RV speed reducer cycloidal gear contour profiling method based on deformation quantity compensation

A cycloidal gear tooth and deformation technology, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve the problem of affecting the transmission stability and transmission accuracy, and does not consider the force and deformation of the cycloidal pin wheel meshing pair transmission, etc. problem, to achieve the effect of improving stiffness and eliminating transmission error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]The following figures will further illustrate the present invention in conjunction with the accompanying drawings and embodiments, and this embodiment should not be regarded as a limitation of the present invention.

[0049] In this embodiment, the cycloidal pin tooth meshing pair of RV40E is taken as an example, and its basic parameters are:

[0050] R z = 64; Z p =40;z g = 39; e = 1.3; r z =3.

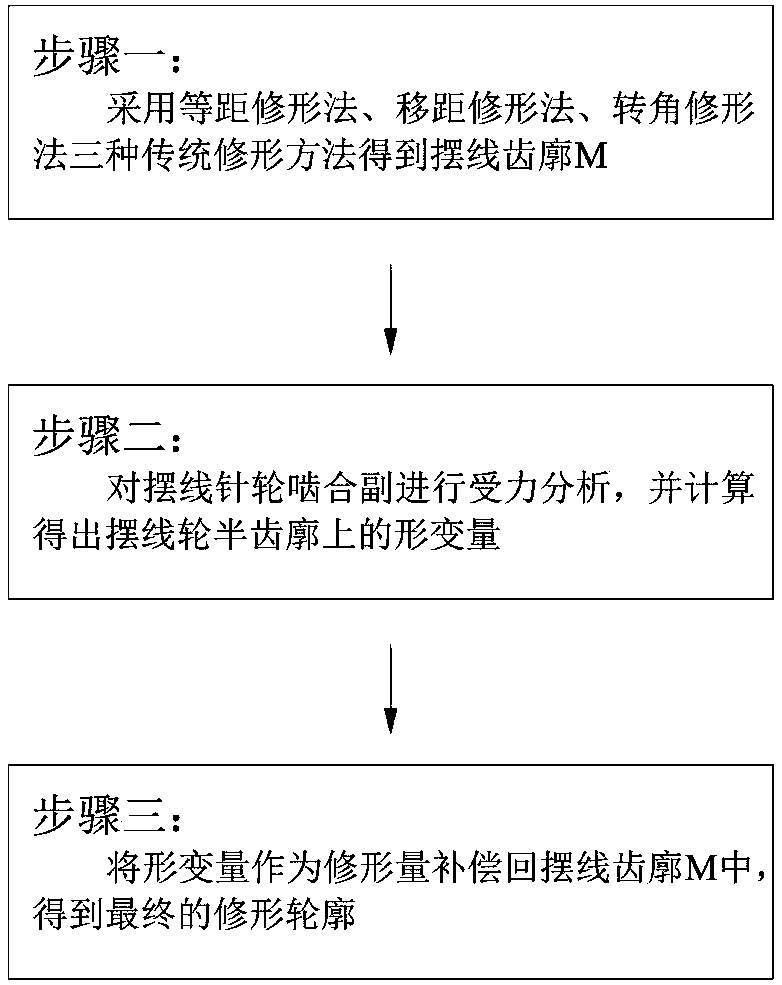

[0051] Step 1: Use three traditional modification methods to obtain the cycloid tooth profile M

[0052] According to the method described in literature [1], solve to obtain the appropriate equidistant modification amount Δr rp =-0.105 and distance modification Δr p =-0.12

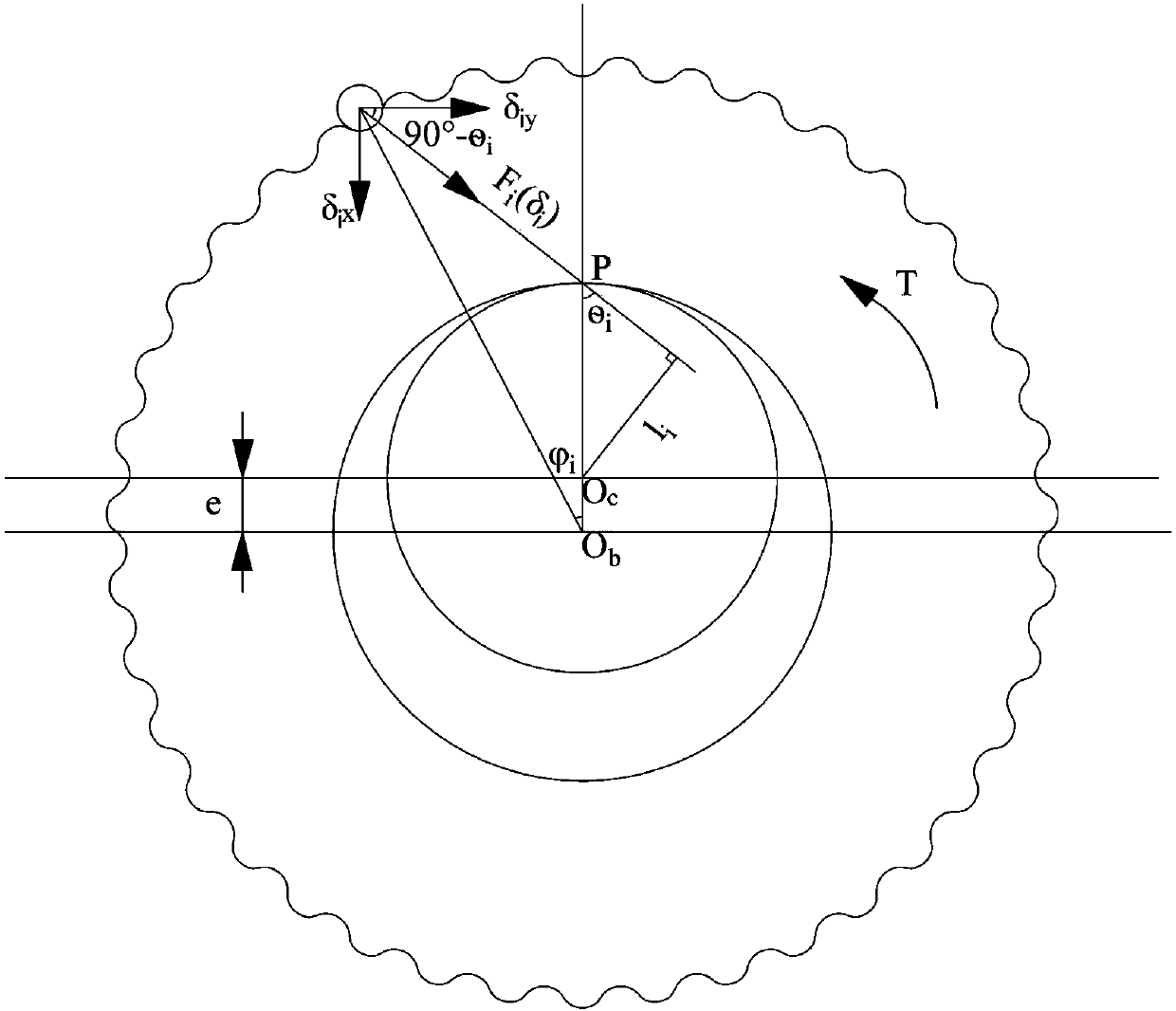

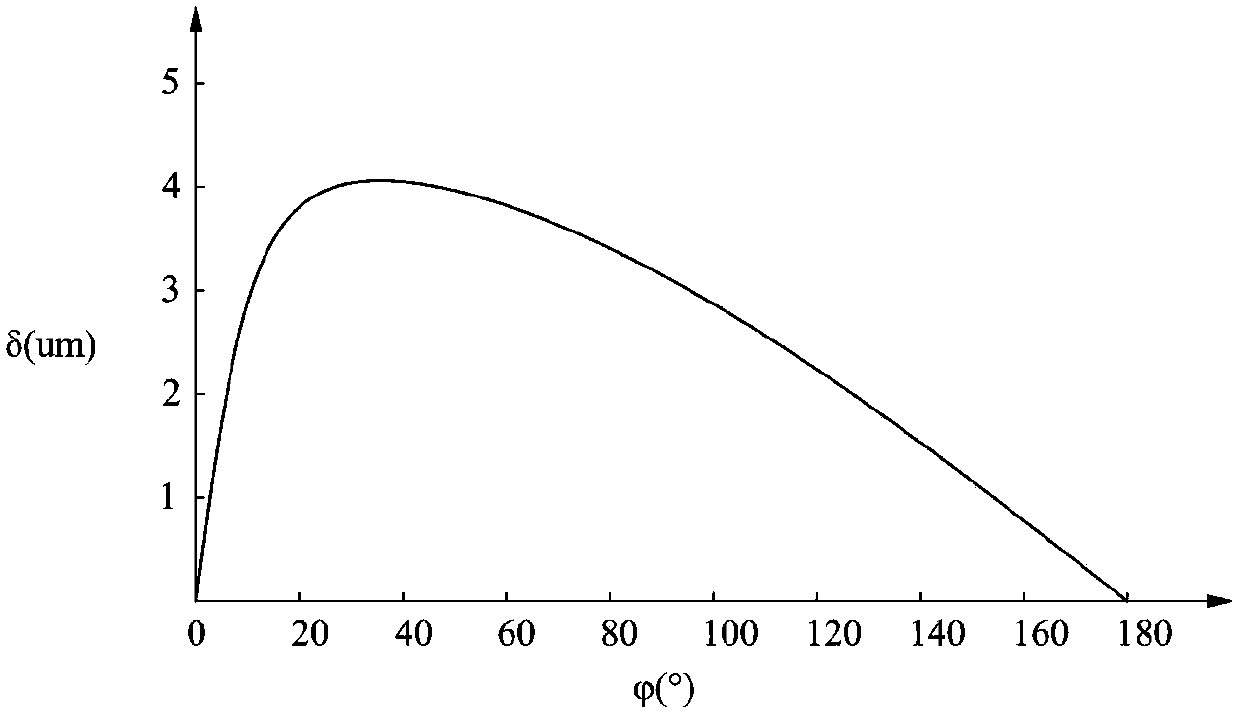

[0053] Step 2: Carry out force analysis on the meshing pair of cycloidal pinwheel, and calculate the tooth profile variable of cycloidal tooth profile

[0054] 1) Calculate the maximum load F of the tooth with the maximum force max

[0055]

[0056] Assuming that the RV reducer works under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com