Forme roller gap-free transmission connection device

A technology of transmission connection and printing plate roller, applied in printing, printing press, rotary printing press, etc., can solve the problems of difficult work, difficult synchronization of each plate roller, transmission error, etc., and achieve the effect of convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

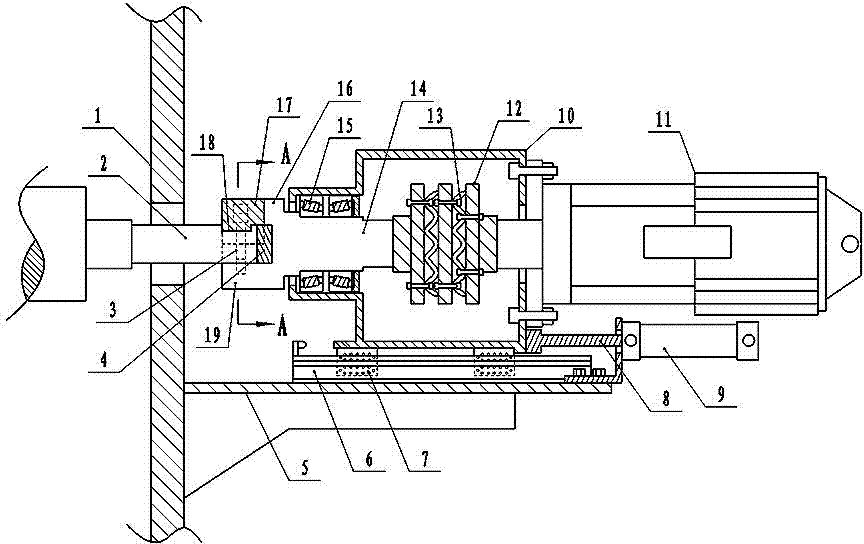

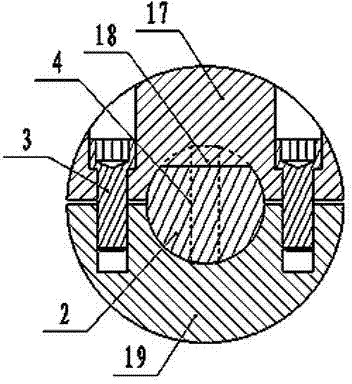

[0012] Example: such as figure 1 and figure 2 As shown, a printing plate roller gapless transmission connection device is installed on the frame 1 of the printing machine and at the corresponding position of the printing plate roller shaft head 2. The device consists of a support plate 5, a slide rail 6, a bearing slider 7, Fixed box 10, servo motor 11, shaft coupling 12, connecting shaft 14 and cylinder 9 are formed, support plate 5 is installed on the frame 1 side of printing press, vertical with frame, slide rail 6 is installed on support plate 5, slides Fixed box 10 is installed on rail 6, is connected with bearing slide block 7 between the bottom of fixed box 10 and slide rail 6, and servomotor 11 is installed in one end of fixed box 10, and the rotating shaft of servomotor 11 goes deep in fixed box 10, and the shaft head Coupling 12 is installed, the other end of coupling 12 is installed connecting shaft 14, the middle part of connecting shaft 14 passes through bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com