Preparation method of micro-nanofiber/ceramic matrix composite

A technology of micro-nano fibers and composite materials, applied in the field of preparation of micro-nano fibers/ceramic matrix composite materials, can solve the problems of poor dispersibility of micro-nano fibers, and achieve the effects of good dispersibility, wide adjustable range and low process temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 1 g of sodium carboxymethyl cellulose in 99 g of deionized water, stir mechanically for 2 h at a stirring speed of 600 r / min, and obtain a colorless and transparent solution with a certain viscosity.

[0029] (2) Add 1.5 g of CNTs to the solution in step (1), and first mechanically disperse at a speed of 300 r / min for 30 min. , and then ultrasonically dispersed for 30 minutes. A suspension of CNTs is obtained.

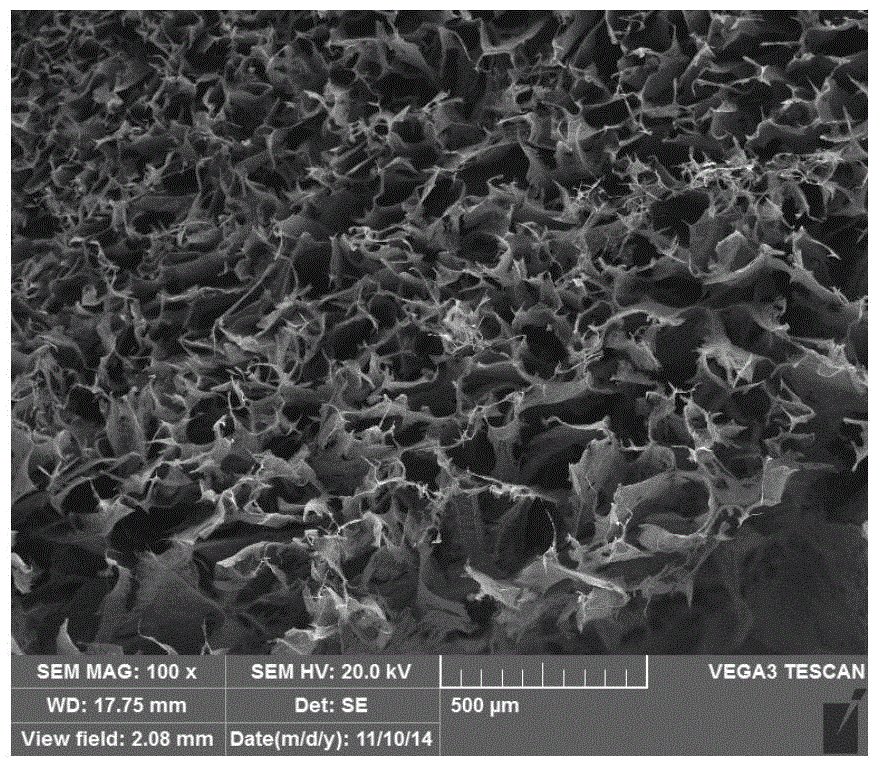

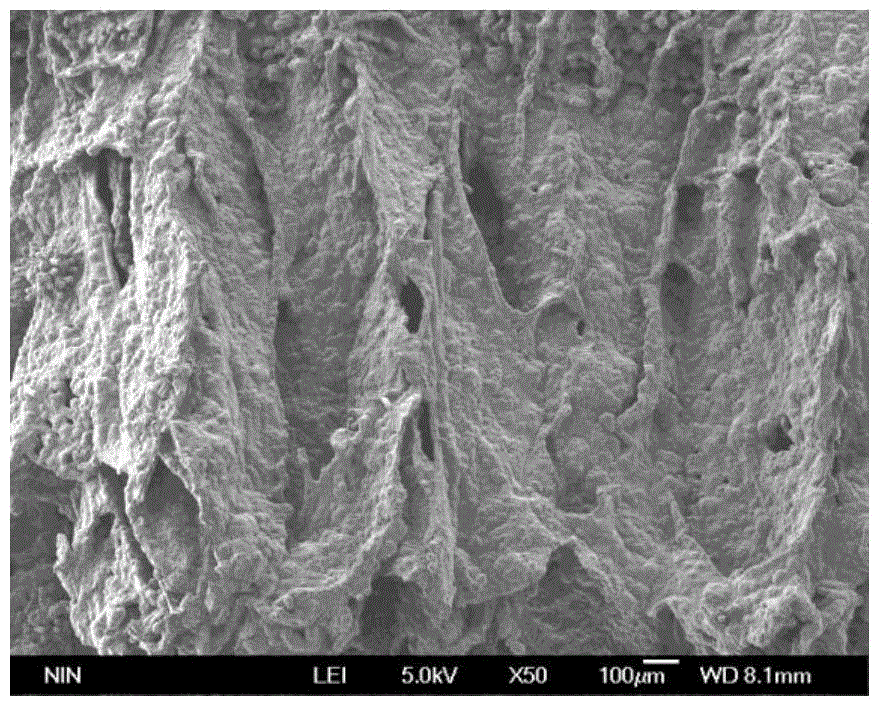

[0030] (3) Put the CNTs suspension in step (2) into a freeze-drying device, freeze at -40°C for 7h, and then freeze-dry at -20°C and 30Pa vacuum for 35h to obtain an airgel preform of CNTs .

[0031] (4) The SiC substrate is deposited by the CVI process. The process conditions are as follows: trichloromethylsilane is the source material, argon is the dilution gas (flow rate 300m1 / min), hydrogen is the carrier gas (flow rate 200m1 / min), hydrogen and trichloro The molar ratio of methylsilane was 10:1, the deposition temperature was 1000 °C, and the...

Embodiment 2

[0033] (1) Dissolve 0.8 g of sodium carboxymethyl cellulose in 99.2 g of deionized water, stir mechanically for 2 h at a stirring speed of 500 r / min, and obtain a colorless and transparent solution with a certain viscosity.

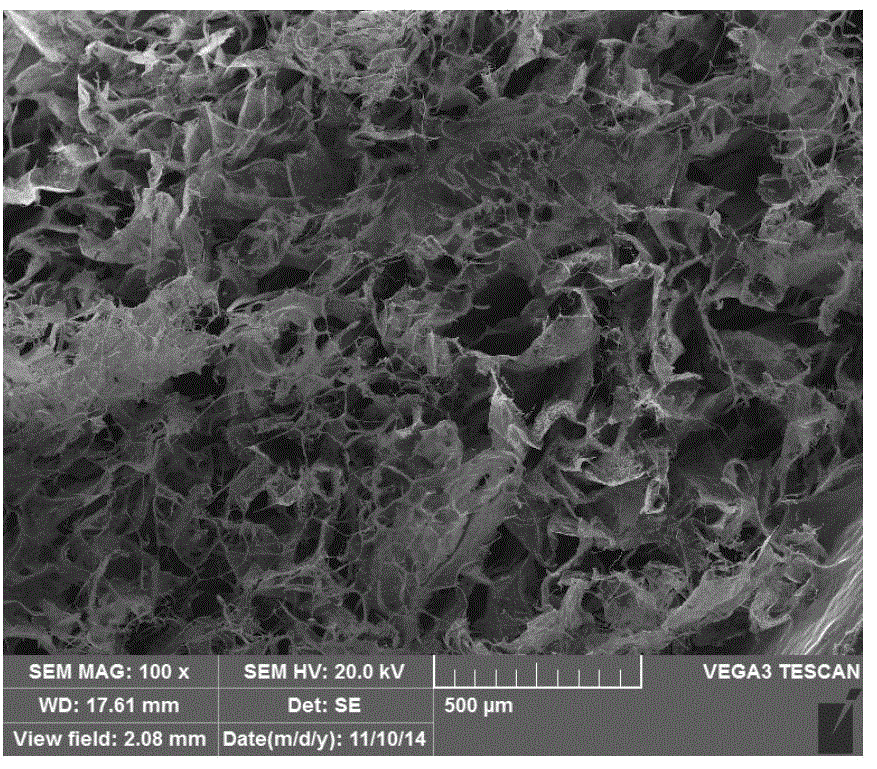

[0034] (2) Add 2 g of SiC nanowires to the solution in step (1), and first mechanically disperse at a speed of 300 r / min for 45 min. , and then ultrasonically dispersed for 50 minutes. A suspension of SiC nanowires was obtained.

[0035] (3) Put the SiC nanowire suspension in step (2) into a freeze-drying device, freeze at -35°C for 5h, and then freeze-dry at -250°C and 15Pa vacuum for 30h to obtain SiC nanowire gas Gel preforms.

[0036] (4) The SiC substrate is deposited by the CVI process. The process conditions are as follows: trichloromethylsilane is the source material, argon is the dilution gas (flow rate 310m1 / min), hydrogen is the carrier gas (flow rate 220m1 / min), hydrogen and trichloro The molar ratio of methylsilane is 10:1, the deposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com