A steel column concrete root deep water foundation structure and its construction method

A deep-water foundation and construction method technology, which is applied in the direction of foundation structure engineering, construction, sheet pile walls, etc., can solve the problems of high economic cost, poor stress of deep-water foundation structures, etc., to reduce the structure's self-weight, save material consumption, and horizontal bearing The effect of high ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

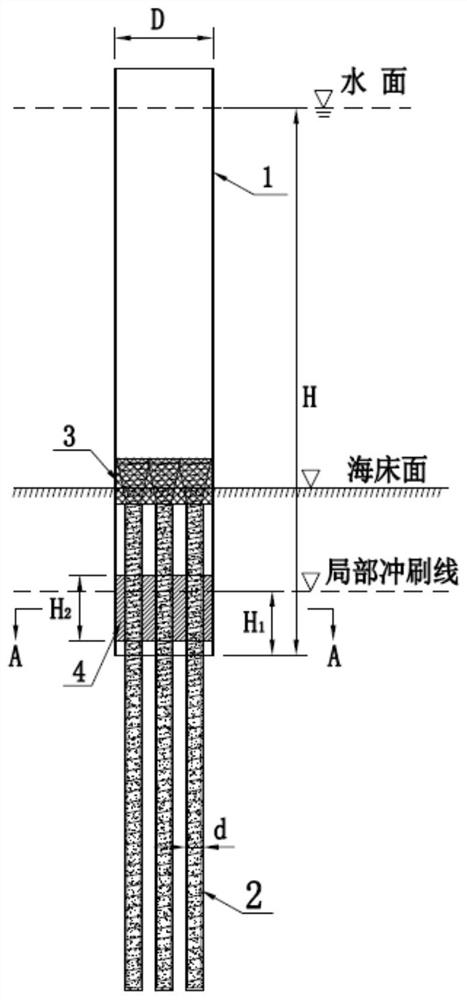

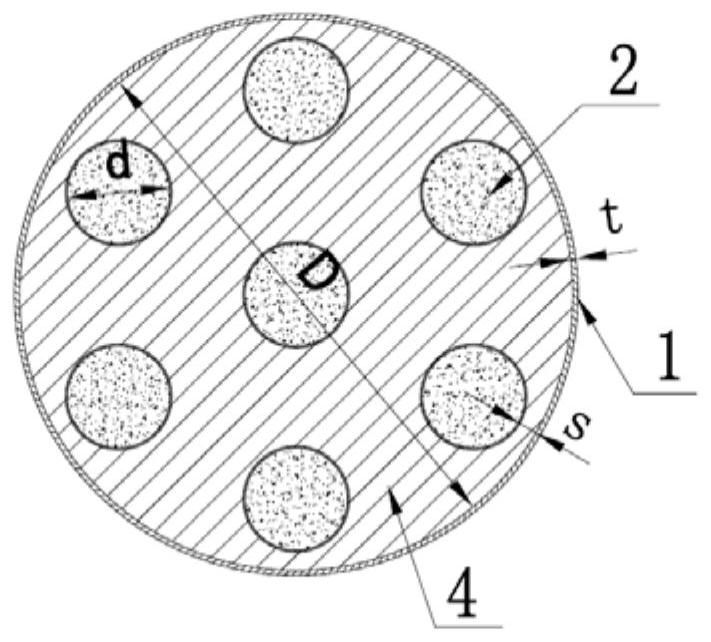

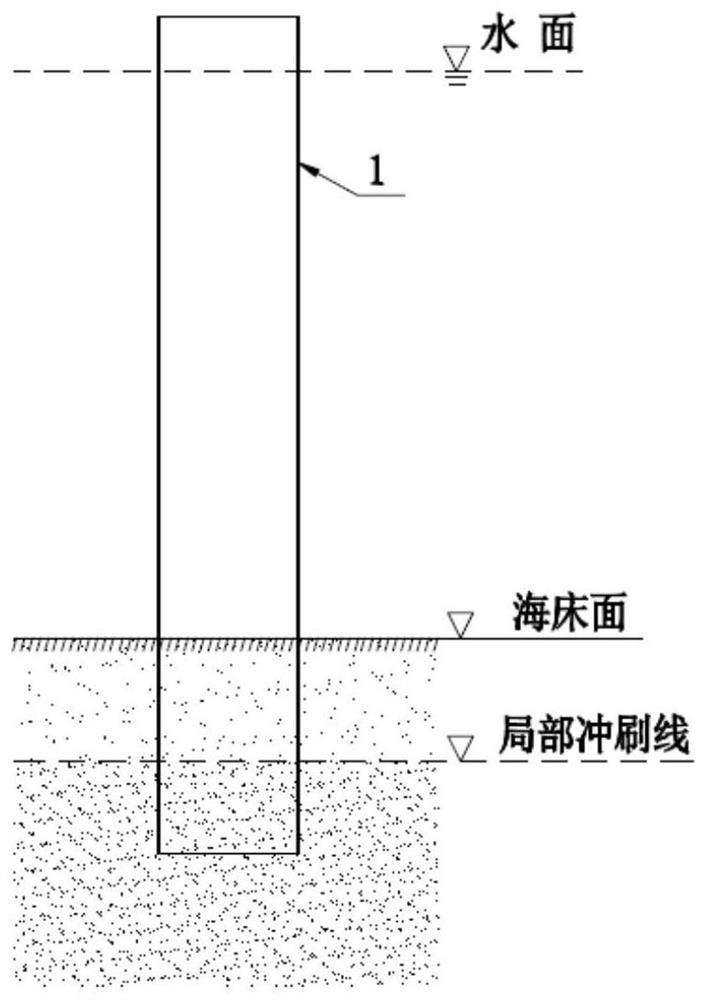

[0051]The invention provides a deep-water foundation structure with steel columns and concrete roots and a construction method thereof. The large-diameter upper steel columns have high rigidity and strong ability to resist horizontal forces, and can be generated under the action of wave current loads, ship collision forces and bridge cross-wind loads. The displacement of the top surface of the foundation is small, the specific surface area of the concrete root under the small diameter is large, and the vertical side friction resistance is large. The structure is simple, the force is reasonable, it has both excellent horizontal bearing capacity and reliable vertical bearing capacity, and fully utilizes the advantages of mechanical properties of different materials, saving the amount of basic materials and reducing the construction cost of deep-water foundations in harsh deep-sea environments. It is reliable in force, technically feasible and economically reasonable, and is sui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com