Concrete hollow slab bridge with horizontal reinforced bridge deck pavement layer

A bridge deck pavement and hollow slab bridge technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve problems affecting the normal use of hollow slab bridges, bridge transverse force transmission performance decline, and bridge deck longitudinal cracks along hinge joints, etc. , to achieve the effect of easy construction quality, obvious reinforcement effect and avoiding longitudinal cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

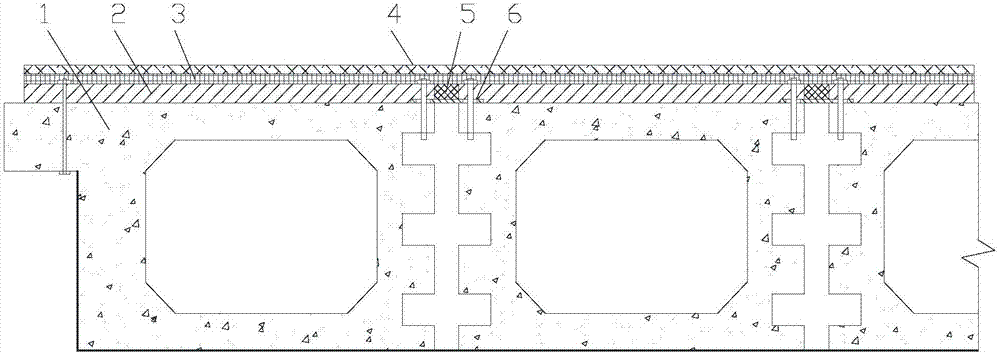

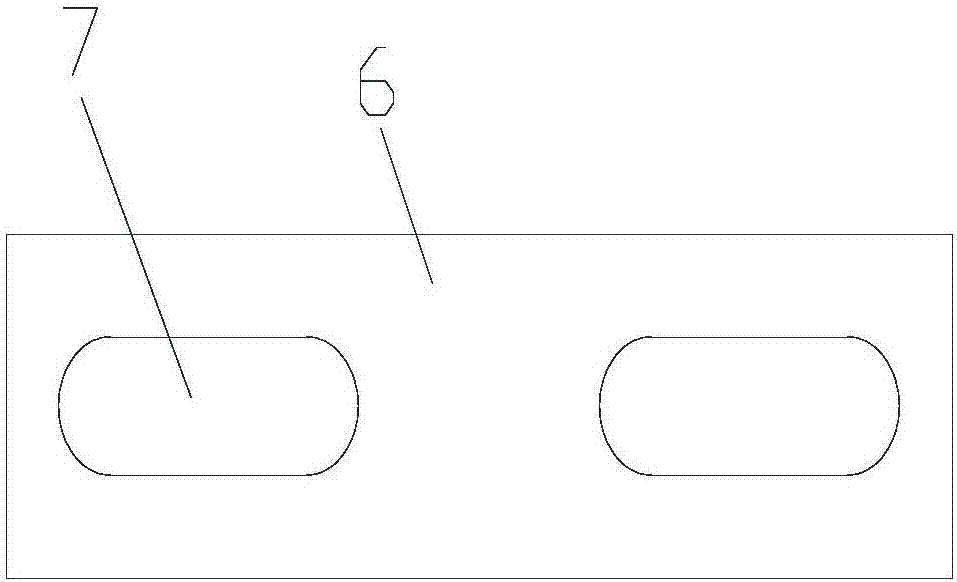

[0016] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the concrete hollow slab bridge with transversely reinforced bridge deck pavement in this embodiment includes a bridge deck beam formed by a plurality of hollow slab girders arranged side by side and arranged on the The transversely reinforced pavement layer on the top surface of the bridge deck beam; the transversely reinforced pavement layer includes a multi-section steel plate 2 correspondingly laid on the hollow plate girder, a sliding layer 4 supported on the steel plate 2 and The asphalt layer laid on the sliding layer 4; the steel plates 2 and the corresponding bridge deck beams are fixed to each other, and two adjacent steel plates 2 are connected by connectors to transmit lateral loads. In this embodiment The transverse load between the hollow slab girders of the hollow slab bridge can be transmitted through the connectors between the steel plates 2, the overal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com