The special lifting and adjusting mechanism for the mouth forming device of the bottle making machine

A lifting adjustment and bottle making machine technology, applied in glass blowing, manufacturing tools, glass molding, etc., can solve the problems of low adjustment accuracy, large cumulative error, complicated adjustment process, etc., to improve production quality and production efficiency, Ensure precise positioning and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

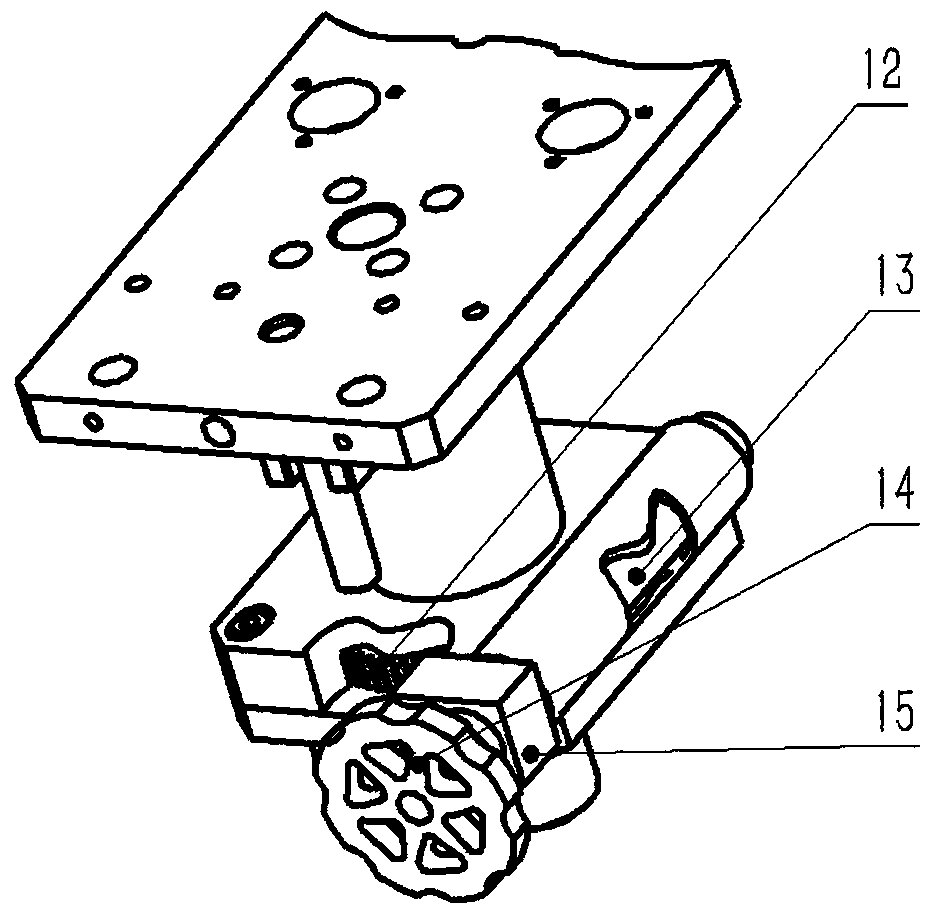

[0015] figure 2 The second embodiment of the present invention differs from the above embodiments in that the drive mechanism adopts a worm gear and a worm drive. The driving mechanism is composed of a worm wheel 12, a worm 13 and an adjusting handwheel 14. The adjusting handwheel 14 is assembled on the end of the worm 13, and the worm 13 is meshed with the worm wheel 12. The worm wheel 12 is set on the lower part of the lifting shaft 2. threaded connection. Simultaneously, a position indicator 15 is assembled on the worm screw 13, and the inner sleeve of the position indicator 15 and the worm screw 13 are connected as one by a jack screw. The working process of this embodiment is basically the same as that of the above embodiment, and will not be described again.

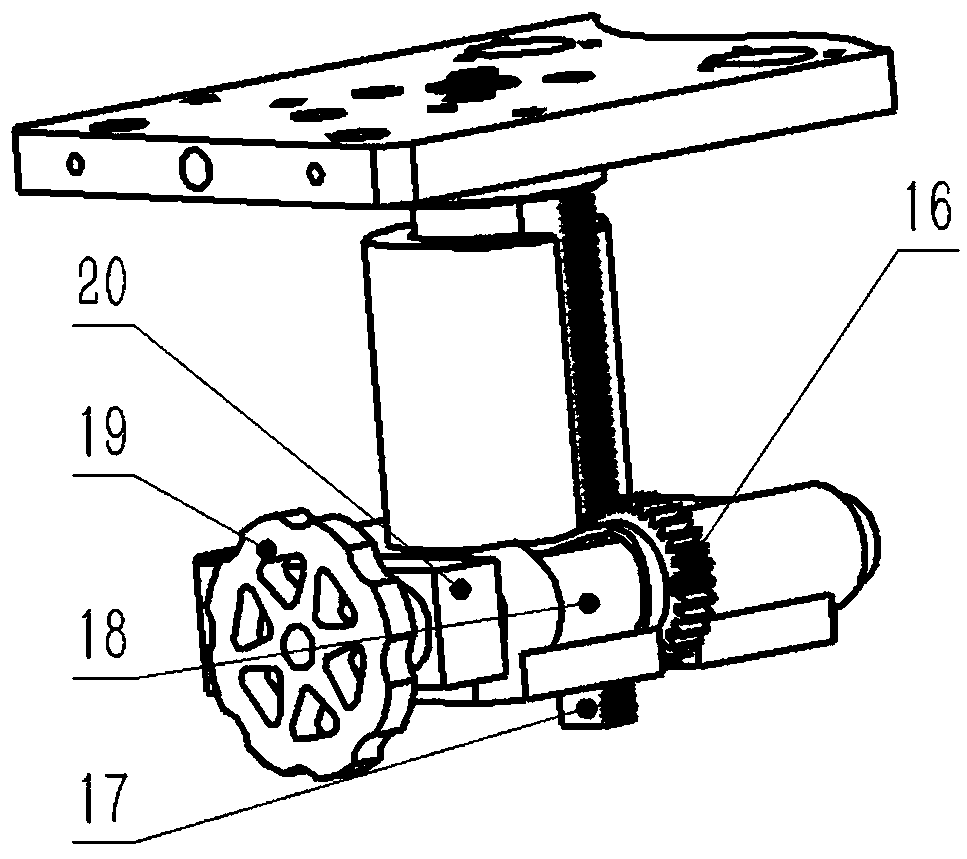

[0016] image 3 The third embodiment of the present invention differs from the above-mentioned embodiment in that the drive

[0017] The mechanism adopts the drive mode of gear and rack. This driving mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com