Piston reciprocating tank engine

An engine and tank technology, applied in the field of piston reciprocating tank engines, can solve the problems of occupying tank space and fixed investment costs, increasing tank fixed investment and complexity, occupying tank space and carrying capacity, etc., to reduce complexity and fixed investment. The effect of cost, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

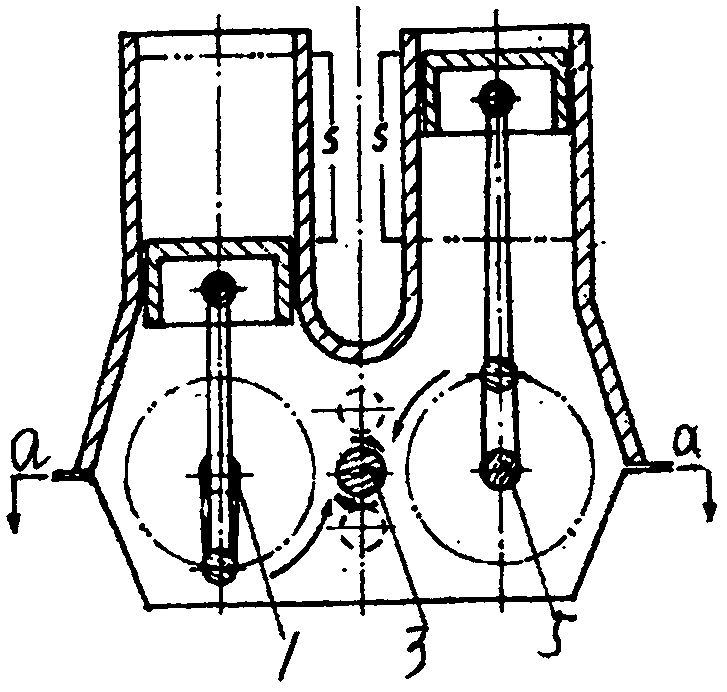

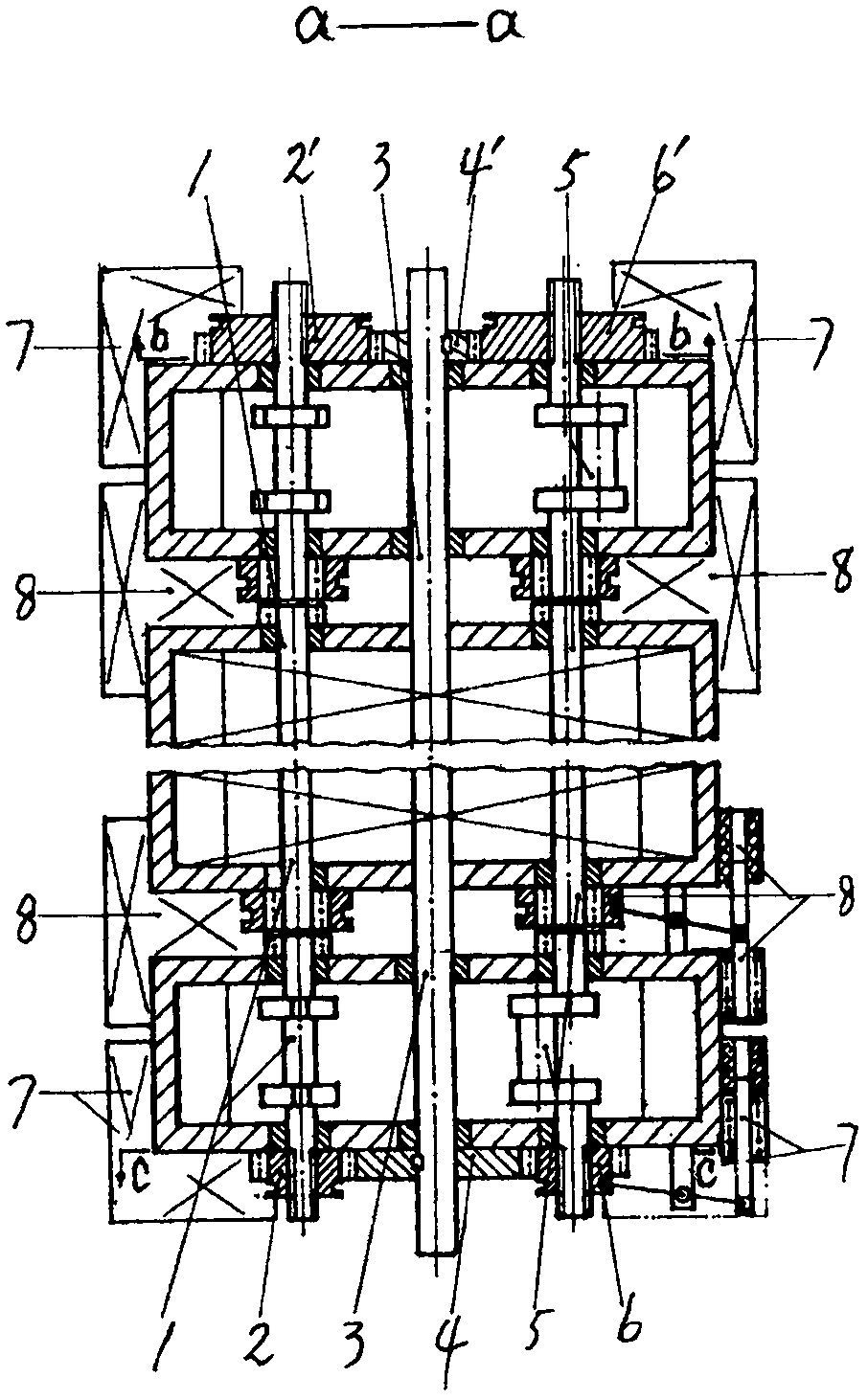

[0044] Such as figure 1 Shown: The same L-shaped two cylinders are connected vertically and parallelly to form a U-shaped double cylinder, combined figure 2 It shows that multiple rows of U-shaped twin cylinders are connected in series to form an engine composed of multiple rows of U-shaped twin cylinders.

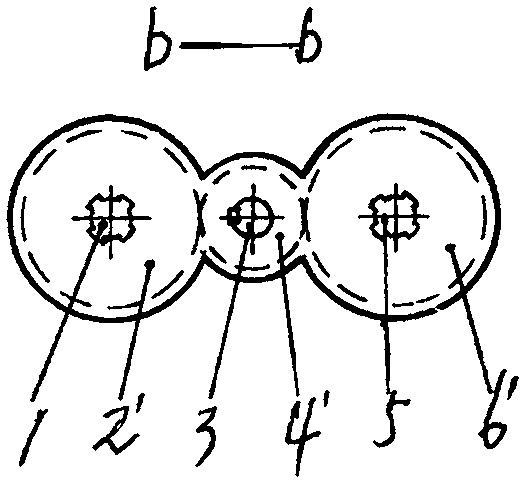

[0045] figure 1 to combine figure 2 Shown: the power transmission system of the engine is composed of left and right crankshafts (1, 5), output shaft (3), left and right crankshaft gears (2, 6), and output shaft gears (4); the output shafts are arranged on the left and right On the vertical line in the middle of the line connecting the crankshaft centers, its up and down positions can be above or below the line connecting the centers of the two crankshafts, such as figure 1 The dotted line in the small circle shows that it can also be made on the connecting lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com