Patents

Literature

49results about How to "Reduce vertical load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

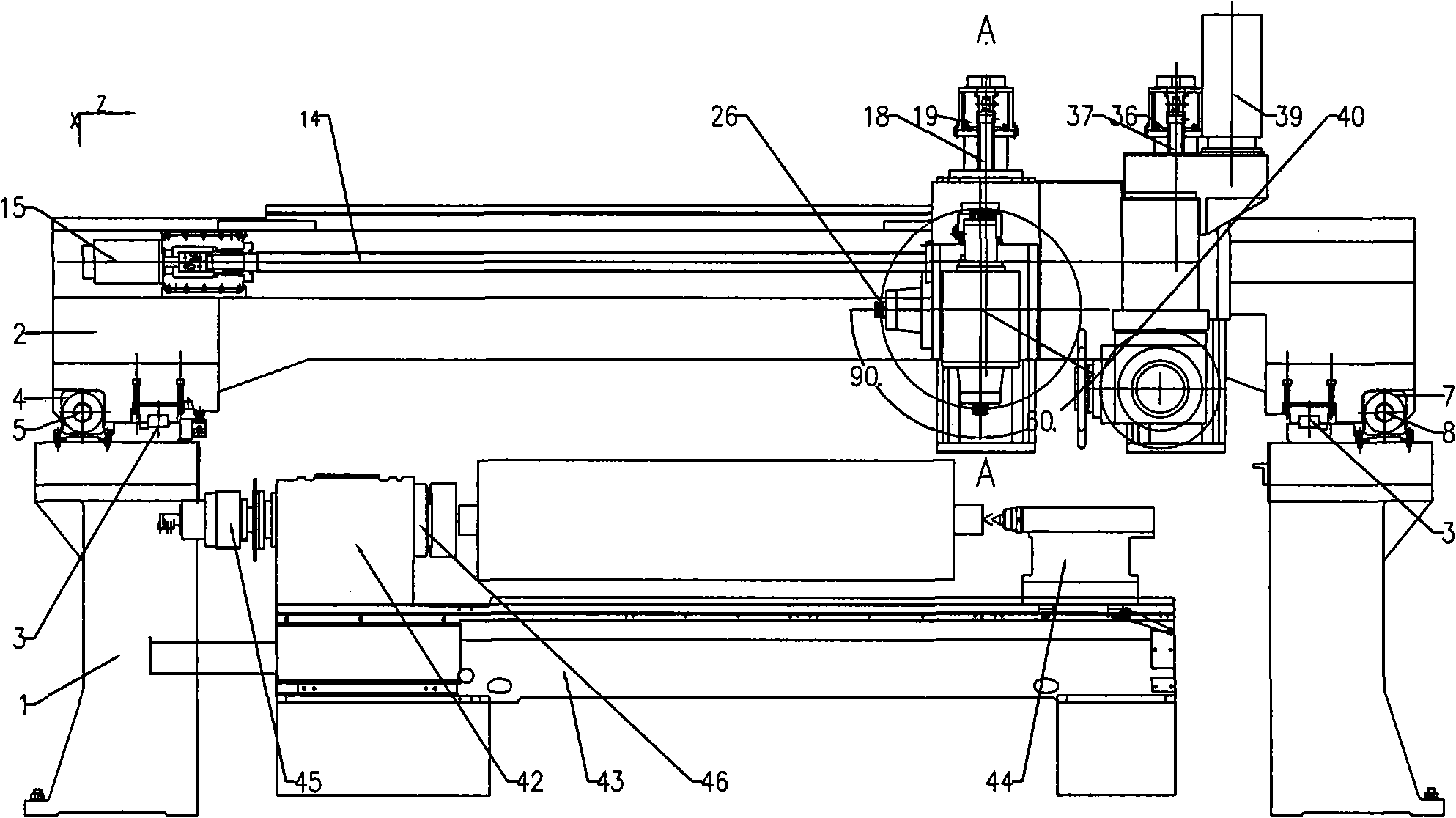

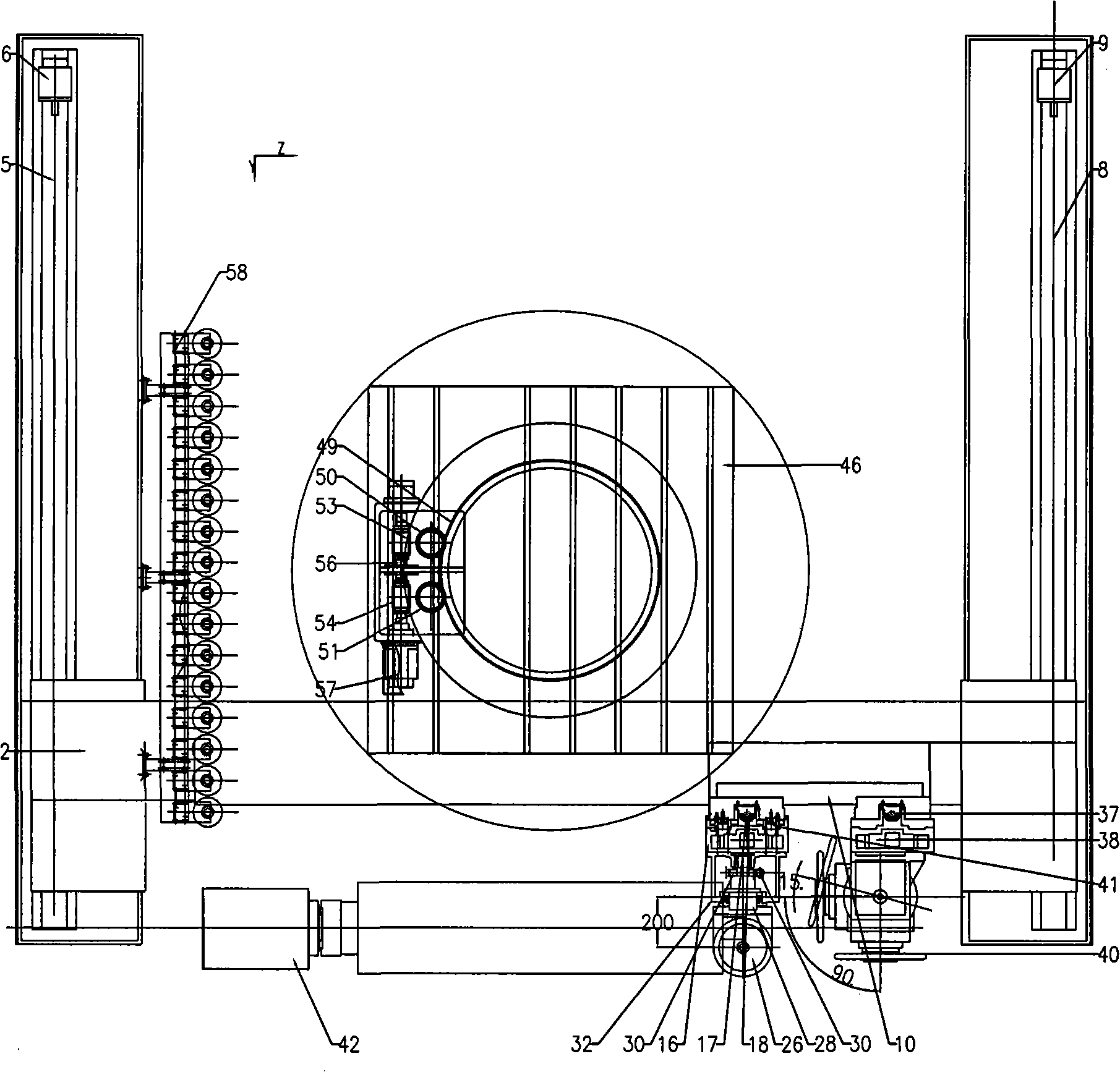

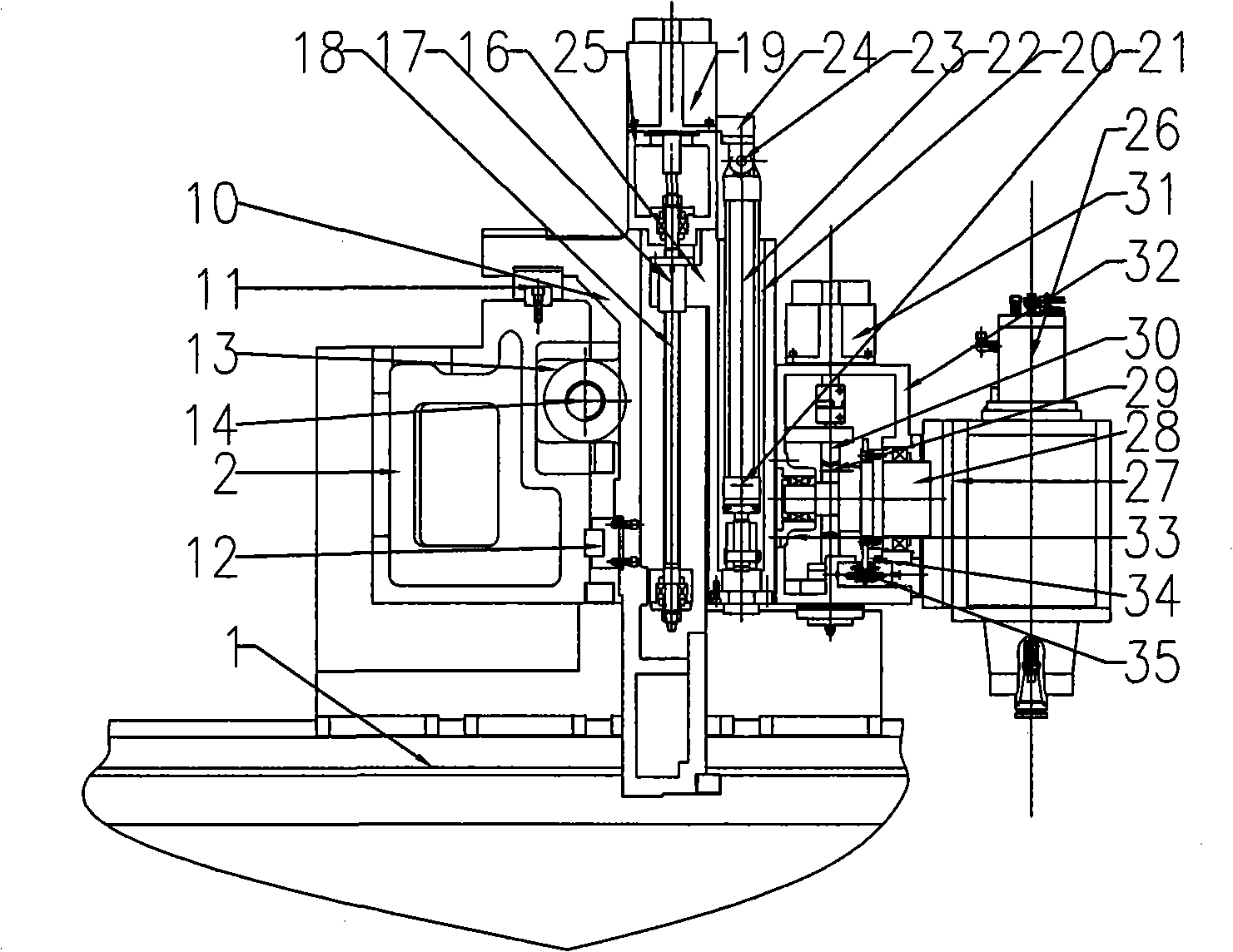

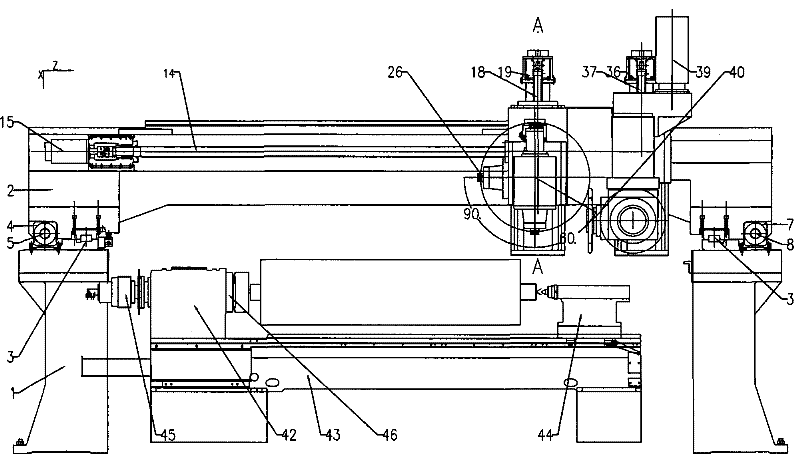

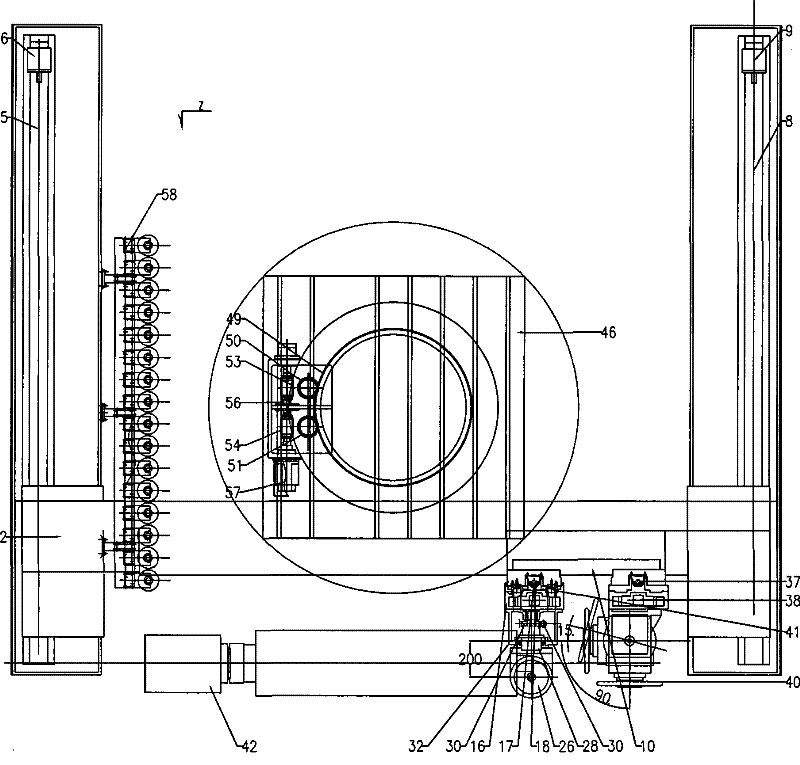

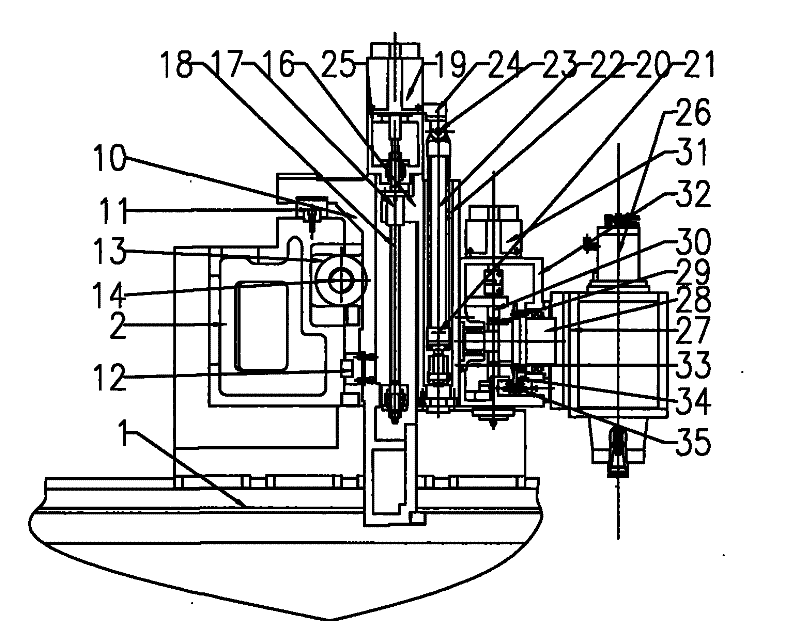

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490AEngraving and milling realizationAchieve turningGrinding machinesStone-like material working toolsEngineeringMechanical engineering

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division around the axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

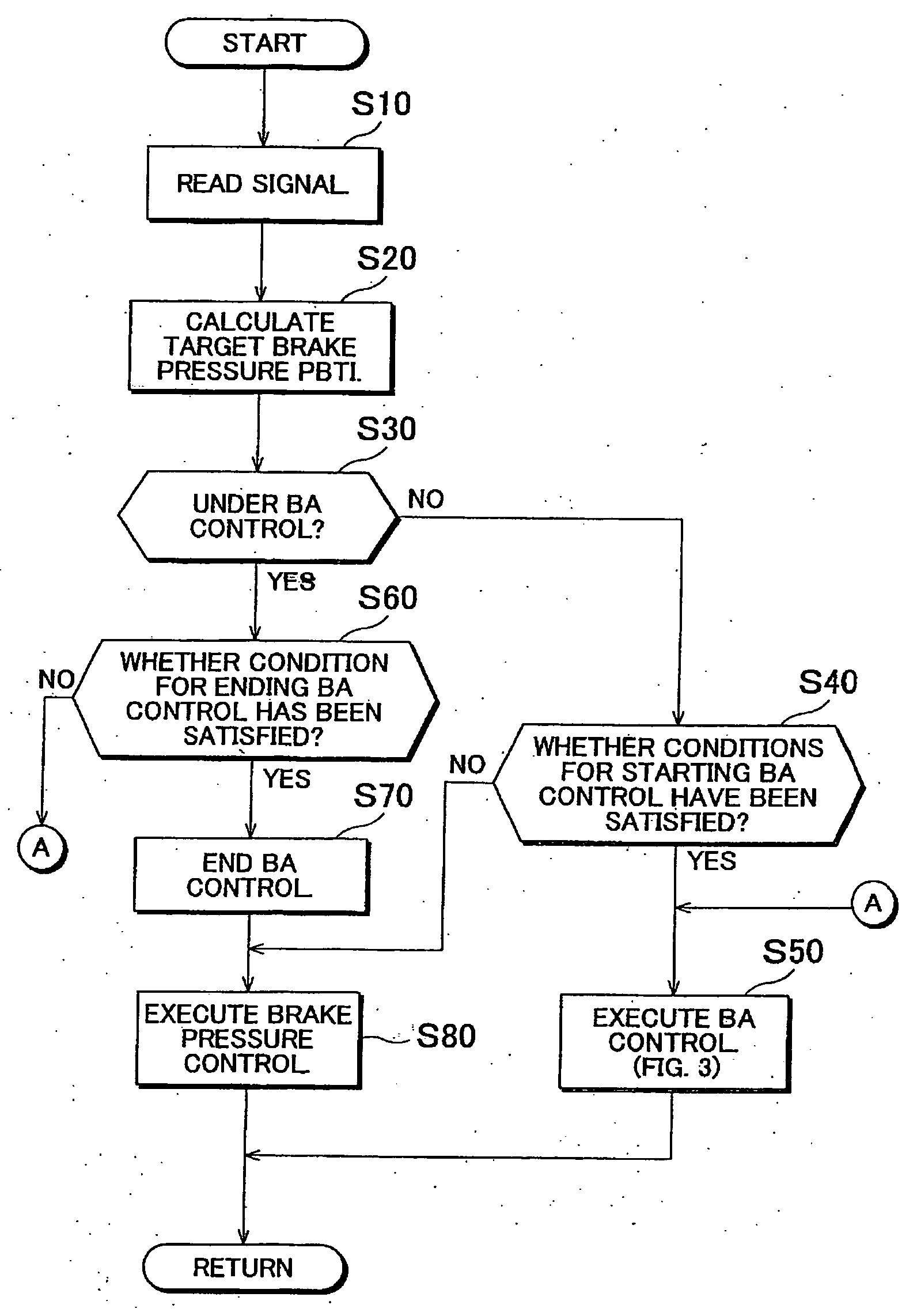

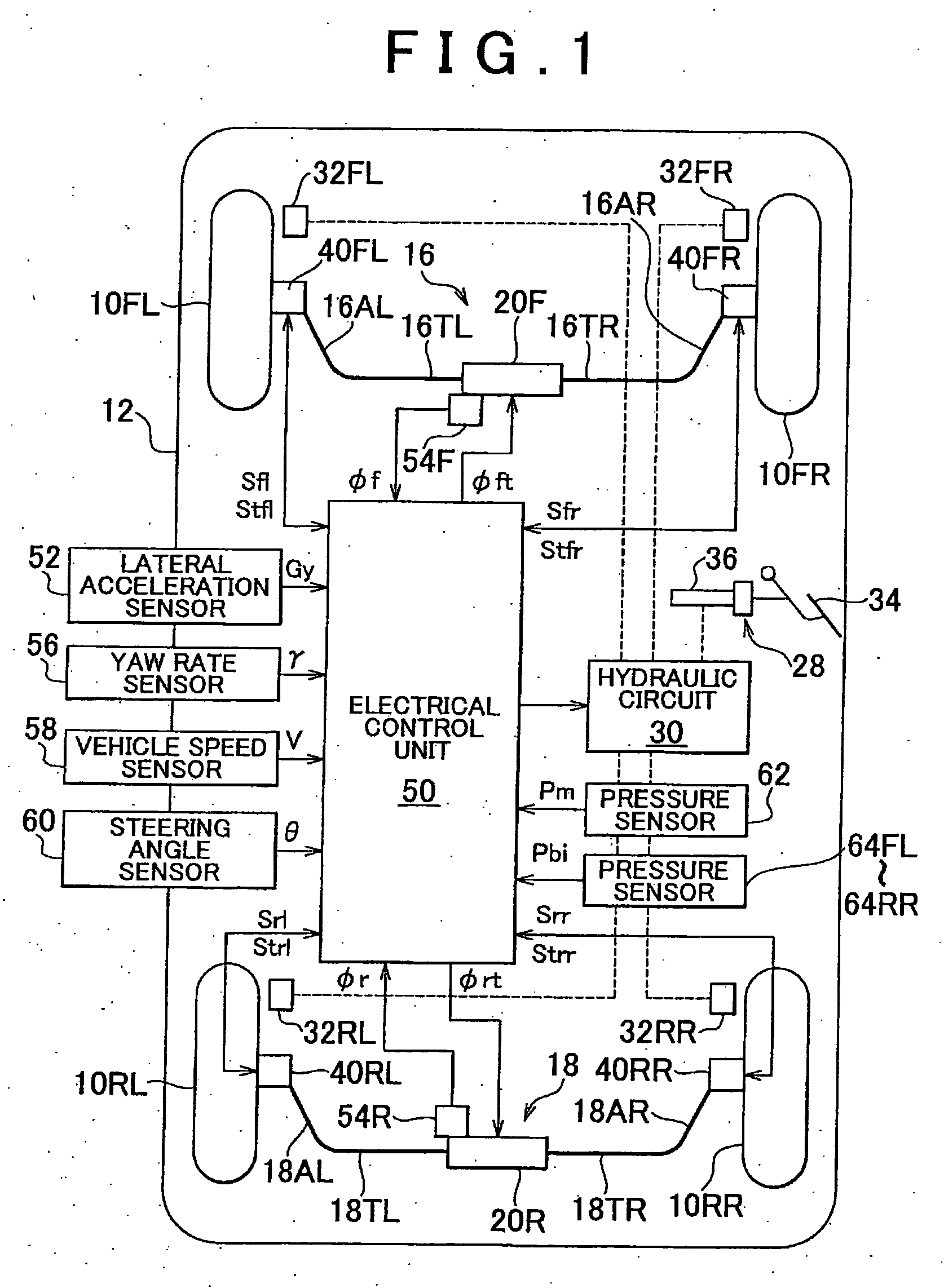

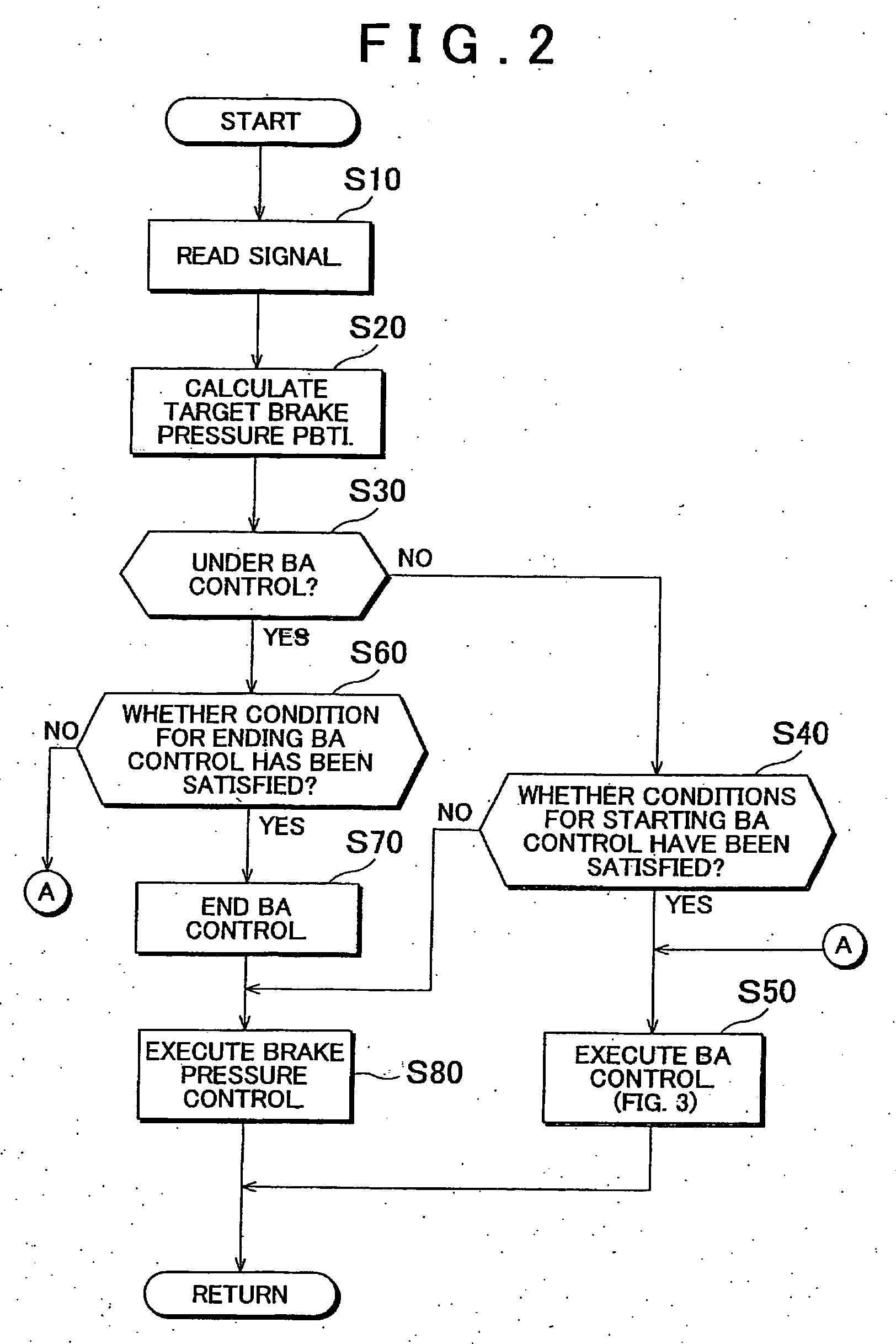

Vehicle drive control system and method

InactiveUS20070124051A1Turn the vehicle easilyAdditional componentBrake system interactionsAnalogue computers for trafficControl systemEmergency situations

A drive control system for a vehicle includes a braking force control mechanism that controls braking forces on the wheels of the vehicle according to a braking operation, a steering characteristic control mechanism that varies the steering characteristic of the vehicle, a determination portion that determines whether an emergency steering operation is likely to de performed when hard braking is being applied, and a main control portion that controls the steering characteristic control mechanism so as to vary the steering characteristic of the vehicle to increase oversteering component of the vehicle if the determination portion determines that an emergency steering operation is likely to be performed.

Owner:TOYOTA JIDOSHA KK

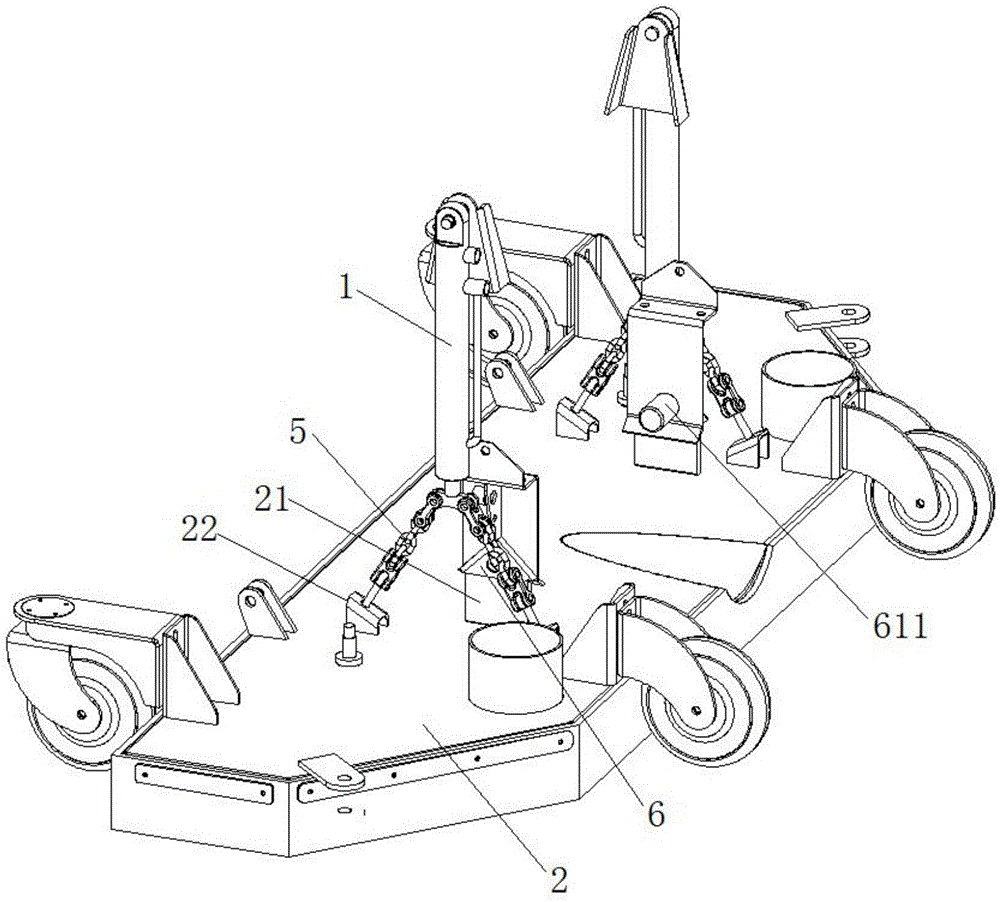

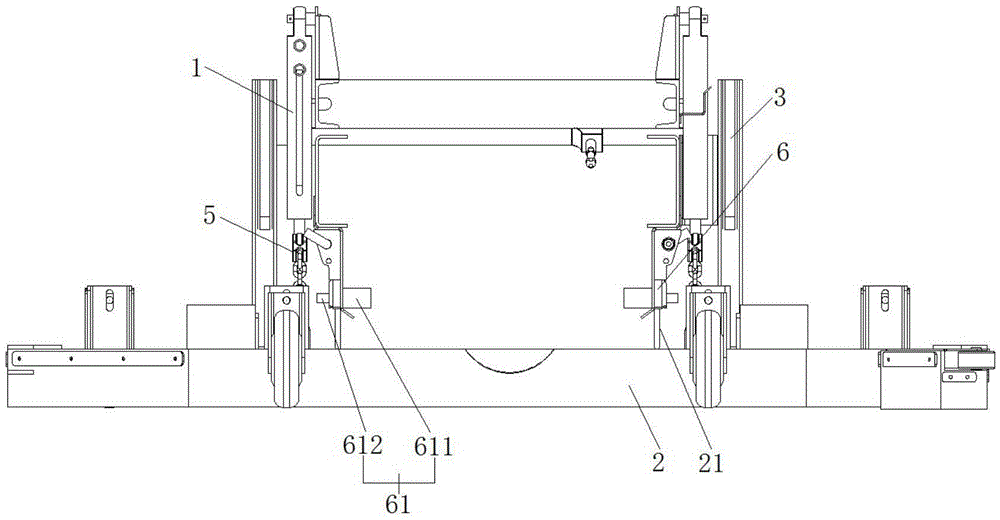

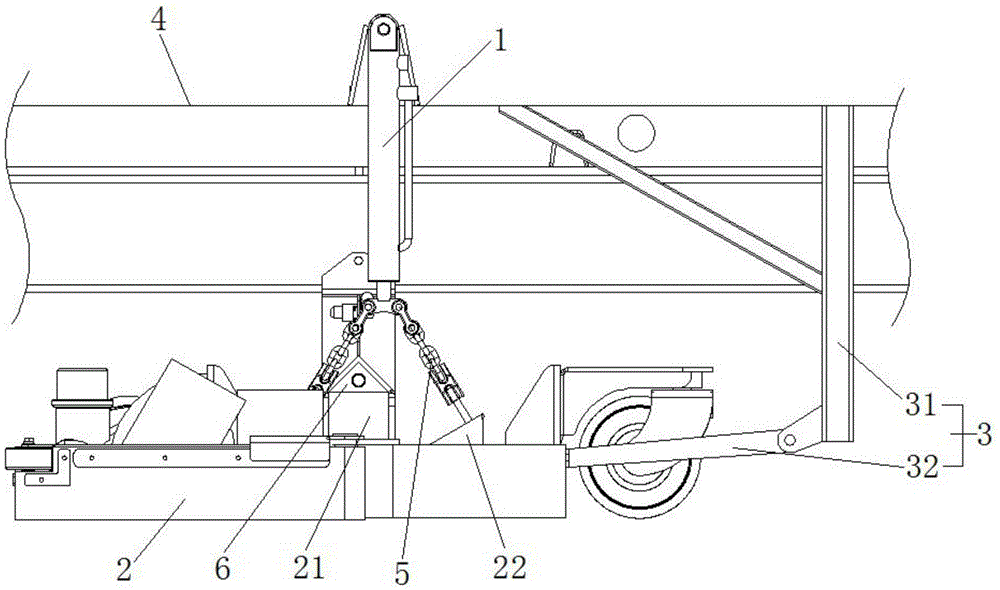

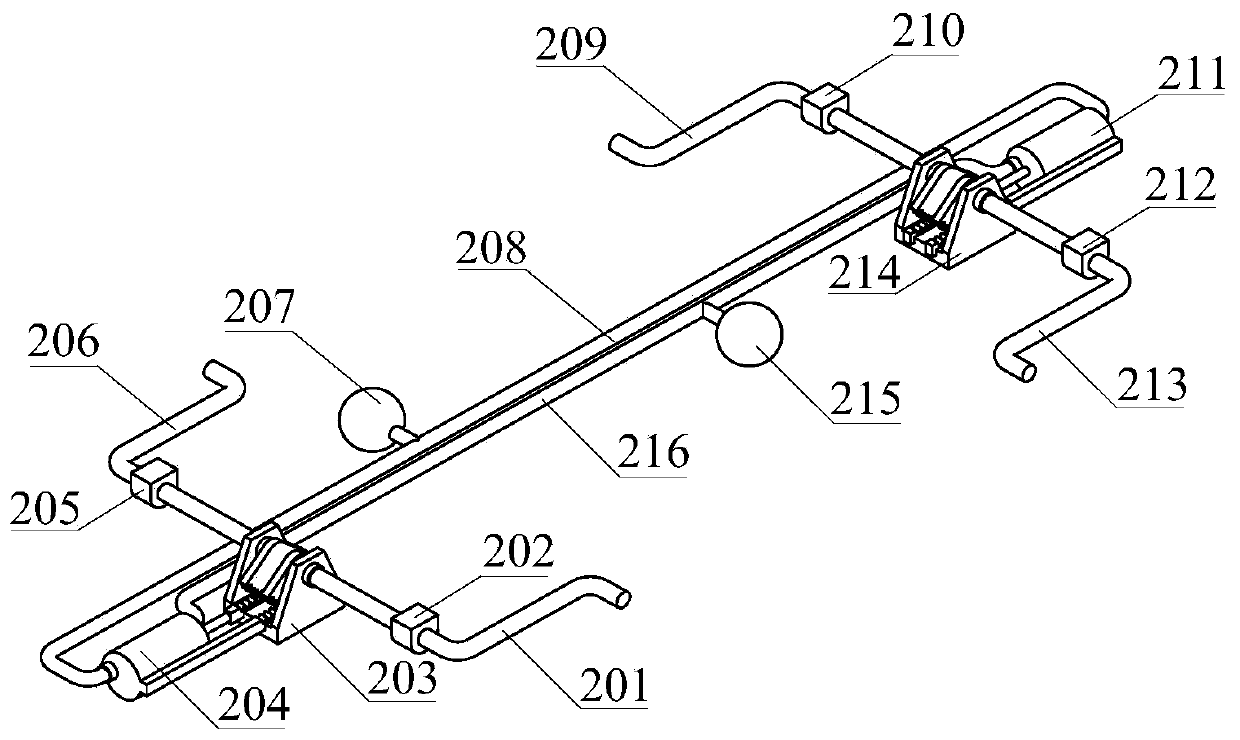

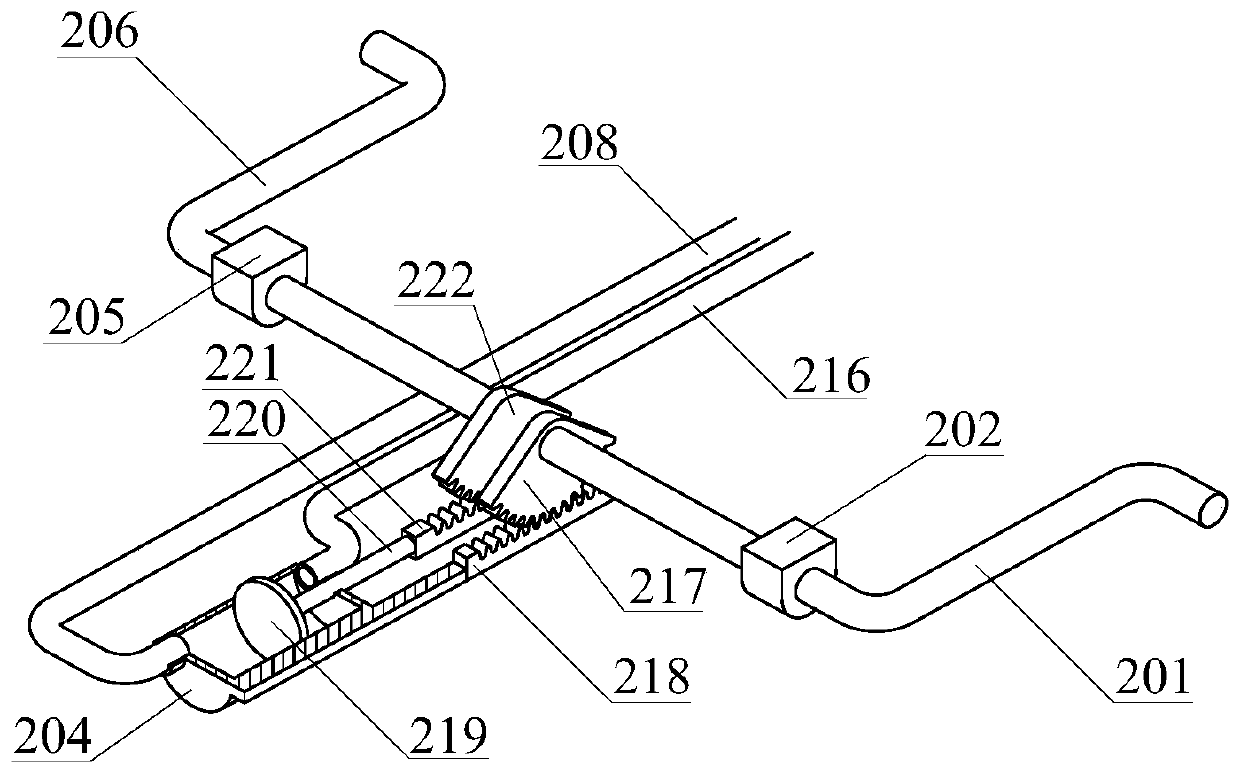

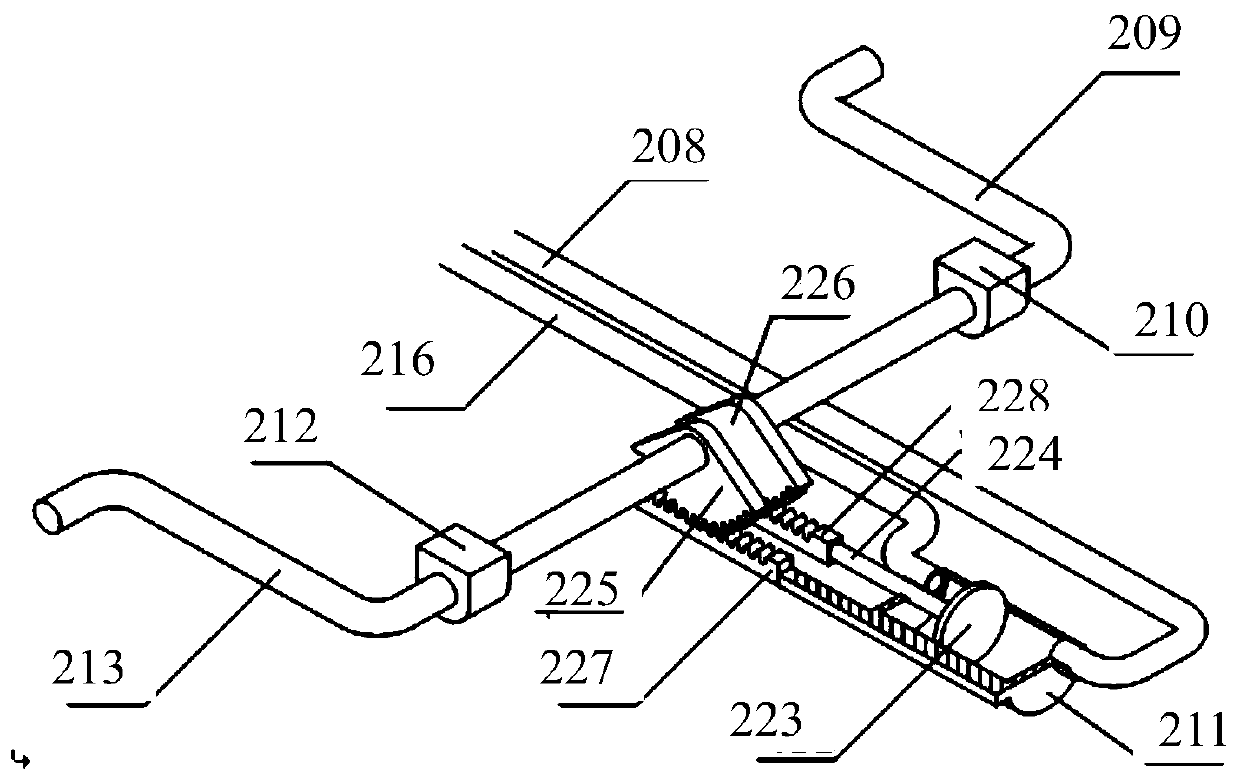

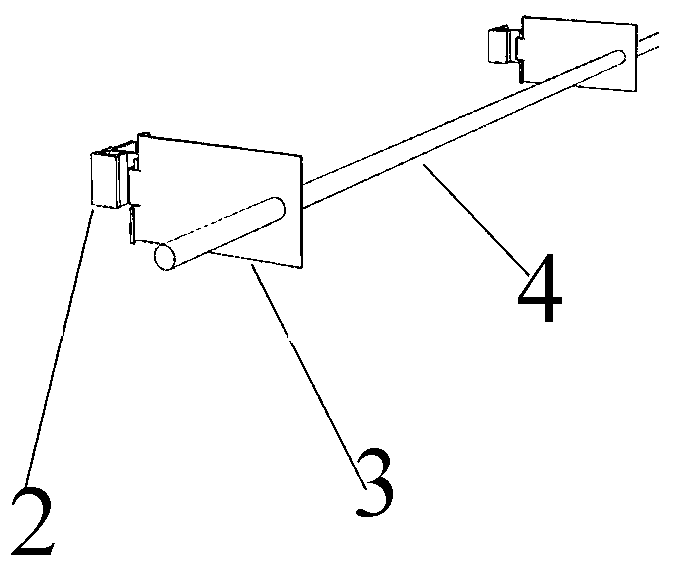

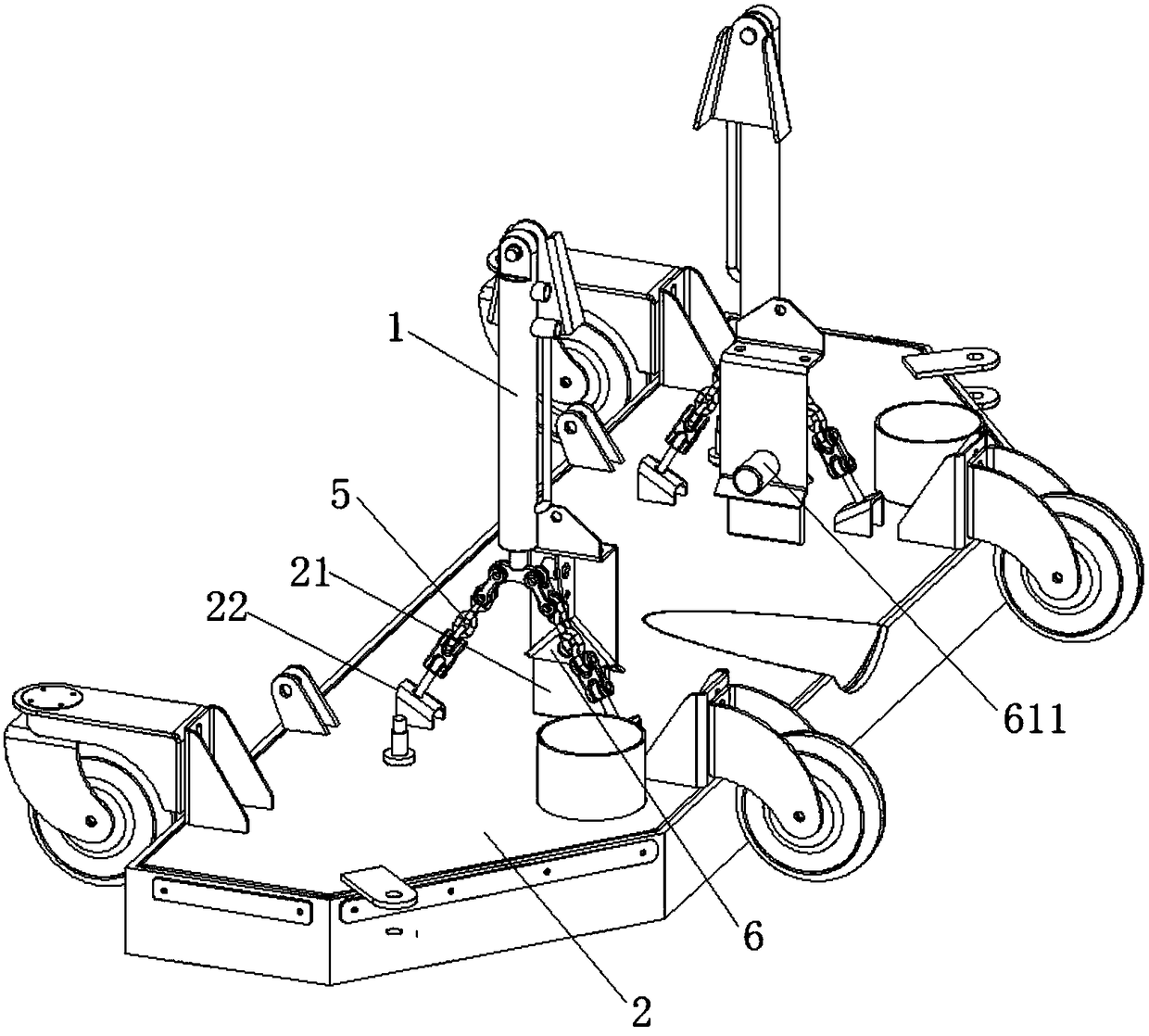

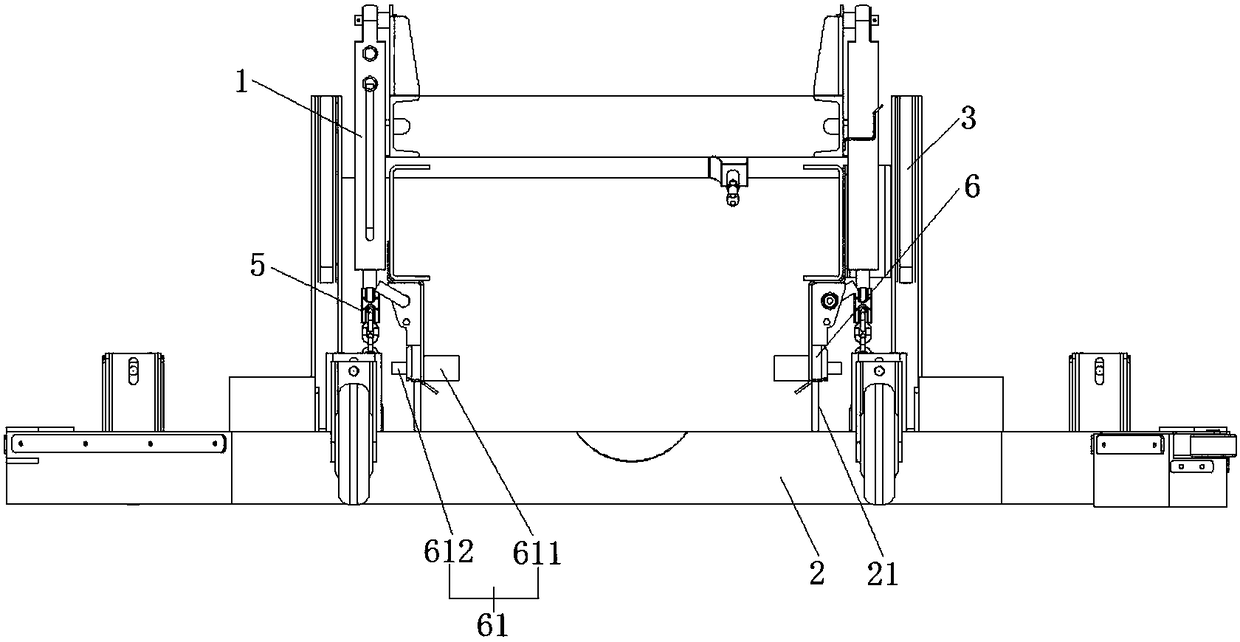

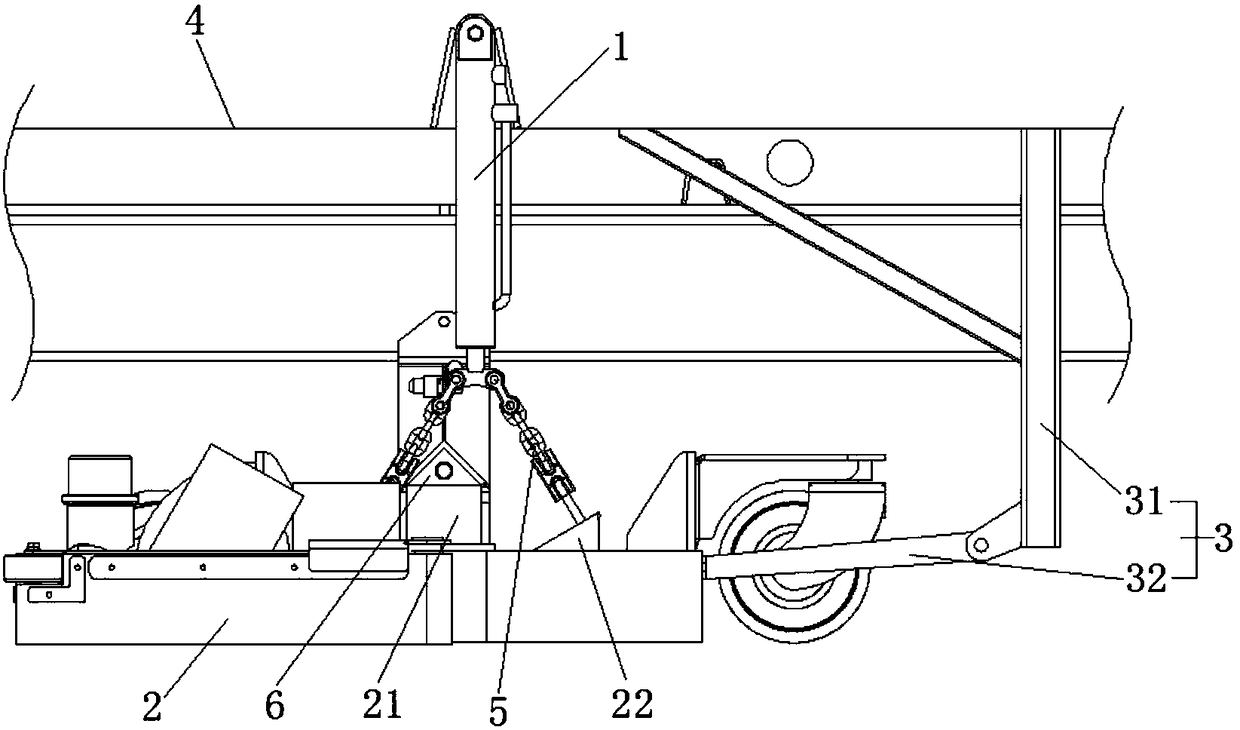

Liftable sucker mechanism of dust collection vehicle

The invention relates to a structural part of a sanitation truck, in particular to a liftable sucker mechanism of a dust collection vehicle. The liftable sucker mechanism of the dust collection vehicle comprises ascending / descending drive mechanisms, a sucker body and an auxiliary walking mechanism; the ascending / descending drive mechanisms are mounted on a chassis beam, the drive ends of the ascending / descending drive mechanisms are arranged downwards and connected with the sucker body through connection pieces, the auxiliary walking mechanism is fixed to the chassis beam and located on the front side of the sucker body in the walking direction, and the sucker body is connected with the auxiliary walking mechanism. The liftable sucker mechanism of the dust collection vehicle has the advantages that the mechanism is simple in structure and convenient to operate and use, and the sucker device is hung flexibly, so that when the sucker meets a highly protruding obstacle, the collision force can be effectively buffered, collision force is dispersed to a large degree, the situation that the sucker is collided and damaged is avoided, good traction force is achieved, and stability of the sucker in the dust collection process is maintained.

Owner:HUBEI JULI AUTOMOTIVE TECH CO LTD

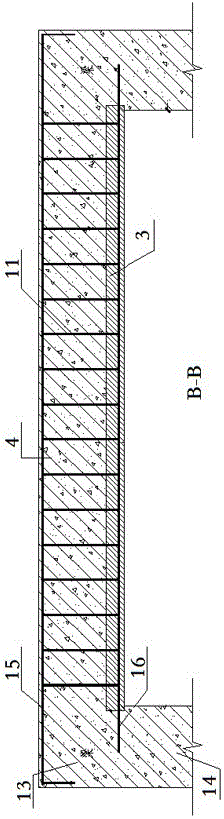

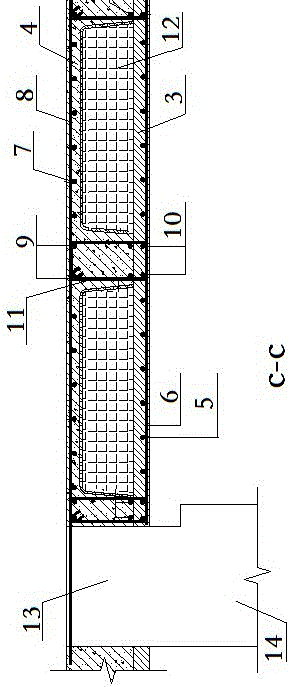

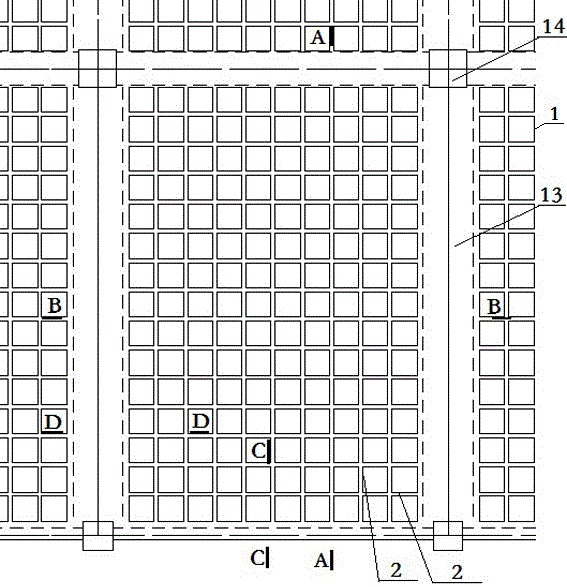

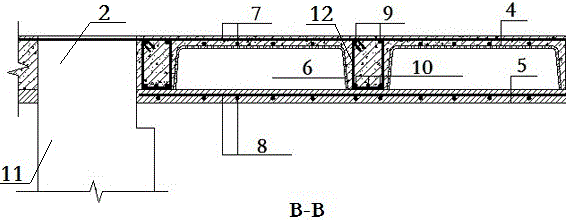

Overlaid assembly-type concrete dense-rib floor structure system and construction method for same

The invention provides an overlaid assembly-type concrete dense-rib floor structure system and a construction method for the same. The system comprises a baseplate and a top plate, wherein the baseplate is composed of multiple prefabricated baseplates which have the same division width and are connected by overlaying steel bars; the top plate is a cast-in-situ top plate with a rib beam; the base plate and the top plate are overlaid and assembled; and a force bearing steel bar which is in overlapped connection with an overlaid beam steel bar is stretched out from an end head of the rib beam. The construction method comprises the steps that the prefabricated baseplate is prepared at a plant; hoisting is conducted on site; rib beam stirrups and rib beam reinforcing bars are disposed, and a hollow box or light material body is disposed; structural steel bars of the top plate are disposed; the rib beam reinforcing bars stretch out from the lateral sides and are in overlapped connection with the overlaid beam; and concrete pouring, maintenance and shaping are carried out. According to the invention, erection and dismounting of templates and supporting tools are omitted; work loads are reduced; construction cost is reduced; construction efficiency is increased; force bearing is more rational; and quality is better.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

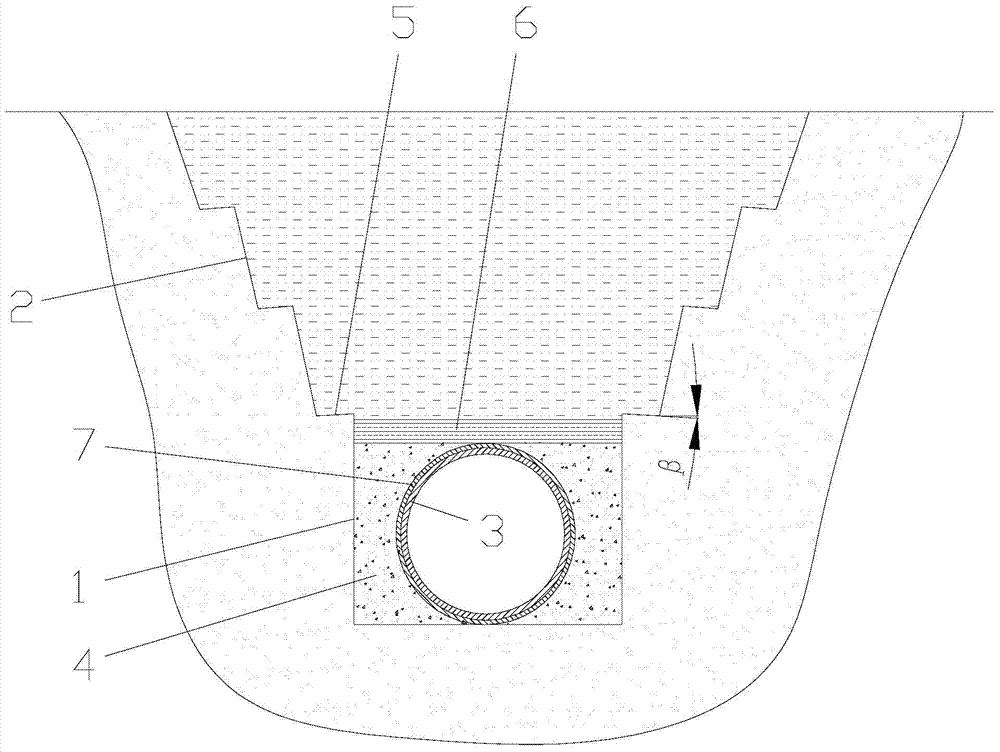

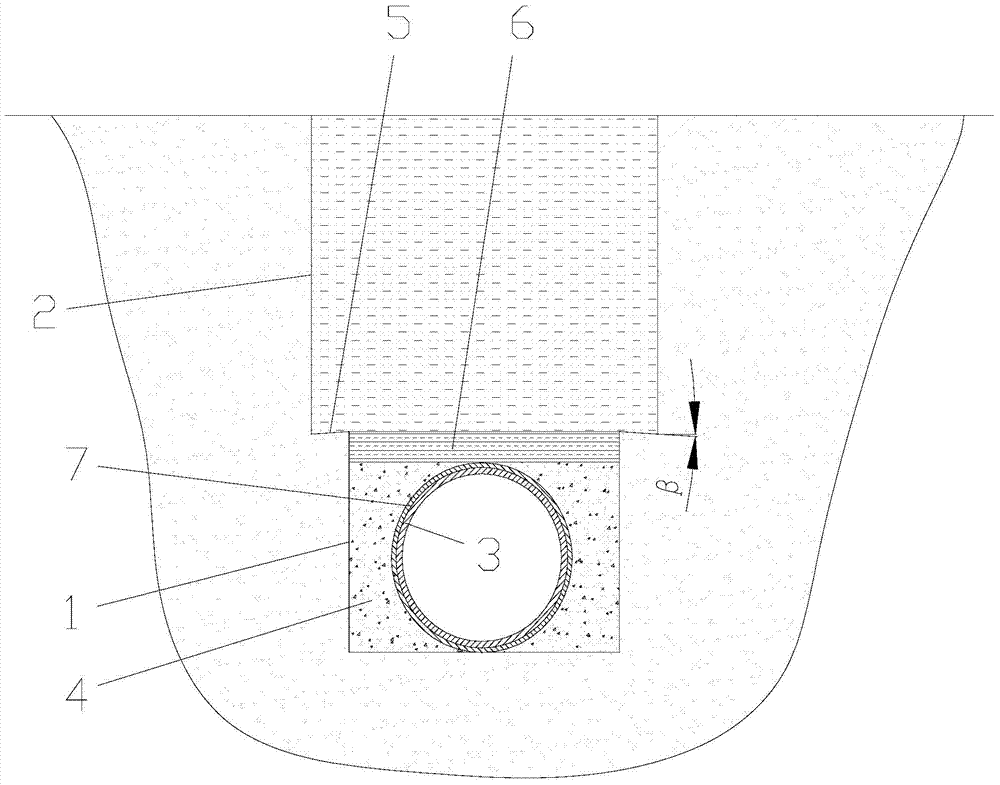

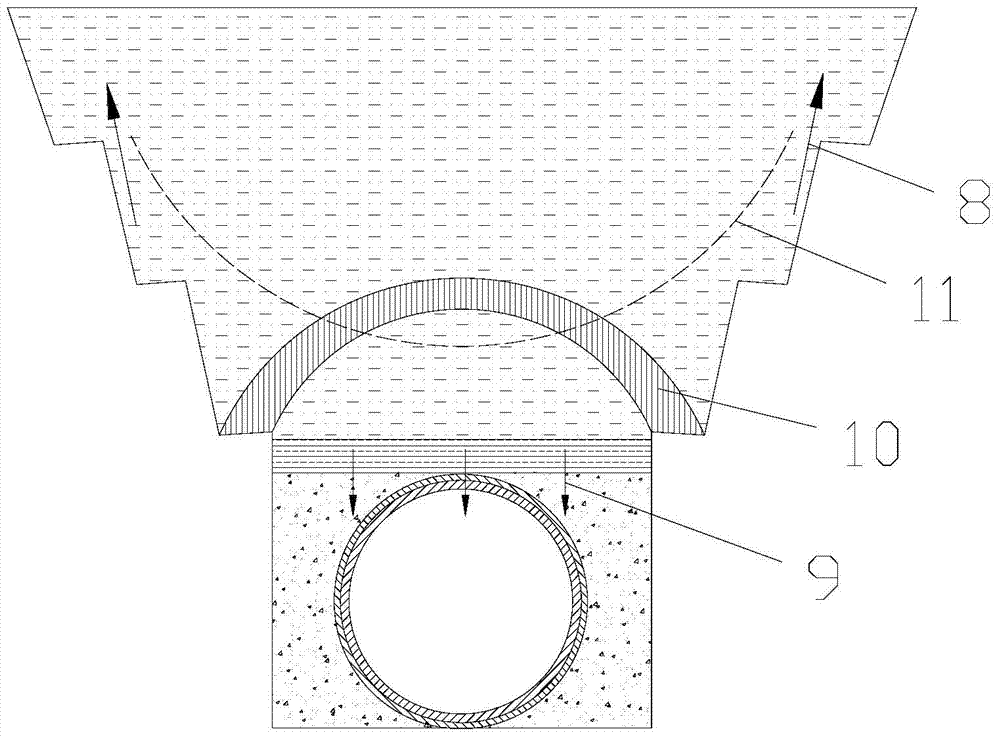

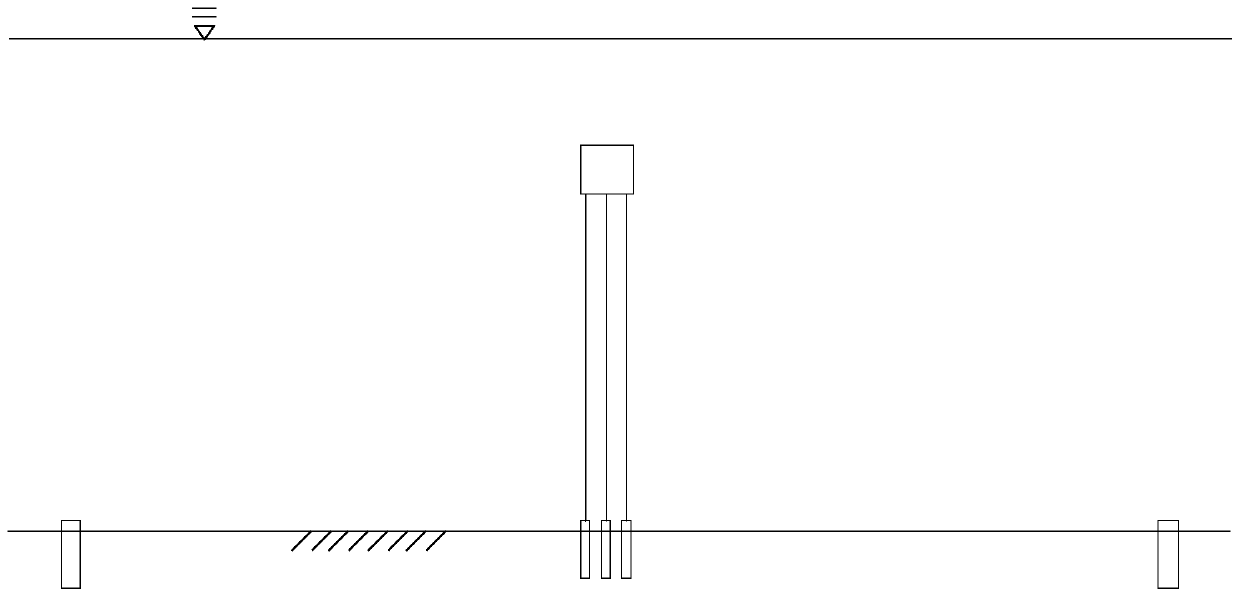

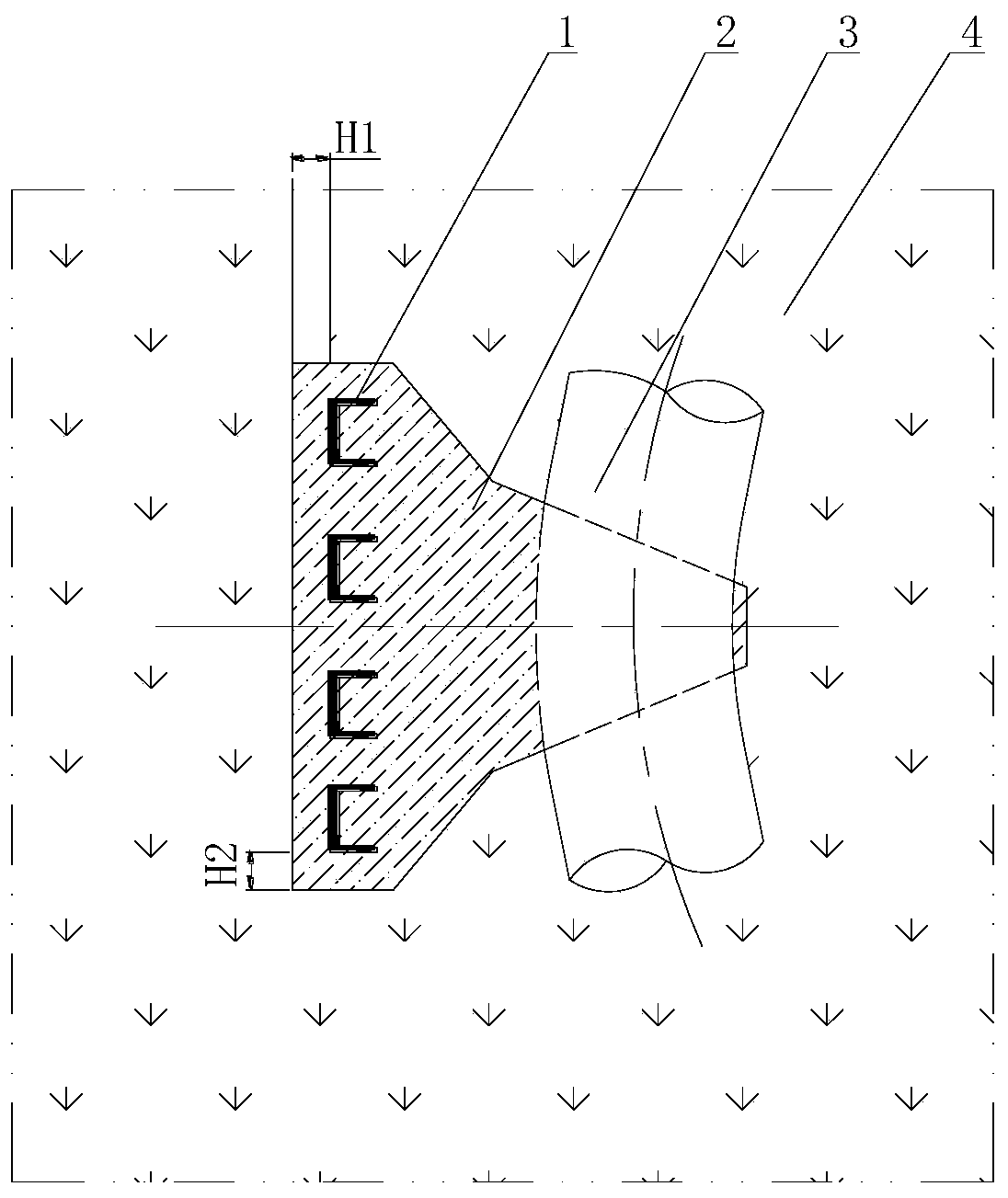

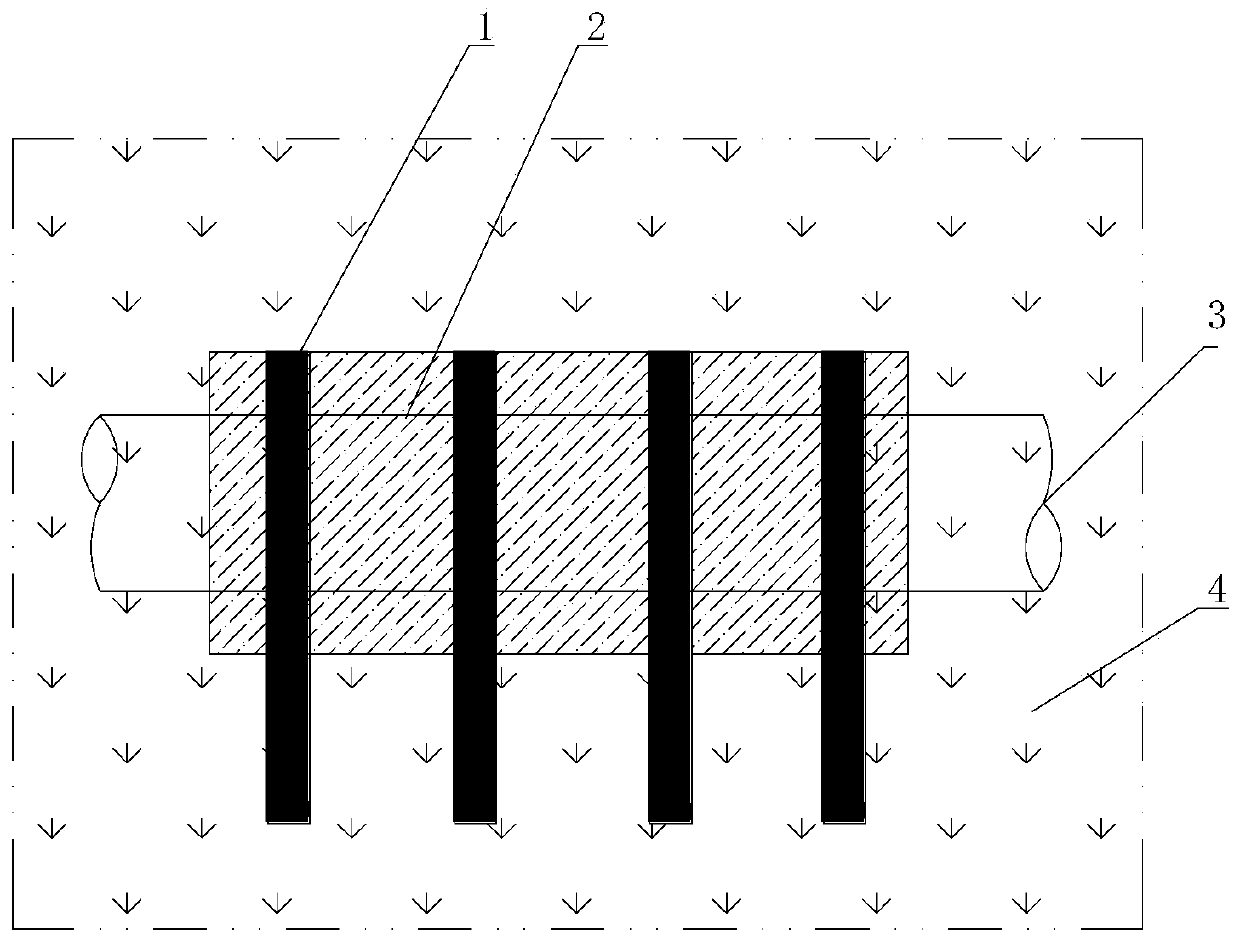

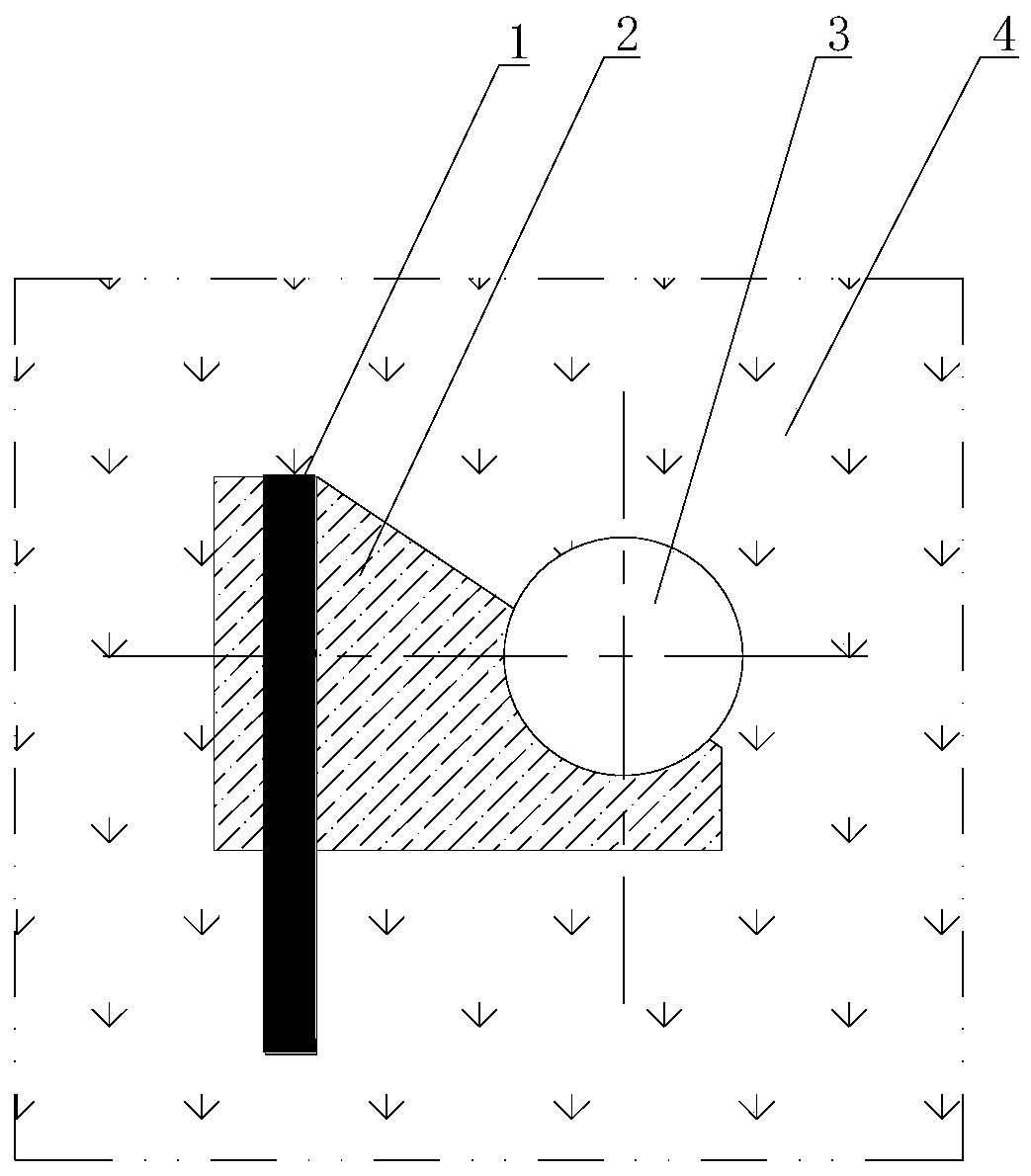

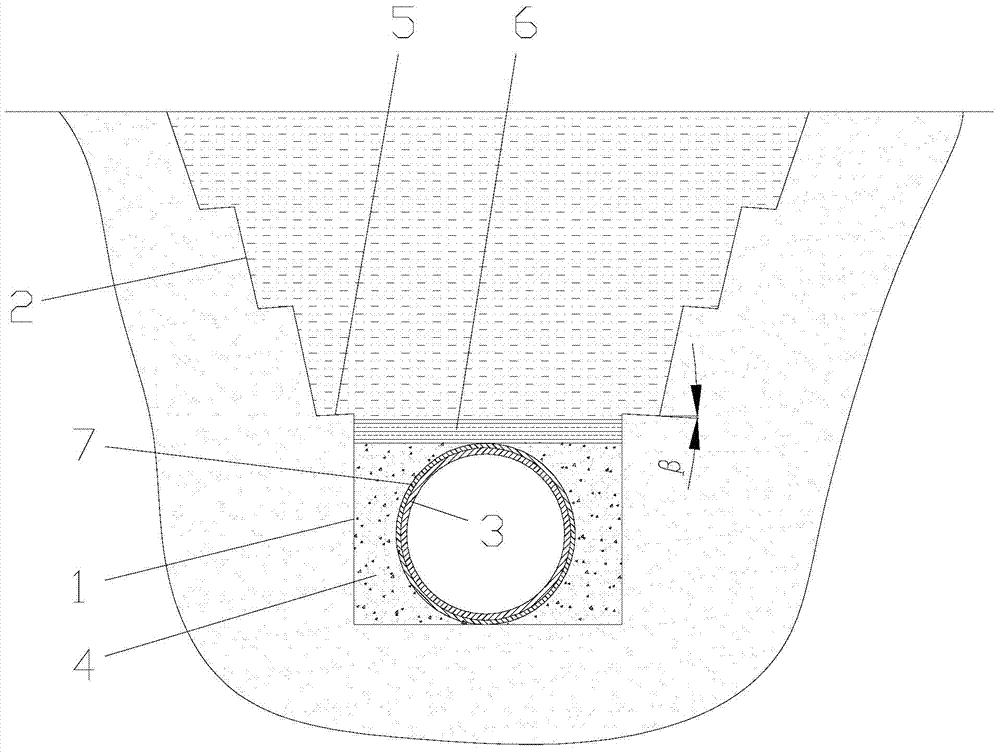

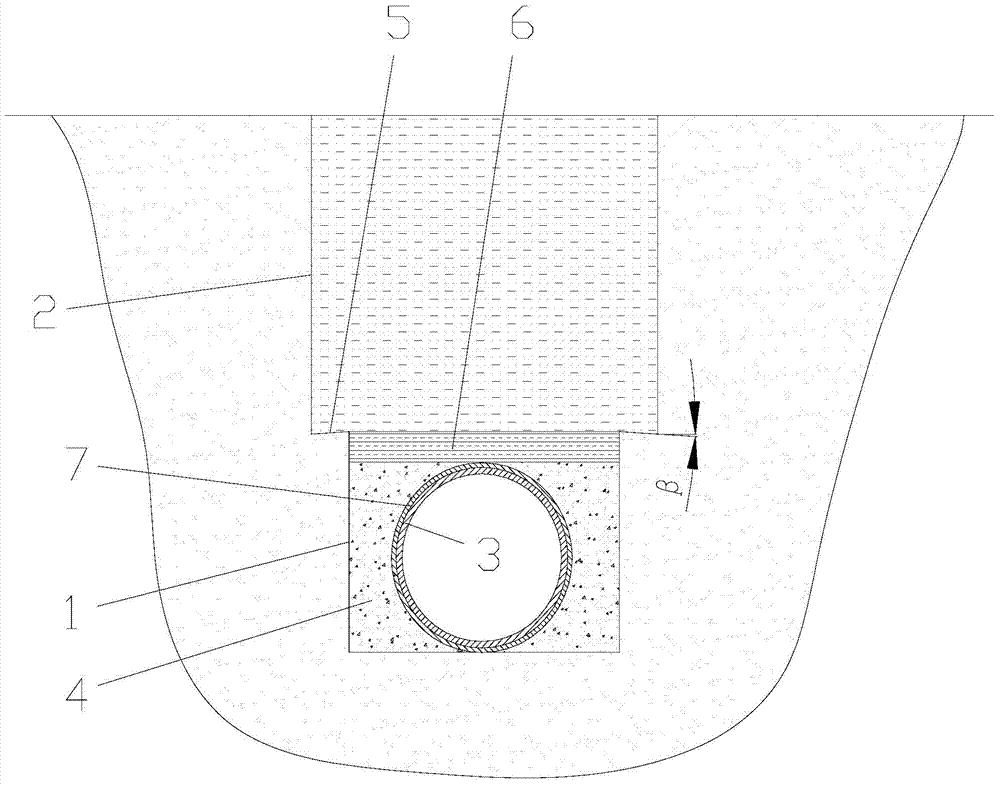

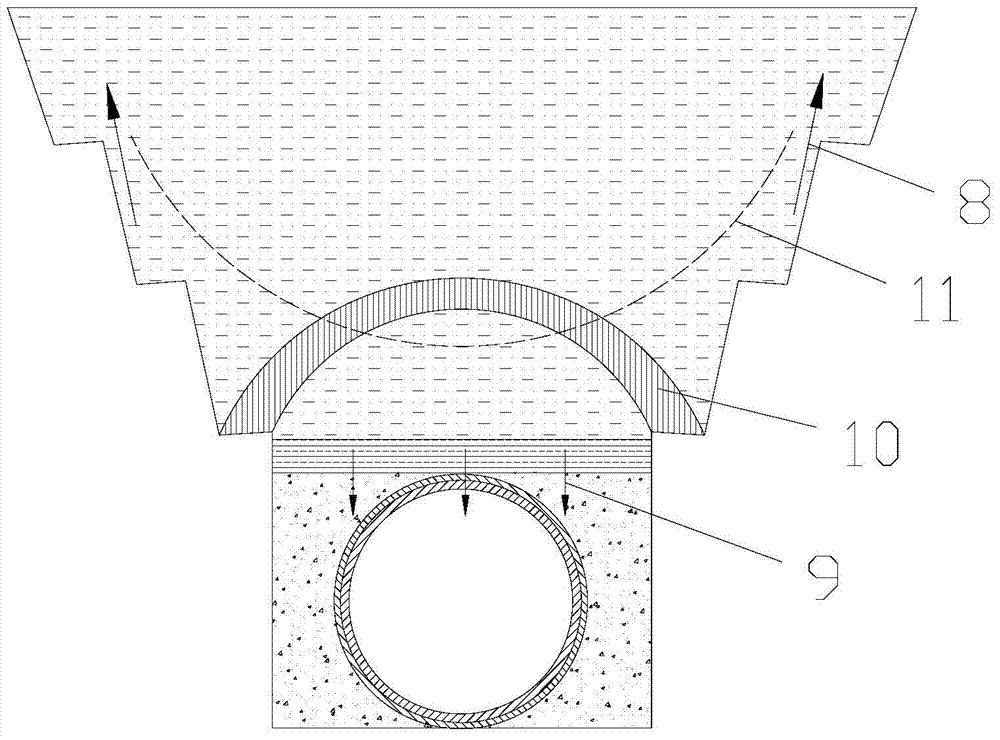

Pipe burying structure capable of reducing pipe top vertical loads and construction method for pipe burying structure

ActiveCN103527847AReduce vertical loadImprove compactness and strengthPipe laying and repairThermal insulationVertical loadCut and fill

The invention discloses a pipe burying structure capable of reducing pipe top vertical loads and a construction method for the pipe burying structure. The construction method comprises the steps of S1, digging a pipe groove and a backfill groove above the pipe groove and digging at least one step on two side walls of the backfill groove; S2, laying pipes in the pipe groove and completing port welding of the pipes; S3, filling earth in the pipe groove, and compacting and flattening the filled earth to the pipe top elevation; S4, laying a degradable material interlayer above the top of the pipe, wherein the degradable material interlayer is disposed below a transverse step plane of the lowest layer of steps; S5, filling earth into the backfill groove and compacting the earth. According to the pipe burying structure and the construction method for the pipe burying structure, an soil arch effect and backfill groove side wall friction can be used for obviously reducing the top pressure of the pipes, and the pipes are protected from being fractured and damaged. The construction process is simple, costs of used materials are low, and the construction method has a good application prospect and a wide generalization performance and applicable to open digging burying of underground shallow buried pipes.

Owner:哈尔滨市政建设有限公司

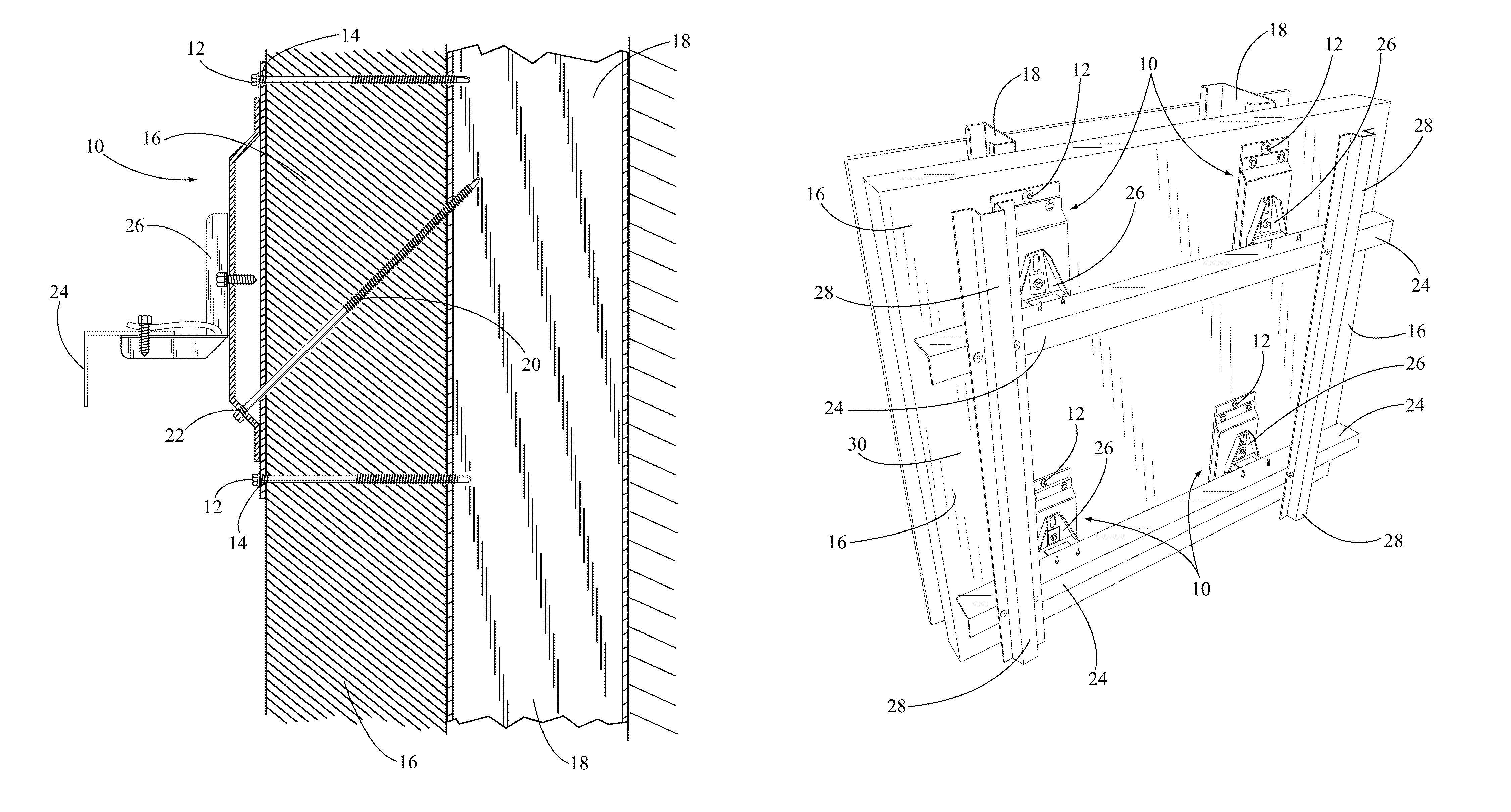

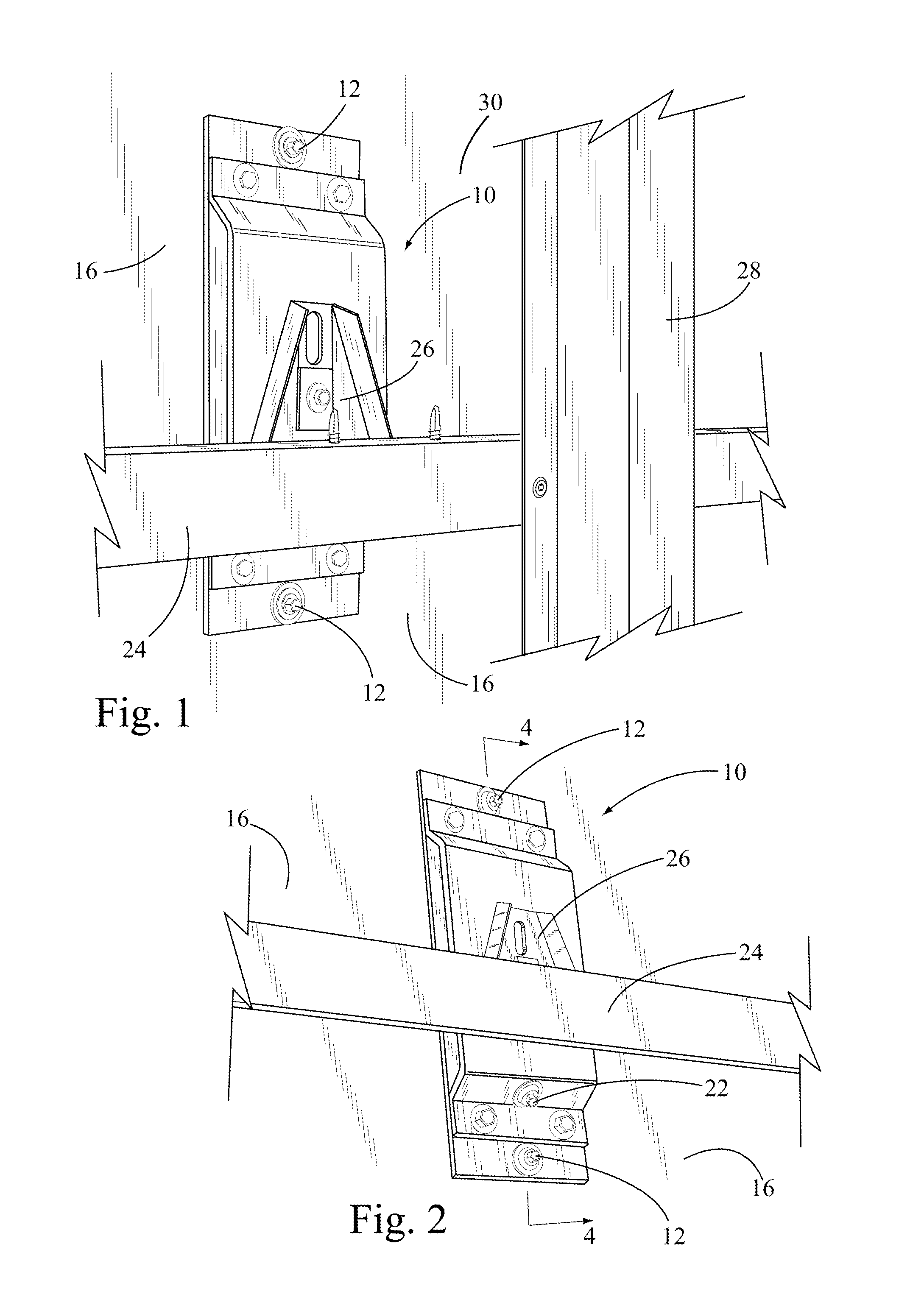

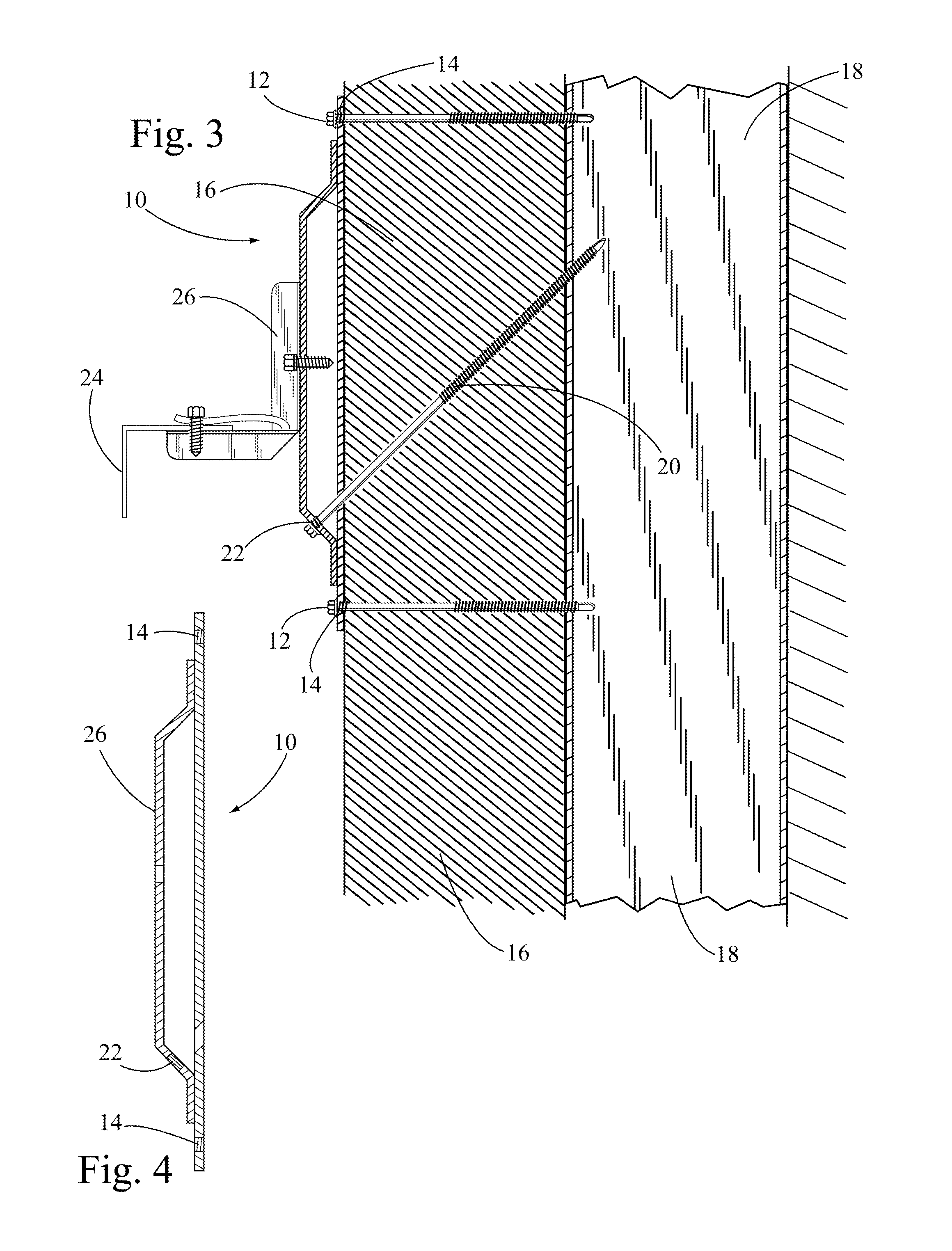

Cladding attachment system to enable an exterior continuous insulation barrier

Owner:HUNTER KENNETH +1

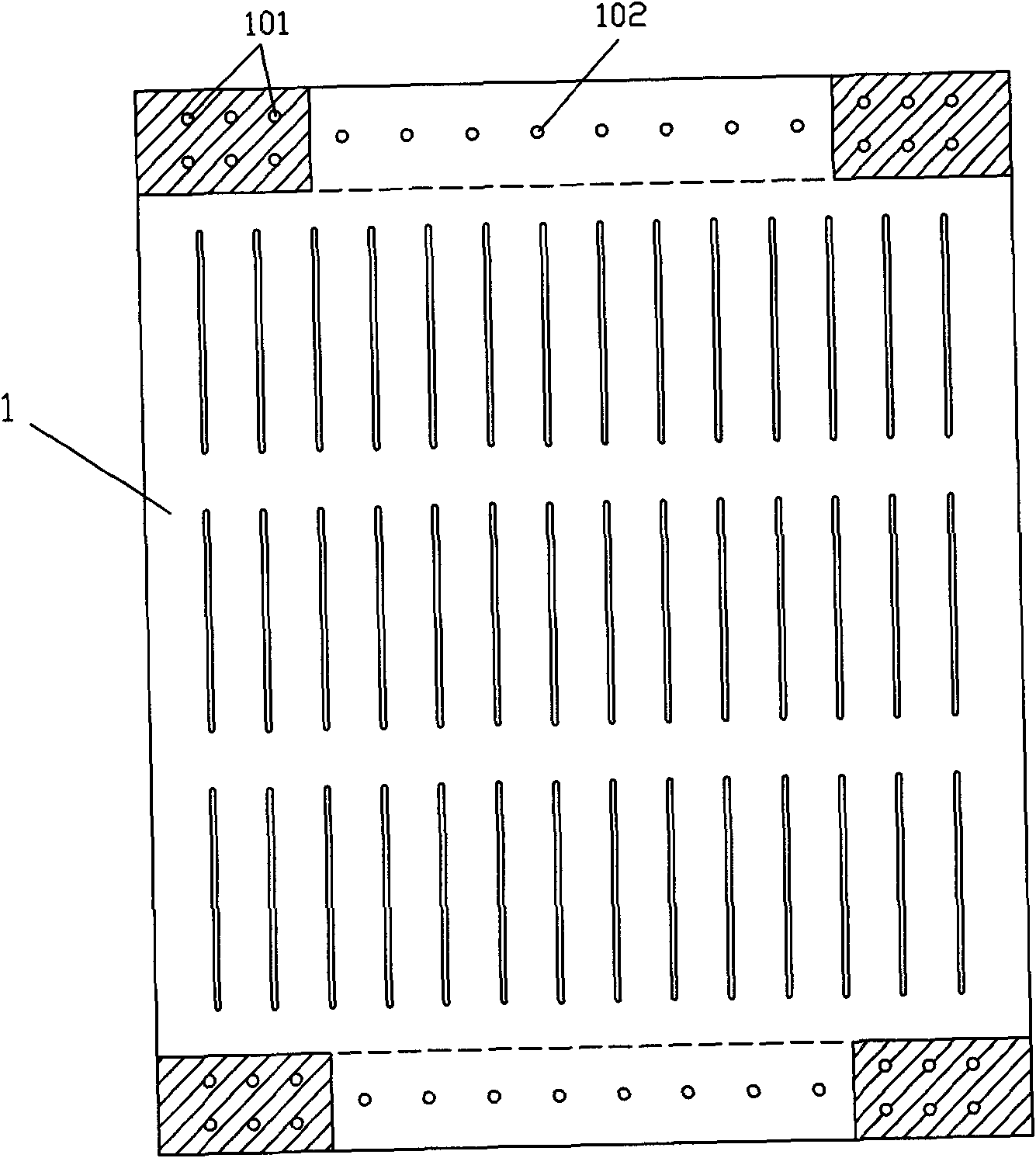

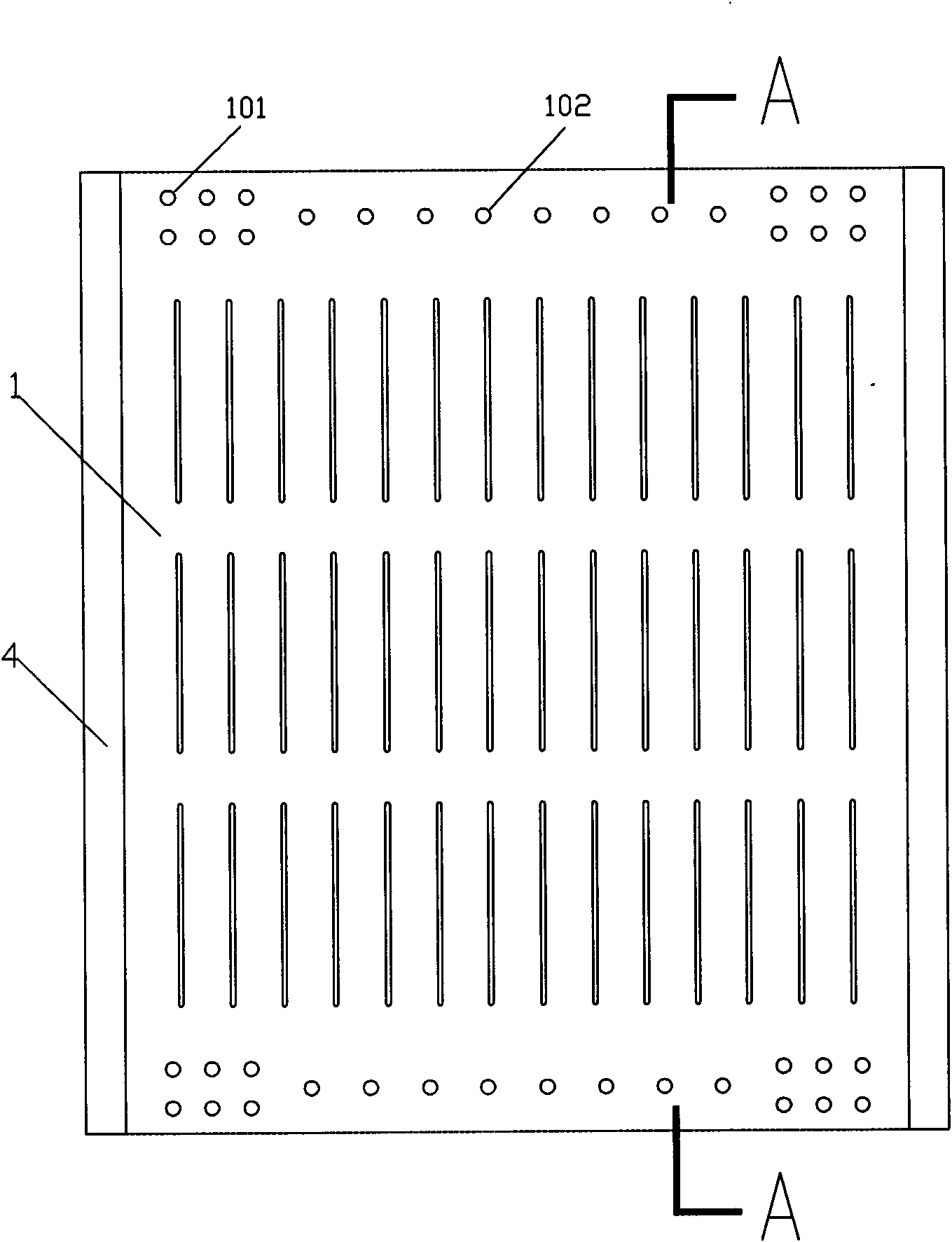

Structure for preventing bolt of steel plate shear wall with slits from slipping

ActiveCN101967850AIncrease the number of rowsOvercome slippageShock proofingEarthquake resistanceSheet steel

The invention discloses a structure for preventing bolts connecting a steel plate shear wall with slits with a frame beam from slipping. Bolt holes for connecting an upper frame beam and a lower frame beam are formed on the upper and lower ends of the main steel plate with slits; the density and row number of the bolt holes at corners at the upper and lower ends of the main steel plate with slits are greater than those of the middle bolt holes; and the four edges of the main steel plate with slits are reinforced to form a closed system. Due to the targeted layout mode of the bolts connecting the steel plate shear wall with slits with the frame beam and the closed edge reinforcing system, the bolt slipping is prevented or delayed, the noise caused by the bolt slipping is eliminated, relatively loss of high earthquake resistance of the steel plate shear wall with slits caused by the bolt slipping is avoided, and the field full-bolt connection of the steel plate shear wall with slits is ensured so as to enable disassembly and replacement after earthquake damage and protect the steel plate shear wall with slits from excessive vertical load. The closed edge reinforcing system also solves the problem of bolt slipping induced or intensified by unbalanced corners of the steel plate shear wall.

Owner:BAOSHAN IRON & STEEL CO LTD +1

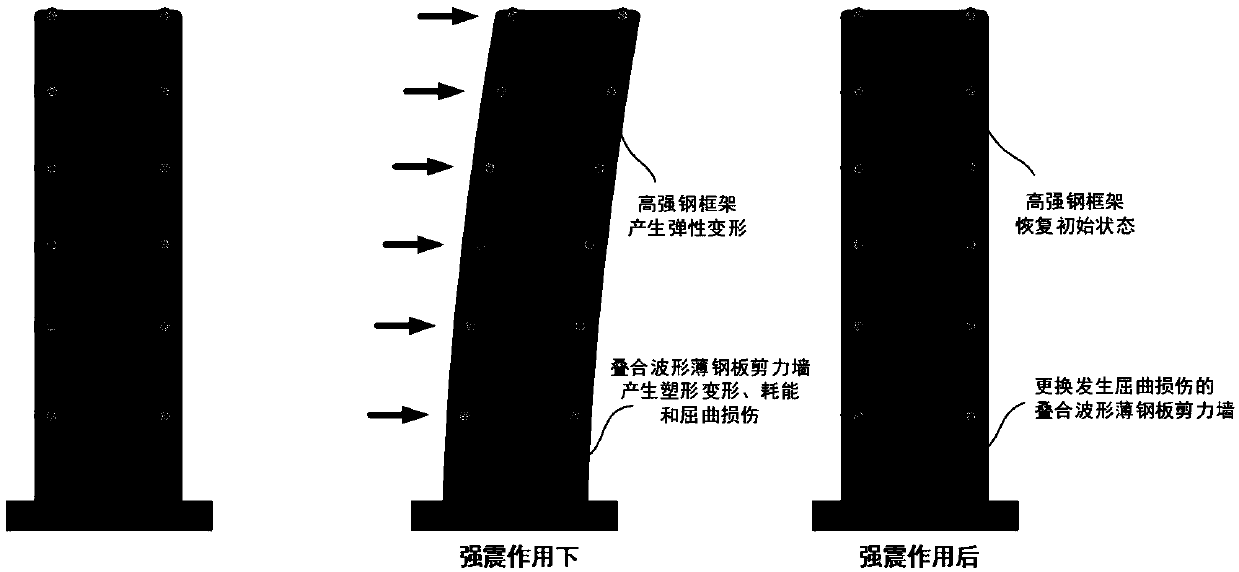

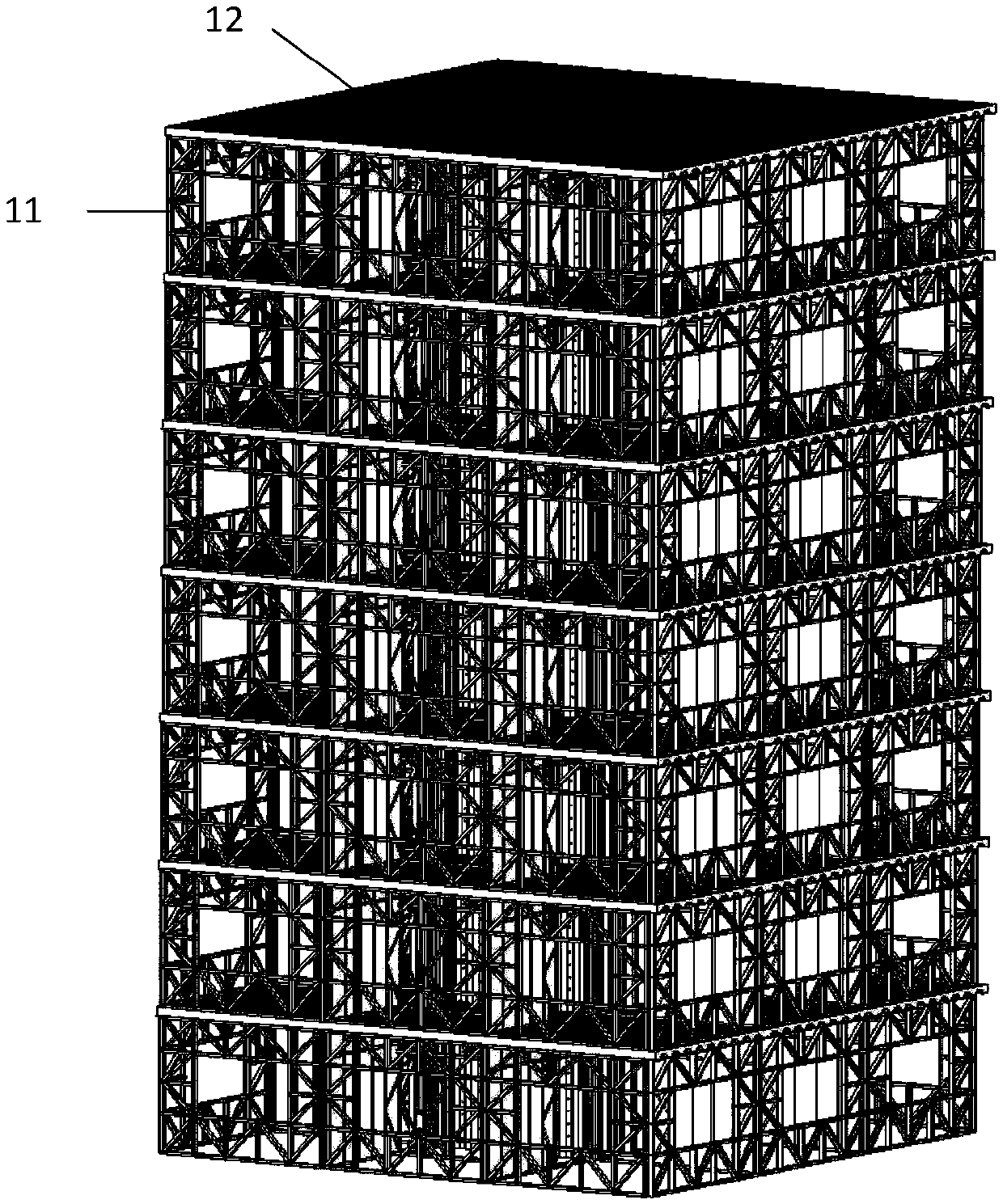

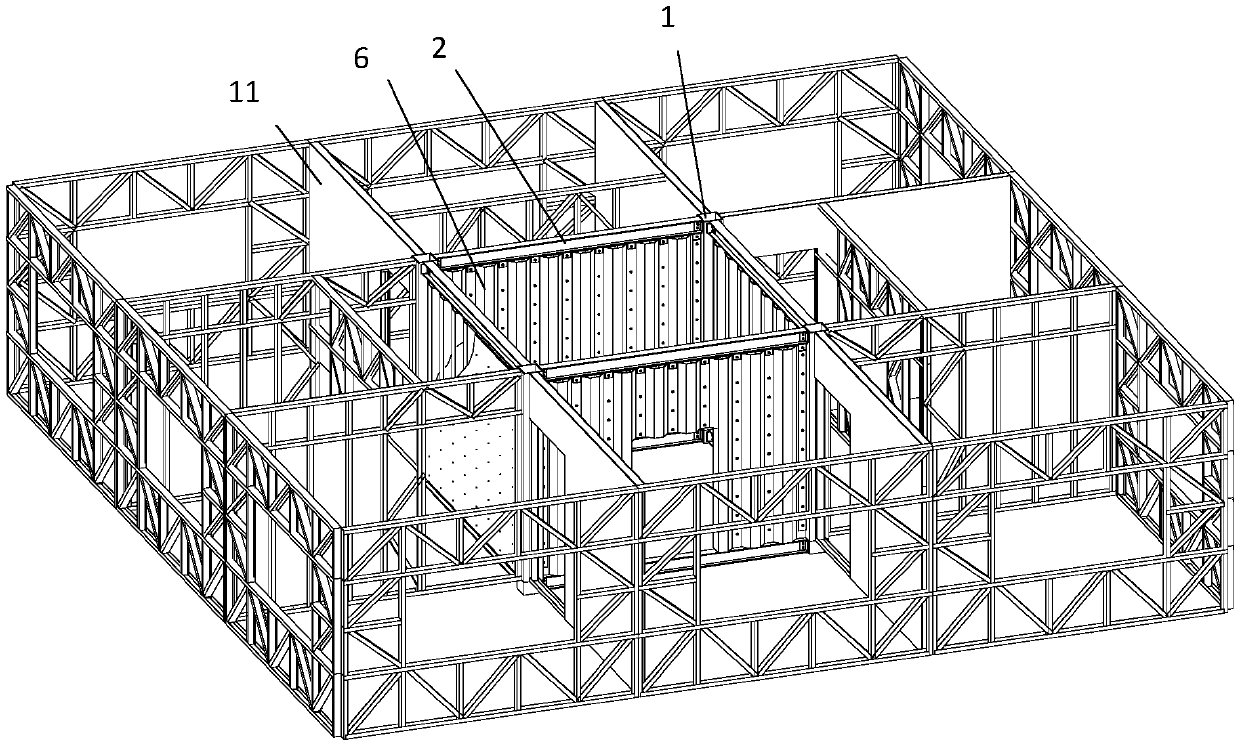

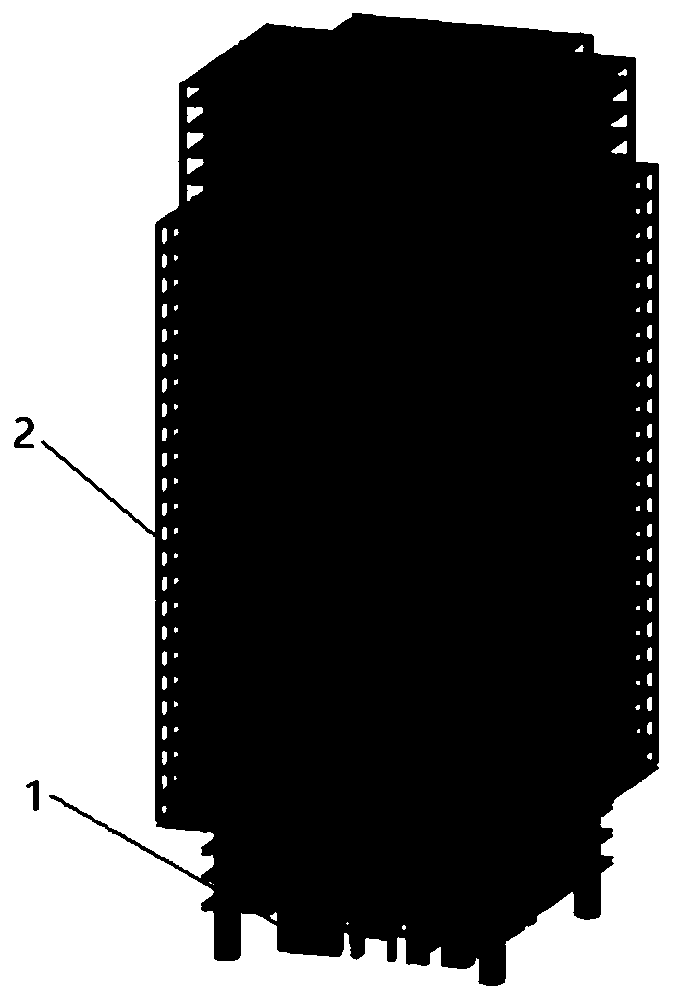

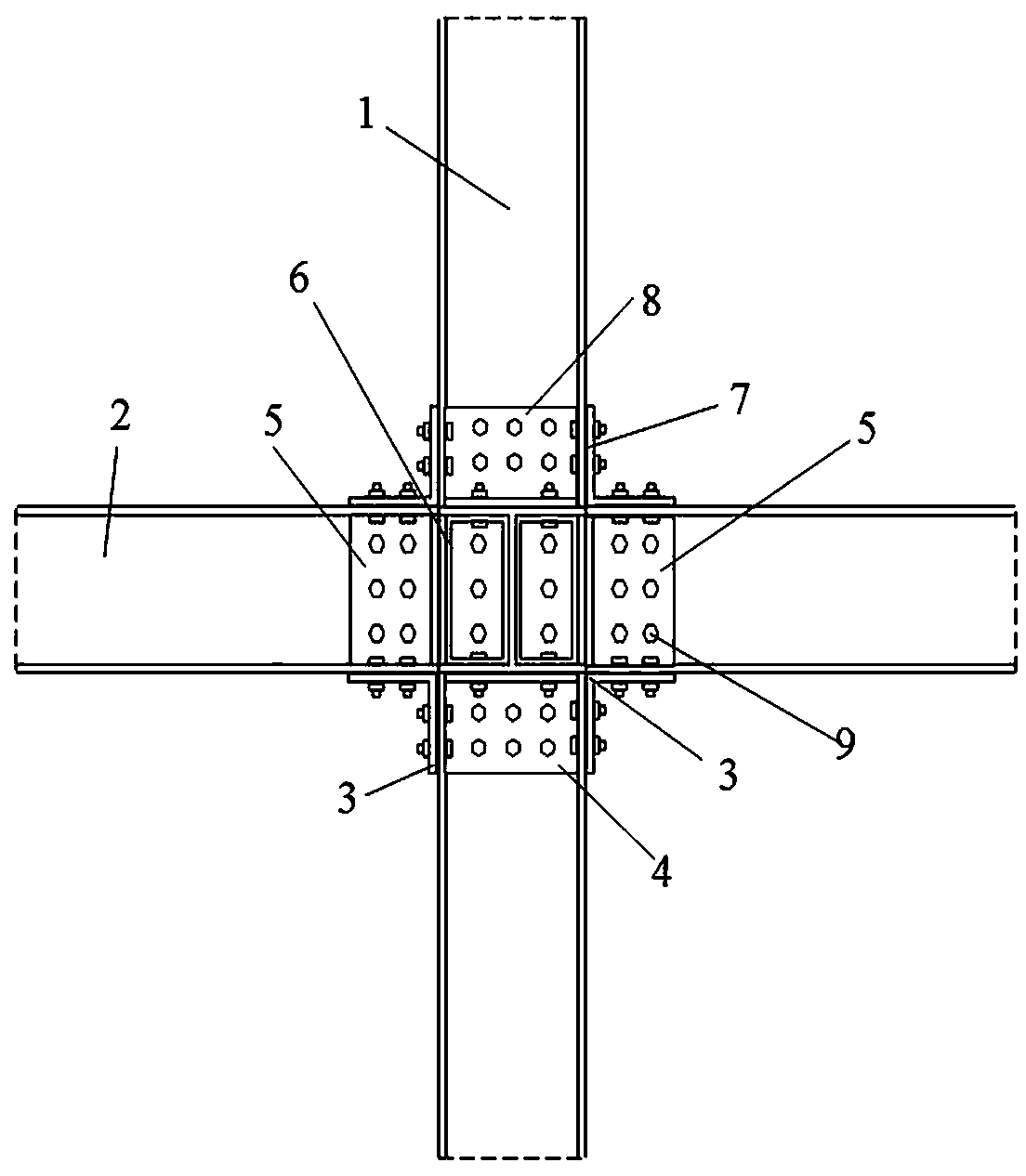

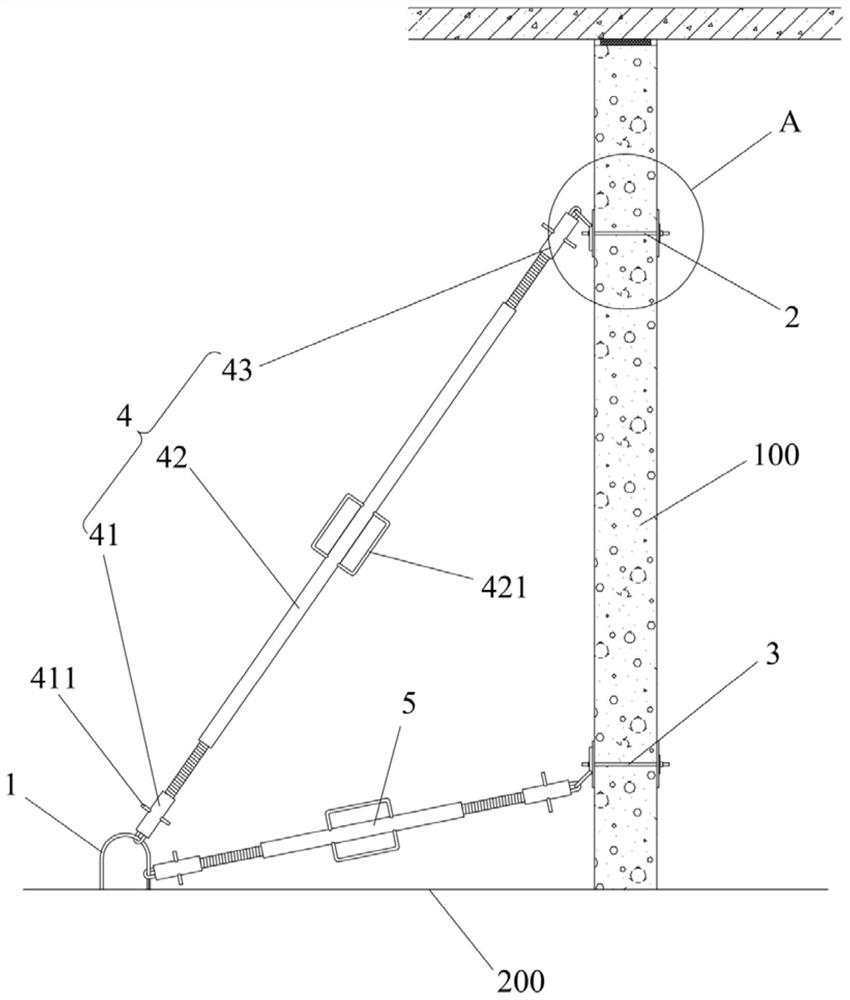

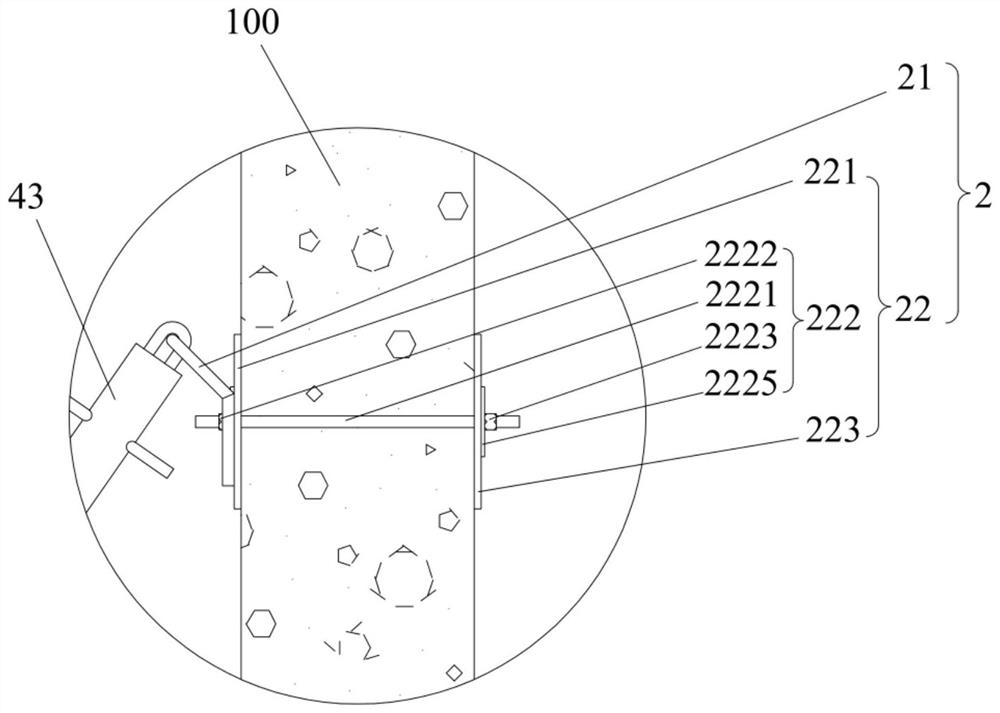

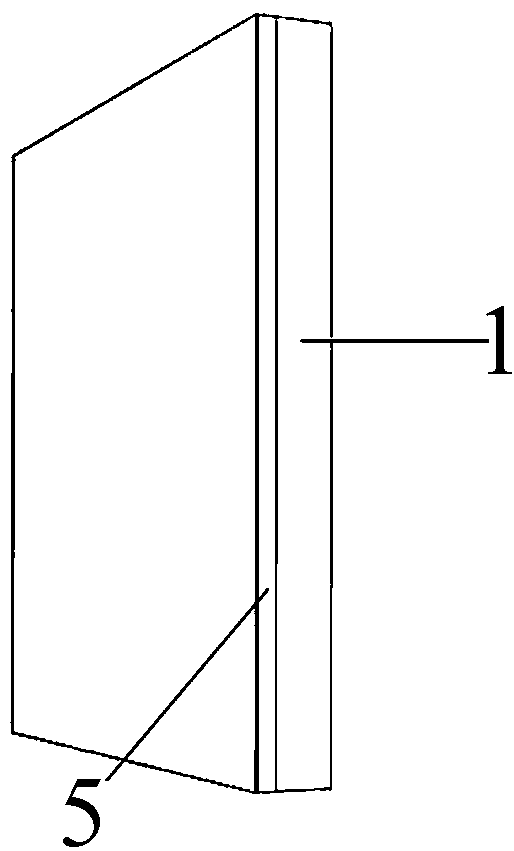

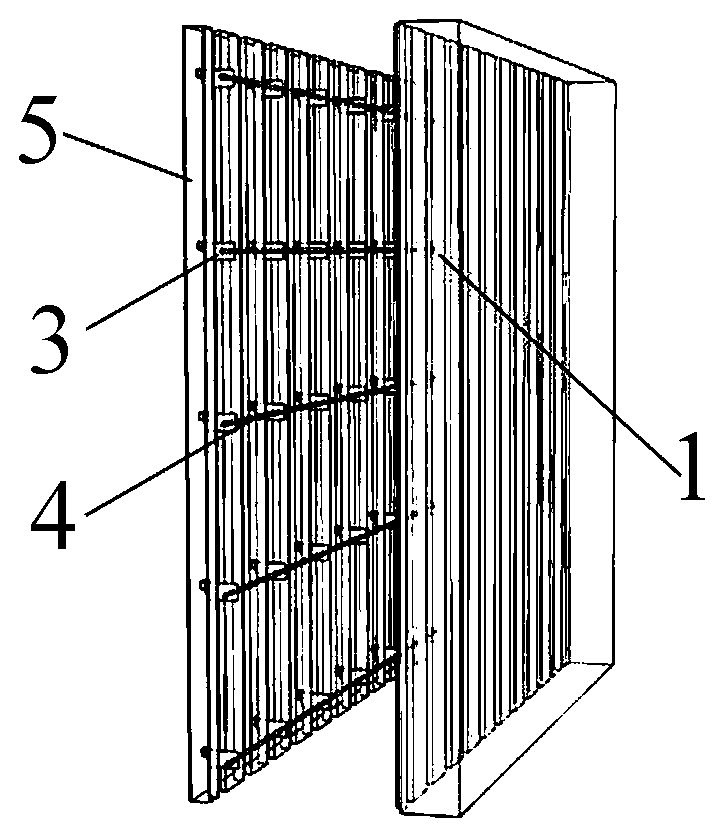

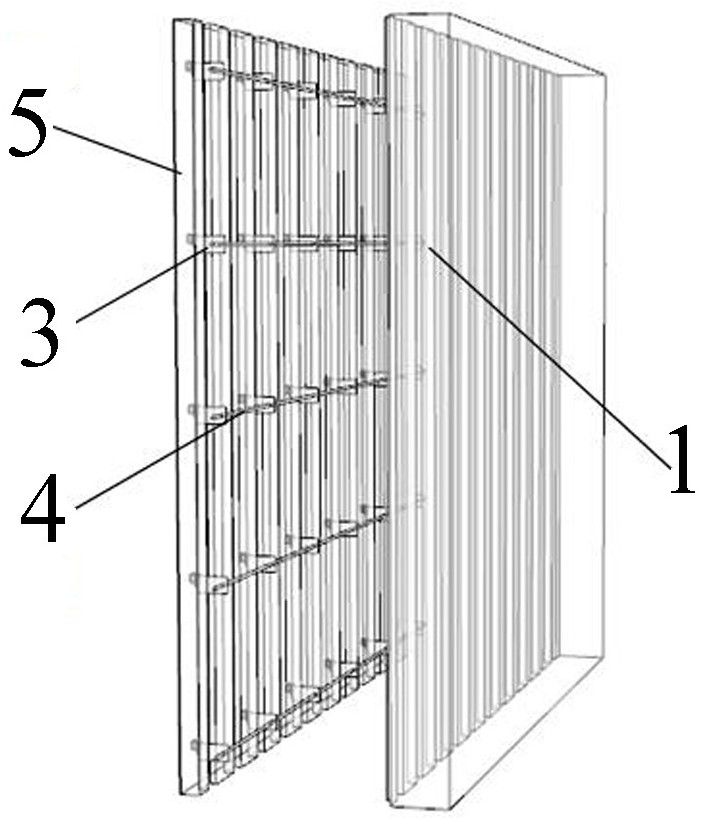

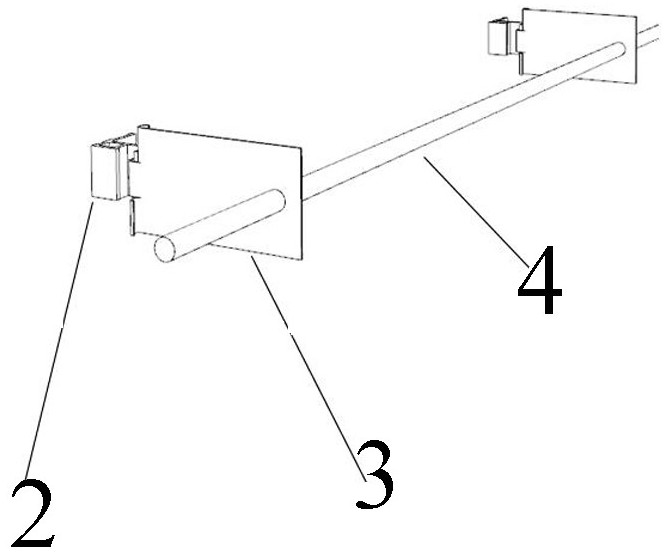

High strength steel frame-laminated corrugated steel sheet wall side-resistant cold-formed thin-walled steel structure

PendingCN109680796AGuaranteed replaceableGuaranteed on-site assembly constructionBuilding constructionsSheet steelCold formed

The invention relates to a high strength steel frame-laminated corrugated steel sheet wall side-resistant cold-formed thin-walled steel structure and belongs to the field of structure engineering. Thehigh strength steel frame-laminated corrugated steel sheet wall side-resistant cold-formed thin-walled steel structure comprises rectangular high strength steel columns, I-shaped high strength steelbeams, connection angle steels, zigzag fish plates, fish plates, corrugated steel sheets, bolts, self-tapping screws, a thermal-insulation, damp-prevention and sound-insulation material, decorative wall boards, cold-formed thin-walled steel composite wall bodies and a profiled steel sheet composite floor, wherein the I-shaped high strength steel beams are arranged at web plates at the two ends andare connected with the corresponding connection angle steels on the corresponding rectangular high strength steel columns through bolts to form a high strength steel frame; and a laminated corrugatedsteel sheet wall is vertically arranged, the upper edge and the lower edge of the laminated corrugated steel sheet wall are connected with the corresponding zigzag fish plates through bolts, the right edge and the left edge of the laminated corrugated steel sheet wall are connected with the corresponding fish plates through bolts, and the high strength steel frame-laminated corrugated steel sheetwall side-resistant structure is formed. The high strength steel frame-laminated corrugated steel sheet wall side-resistant cold-formed thin-walled steel structure improves the deficiency of anti-seismic property of a traditional cold-formed thin-walled composite wall body, has the advantages of strong energy-dissipating capacity, capability of restoration after an earthquake and integration of functions of a structure and a building and can be widely applied to multi-layer building engineering.

Owner:CHONGQING UNIV

Horizontally-arranged hydraulic cylinder dynamic adjusting suspension

ActiveCN111422020AReduced torque differentialReduce vertical loadInterconnection systemsHydraulic cylinderTorque transmission

The invention relates to a horizontally-arranged hydraulic cylinder dynamic adjusting suspension. The suspension at least comprises two energy conversion units and a hydraulic adjusting unit, whereinan energy adjusting unit is arranged between the two energy conversion units through a pipeline; each energy conversion unit at least comprises a hydraulic cylinder and a torque transmission mechanismwhich are connected with each other; one of the energy conversion units is respectively connected with front wheels of the vehicle through two connecting rods; the other energy conversion unit is respectively connected with rear wheels of the vehicle through two connecting rods; under the condition that the wheels are stressed, a torque transmission mechanisms associate the torsion state of the connecting rods with the hydraulic state of the hydraulic cylinders so as to change the piston movement state of the hydraulic cylinders on the basis of the torque of the connecting rods. Therefore, under the condition that the hydraulic pressure difference occurs between the hydraulic cylinders with the connection relation, the hydraulic pressure adjusting unit adjusts the hydraulic pressure states of the hydraulic cylinders in a hydraulic pressure absorbing and / or releasing mode, the torsion state of the connecting rods is correspondingly adjusted based on the hydraulic pressure states of thehydraulic cylinders, and therefore the vertical load of wheels on a vehicle body is reduced.

Owner:HEFEI UNIV OF TECH

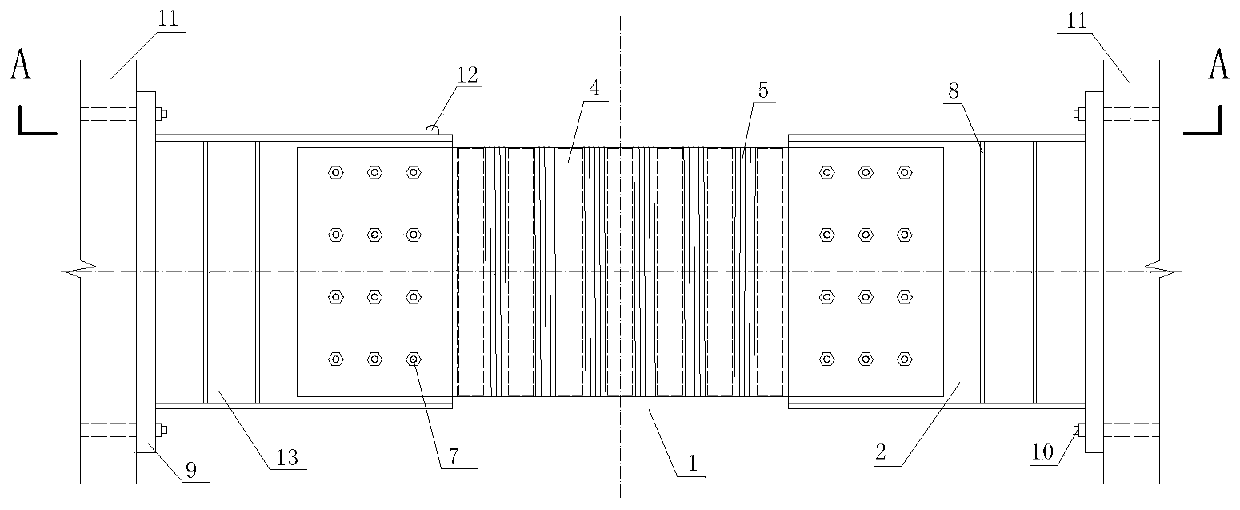

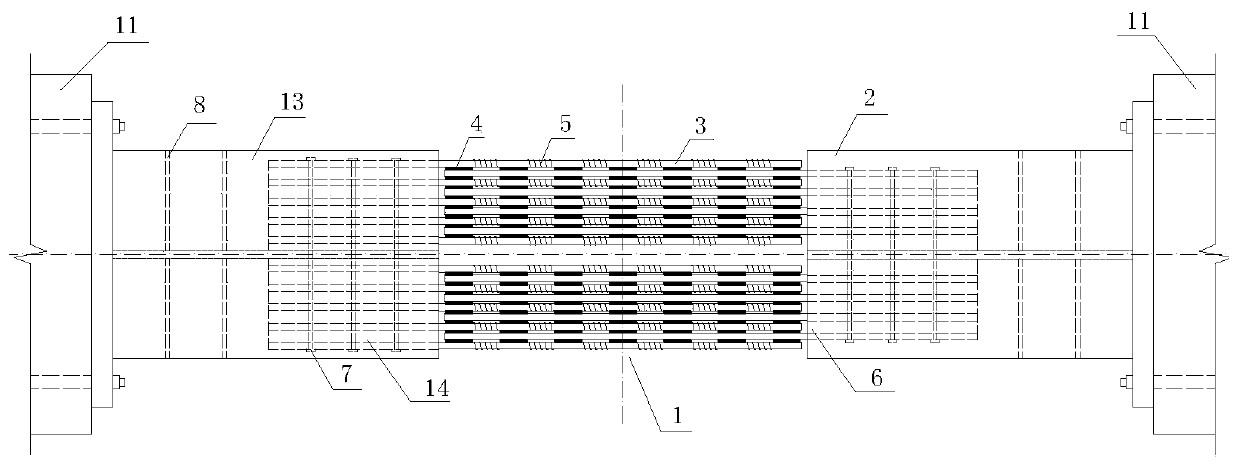

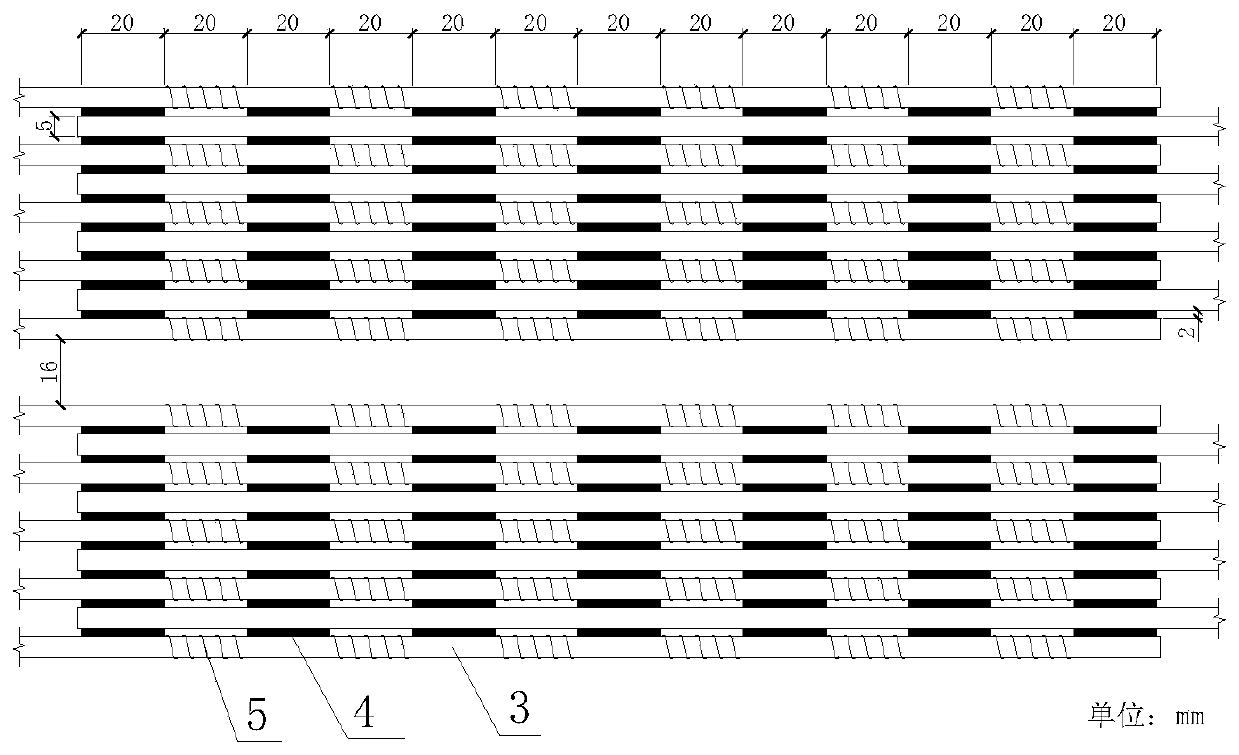

Coupling beam damper based on magneto-rheological elastomer material

ActiveCN110761430AChange mechanical propertiesAchieving semi-active controlGirdersJoistsElastomerMagneto

The invention discloses a coupling beam damper based on a magneto-rheological elastomer material. The coupling beam damper comprises first H-shaped steel and second H-shaped steel, and further comprises a shock absorption device for connecting the first H-shaped steel and the second H-shaped steel. The inner end of the first H-shaped steel / second H-shaped steel is connected with the shock absorption device, and the outer end of the first H-shaped steel / second H-shaped steel is connected with a shear wall through joint plates. The shock absorption device comprises a plurality of steel clampingplates, excitation coils and magneto-rheological elastomer blocks. The plate surfaces of the steel clamping plates are vertical, and the steel clamping plates are transversely distributed at intervals. The excitation coils are longitudinally wound on the steel clamping plates at intervals and connected with an outer power supply through wires. The magneto-rheological elastomer blocks are arrangedin gaps between every two adjacent steel clamping plates at intervals. The coupling beam damper has the beneficial effects that the magneto-rheological elastomer material is adopted, the excitation coils are wound outside the steel clamping plates, the mechanical property of the magneto-rheological elastomer blocks can be changed by changing magnetic fields which are changed by changing excitationcurrents, and therefore the coupling beam damper can achieve semi-active control to achieve the better shock absorption effect.

Owner:WUHAN UNIV OF TECH

Core tube structure system with transfer layer

PendingCN109853741AMeet the requirements of transparencyIncrease the vertical force transmission pathExtraordinary structuresViscous dampingReinforced concrete

The invention relates to a core tube structure system with a transfer layer. The core tube structure system with the transfer layer comprises a core tube and an outer frame, the outer frame is arranged on the periphery of the core tube, the outer frame is an outer frame with a transfer structure, and a connected frame body and an umbrella shape transfer layer are included. The core tube structuresystem is a high-rise structure system with a shelter layer. In the shelter layer, a prestressed cable-stayed cable is connected between the outer frame and the core tube. Compared with the prior art,the core tube structure system with the transfer layer meets the requirements of a building form and meanwhile, increases the vertical force transmission path of the structure; the vertical load of the outer frame is transferred to the core tube in batches through the cable, the load of an outer frame column and a lower part transfer structure is reduced, and the structural redundancy is increased; and meanwhile, a viscous damping wall is arranged in the core tube, the seismic force of the core tube of reinforced concrete of a lower part floor is reduced, and the thickness of the core tube wall and the amount of steel bars and steel bones are reduced.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD

H-shaped steel bearing frame structure joint

InactiveCN107761955AImprove ductilityHave the ability to deformBuilding constructionsSteel frameEngineering

The invention relates to an H-shaped steel bearing frame structure joint and belongs to the technical field of steel structures. The H-shaped steel bearing frame structure joint comprises an H-shapedsteel through column, H-shaped steel beams, external assembled supporting and reinforced connecting angle steel, column-interior assembled supporting and reinforced connecting angle steel, beam-interior reinforced connecting angle steel, beam-and-column-interior reinforced connecting end sealing cylinders, external reinforced connecting angle steel, column-interior reinforced connecting angle steel and bolts. The center of the H-shaped steel bearing frame structure joint is the H-shaped steel through column, the external assembled supporting and reinforced connecting angle steel is mounted onthe outer sides of the two flanges of the H-shaped steel through column, the peripheral H-shaped steel beams are directly placed and mounted, and serial reinforcing is conducted through the beam-interior reinforced connecting angle steel, the beam-and-column-interior reinforced connecting end sealing cylinders, the external reinforced connecting angle steel and the column-interior reinforced connecting angle steel. According to the H-shaped steel bearing frame structure joint, the rigidity is large, the strength is high, and the joint can be well protected; the vertical through column and theserial reinforcing measures are adopted, so that the rigidity and the integrity are remarkably promoted; and additional support is not needed in mounting, rapid and simple effects are achieved, usingis convenient, the construction period can be shortened, and the cost is reduced.

Owner:SHENYANG JIANZHU UNIVERSITY

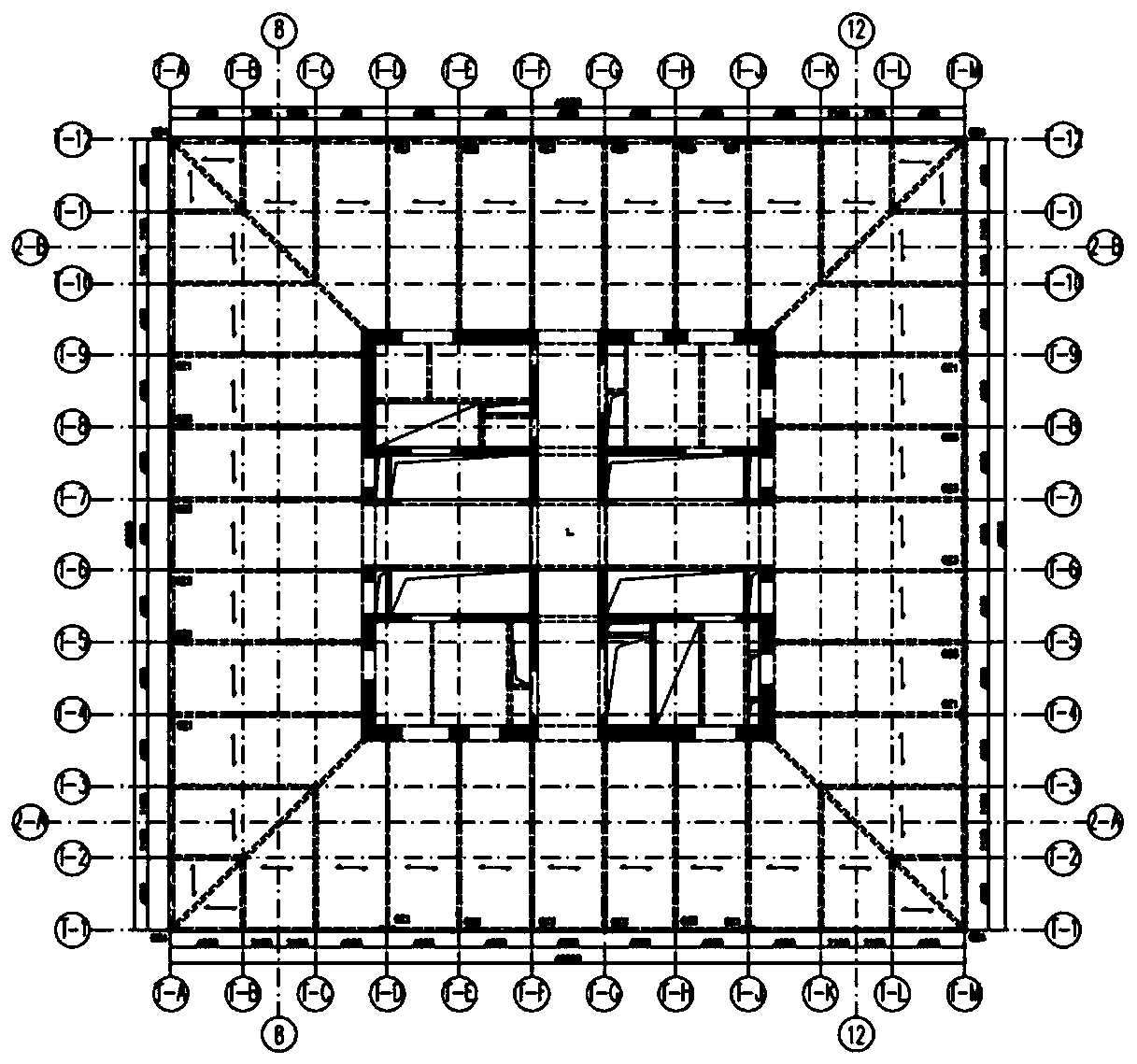

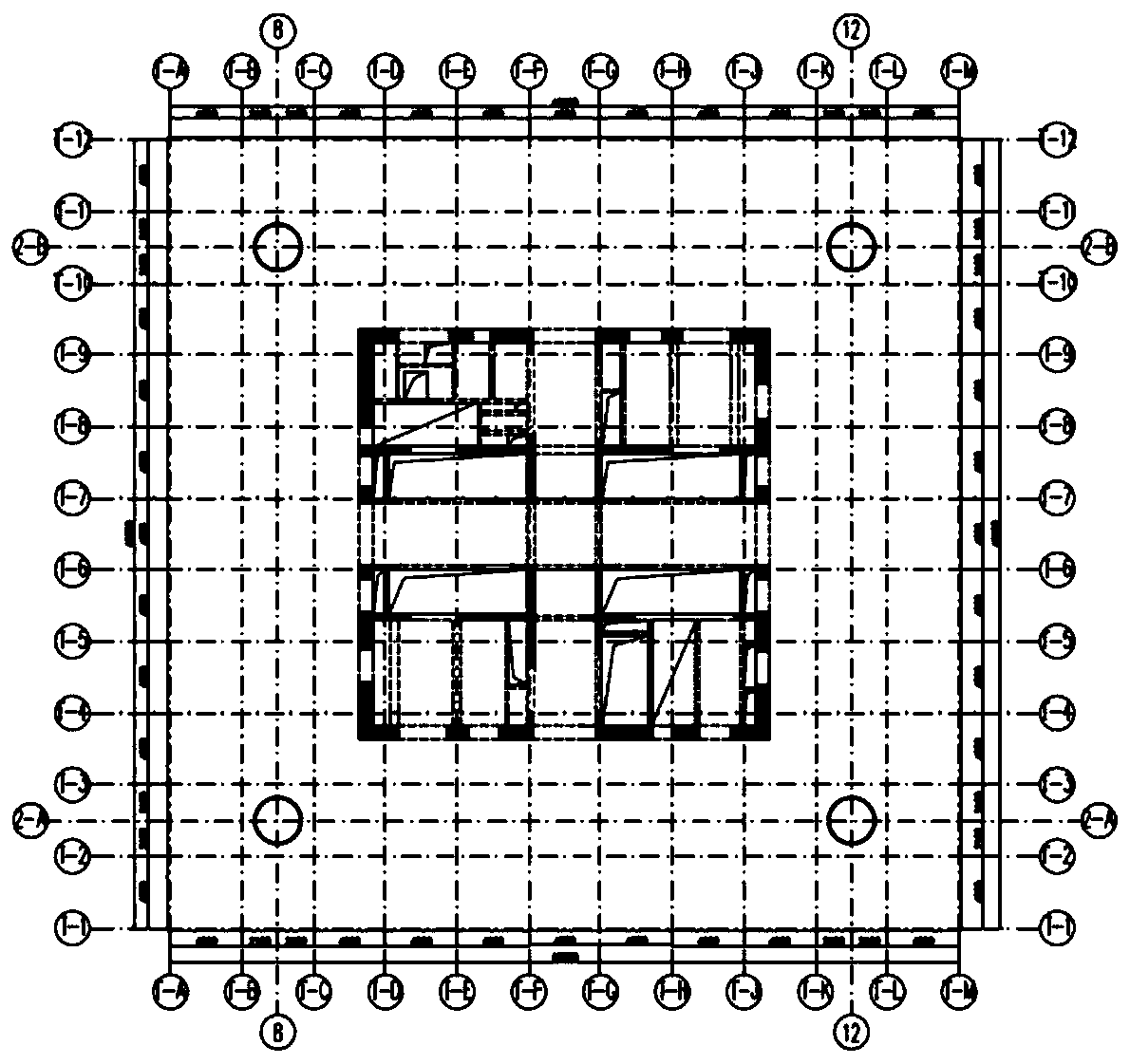

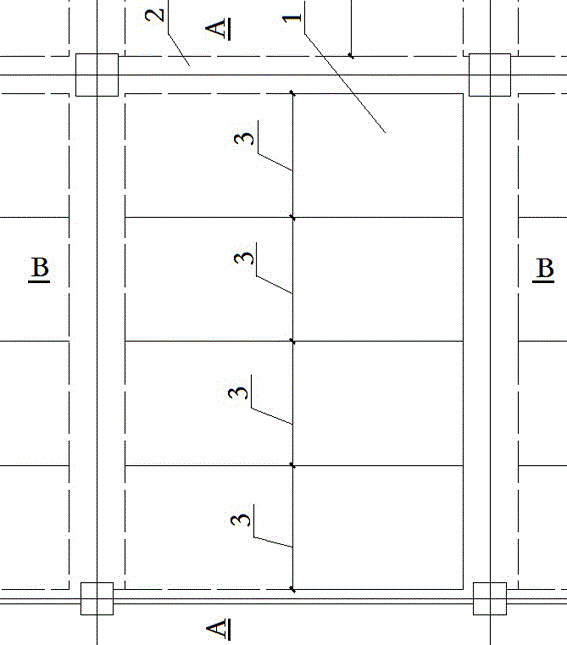

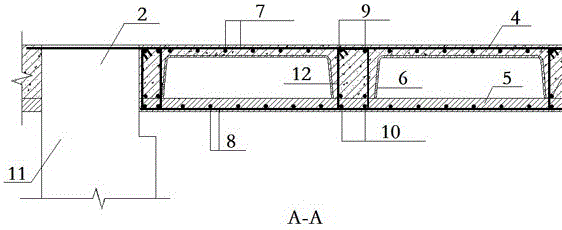

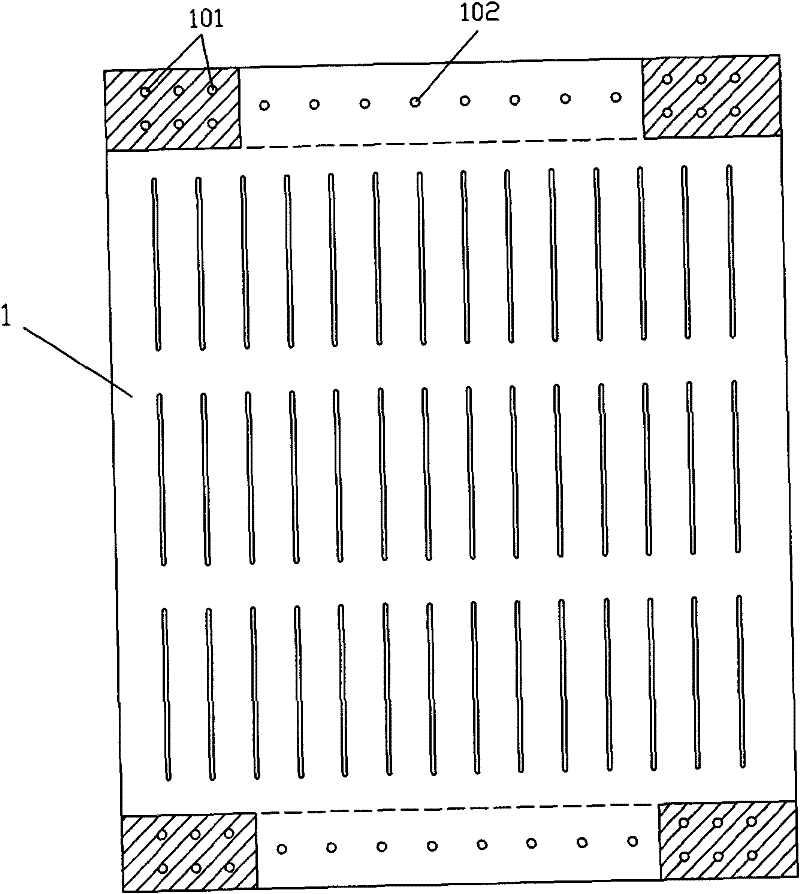

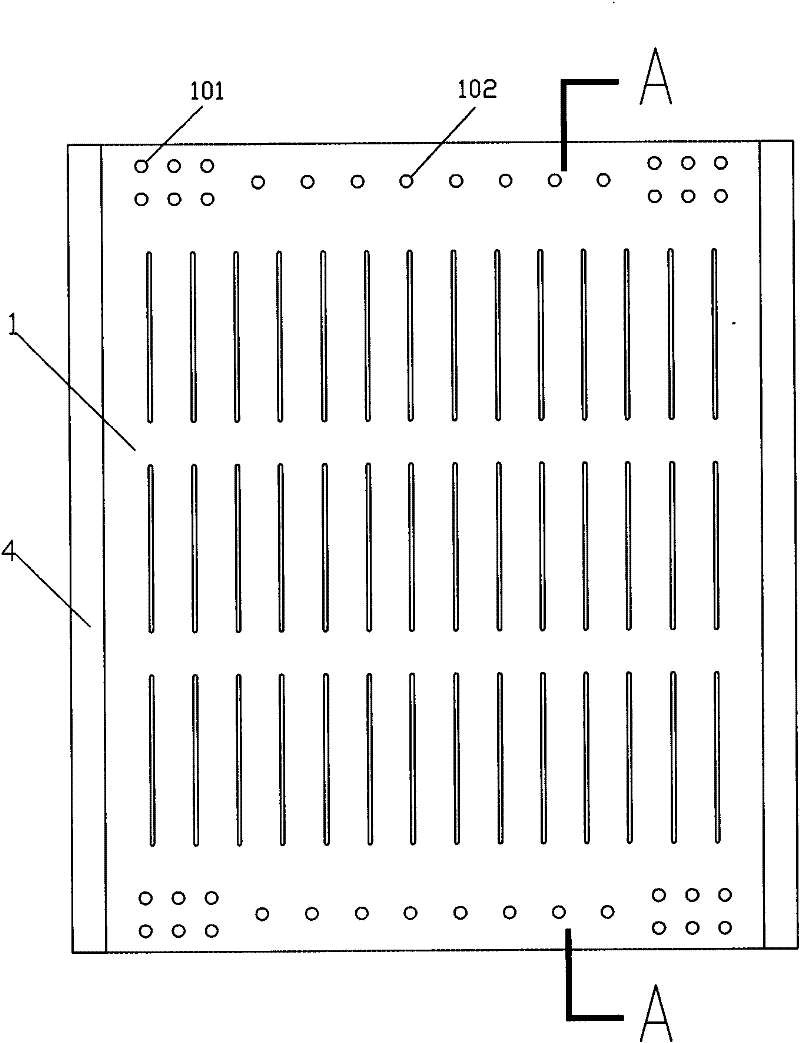

Fabricated concrete hollow floor structural system

The invention relates to a fabricated concrete hollow floor structural system. The fabricated concrete hollow floor structural system is formed by means of stacking and assembling of a floor cast-in-situ layer and a floor pre-fabricated layer; a plurality of hollow structures are arranged in the floor cast-in-situ layer; each hollow structure is a hollow box or a light material body; slab top constructional steel bars are arranged in the floor cast-in-situ layer; pre-fabricated slab constructional steel bars are arranged in the floor pre-fabricated layer; the floor cast-in-situ layer is provided with a ribbed beam top reinforcement, ribbed beam bottom reinforcement, and ribbed beam stirrup, or the bottom of the ribbed beam bottom reinforcement is pre-embedded in the floor pre-fabricated layer; and the ribbed beam top reinforcement and the ribbed beam bottom reinforcement stretch to the side edge of the floor, and become the load-bearing bars lapped with the beam. The fabricated concrete hollow floor structural system has the advantages of being low in cost, being high in efficiency, saving materials, reducing self-weight, being relatively more reasonable in stress, being high in structural strength, and being high in quality.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

A structure to prevent bolt slippage in steel plate shear wall with seams

ActiveCN101967850BIncrease the number of rowsOvercome slippageShock proofingInstabilityVertical load

A structure for preventing slippage of connecting bolts between a steel plate shear wall with a vertical seam and a frame beam. The upper and lower ends of the main steel plate with vertical seams are provided with bolt holes for connecting with the upper and lower frame beams, and the bolt holes at the corners of the upper and lower ends of the main steel plate with vertical seams are provided. The arrangement density and the number of rows are larger than those in the middle part; the edges of the main steel plates with vertical seams are stiffened to form a closed system. The present invention adopts a targeted layout form for the bolts connecting the steel plate shear wall with slits and the frame beam, and adopts a closed edge stiffening system at the same time, which overcomes or delays the occurrence of bolt slippage and eliminates the bolt slippage caused by bolt slippage. noise, and avoid the great loss of the good seismic performance of the steel plate shear wall with slots caused by the slippage of the bolts, to ensure that the steel plate shear walls with slots are fully bolted on site so that they can be disassembled and replaced after earthquake damage, and to avoid steel plates with seams Shear walls are subjected to excessive vertical loads. The closed edge stiffening system also solves the corner instability problem of the slotted steel plate shear wall that induces or aggravates bolt slippage.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Laminated assembly type concrete ribbed floor

A laminated assembly type concrete ribbed floor comprises a prefabricated base plate and a top plate which is an on-site casted top plate with ribbed beams, and the base plate and the top plate are assembled in a laminated manner. Longitudinal and lateral construction steel ribs are arranged in the prefabricated base plate, and longitudinal and lateral top plate construction steel ribs are arranged in the on-site casted top plate. The ribbed beams comprise lateral ribbed beams and longitudinal ribbed beams, and ribbed beam top reinforcing ribs, ribbed beam bottom reinforcing ribs and ribbed beam stirrups are arranged in the ribbed beams. Hollow boxes or light material bodies are filled in the space between the ribbed beams. Erecting and dismounting of templates and associated tool type supporting systems are not needed, thereby lowering cost, improving efficiency, saving construction materials, and reducing the dead weight. Force bearing is more reasonable, the structural strength is high, and the quality is good.

Owner:CHANGSHA BROAD HOMES IND GRP CO LED

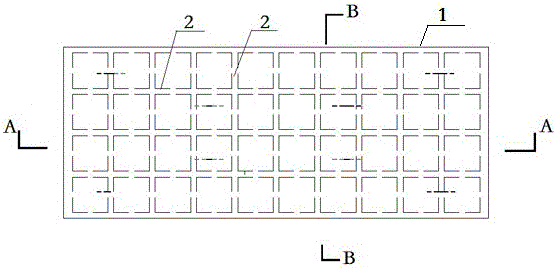

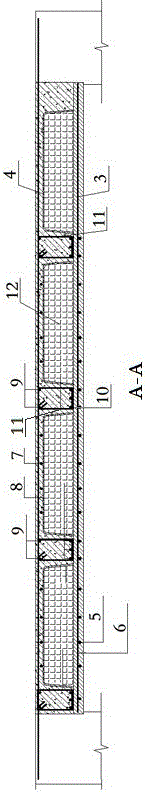

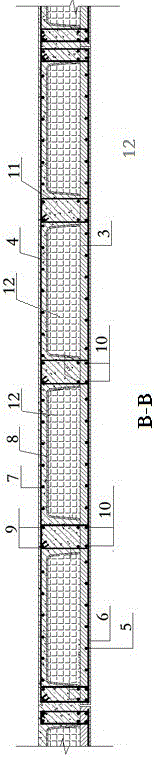

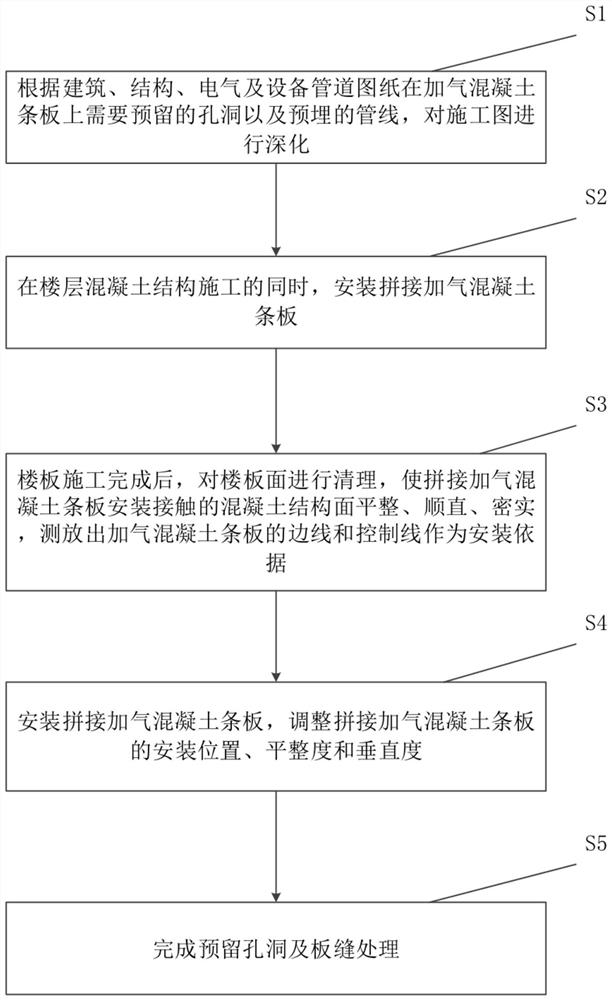

Spliced aerated concrete batten construction method

InactiveCN112177352ALight weightHigh strengthBuilding material handlingEarthquake resistanceFloor slab

The invention relates to the technical field of building construction, and discloses a spliced aerated concrete batten construction method. The spliced aerated concrete batten construction method comprises the following steps of S1, deepening a construction drawing according to holes needing to be reserved and pre-buried pipelines on aerated concrete battens in building, structure, electrical andequipment pipeline drawings; S2, mounting and splicing the aerated concrete battens while a floor concrete structure is constructed; S3, after floor slab construction is completed, cleaning a floor slab surface, enabling a concrete structure surface making contact with the spliced aerated concrete battens during installation to be smooth, straight and compact, and measuring side lines and controllines of the aerated concrete battens to serve as the installation basis; S4, mounting the spliced aerated concrete battens, and adjusting the installation positions, flatness and perpendicularity ofthe spliced aerated concrete battens; and S5, finishing reserved hole and slab joint treatment. According to the spliced aerated concrete batten construction method, a construction process is simplified, the mechanical construction degree is improved, the total construction period is shortened, and the anti-seismic property is improved.

Owner:唐山盾石建筑工程有限责任公司

Heat-preservation and decoration composite light PC peripheral enclosure wall and manufacturing method thereof

ActiveCN110905118AReduce weightReduce vertical loadCeramic shaping apparatusBuilding componentsAggregate (composite)Heat conservation

The invention discloses a heat-preservation and decoration composite light PC peripheral enclosure wall and a manufacturing method thereof. The heat-preservation and decoration composite light PC peripheral enclosure wall comprises light aggregate concrete and a heat-preservation and decoration integrated plate fixedly connected with the light aggregate concrete through connecting pieces, whereinthe heat-preservation and decoration integrated plate comprises a decoration layer and a heat-preservation layer; the connecting pieces comprise the first connecting piece pre-buried in the heat-preservation and decoration integrated plate and the second connecting piece fixedly connected with a structural framework steel bar in the light aggregate concrete; the first connecting piece comprises abottom plate used for being fixedly pasted to the decoration layer, a hollow frame pre-buried in the heat-preservation layer and a right-angle hook used for being in hooked connection with the secondconnecting piece; and the second connecting piece comprises an arc hook and a connecting part fixed to the structural framework steel bar. According to the heat-preservation and decoration composite light PC peripheral enclosure wall and the manufacturing method thereof, facing treatment does not need to be conducted in the construction process, on-site wet operation is reduced, the labor and construction cost is saved, and decoration-heat-preservation-enclosure integration is achieved.

Owner:CHINA CONSTR SCI & TECH CO LTD

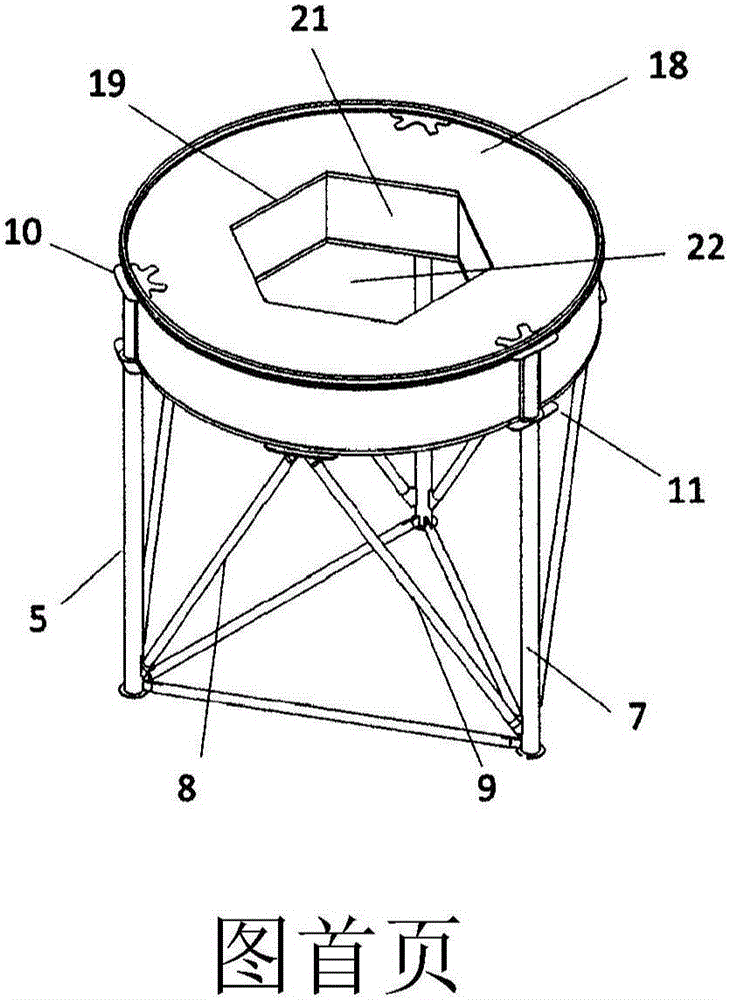

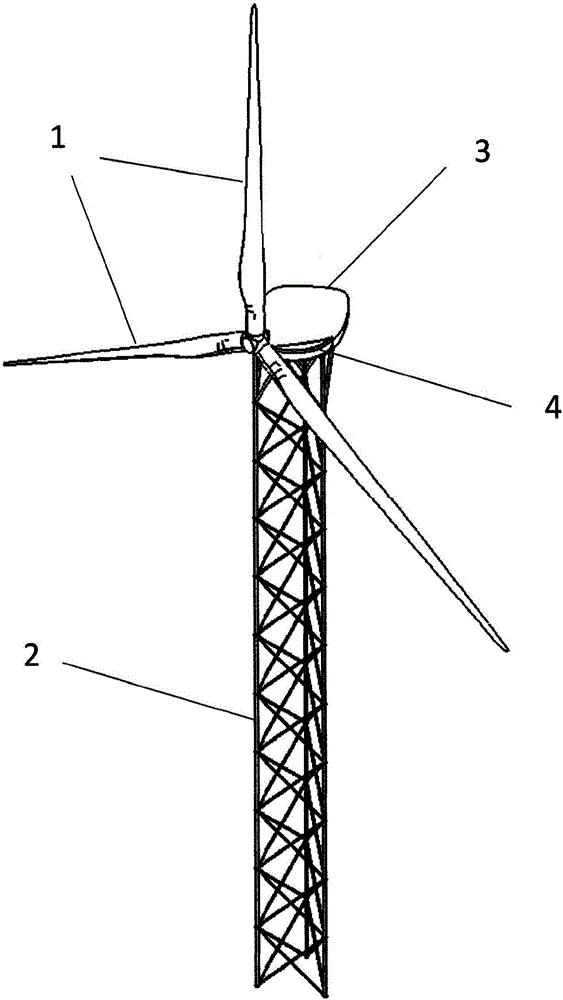

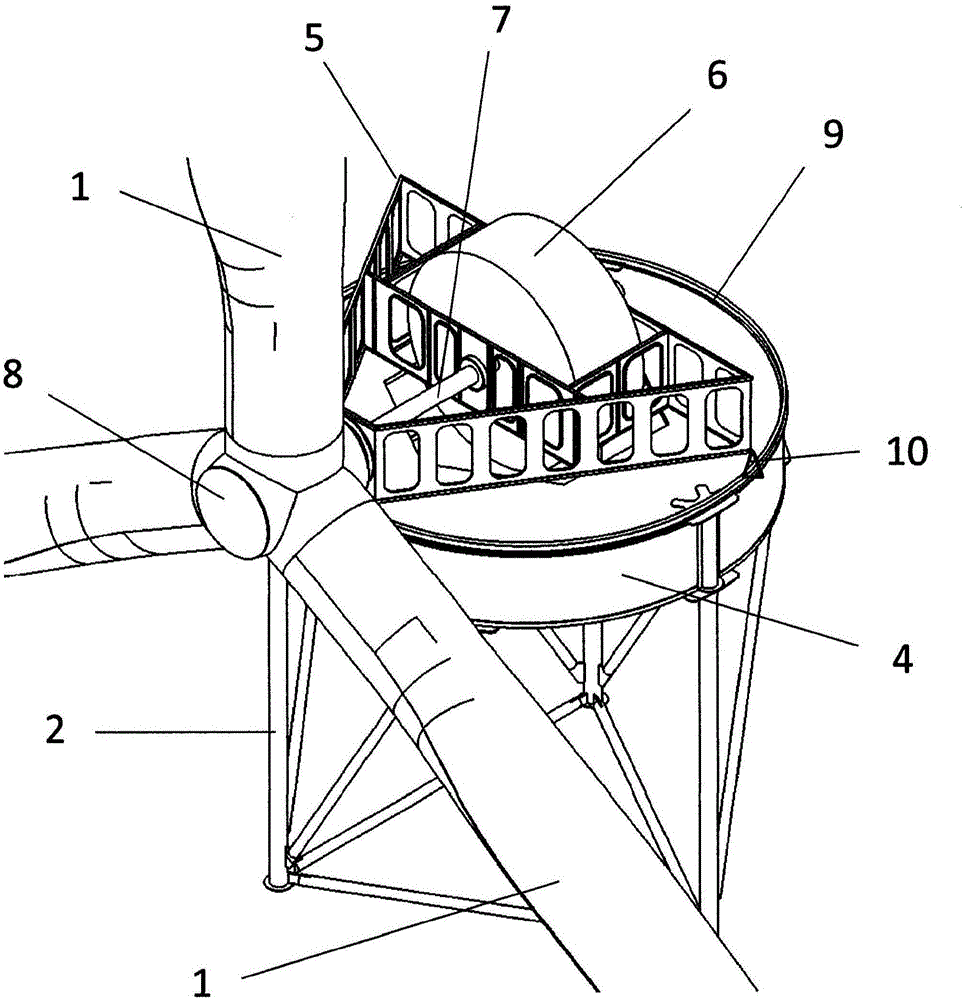

Wind turbine drive train

InactiveCN106062360AIncrease distanceLoad minimizationRolling contact bearingsWind motor controlNacelleYaw system

Wind turbine drive train with a nacelle (3) as much compact as possible in a tower (2) with a big diameter which allows to embed the generator (6) inside and reduce the loads in the supports (10) of the yaw system and in the tower (2). The mainframe (5) of the nacelle (3) has a triangular shape based on structural frames or ribs, taking profit of the big reaction arm with the most compact solution. The generator (6) is integrated in this mainframe (5) and partially crosses the connection piece (4) of the tower (2). The yaw system is made by individual supports in a continuous raceway and the traction elements provokes the rotation of the nacelle (3) around the tower (2) without the need of the usual geared pinion - zip systems, using pneumatic wheels (20) which roll by the raceway made by the rotation ring (9) with inverted T shape with one or two circular sections on the top of its profile.

Owner:纳巴风力公司

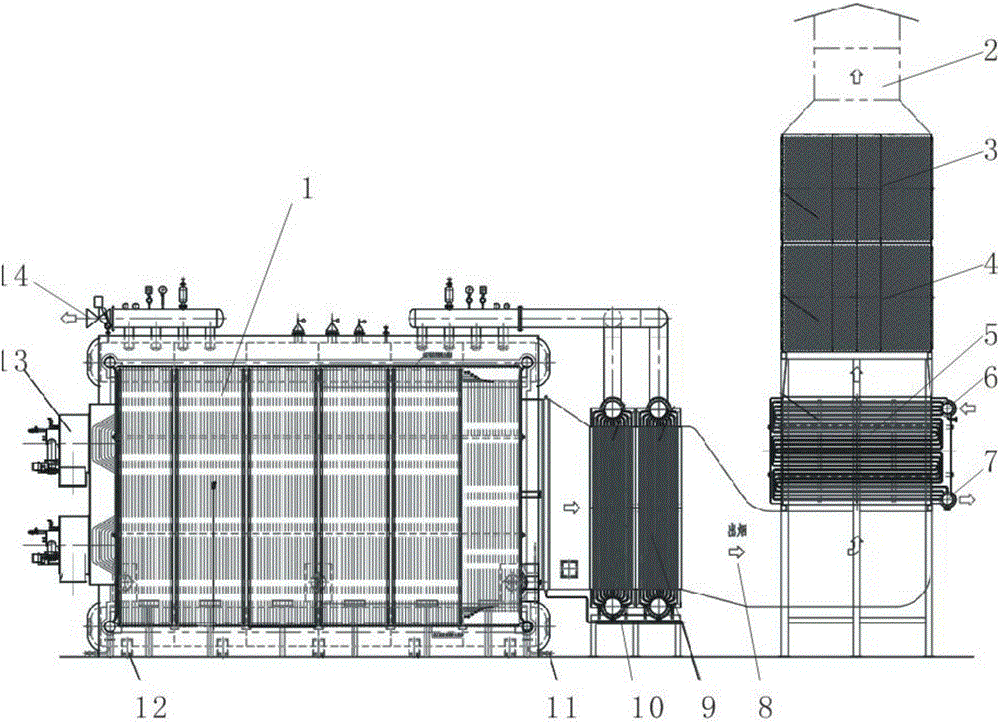

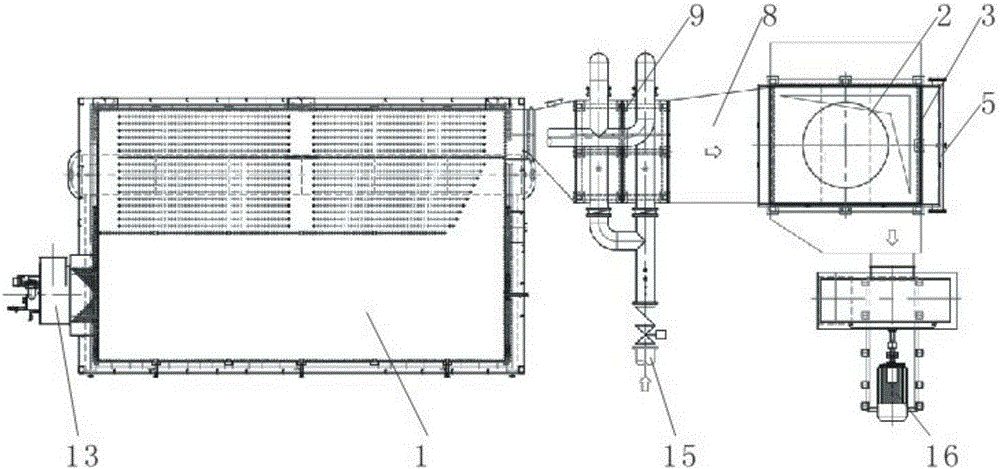

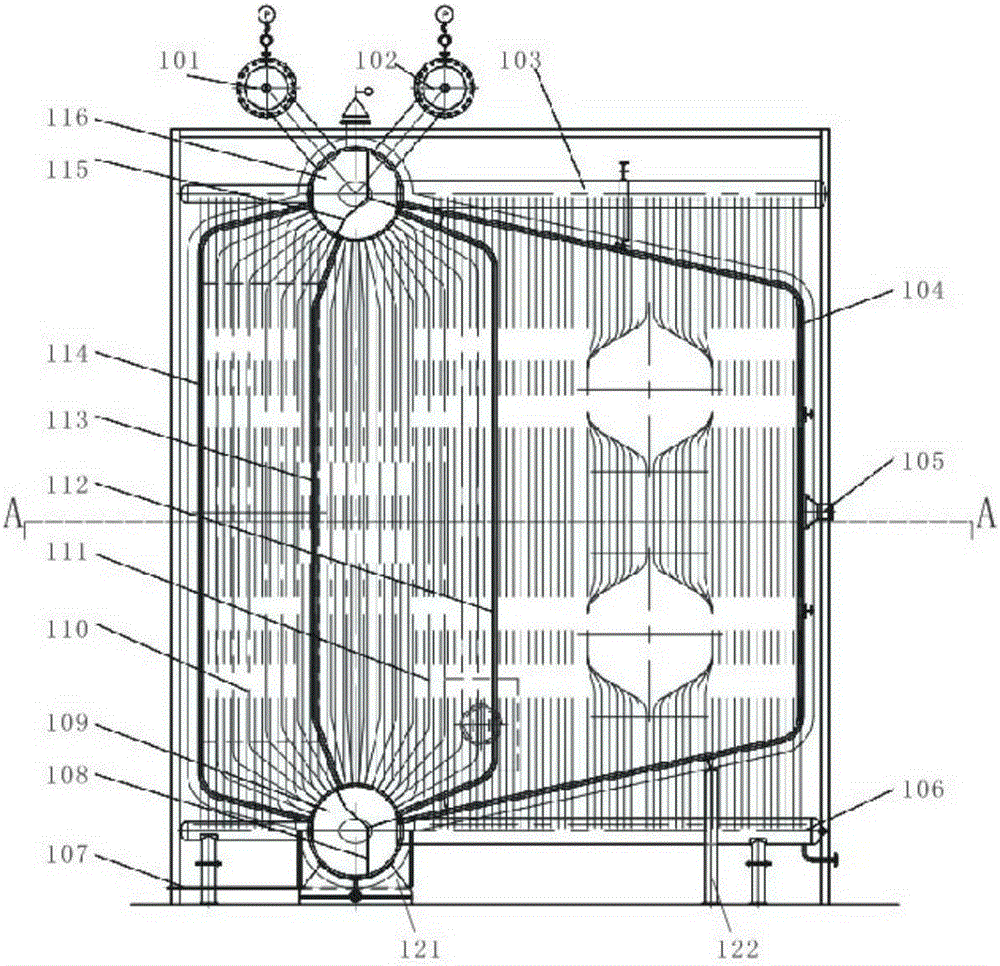

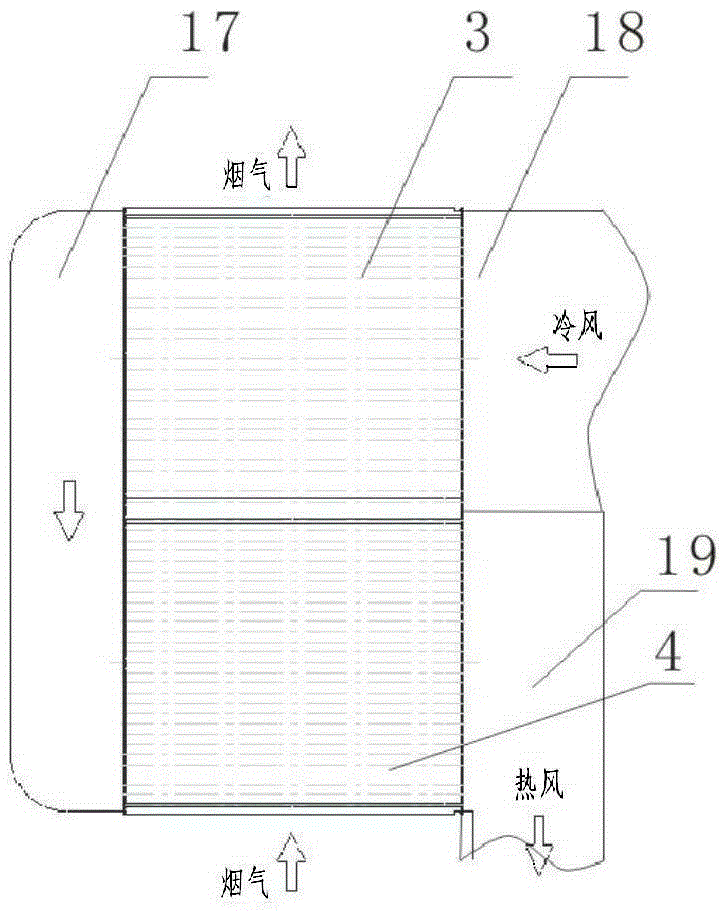

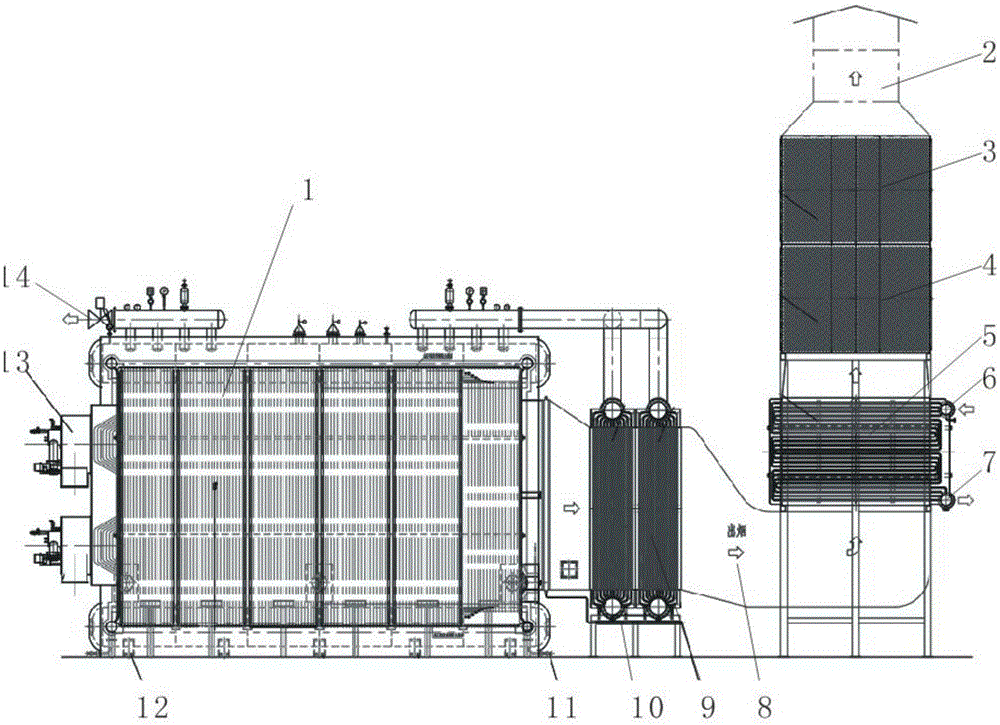

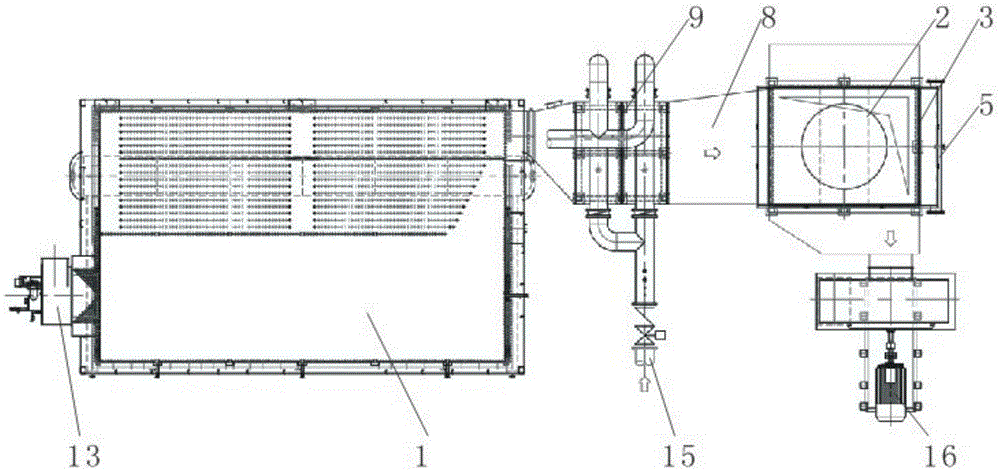

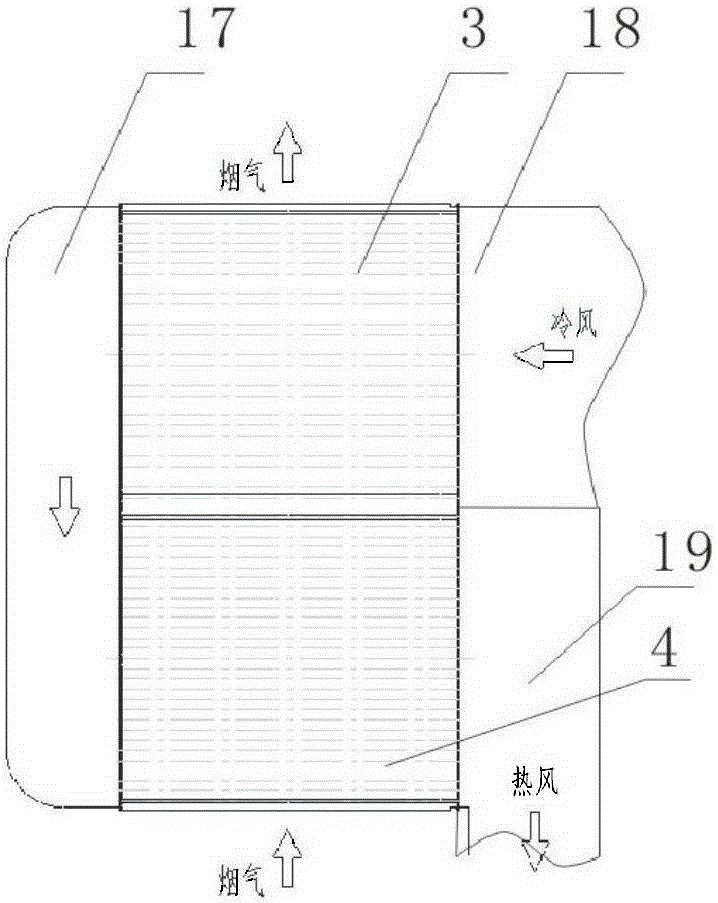

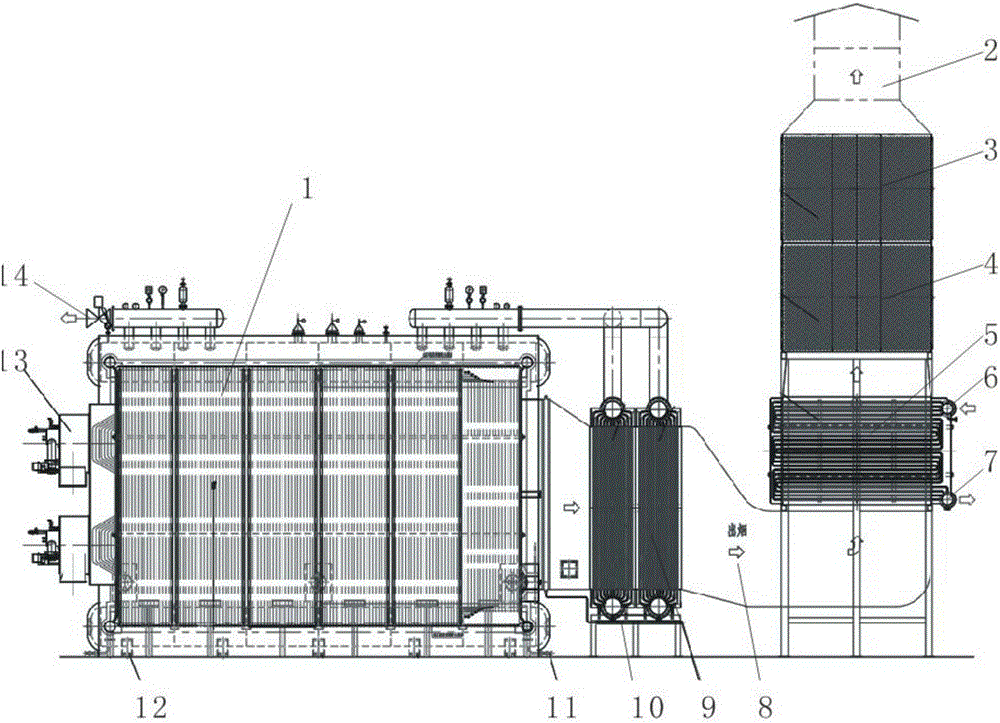

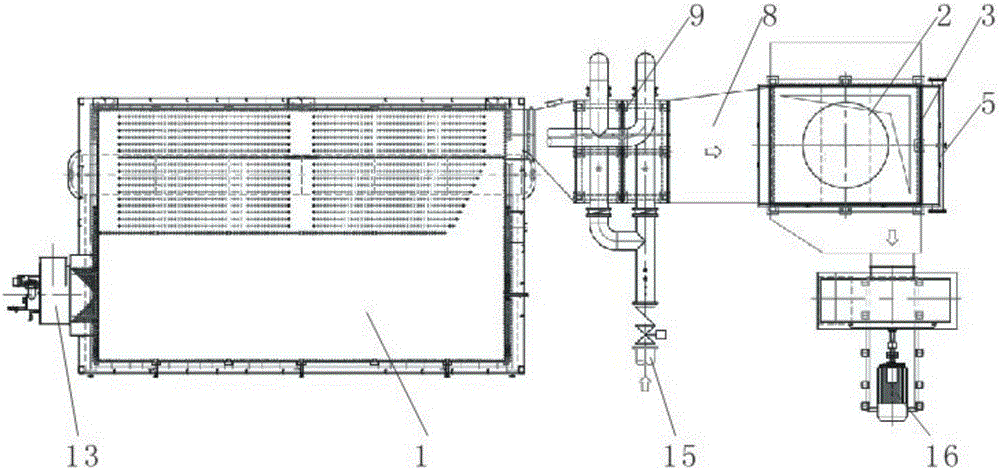

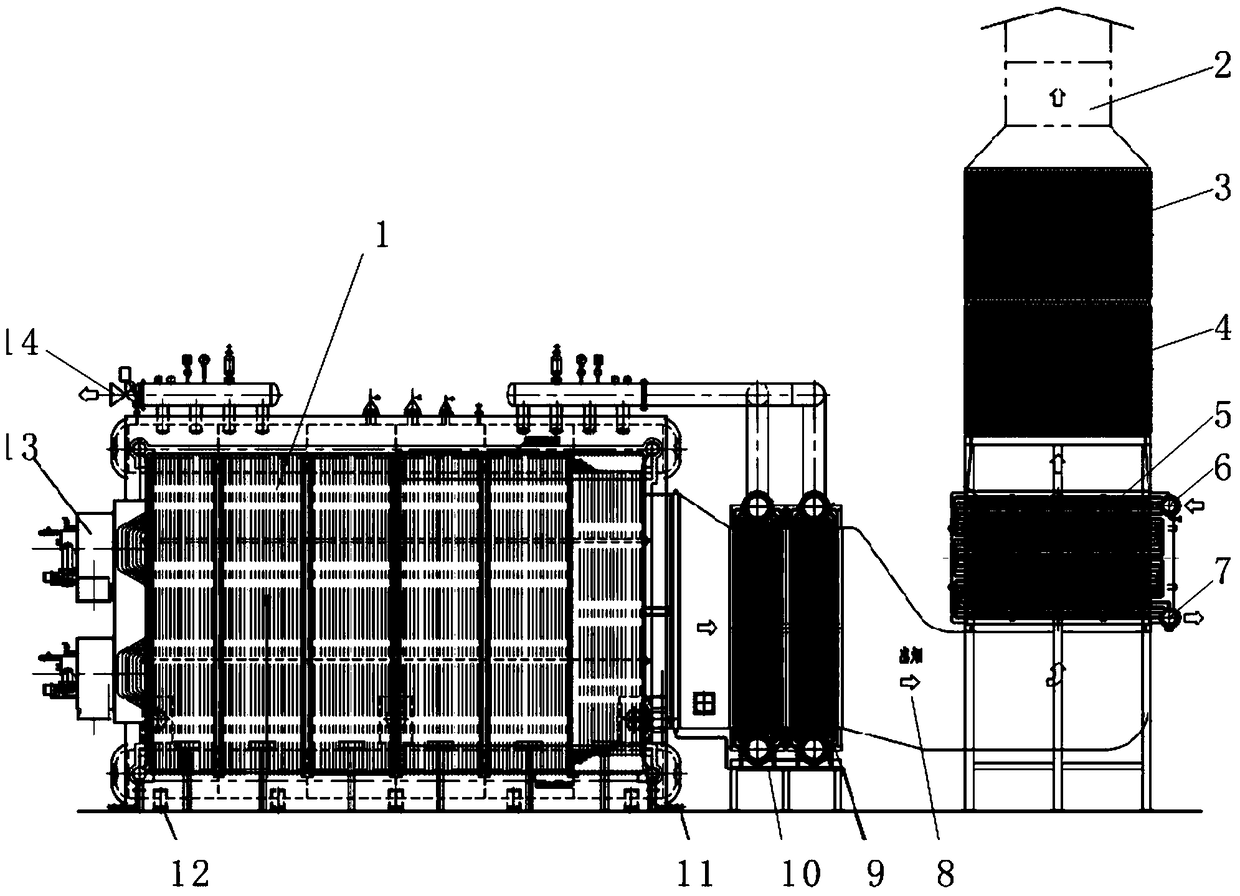

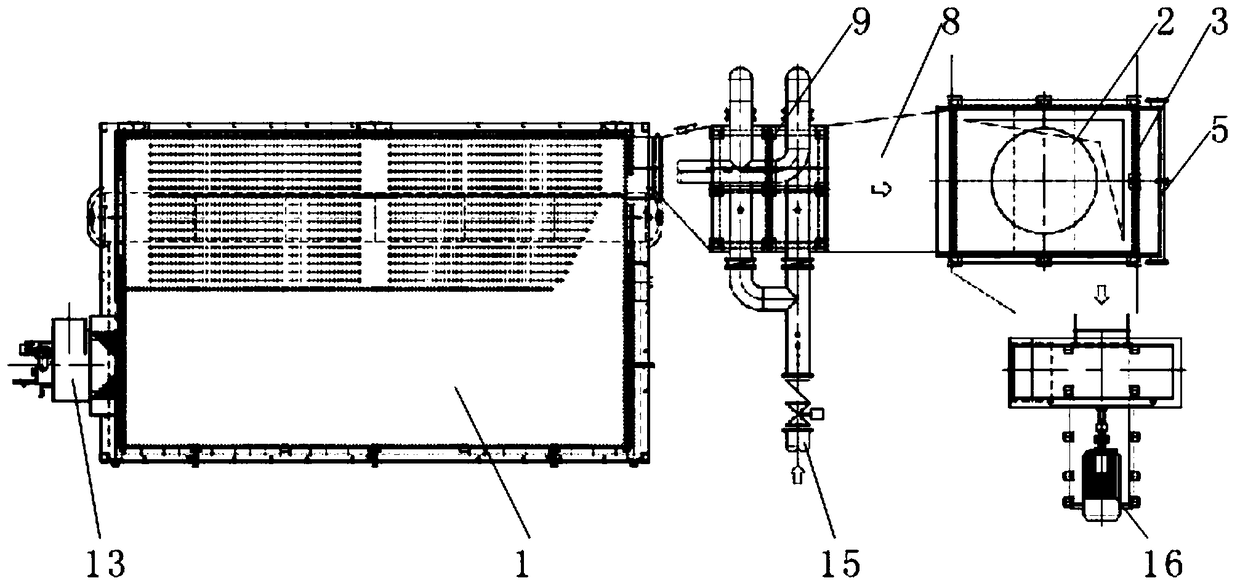

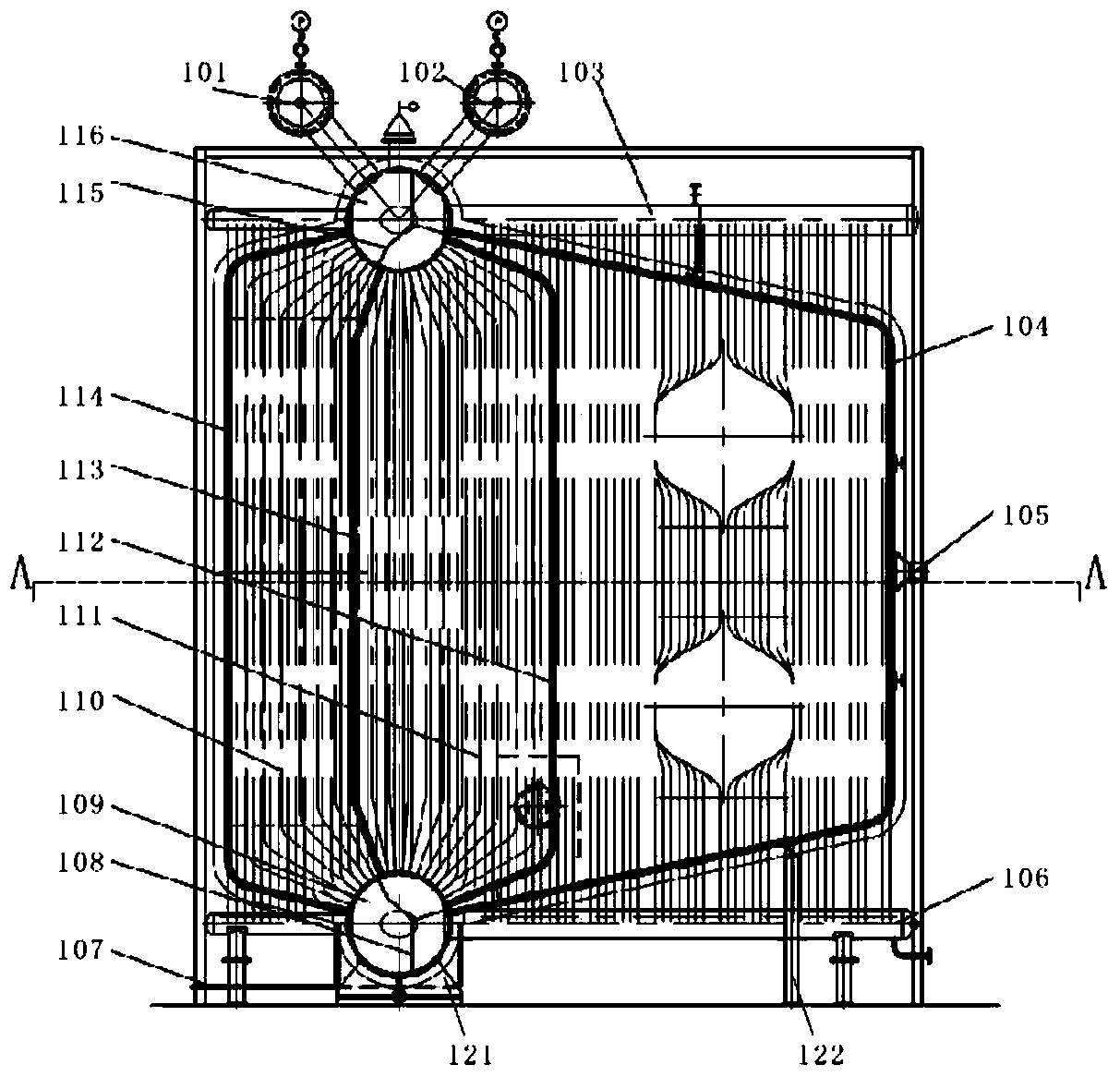

Gas-fired hot water boiler air circulation energy saving system

ActiveCN105299894AAvoid resonanceAdvanced technologyAir heatersSustainable buildingsCombustorFlue gas

The invention relates to a gas-fired hot water boiler air circulation energy saving system which comprises a boiler body, two burners, a flue, a chimney, energy savers, a water-cooling type condenser, a secondary air type condenser and a primary air type condenser, wherein the two burners arranged at intervals in an up-and-down manner are mounted at one end of the boiler body; a flue gas outlet is formed at the other end of the boiler body, and is in sealing connection with the flue; an outlet of the flue is connected to the upright chimney; the energy savers sequentially arranged in a two-stage manner are mounted in the flue between the boiler body and the chimney; the chimney is provided with the water-cooling type condenser, the secondary air type condenser and the primary air type condenser from bottom up sequentially; an air blower is communicated with and mounted at one side of the lower part of the chimney; and an exhaust outlet of the air blower is communicated with air inlets of the burners of the boiler body through sealed pipelines. The gas-fired hot water boiler air circulation energy saving system operates stably, is safe and reliable, has strong output, is high in efficiency and low in exhaust gas temperature, reaches flue gas emission indexes, and meets the requirements of market development better.

Owner:TIANJIN BAOCHENG MACHINERY MFG

Large gas-fired hot water boiler

The invention relates to a large gas-fired hot water boiler. The large gas-fired hot water boiler comprises a boiler body, combustors, a flue, a chimney, economizers, a water-cooling-type condenser, a second-stage air-type condenser and a first-stage air-type condenser, wherein one end of the boiler body is provided with the two combustors which are vertically arranged at an interval; the other end of the boiler body is provided with a smoke outlet and is connected with the flue in a sealed manner; the outlet of the flue is connected with the vertical chimney; two stages of economizers are sequentially arranged in the flue between the boiler body and the chimney; the water-cooling-type condenser, the second-stage air-type condenser and the first-stage air-type condenser are sequentially arranged on the chimney from bottom to top; and smoke in the boiler body is exhausted from the boiler body, sequentially passes through the two stages of economizers, the water-cooling-type condenser, the second-stage air-type condenser and the first-stage air-type condenser, and is finally exhausted through the upper end of the chimney. The large gas-fired hot water boiler has the advantages that the operation is stable; safety and reliability are ensured; the output is sufficient; the exhaust gas temperature is low; the efficiency is high; the smoke emission index meets the requirement; and the market development requirement is better met.

Owner:TIANJIN BAOCHENG MACHINERY MFG

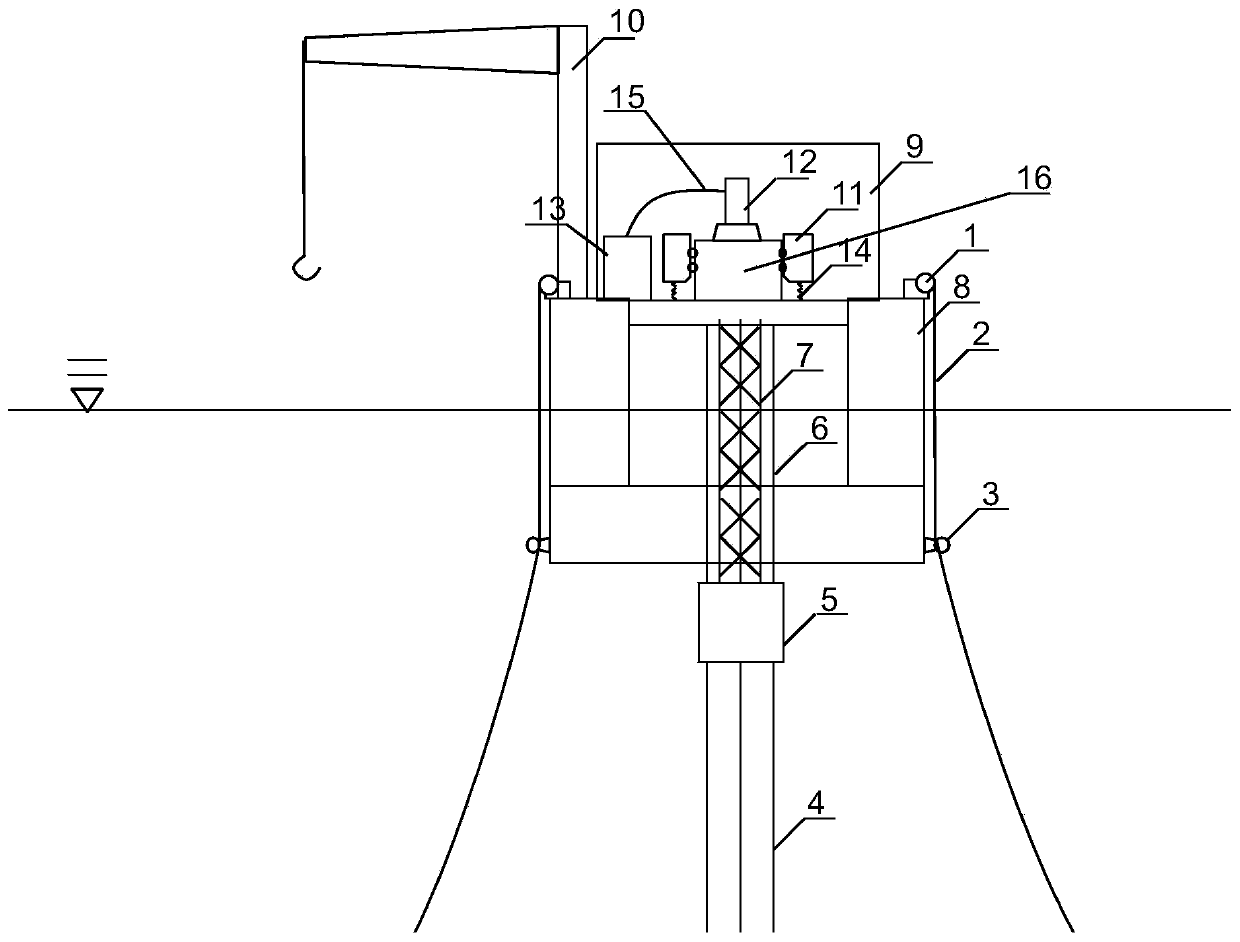

Novel semi-submersible platform and mounting method thereof

ActiveCN111439348AReduce vertical loadAchieve decouplingWaterborne vesselsFloating buildingsBuoyant flowReclaimed water

The invention discloses a novel semi-submersible platform and a mounting method thereof. The novel semi-submersible platform comprises a platform hull and a top tensioning type steel vertical pipe; the top tensioning type steel vertical pipe comprises an upper-end oil extraction vertical pipe and a lower-end oil extraction vertical pipe; a reclaimed water buoy is connected between the upper-end oil extraction vertical pipe and the lower-end oil extraction vertical pipe; a truss is arranged on the reclaimed water buoy, a vertical pipe guide frame is arranged at the upper end of the truss, the vertical pipe guide frame is movably connected with a main deck of the platform hull through a spring support, and the spring support is fixedly connected with a main deck; the top of the upper-end oilextraction vertical pipe is matched with the vertical pipe guide frame; a Christmas tree is arranged on a vertical pipe fixing frame; and the Christmas tree is connected with a crude oil treatment device arranged on the main deck of the platform hull. The novel semi-submersible platform has independent buoyancy, and the vertical load of the novel semi-submersible platform on the platform is reduced; and decoupling of heaving motion and longitudinal and transverse shaking motion of the top of the vertical pipe and the platform hull is achieved, so motion of the platform is not directly transmitted to the vertical pipe, and the dry tree oil extraction function can be achieved.

Owner:CNOOC RES INST +1

Modified buttress capable of reducing buttress volume on horizontal bending point of pressure pipeline and construction method thereof

The invention relates to a modified buttress capable of reducing buttress volume on a horizontal bending point of a pressure pipeline and a construction method thereof. The modified buttress capable of reducing the buttress volume on the horizontal bending point of the pressure pipeline comprises a buttress body formed through cast-in-situ of concrete, wherein the buttress body is in a trapezoid shape gradually widened from the front to the rear, a pipeline installing groove is formed in a bevel in the front of the buttress body, a plurality of profile steels arranged in parallel are fixedly inserted into the rear position of the buttress body, the profile steels are perpendicular to the buttress body, the lower half parts of the profile steels are stretched out from the lower end of the buttress body, and form an exposed segment, and the exposed segment makes embedding contact with a soil body. The construction method of the modified buttress capable of reducing the buttress volume onthe horizontal bending point of the pressure pipeline includes: S1, after excavation of a foundation pit for installing the pressure pipeline, inserting the profile steels into the foundation pit; and S2, erecting a template for casting of the buttress body in the foundation pit, pouring the concrete in the template, solidifying the concrete for forming the buttress body, and burying the upper half parts of the profile steels in the concrete. The modified buttress capable of reducing the buttress volume on the horizontal bending point of the pressure pipeline effectively reduces the buttressvolume, and improves shock resistance capability and environment applicability.

Owner:TIANJIN CHENGJIAN UNIV

Water way circulation energy saving system of gas-fired hot water boiler

InactiveCN105299726AAvoid resonanceAdvanced technologyFluid heatersHot-water central heatingCombustorProcess engineering

The invention relates to a water way circulation energy saving system of a gas-fired hot water boiler. The system comprises a furnace body, combustors, a flue, a chimney, an energy economizer and a water cooling type condenser, wherein two combustors are vertically spaced at one end of the furnace body; a smoke outlet is formed in the other end of the furnace body, and is tightly connected with the flue; an outlet of the flue is connected to the vertical chimney; the two-grade energy economizer is mounted in the flue between the furnace body and the chimney in sequence; and the water cooling type condenser is mounted on the chimney. The system is stable in operation, safe, reliable, sufficient in force, low in smoke discharge temperature and high in efficiency, reaches the smoke discharge index, and is more accordant with the market development demands.

Owner:TIANJIN BAOCHENG MACHINERY MFG

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490BEngraving and milling realizationRealize the processing effectGrinding machinesStone-like material working toolsEngineeringMachining

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division aroundthe axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

Pipe burying structure capable of reducing pipe top vertical loads and construction method for pipe burying structure

ActiveCN103527847BRelieve pressureIncrease frictionPipe laying and repairThermal insulationCut and fillVertical load

The invention discloses a pipe burying structure capable of reducing pipe top vertical loads and a construction method for the pipe burying structure. The construction method comprises the steps of S1, digging a pipe groove and a backfill groove above the pipe groove and digging at least one step on two side walls of the backfill groove; S2, laying pipes in the pipe groove and completing port welding of the pipes; S3, filling earth in the pipe groove, and compacting and flattening the filled earth to the pipe top elevation; S4, laying a degradable material interlayer above the top of the pipe, wherein the degradable material interlayer is disposed below a transverse step plane of the lowest layer of steps; S5, filling earth into the backfill groove and compacting the earth. According to the pipe burying structure and the construction method for the pipe burying structure, an soil arch effect and backfill groove side wall friction can be used for obviously reducing the top pressure of the pipes, and the pipes are protected from being fractured and damaged. The construction process is simple, costs of used materials are low, and the construction method has a good application prospect and a wide generalization performance and applicable to open digging burying of underground shallow buried pipes.

Owner:哈尔滨市政建设有限公司

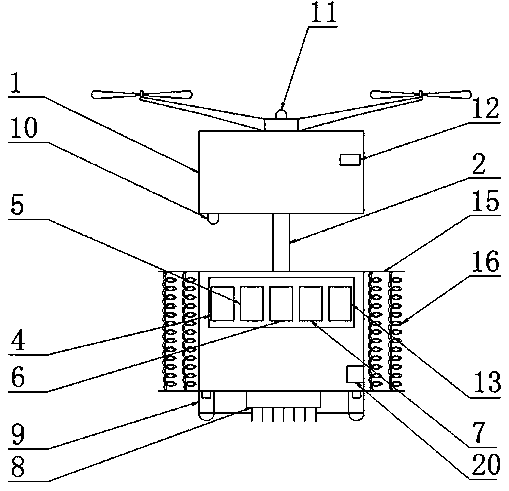

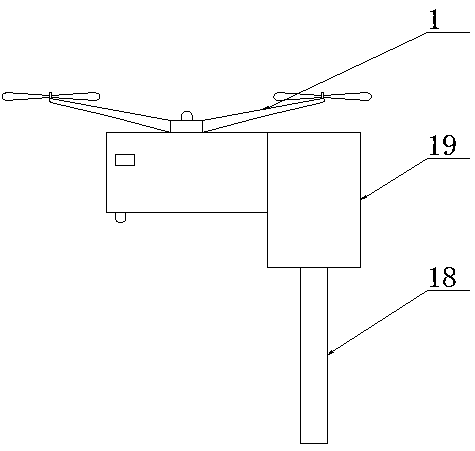

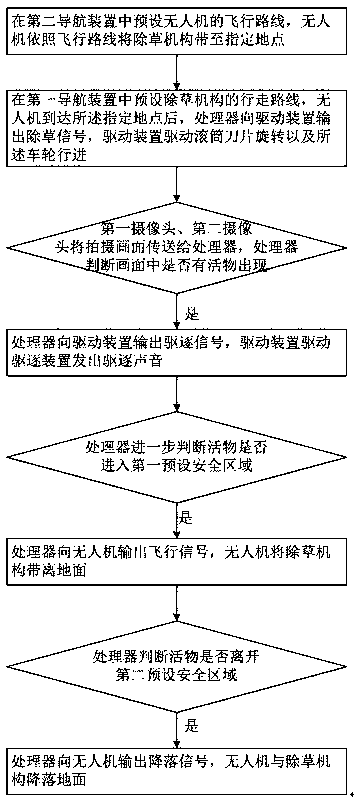

An automatic weeding device based on the joint operation of drones

ActiveCN107333513BWith energy savingChange rotation speedAircraft componentsTelevision system detailsUncrewed vehicleEmbedded system

The invention discloses an automatic weeding device based on the joint operation of a drone, which includes a drone, a connecting device, and a weeding mechanism. The weeding mechanism includes a processor, a driving device, a first navigation device, a repelling device, a roller blade, and wheels The first navigation device is connected with the processor and is used to set the walking route of the weeding mechanism, the expelling device is connected with the driving device, and is used to expel living things close to the weeding mechanism, and the roller blade is connected with the driving device through a transmission mechanism, and is used for cutting weeds. Grass, the wheels are connected to the driving device to drive the weeding mechanism to walk, the drone includes a first camera, a second camera and a second navigation device, the first camera is connected to the processor, and is used to shoot the picture below the drone and Send to the processor, the second camera is connected with the processor, and is used to take pictures above the UAV and send it to the processor, and the second navigation device is connected with the processor, and is used to set the flight route of the UAV.

Owner:安徽舒州生态农业科技股份有限公司

A gas-fired hot water boiler air circulation energy-saving system

ActiveCN105299894BAvoid resonanceAdvanced technologyAir heatersSustainable buildingsCombustorFlue gas

Owner:TIANJIN BAOCHENG MACHINERY MFG

A kind of thermal insulation decoration compound lightweight PC outer protection wall and its manufacturing method

ActiveCN110905118BReduce weightReduce vertical loadCeramic shaping apparatusBuilding componentsAggregate (composite)Insulation layer

A thermal insulation and decoration composite lightweight PC outer enclosure wall and a manufacturing method thereof, comprising lightweight aggregate concrete and an integrated thermal insulation and decorative panel connected and fixed to the lightweight aggregate concrete through connectors, the integrated thermal insulation and decorative panel includes a decorative layer and an thermal insulation layer, the connectors include the first connector pre-embedded in the thermal insulation and decoration integrated panel and the second connector fixed to the structural skeleton reinforcement in the lightweight aggregate concrete, the first connector includes a The bottom plate, the hollow frame pre-embedded in the insulation layer, and the right-angle hook for hooking with the second connecting piece, the second connecting piece includes a circular arc hook and a connecting part fixed to the steel bar of the structural skeleton. The present invention does not need to carry out finishing treatment during the construction process, reduces on-site wet work, saves labor and construction costs, and realizes the integration of decoration-insulation-enclosure.

Owner:CHINA CONSTR SCI & TECH CO LTD

A liftable suction cup mechanism for a vacuum cleaner

Owner:HUBEI JULI AUTOMOTIVE TECH CO LTD

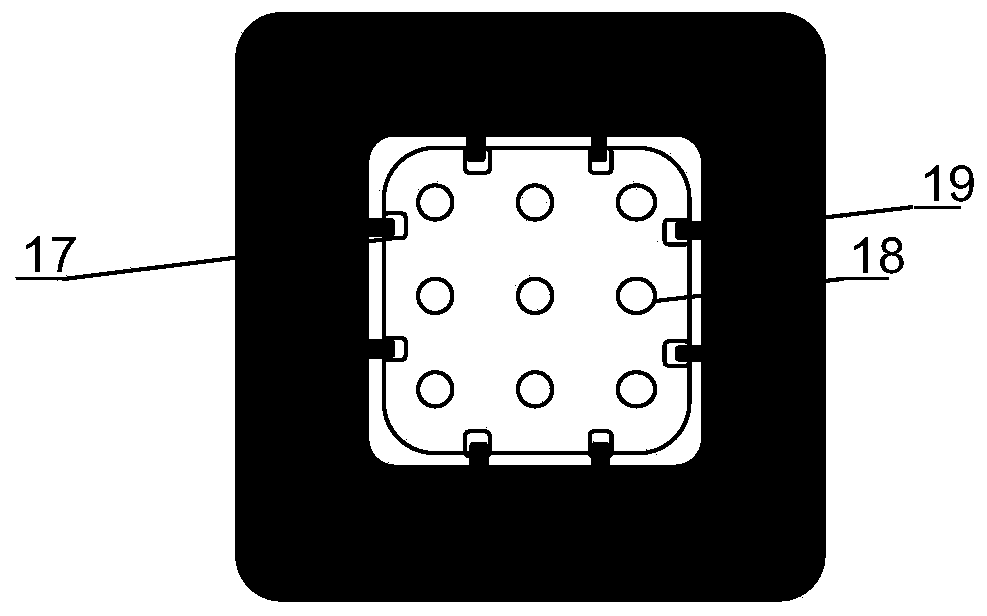

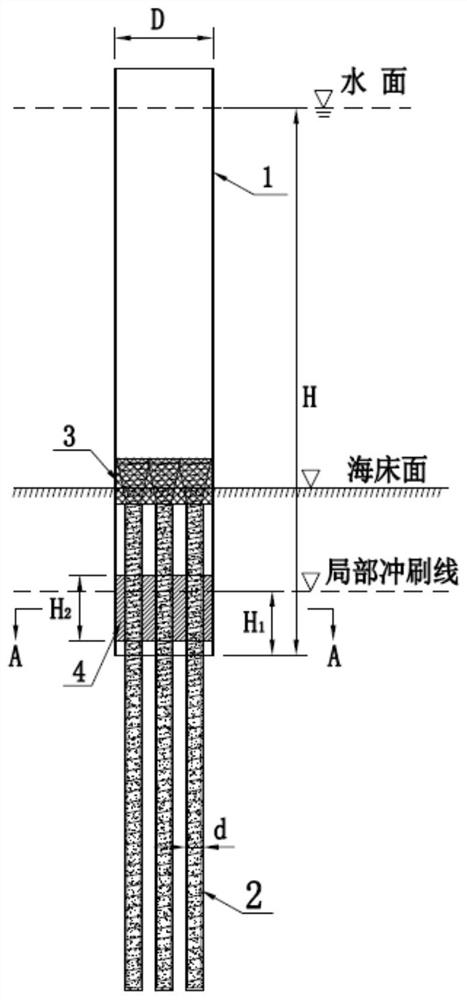

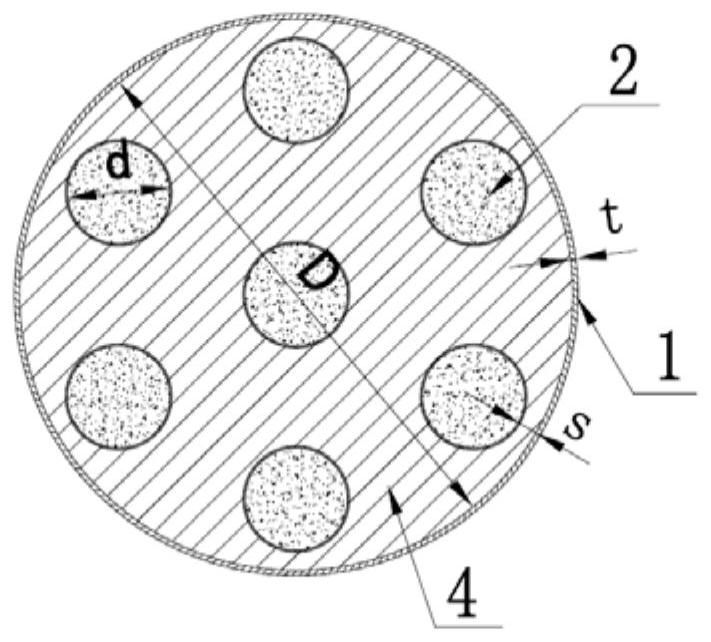

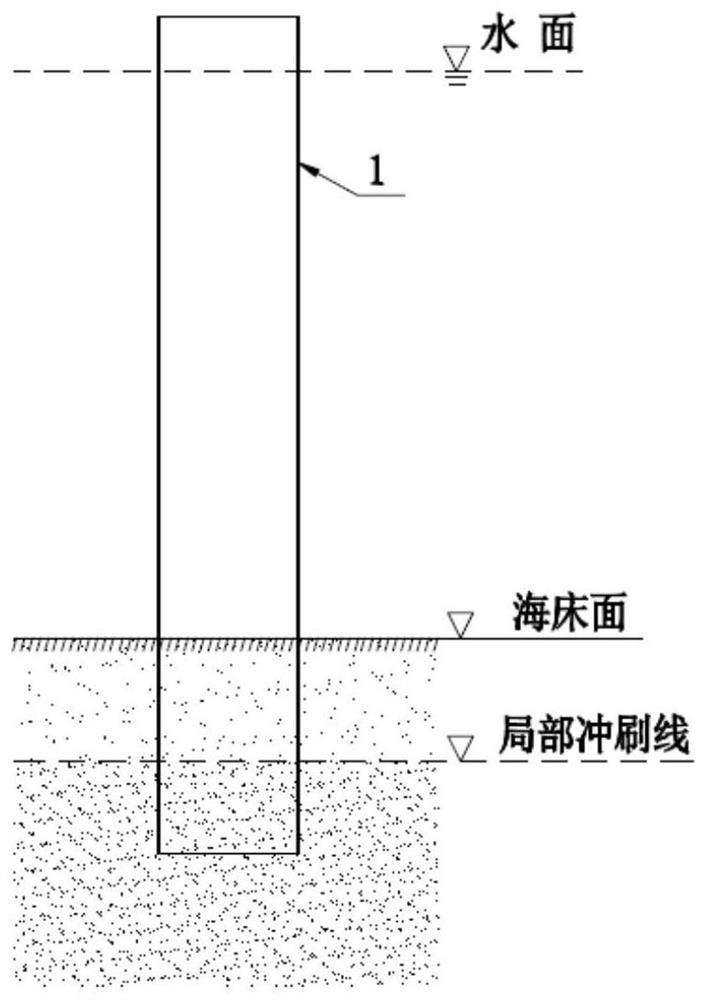

A steel column concrete root deep water foundation structure and its construction method

ActiveCN109024578BGive full play to mechanical propertiesReduce dosageBulkheads/pilesSteel columnsSeabed

Owner:CHINA MAJOR BRIDGE ENERGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com