Small precise leveling device

A leveling device and precise technology, applied in the direction of instruments, instrument parts, etc., can solve the problems of small elastic deformation of flexible hinges, difficult to meet the requirements of adjustment and heavy load conditions, and achieve space saving and compact structure. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described now in conjunction with the preferred implementation examples of the accompanying drawings.

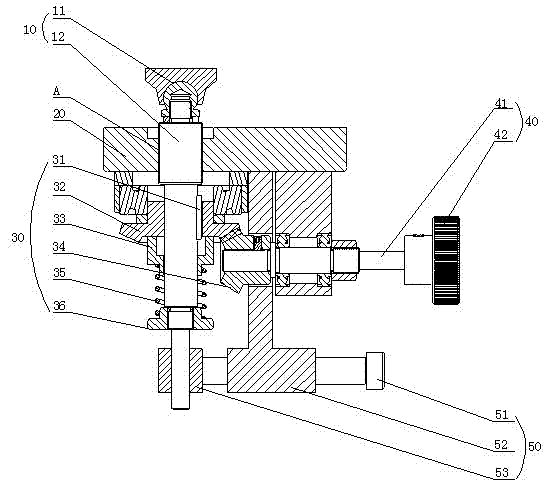

[0014] see figure 1 , The preferred embodiment of the present invention includes a spherical subassembly 10 , a support assembly 20 , a bevel gear subassembly 30 , an adjustment handwheel assembly 40 and a main locking assembly 50 .

[0015] The supporting component 20 is responsible for fixing the other components of the whole set of devices as a whole, and can be connected with other devices or mechanisms of required equipment.

[0016] The adjustment hand wheel assembly 40 includes two parts, the hand wheel 42 and the drive shaft 41, which are responsible for driving the small bevel gear 34 of the bevel gear sub-assembly 30 to rotate, thereby driving the large bevel gear 32 to rotate, and the large bevel gear drives the main adjustment screw 12 to rotate through the key 31 The main adjustment screw 12 and the support assembly 20 are thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com