High-molecular-weight polyester amide resin based on 1, 2-propylene glycol and preparation method of high-molecular-weight polyester amide resin

A polyester amide and high molecular weight technology, which is applied in the field of high molecular weight polyester amide resin and its preparation, can solve the problems of poor mechanical properties, difficulty in obtaining high molecular weight polyester materials, low reactivity, etc., and achieve product mechanical properties better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

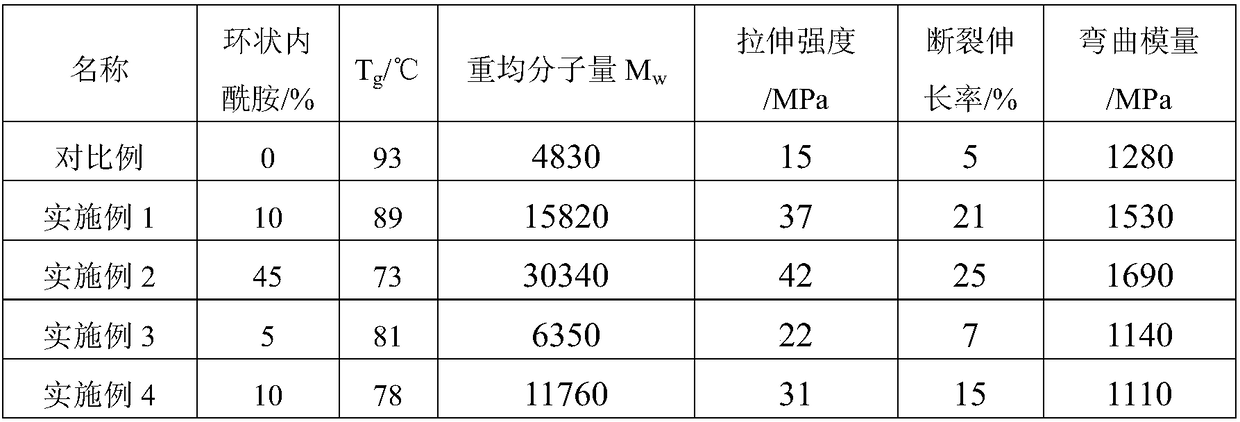

Examples

Embodiment 1

[0055] (1) 45 parts of terephthalic acid, 45 parts of 1,2-propanediol, and 0.02 parts of the first catalyst zinc acetate are sequentially added to a high-pressure reactor with a condensation and vacuum device;

[0056] (2) Vacuumize the autoclave and fill it with nitrogen three times, replace the air in the autoclave to ensure that the esterification reaction is carried out under nitrogen, and heat up to 220 ° C for 2 hours under stirring and condensation until the condensate The amount of water reaches 92% of the theoretically calculated amount (the theoretically calculated amount of condensate water reaches twice the molar amount of terephthalic acid);

[0057] (3) Add 0.02 parts of the second catalyst tetra-n-butyl titanate and 0.02 parts of triphenyl phosphite, and when the temperature is raised to 260 ° C, the vacuum is pumped to 50 Pa, and the reaction is carried out for 1.5 hours;

[0058] (4) Add 10 parts of caprolactam, fill the reactor with nitrogen until the pressur...

Embodiment 2

[0061] (1) Add 25 parts of dimethyl terephthalate, 30 parts of 1,2-propanediol, and 0.01 part of the first catalyst dibutyltin oxide into a high-pressure reactor with a condensation and vacuum device;

[0062] (2) Vacuumize the autoclave and fill it with nitrogen three times, replace the air in the autoclave to ensure that the transesterification reaction is carried out under nitrogen, and heat up to 170°C for 3 hours under stirring and condensation until the condensate The amount of methanol reaches 92% of the theoretically calculated amount (the theoretically calculated amount of condensate methanol reaches twice the molar amount of dimethyl terephthalate);

[0063] (3) Add 0.01 part of the second catalyst antimony trioxide, 0.01 part of trimethyl phosphate, vacuumize to 300 Pa when the temperature is raised to 240 ° C, and react for 3 hours;

[0064] (4) Add 45 parts of caprolactam, fill the reactor with nitrogen until the pressure reaches 50kPa, and react at a constant tem...

Embodiment 3

[0067] (1) 50 parts of terephthalic acid, 45 parts of 1,2-propanediol, and 0.06 parts of the first catalyst tetraethyl titanate were sequentially added to a high-pressure reactor with a condensation and vacuum device;

[0068] (2) Vacuumize the autoclave and fill it with nitrogen three times, replace the air in the autoclave to ensure that the esterification reaction is carried out under nitrogen, and heat up to 230°C for 1 hour under stirring and condensation until the condensate The amount of water reaches 92% of the theoretically calculated amount (the theoretically calculated amount of condensate water reaches twice the molar amount of terephthalic acid);

[0069] (3) Add 0.06 parts of the second catalyst dibutyltin dilaurate, 0.06 parts of triphenyl phosphate, and vacuumize to 450Pa when the temperature is raised to 280 ° C, and react for 1 hour;

[0070] (4) Add 5 parts of lauryl lactam, fill the reactor with nitrogen until the pressure reaches 10kPa, and react at a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com