Irregular stone multifunctional composite processing center with double five-axle linkage system

A compound machining center and five-axis linkage technology, which is applied in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve the problems of low feed speed, machine tool damage, and high processing cost, so as to increase feed speed and reduce Effect of vertical load, high feed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

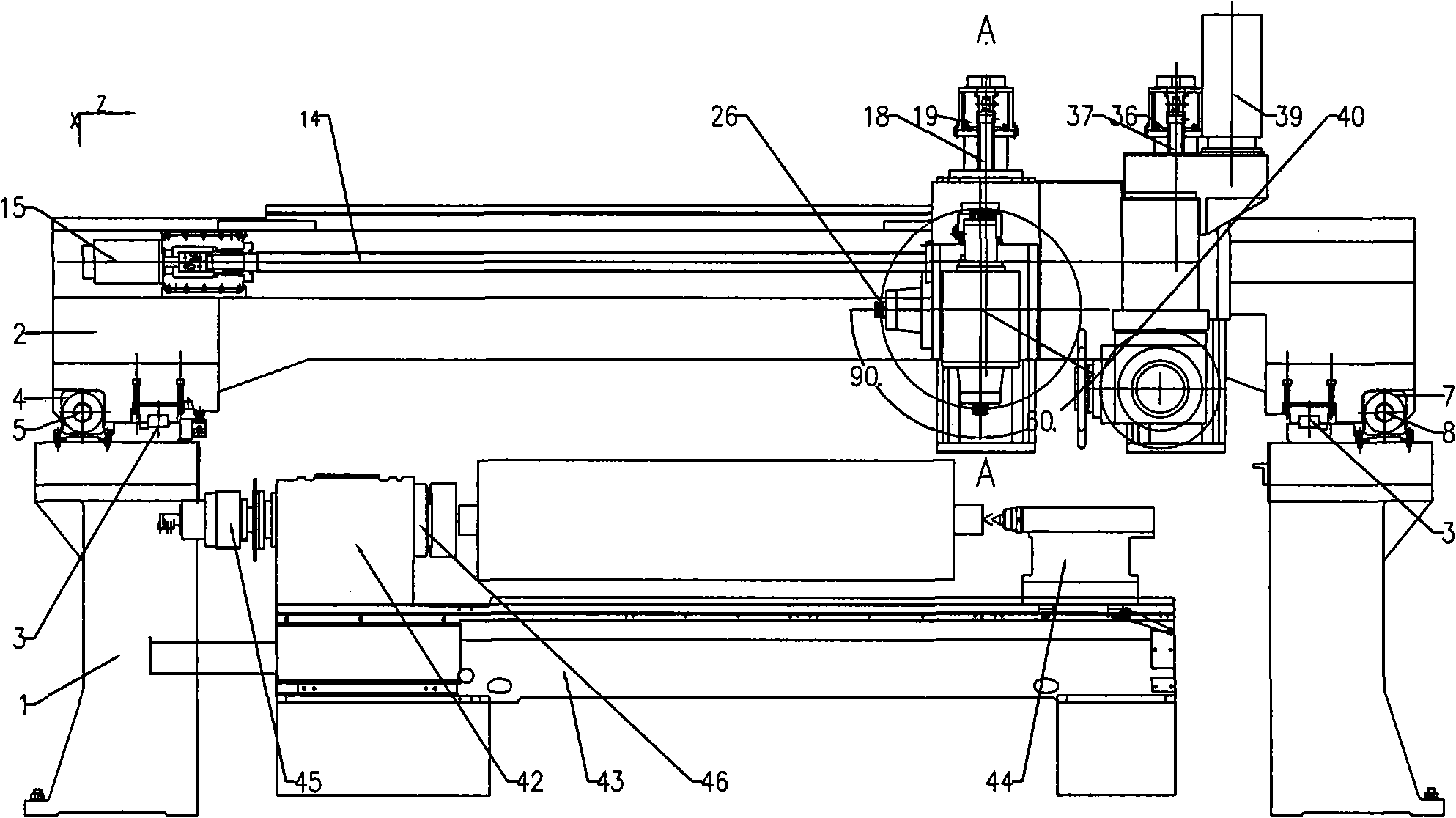

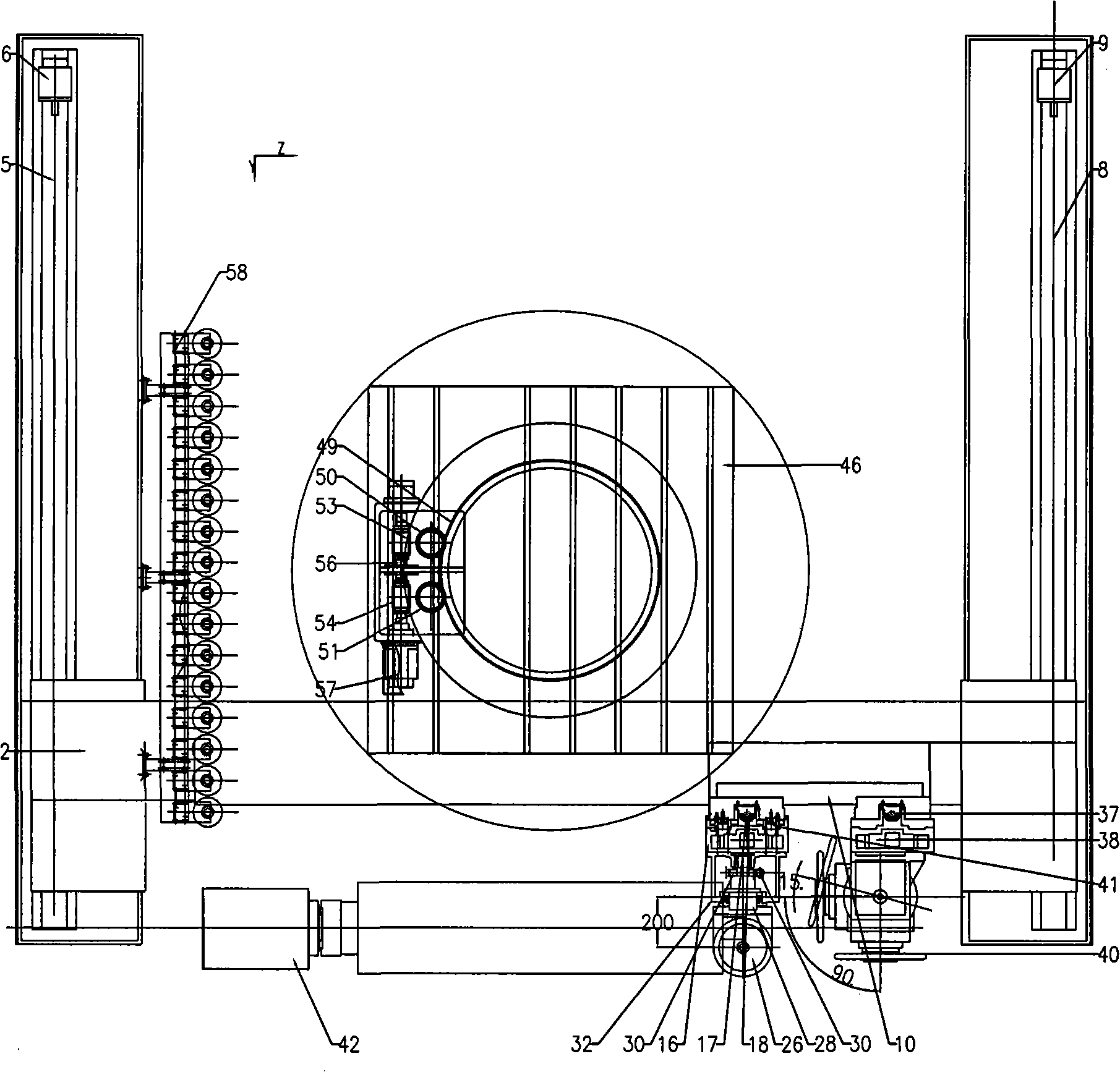

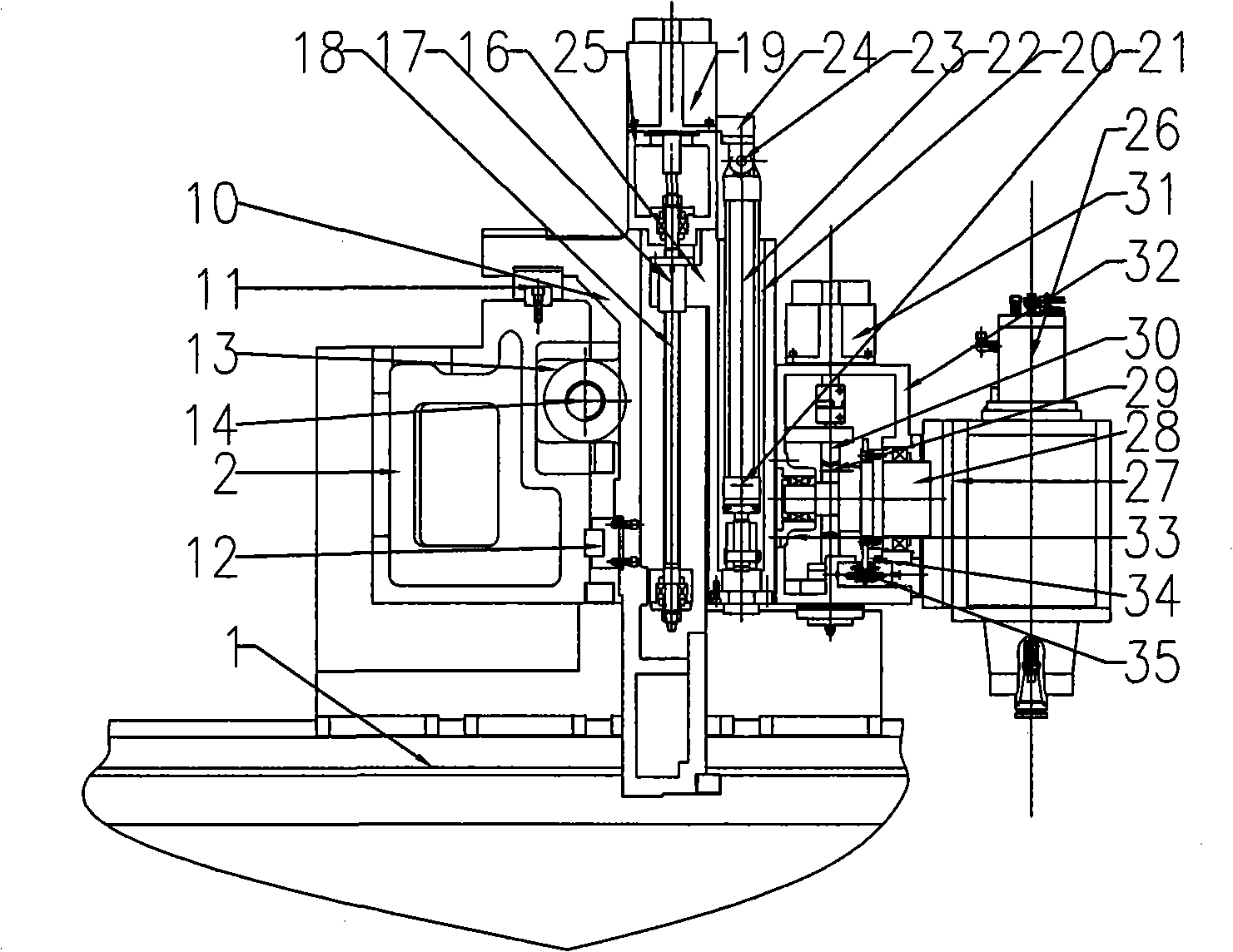

[0025] The present invention will be described in detail below with reference to the accompanying drawings.

[0026] The special-shaped stone multifunctional compound machining center with double five-axis linkage system has a Z-axis horizontal sliding saddle installed on the beam, and the engraving and milling working head part and the turning working head part are installed side by side on the sliding saddle. Among them, the engraving and milling working head part is composed of a high-speed electric spindle with automatic tool change function and a set of turbine worm rotary indexing mechanism, which can realize the B-axis rotary indexing, and a set of hydraulic locking is installed on the indexing spindle. Auxiliary device; the turning head part can not only provide the main cutting force for the turning movement of the turning head through a high-power servo motor, but also realize the rotation indexing of the turning head around the A axis. The turning head and the engra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com