Micro double-spindle false tooth repair machine

A dual-spindle, micro-miniature technology, applied in the direction of dentures, etc., can solve the problems of inconvenient operation, long production cycle, and large volume, and achieve the effect of compact structure, low cost, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

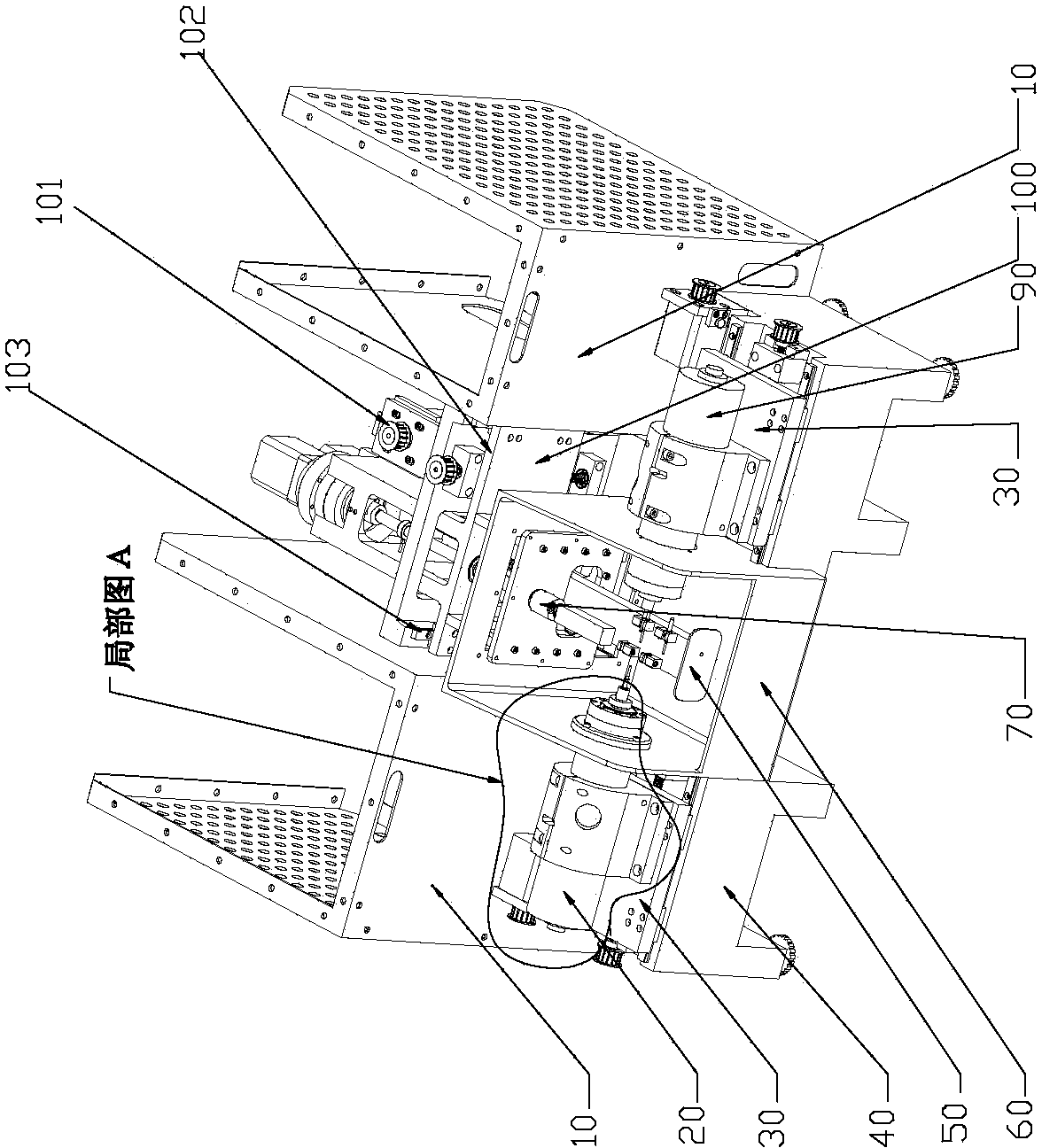

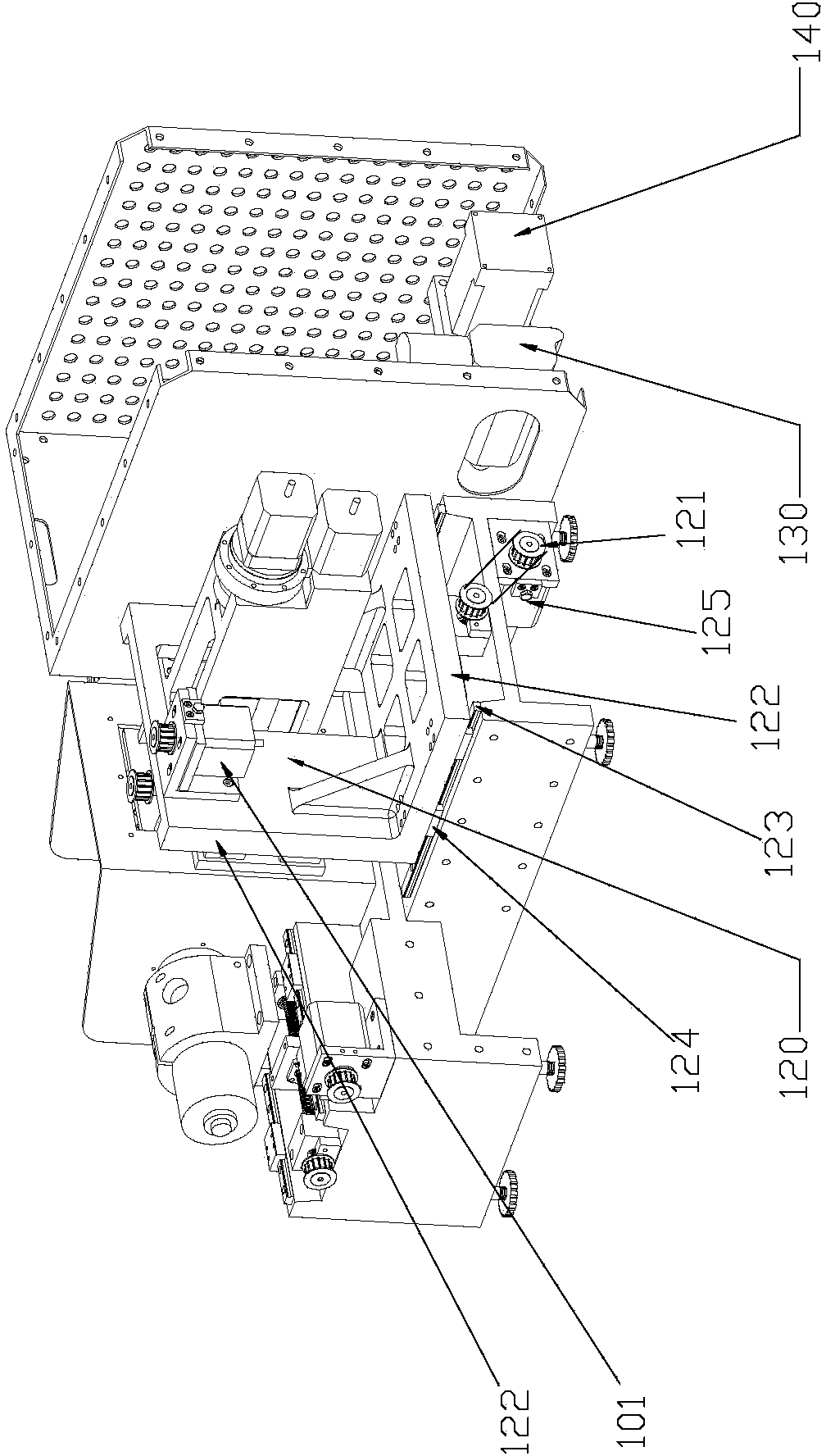

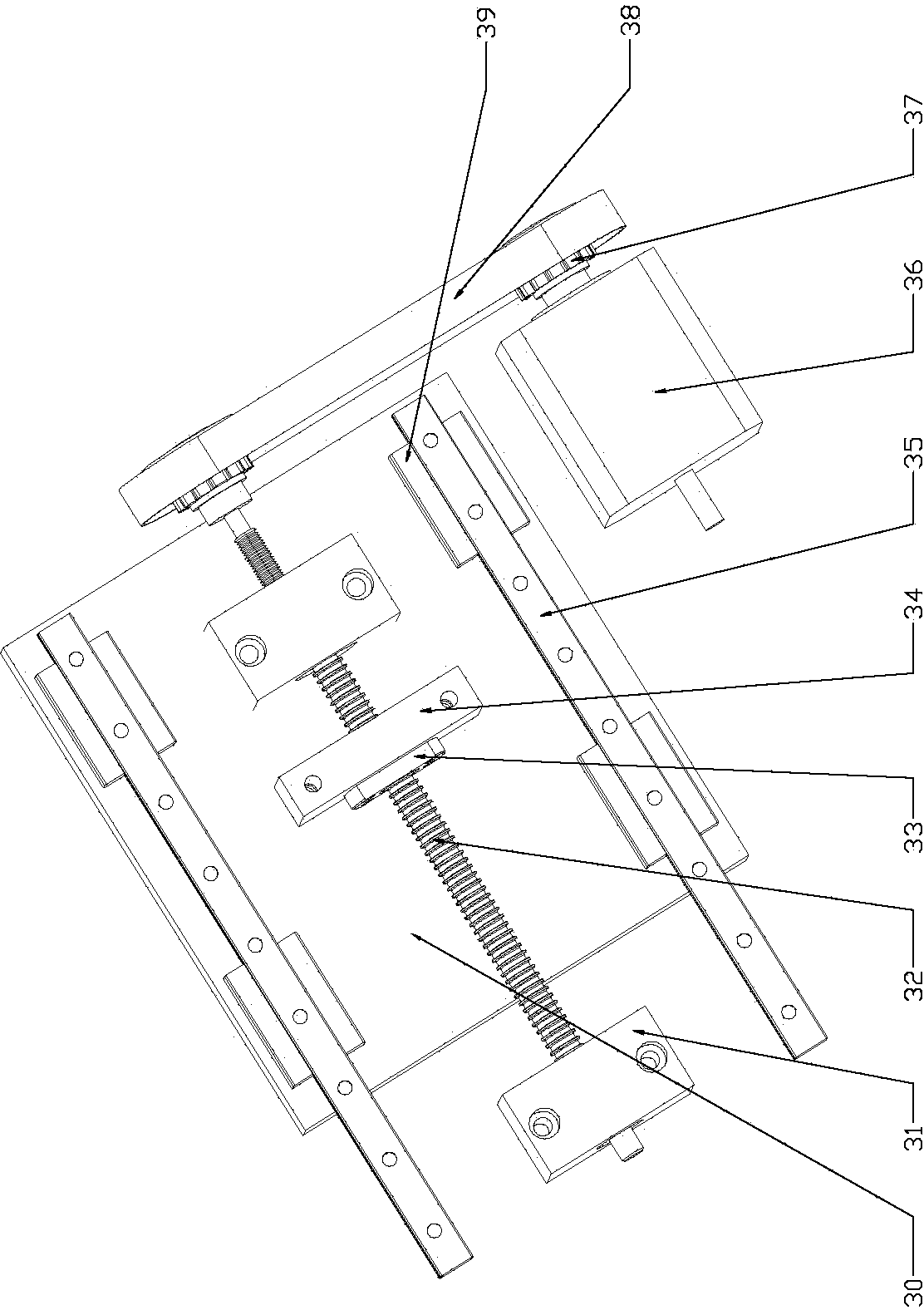

[0041] Such as Figure 1-8 shown.

[0042] A miniature double-spindle denture restoration machine, which includes a base 40, a first electric spindle system 20 installed on the base 40, a second electric spindle system 90, an electrical box 10, a workpiece rotating mechanism 70, an air pump, an oil pump, and a coolant system, etc., the first spindle system 20 and the second spindle system 90 are coaxially arranged, and the tools installed on the first electric spindle system 20 and the second electric spindle system 90 and the workpiece installed on the workpiece rotating mechanism 70 are both Extend into the processing space 60 and install vertically on a horizontal plane; the first electric spindle system 20 and the second electric spindle system 90 are installed on their respective X-axis feed mechanisms 30; the workpiece rotation mechanism 70 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com