Power transformer winding deformation on-line detection method based on pulse coupling injection

A power transformer and winding deformation technology, which is applied in the direction of electromagnetic measuring devices, electric/magnetic contour/curvature measurement, etc., can solve the problem of being unable to resist sudden faults, unable to detect the deformation of power transformer windings, and unable to obtain winding deformation information in time, etc. problem, to achieve light weight, improve the ability to resist electromagnetic interference, and quickly detect the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

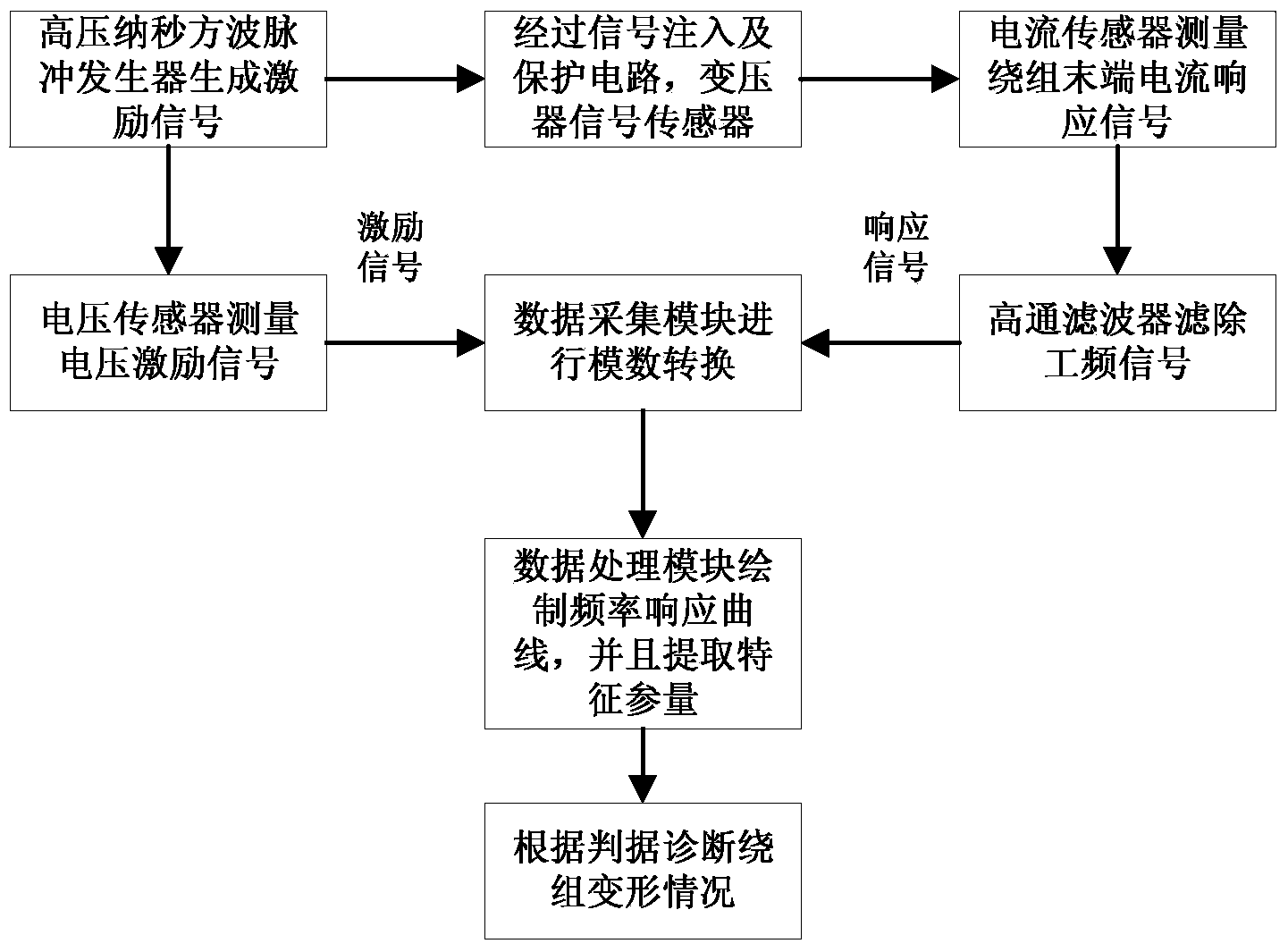

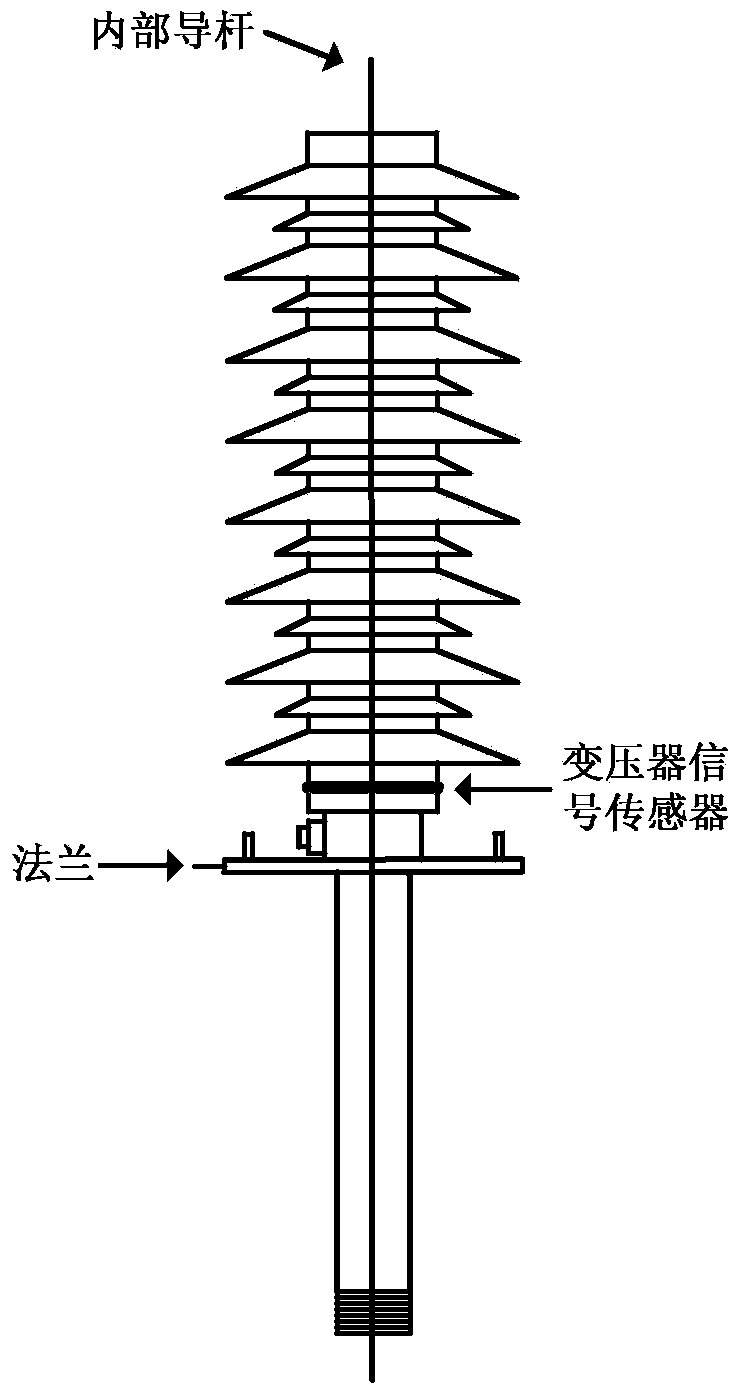

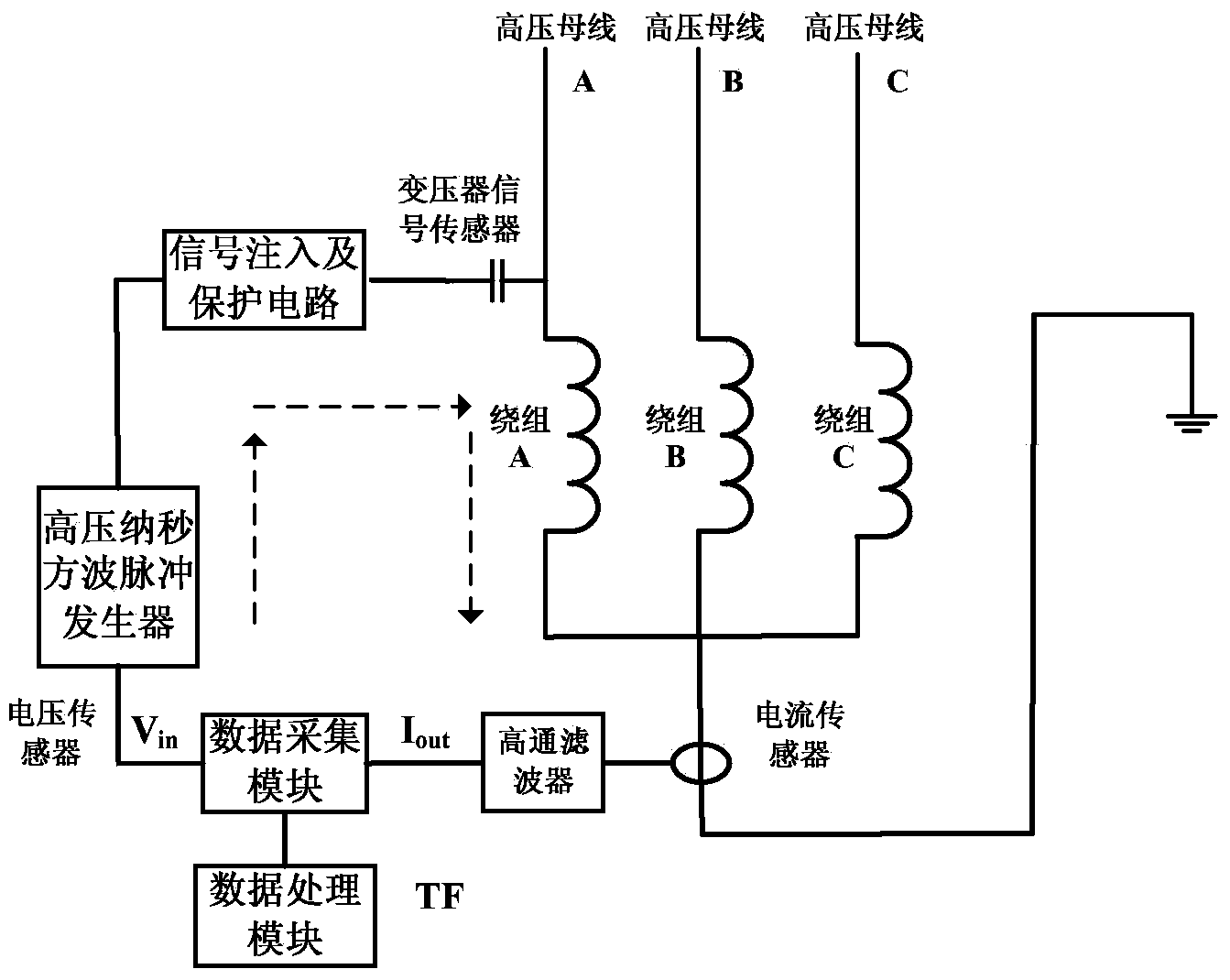

[0026] figure 1 It is a flow chart of the method of the present invention, and the method of the present invention comprises the following steps: Step 1: the high-voltage nanosecond square wave pulse generator generates a high-voltage nanosecond pulse signal; Step 2: the high-voltage nanosecond pulse signal is injected and protected by a signal The circuit is transmitted to the transformer signal sensor installed in the transformer bushing, and the nanosecond pulse signal is coupled to the winding; Step 3: The data acquisition module collects the high-voltage nanosecond pulse signal and the current response signal of the neutral point at the end of the winding, and converts it into Digital signal; step 4: the data processing module carries out Fourier transform to described digital signal, obtains the frequency response curve of winding, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com