Method for treating corbel with longitudinal crack in riverine highway

A technology of longitudinal cracks and highways, applied in the directions of roads, roads, pavement details, etc., can solve problems such as failure to be effectively solved, longitudinal cracking of pavement, etc., and achieve the effect of solving problems thoroughly, preventing longitudinal cracking, and ensuring durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

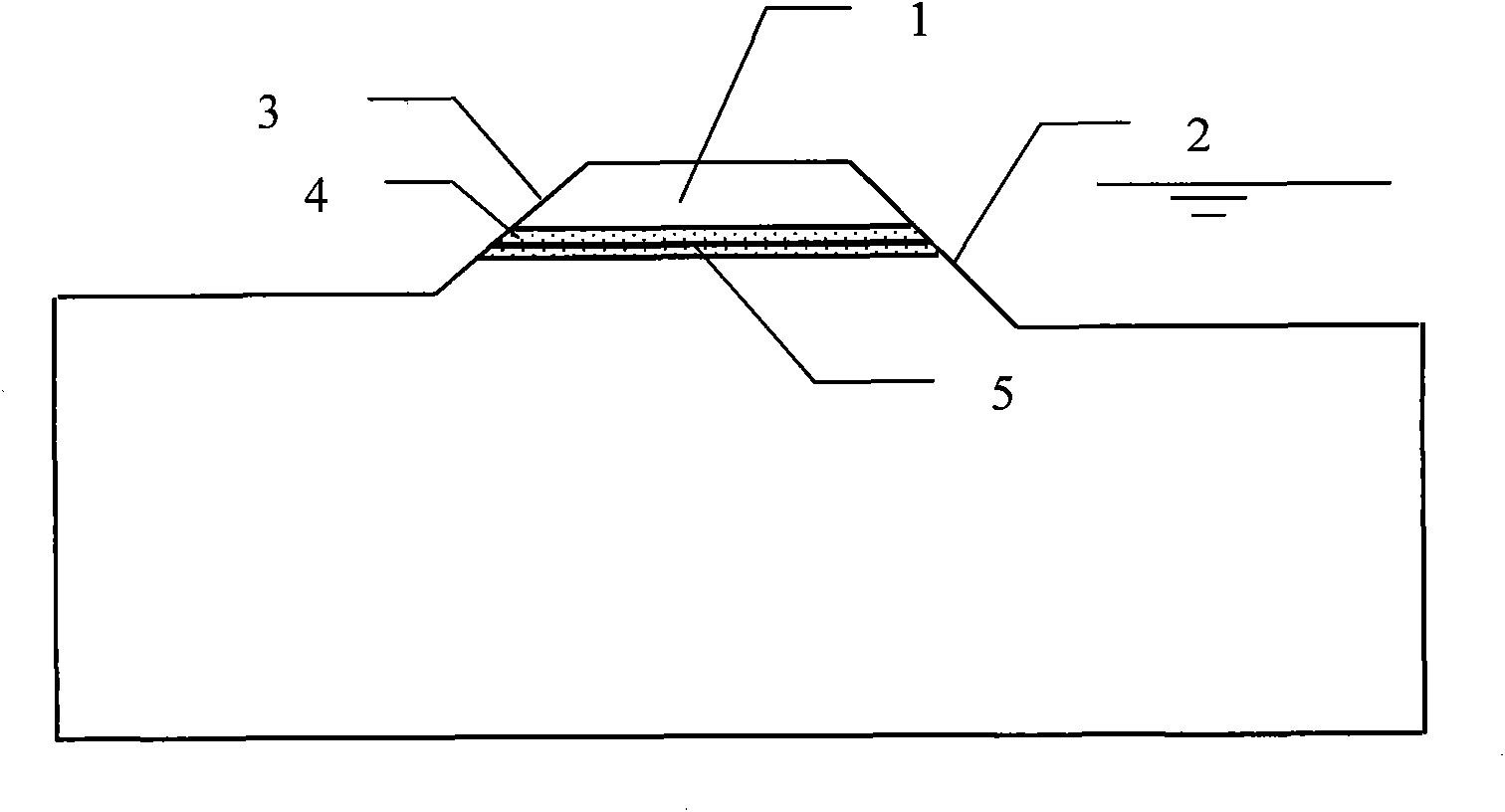

[0020] The purpose of the present invention is achieved like this:

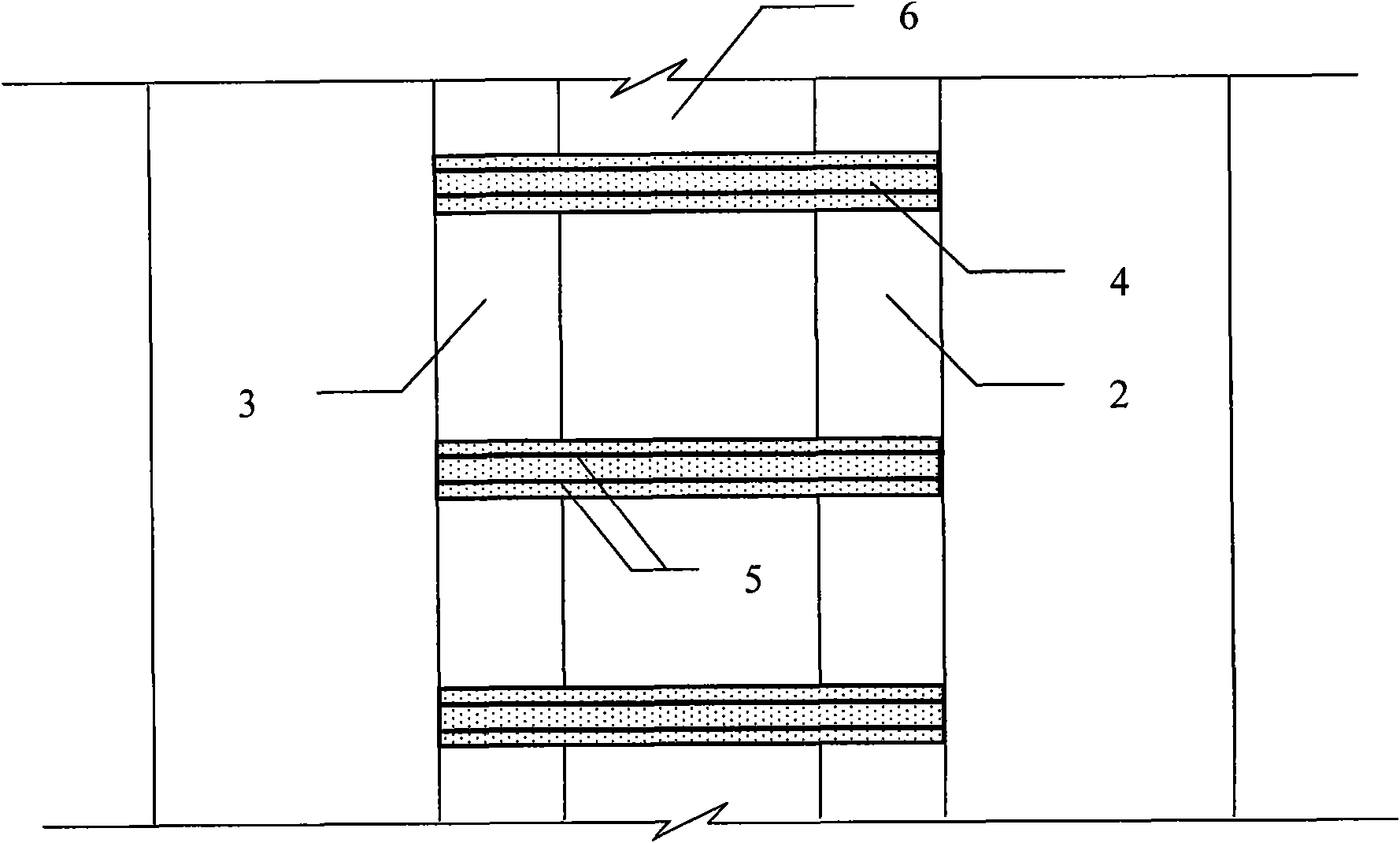

[0021] On the subgrade 1 of the cracked road section, use a cutting machine to groove the road surface in the horizontal direction, the groove width is 200-300mm, dig to the base layer, tamp the base layer and level it, set a full-length steel bar 5 on the leveling layer, pour concrete, and maintain it to form reinforced concrete The corbel 4 is then backfilled with soil, and the pavement is paved; the corbel 4 needs to be placed in parallel at intervals in the cracked road section, with a distance of 5-15 meters, usually 10 meters is better, but it should be selected according to the severity of the crack; The two ends of the corbel 4 are integrally consolidated with the upstream surface 2 and the backwater surface 3 respectively. The slope of the water surface 3 forms a whole; the arrangement of a plurality of corbels 4 forms a roadbed corbel similar to railroad ties.

[0022] On the road surface 6 along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com