in the shape of a square frame, and a nozzle 22 will be installed on each side edge of the movable frame 2, and the working platform 3 is located under the movable frame 2, so in this embodiment , the workpiece can be in the shape of a regular quadrangular prism, a regular hexagonal prism, and a regular octagonal prism. When the workpiece is manufactured, the central angle between multiple dividing lines can be 90°, and the dividing lines pass through the vertical edges of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com