A structure to prevent bolt slippage in steel plate shear wall with seams

A steel plate shear wall and slotted technology, which is applied in building construction, earthquake resistance, building components, etc., can solve problems such as loud noise, bolt slippage, reducing bearing capacity, deformation and energy dissipation capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

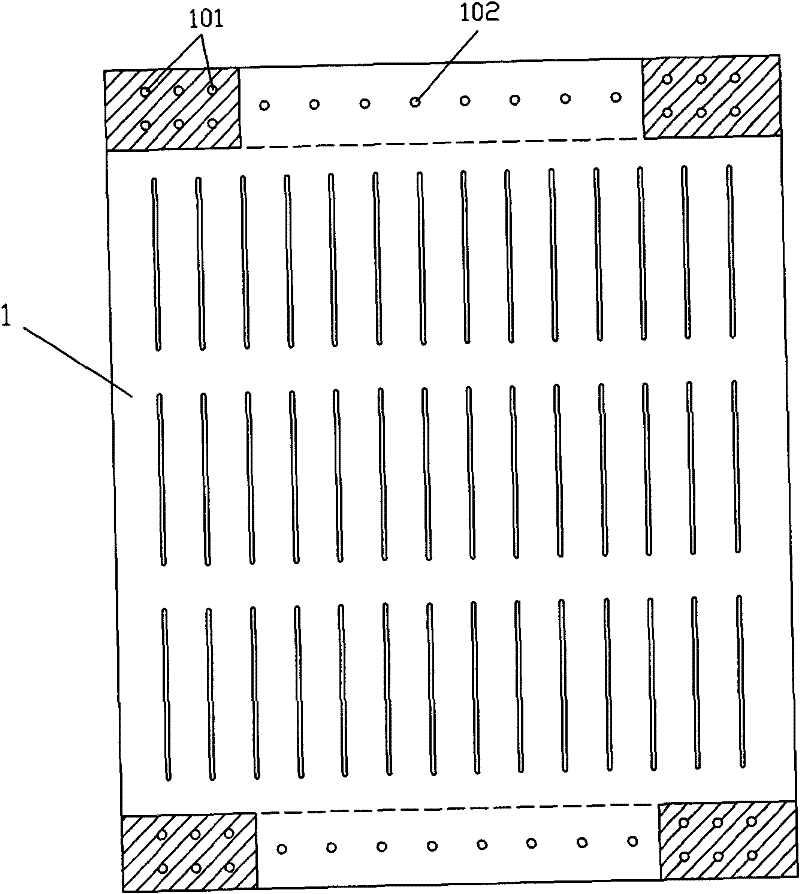

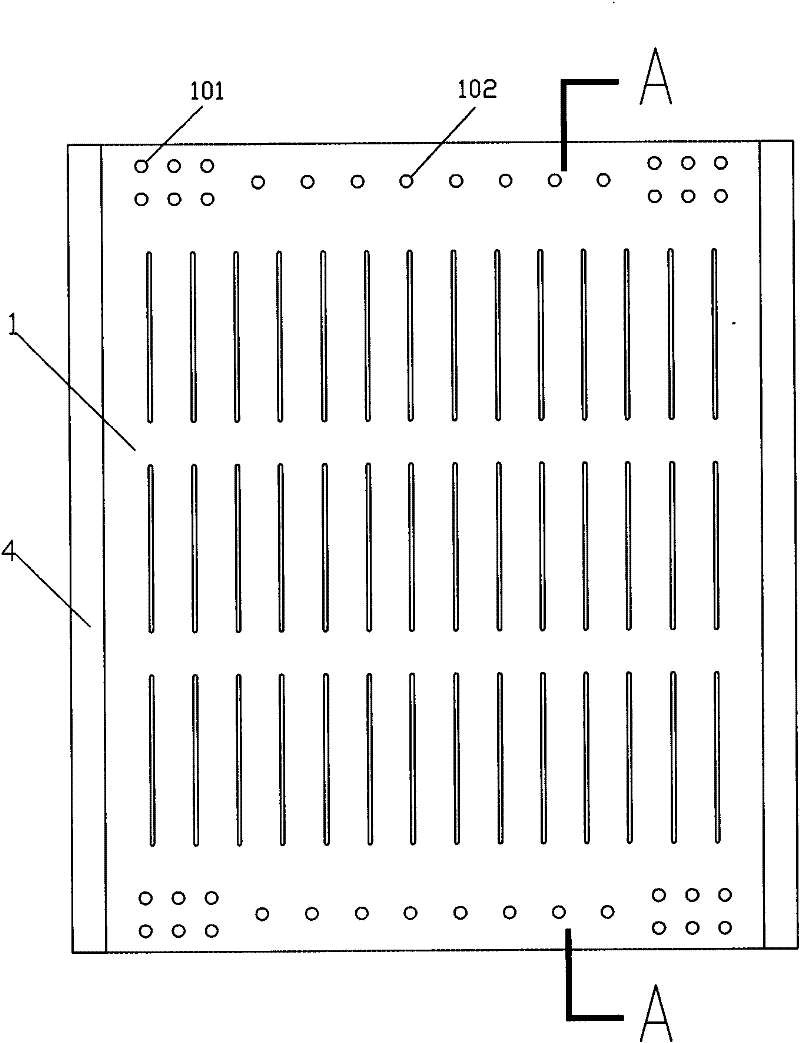

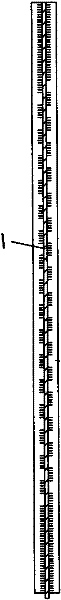

[0046] see Figure 1 to Figure 6 , the structure of the present invention to prevent the bolts connecting the steel plate shear wall with seams and the frame beam from slipping, the upper and lower ends of the main steel plate with vertical seams 1 are respectively provided with bolt holes 101, 102 for connecting with the upper and lower frame beams 2, 3, and the bolts The holes 101, 102 adopt a non-uniform arrangement form, that is, the arrangement density of the bolt holes 101 at the upper and lower corners of the main steel plate 1 with vertical seams is greater than the arrangement density of the bolt holes 102 in the middle part; Stiffening 4, and the stiffening 4 forms a closed stiffening system along the periphery of the main steel plate 1 with vertical seams.

[0047]The bolt holes 101 at the upper and lower corners of the main steel plate 1 with vertical seams are arranged in two rows, and each row is provided with three bolt holes; the middle bolt holes 102 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com