Wind turbine drive train

A technology for wind turbines and driving mechanisms, which is applied in the directions of wind turbines, wind turbine control, wind turbine combination, etc., can solve problems such as discrete supports, and achieve the effects of reducing the number, reducing the cost of components, and reducing subsequent loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

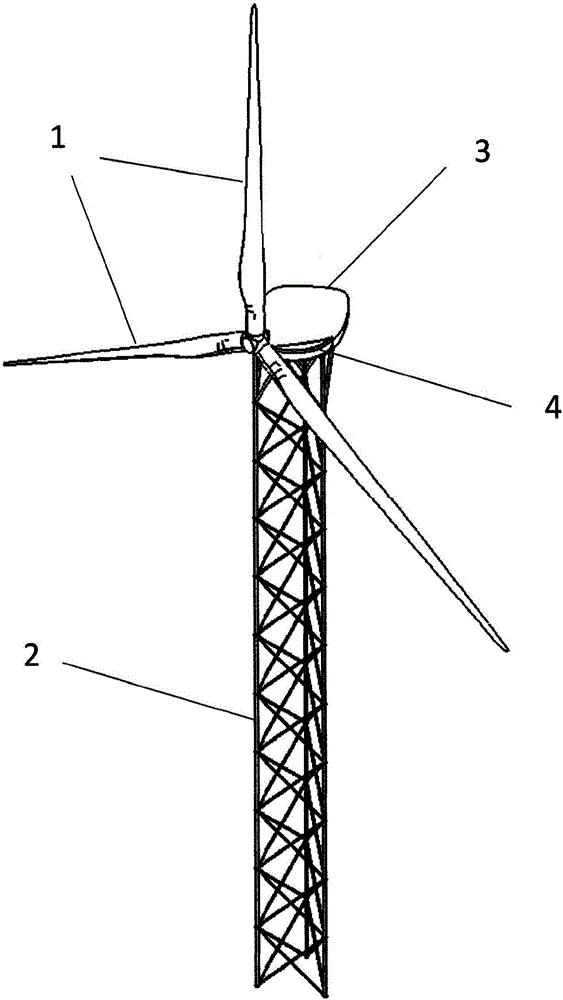

[0029] figure 1 The wind turbine shown is a horizontal axis wind turbine with three blades (1) facing downwind and a lattice tower (2) whose three legs are equal to each other along its entire length separated by distance. A connecting piece (4) is arranged between the nacelle (3) and the tower (2), on which connecting piece (4) the drive mechanism of the object of the invention (not shown in the figure) is arranged.

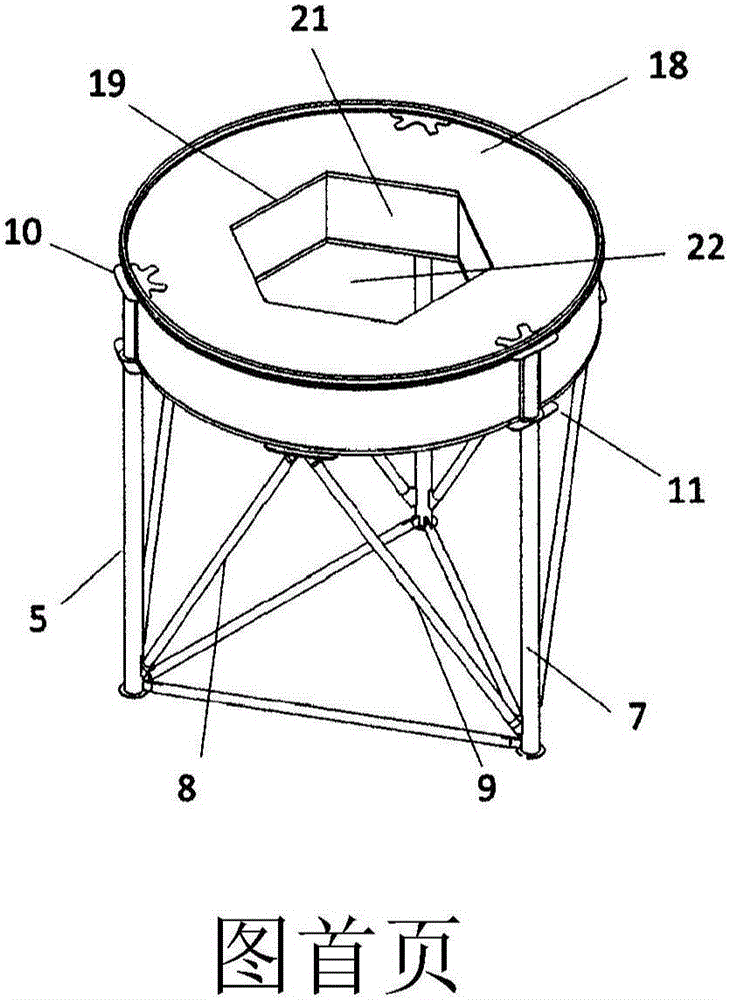

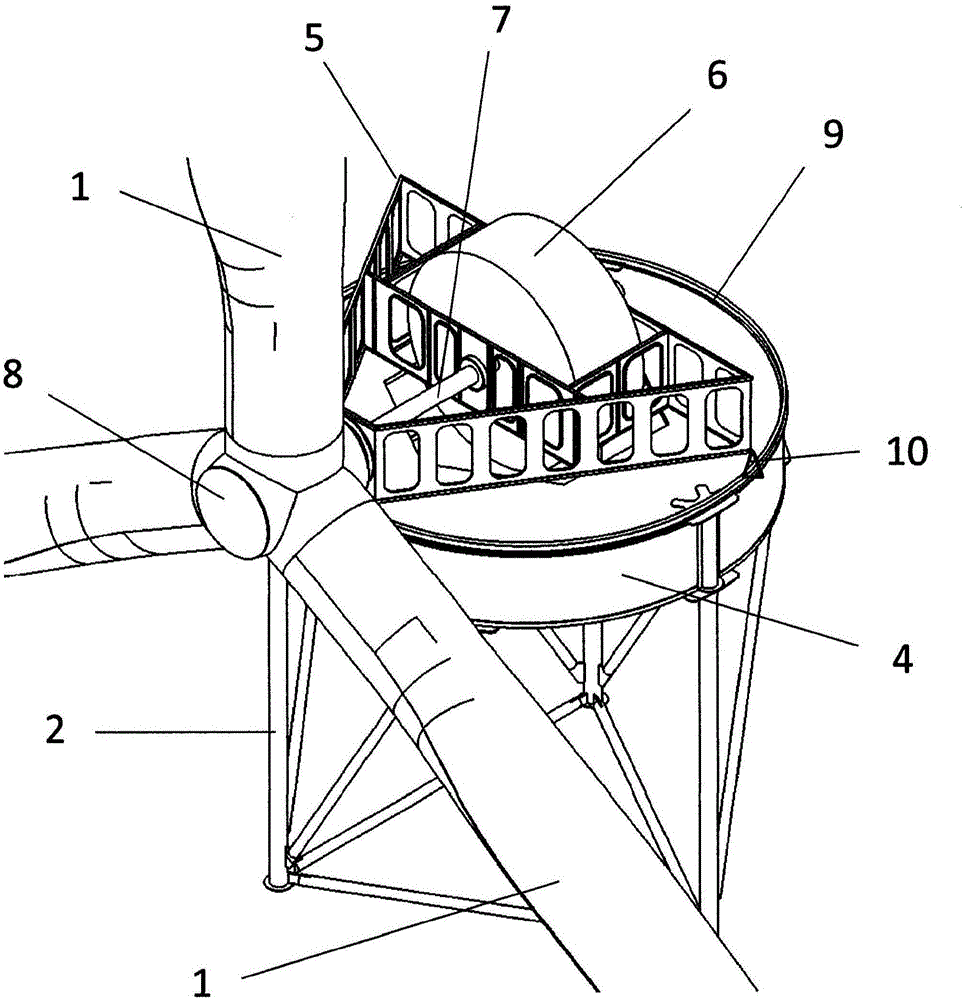

[0030] like figure 2 and image 3 As shown, the lattice tower (2) supports the connector (4), the triangular main frame (5) houses the generator (6) and the main shaft (7) inside and supports the rotor (8) at one end thereof, and the triangular The main frame (5) is arranged on the connecting piece (4). The rolling ring or raceway (9) is part of the rotation system (yaw) and is arranged on top of the link (4). Said rotation system consists of the mentioned ring (9) and three supports (10) each arranged at each vertex of the triangle forming the main frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com