Driving device capable of accurately controlling valve

A technology for driving devices and valves, applied in valve devices, valve operation/release devices, valve details, etc., can solve problems such as machining errors, wear, and inability to accurately control valve opening and closing, and achieve the effect of eliminating transmission errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

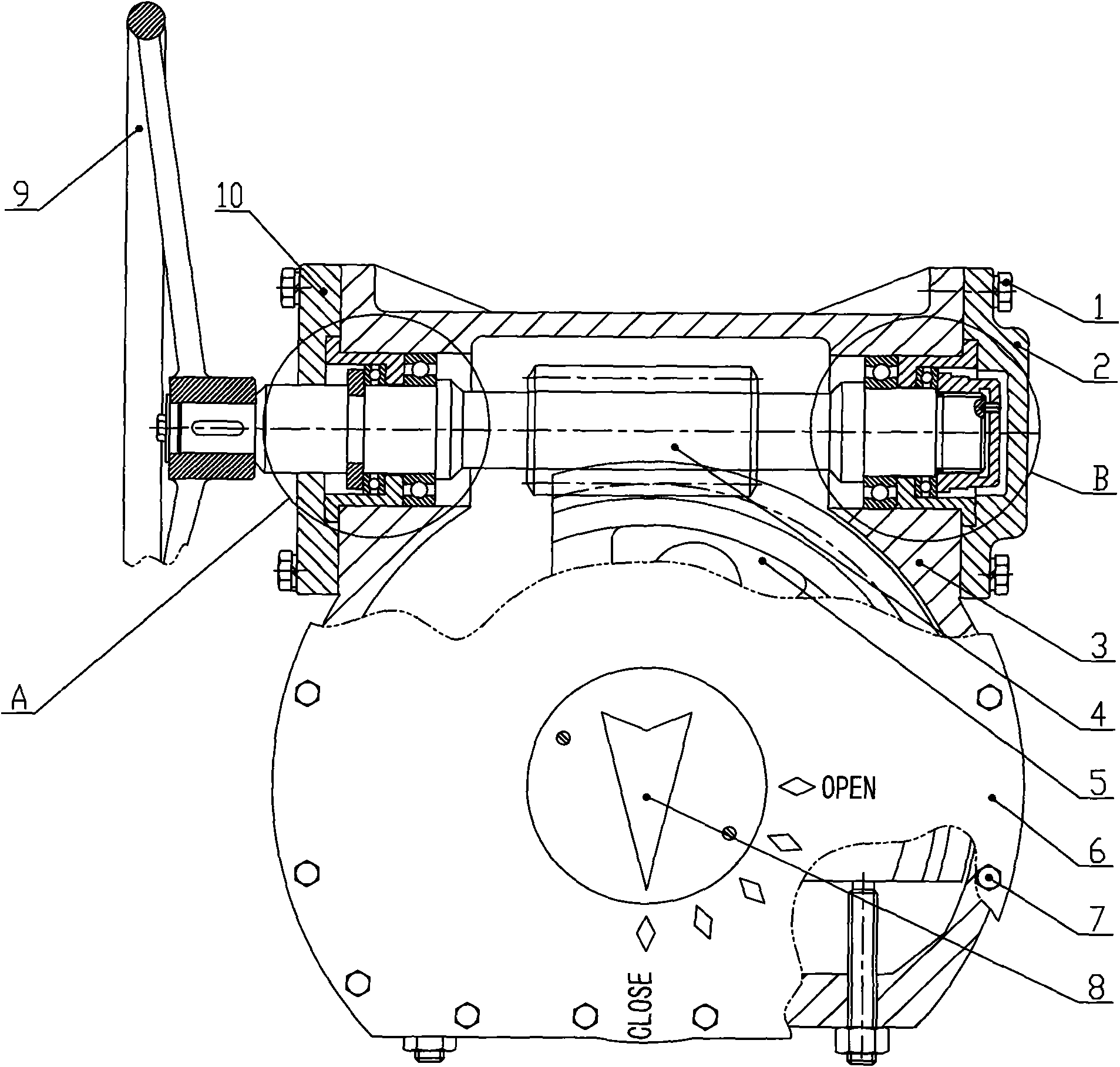

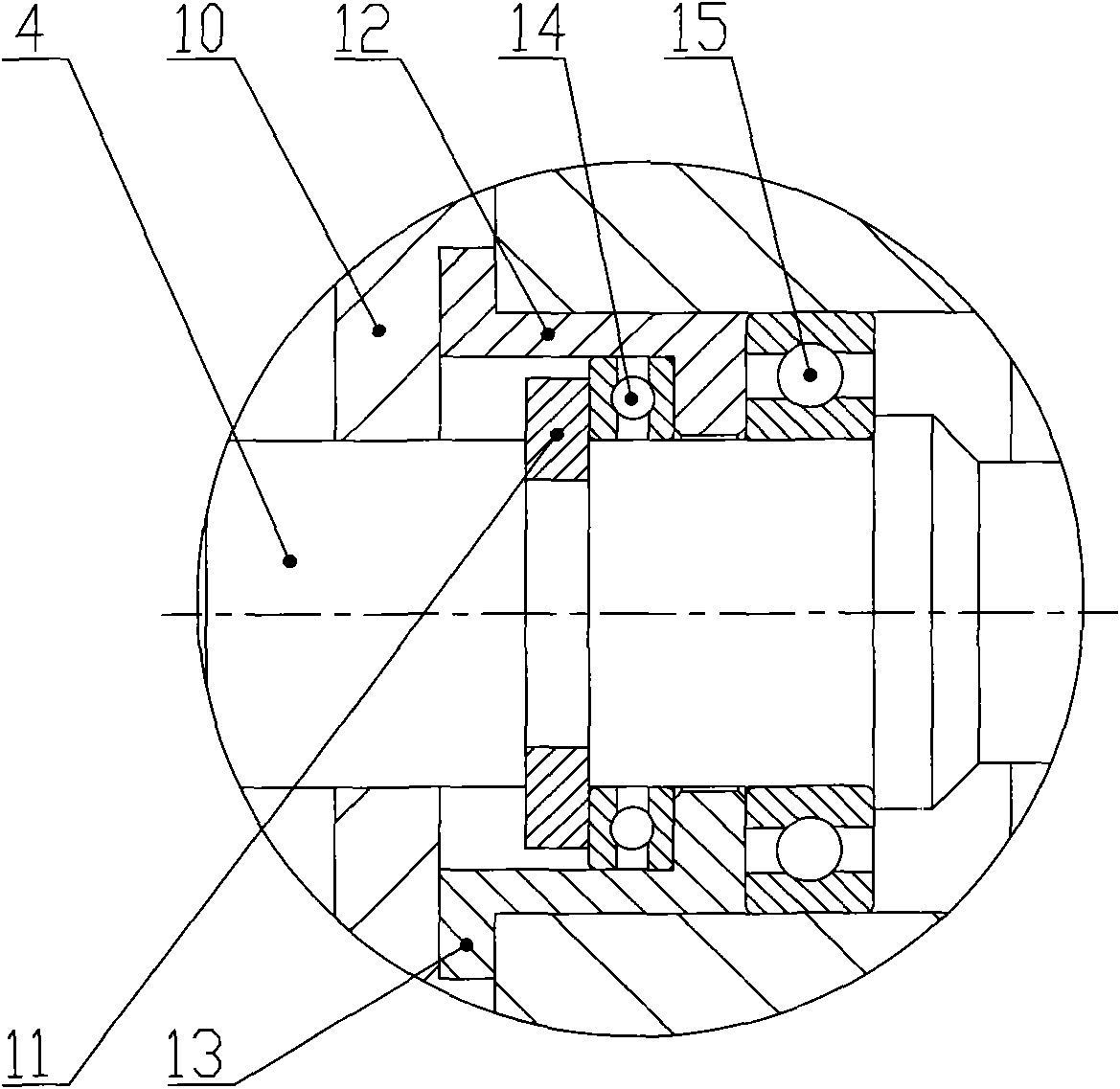

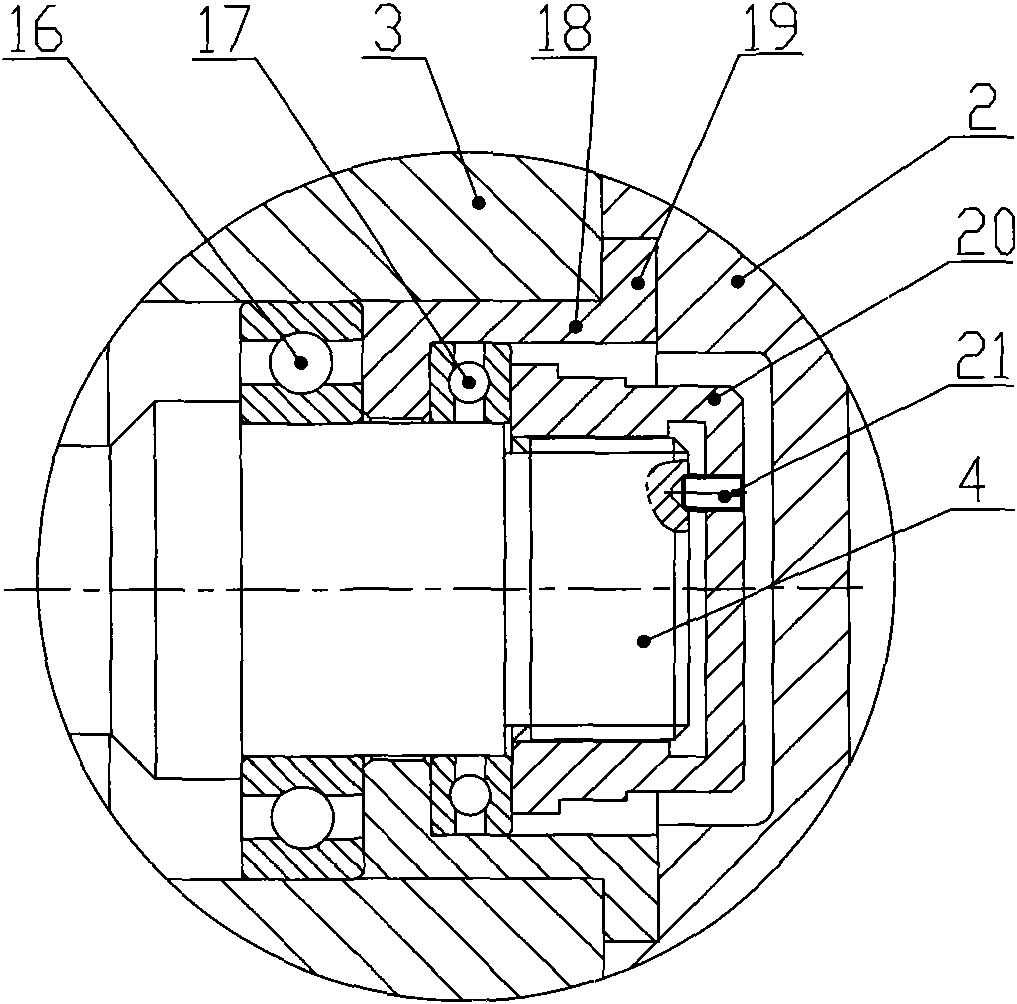

[0012] Such as figure 1 As shown, the worm gear 5 is installed in the box body 3, and the worm screw 4 is fixed on the box body 3 by deep groove bearings 15 and 16, bearing sleeves 12 and 18, thrust bearings 14 and 17, and left and right end covers 10 and 2, and the thrust bearings 14 and 17 are respectively installed in the stepped holes of the bearing sleeves 12 and 18, and the left and right end covers 10 and 2 respectively press and fix the outer edge steps 13 and 19 of the bearing sleeves 12 and 18 on the box body 3 through bolts 1, and the handwheel 9 Be fixed on worm screw 4 left ends. There is a snap ring groove on the worm 4 at the outer end of the thrust bearing 14 at one end of the handwheel 9, and the snap ring 11 is stuck in the snap ring groove of the worm, and the snap ring 11 presses the thrust bearing 12 at the left end of the worm on the bearing sleeve 12, The right end of the worm screw 4 has a locking nut 20 that is threadedly connected with the worm screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com