Core tube structure system with transfer layer

A core tube and transfer layer technology, applied in special structures, building components, etc., can solve the problems of reducing the proportion of earthquake shear force, increasing the thickness of the core tube wall, increasing the cost, etc., reducing the axial force and increasing the vertical structure of the structure. The effect of the force transfer path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

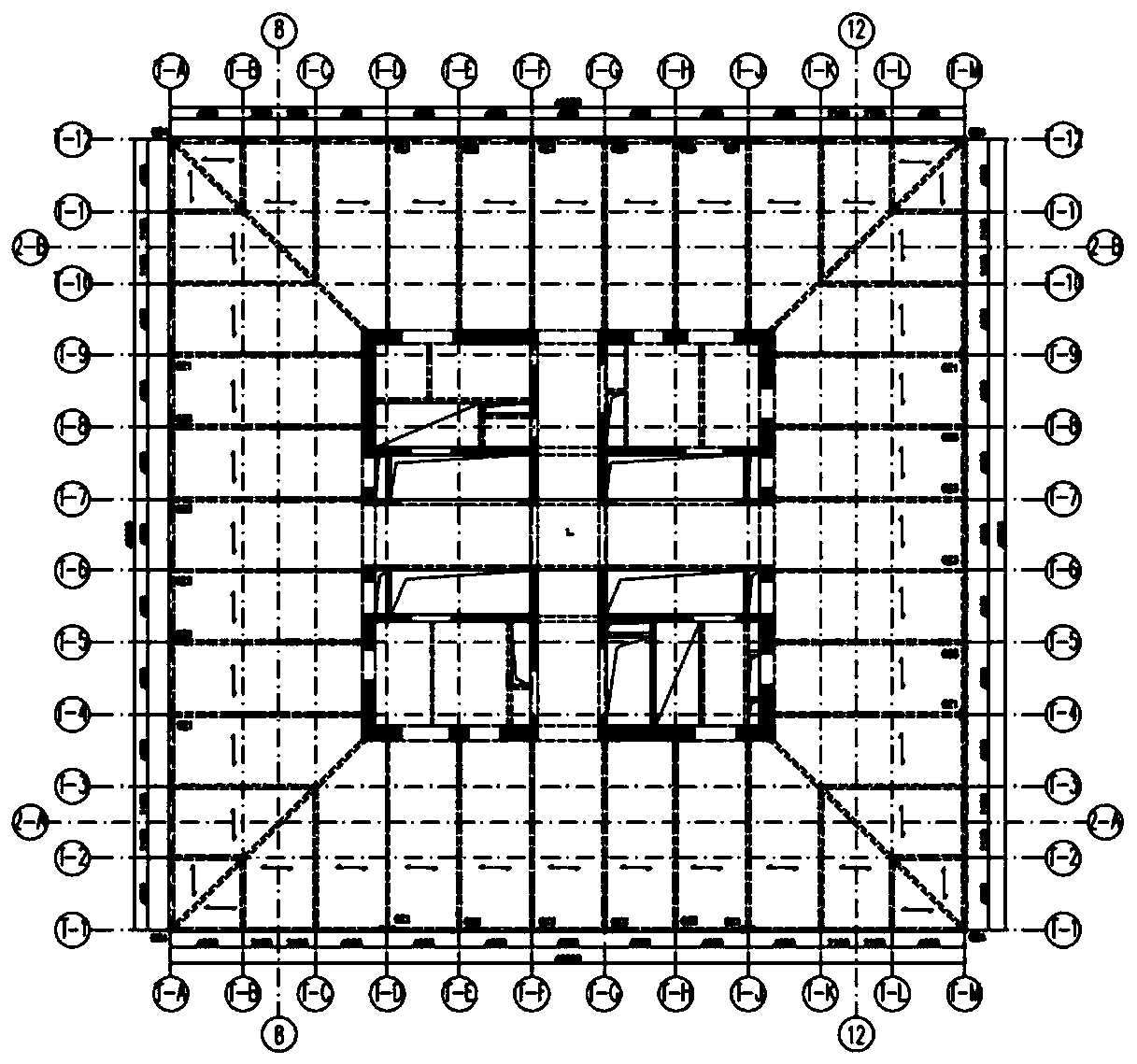

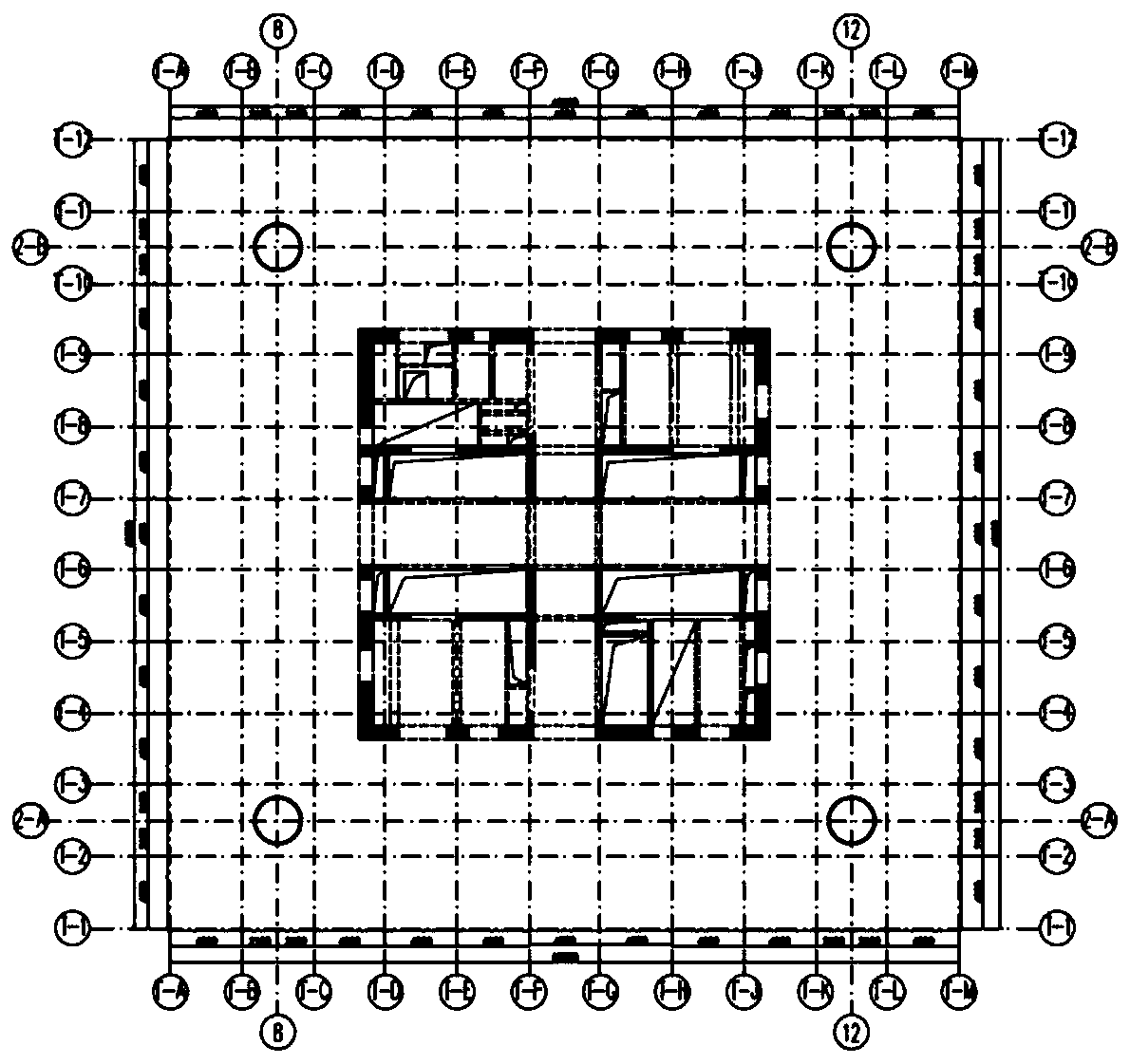

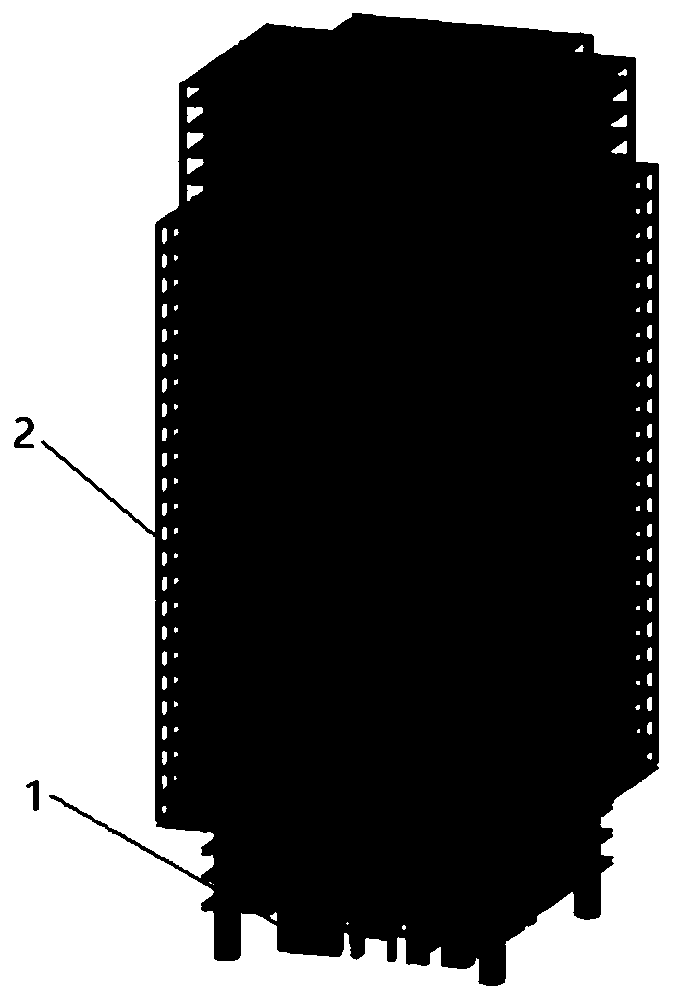

[0027] This embodiment provides a core tube structure system with a conversion layer, including a core tube 1 and an outer frame 2, and the outer frame 2 is arranged on the periphery of the core tube 1, such as image 3 shown.

[0028] The outer frame 2 is an outer frame with a conversion structure, including a frame body and an umbrella-shaped conversion layer. The system adopts an umbrella-shaped transfer layer, so that the upper outer frame column does not fall to the ground, which meets the requirements of the architectural form, and at the same time increases the vertical force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com