Coupling beam damper based on magneto-rheological elastomer material

A magnetorheological elastomer and magnetorheological elasticity technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of high engineering cost, small control range, and easy resonance, so as to improve the ability to resist horizontal loads , Wide tuning range and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

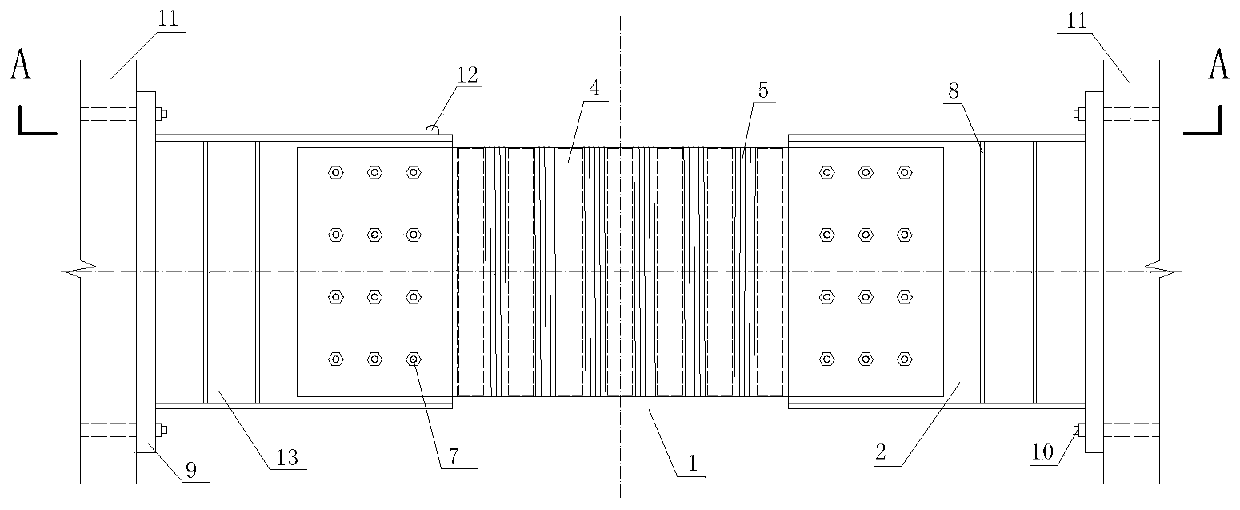

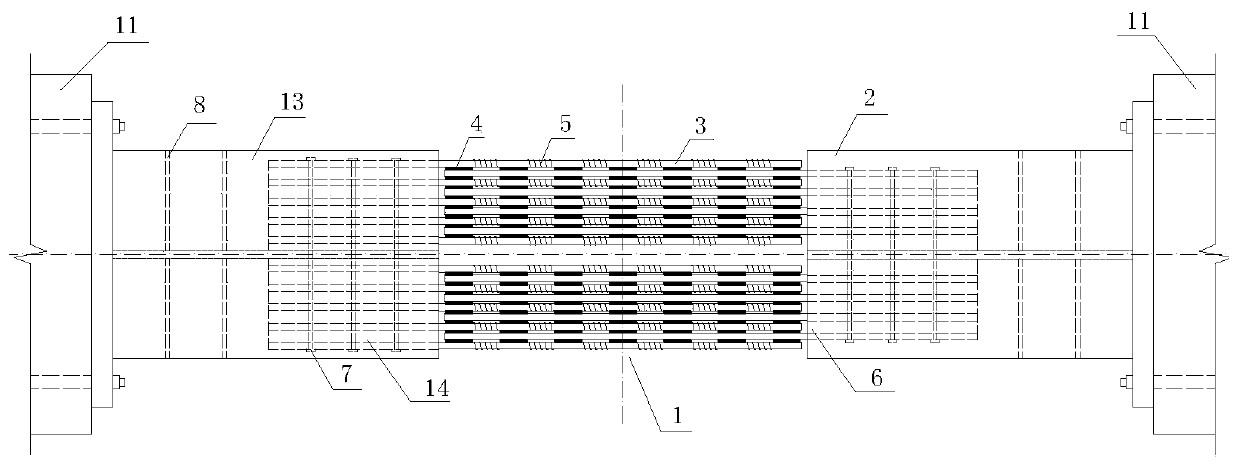

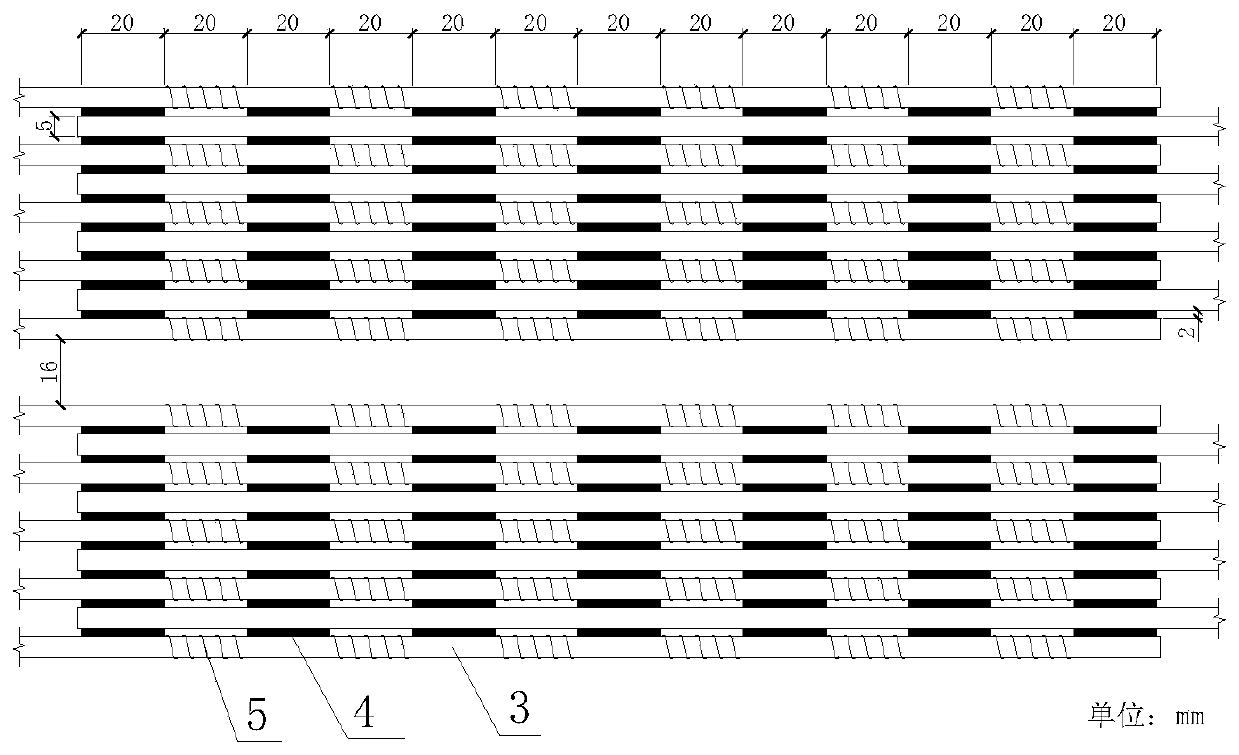

[0029] like figure 1 and figure 2 A coupling beam damper based on a magnetorheological elastomer material as shown, including a first H-shaped steel 13 and a second H-shaped steel 2, and a damping device for connecting the first H-shaped steel 13 and the second H-shaped steel 2 1; Specifically, the inner end of the first H-shaped steel 13 / second H-shaped steel 2 is connected to the shock absorbing device 1, and the outer end of the first H-shaped steel 13 / second H-shaped steel 2 is connected to the shear force through the gusset plate 9 respectively. Wall 11 is connected. In this embodiment, the outer ends of the first H-shaped steel 13 and the second H-shaped steel 2 are respectively welded and fixed to one side of the gusset plate 9, and the gusset plate 9 is connected to the shear wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com