A Precisely Adjustable Gas Flow Nozzle

A gas flow and nozzle technology, which is applied in the direction of valve devices, safety valves, and functional valve types, can solve the problems of inability to adjust air flow in a large range, low flow control accuracy, and limited flow working conditions, and achieve simplified structure. and control, simplify the sealing mechanism, and realize the effect of automatic adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

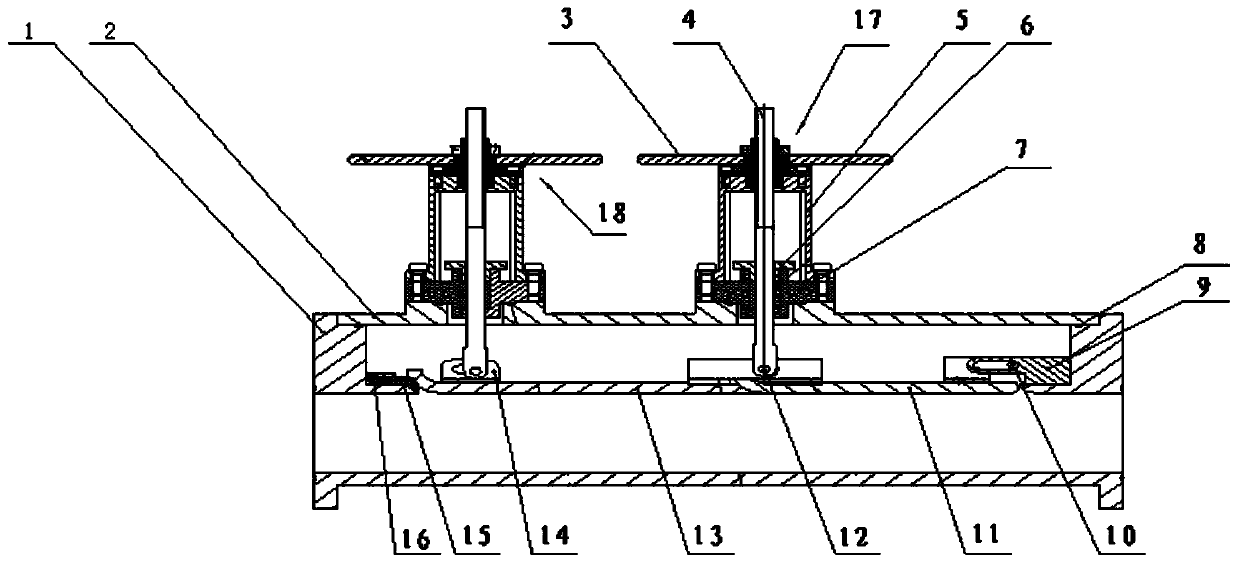

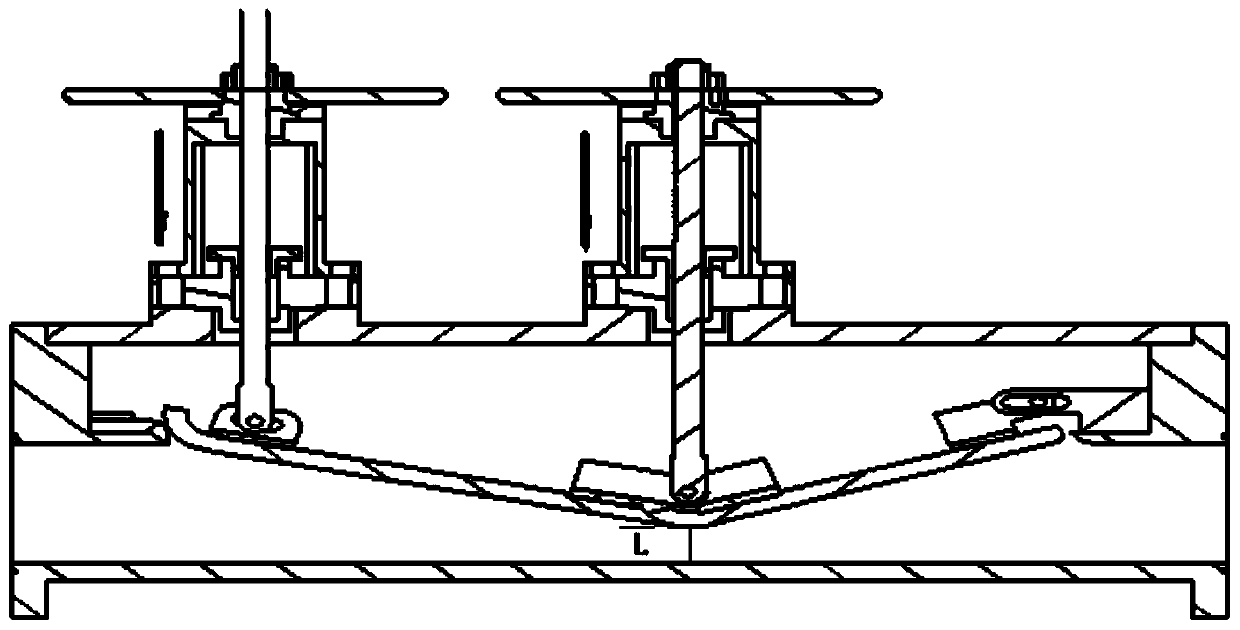

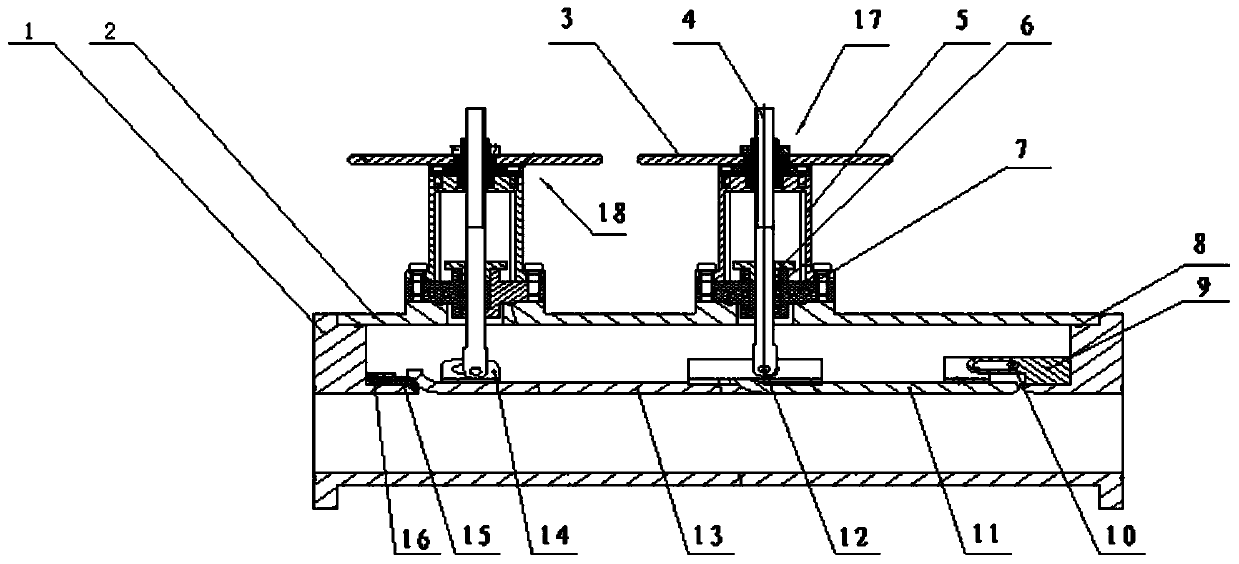

[0026] Such as figure 1 Shown is a schematic diagram of an adjustable flow nozzle. It can be seen from the figure that a precise adjustable gas flow nozzle includes a device casing 1, an upper end cover 2, a first mounting support 9, a front adjustment sealing plate 15, and a sealing gasket 16 , the spout adjustment mechanism 17 and the compression sealing mechanism 18; wherein, the equipment casing 1 is located at the bottom; the top of the equipment casing 1 is provided with a stepped groove; the upper end cover 2 is fixedly installed in the equipment casing 1 stepped groove On the outer edge of the device housing 1 and at the same level as the upper surface of the device housing 1; the contact position between the device housing 1 and the upper end cover 2 is fixedly installed with a sealing ring 8, which is made of polytetrafluoroethylene ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com