Amorphous alloy-gypsum composite board, preparation method and application thereof.

A technology of gypsum composite board and amorphous alloy, which is applied in the direction of chemical instruments and methods, metal layered products, hydraulic material layered products, etc., and can solve the limitation of the application range of amorphous alloy-metal and the complicated process of electromagnetic shielding materials , difficulty in preparation and other issues, to achieve the effect of improving the flexural strength and cracking resistance, realizing the electromagnetic shielding efficiency, and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

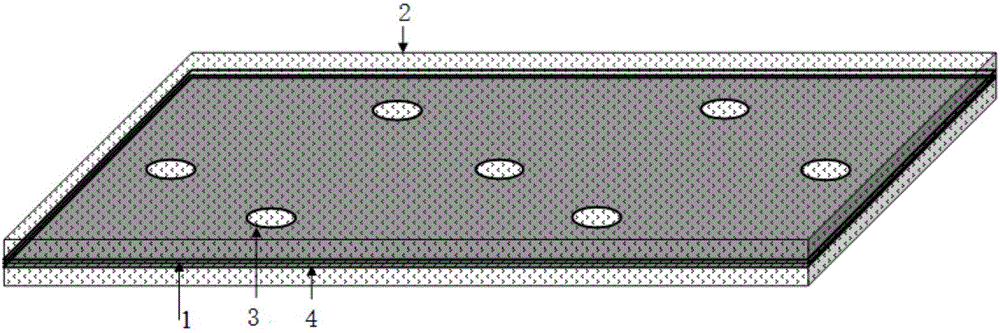

[0079] Provided according to the present invention is an embodiment, providing an amorphous alloy-gypsum composite board, which includes: when the composite board is placed horizontally, one or more layers (preferably 2-10 layers, such as 2 layers or 3 layers or 4 layers) of the amorphous alloy layer 1 and two gypsum layers 2 as the upper and lower layers, and when the composite panel includes the amorphous alloy layer 1 of multiple layers (such as 2 layers or 3 layers), the The composite panel also includes a gypsum layer (or gypsum core layer) 2 as a spacer layer between two adjacent amorphous alloy layers 1 .

[0080] In the above composite board, at least one layer of amorphous alloy layer 1 is included. The gypsum layer 2 is used as the two surface layers of the composite board and, optionally, as the spacer layer between the amorphous alloy layers 1 of two adjacent layers, that is, when the composite board includes a multilayer amorphous alloy layer 1, the gypsum Layer ...

Embodiment 1

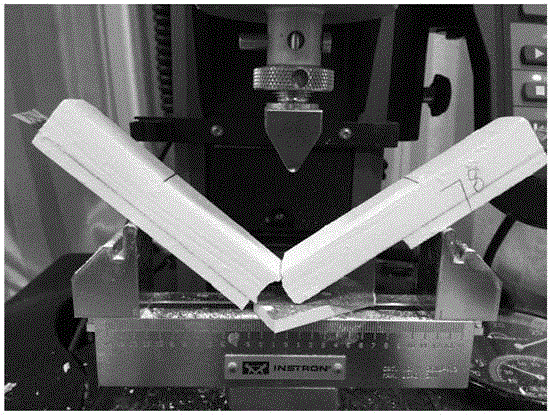

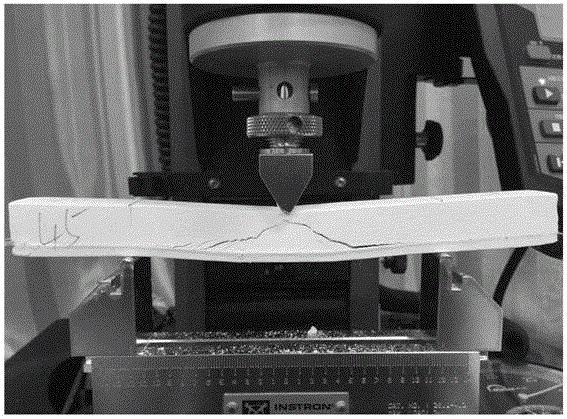

[0118] like figure 1 and figure 2 As shown, an amorphous alloy-gypsum composite board includes: 1 layer of Fe-Si-B amorphous alloy strip layer 1, the grade is 1K101, and a gypsum layer 2, and the amorphous alloy strip layer 1 is set There are circular holes 3 with a diameter of 5mm, and the ratio of the opening area to the area of the amorphous alloy is 2%. The amorphous alloy strip layer 1 is set in the gypsum layer 2 in a sandwich mode. A pre-tensioning force is applied to the amorphous alloy strip layer 1, and the value of the pre-tensioning stress is 60% of the yield strength of the amorphous alloy strip. The thickness of the gypsum layer as the upper layer is 20mm, and the thickness of the gypsum layer as the lower layer is 10mm.

Embodiment 2

[0120] Example 1 was repeated, only the Fe-Si-B amorphous alloy strip layer was 2 layers, the interlayer distance was 3mm, and the diameter of the circular aperture was 5mm. The pre-tension stress value is 40% of the yield strength of the amorphous alloy strip. The thicknesses of the two gypsum layers as the upper and lower layers are 8mm and 4mm respectively. The thickness of the gypsum layer as the spacer layer was 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com