Fabricated concrete hollow floor structural system

A hollow floor and hollow structure technology, which is applied to floors, building components, building structures, etc., can solve the problems of high quality of hollow floors, easy occurrence of air bubbles on the lower flange, time-consuming and labor-intensive formwork, etc., and achieve the goal of construction work The effect of weight reduction, self-weight reduction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

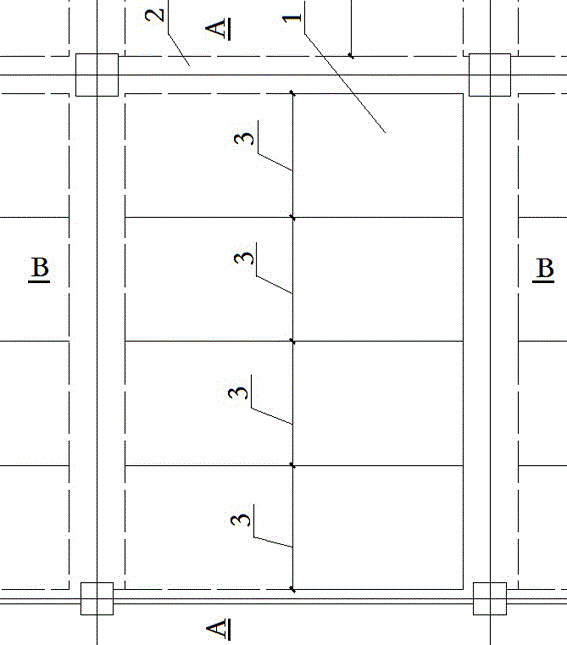

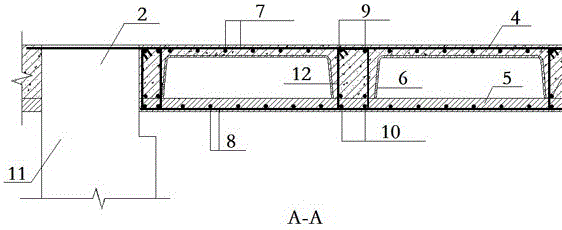

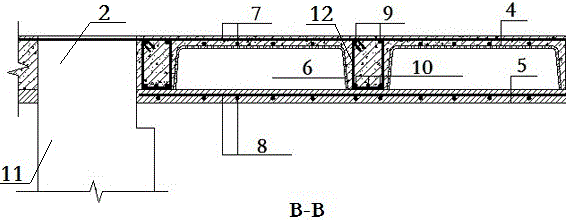

[0029] Embodiment: the cast-in-place thickness of the slab top in the hollow slab is 50-100mm, the prefabricated thickness of the slab bottom is 60-100mm, and the size of the hollow box in the middle is 500X500-900x900mm. During the construction process, the bottom formwork of the floor slab is formed by prefabricating the bottom slab and the intermediate foam box. After the upper steel bars are installed, concrete is poured to form a hollow floor. The shaped beam bears the vertical load, and the force is more reasonable, which greatly reduces the self-weight of the floor slab, and saves materials such as formwork, steel bars and concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com