Glass fiber bobbin transporting device and control method thereof

A technology of transportation device and glass fiber yarn, which is applied in the field of glass fiber yarn bobbin transportation device and its control, can solve the problems of high labor cost and low work efficiency, achieve low labor cost, high work efficiency, and improve speed and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

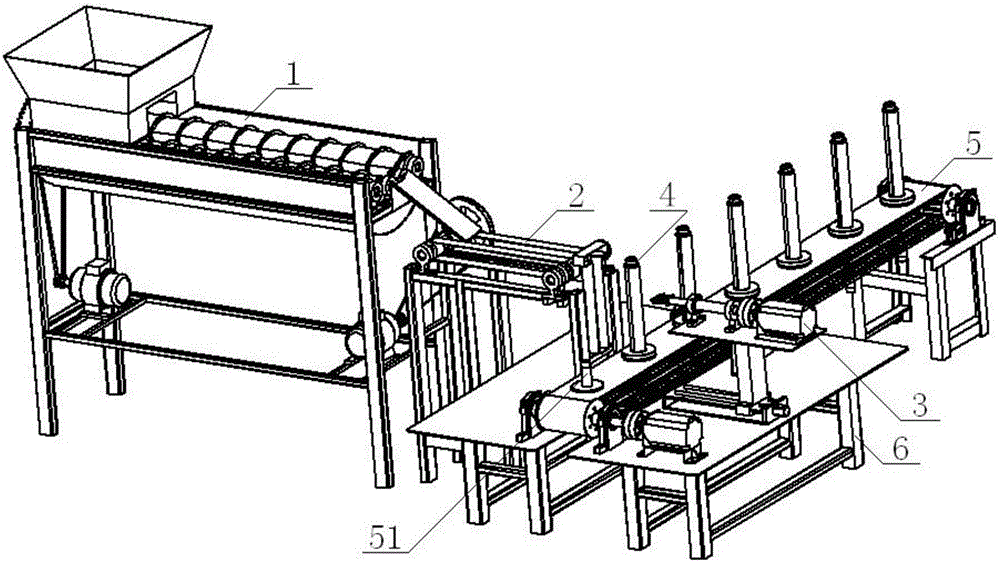

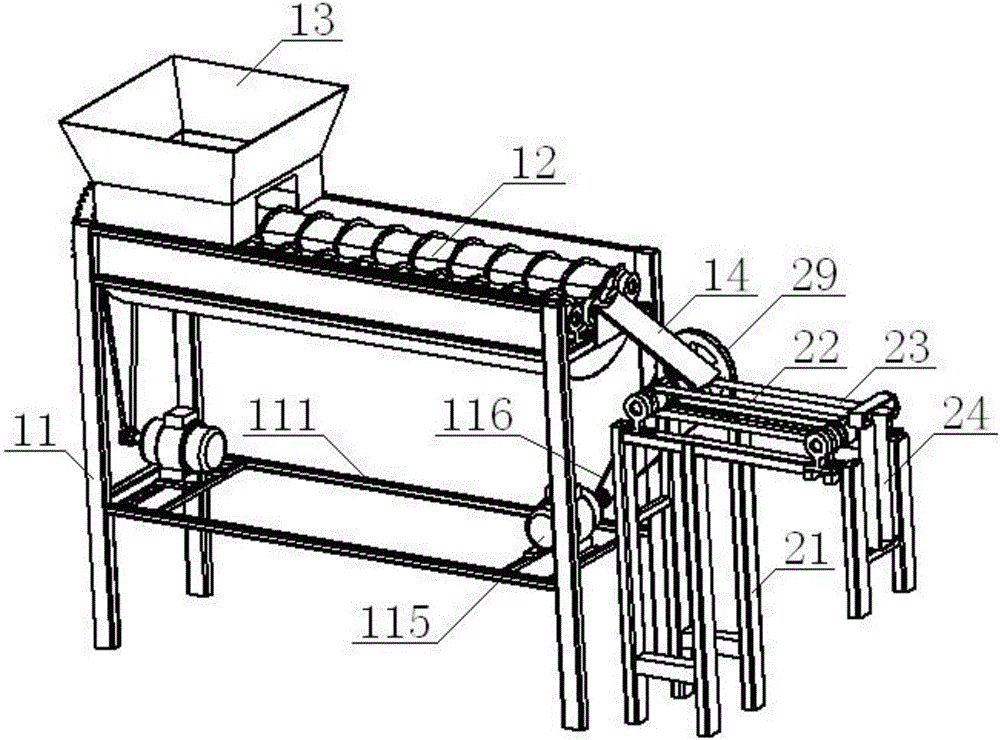

[0061] see Figure 1 to Figure 8 , a glass fiber bobbin transport device, comprising a synchronous toothed belt 5, bobbin 4, the bobbin 4 is placed on the synchronous toothed belt 5; the glass fiber bobbin transport device also includes a feeding part 1, Bobbin positioning part 2, bobbin turning part 3, described synchronous toothed belt 5 is installed on the frame 6, one side of synchronous toothed belt 5 is provided with bobbin positioning part 2, the other side of synchronous toothed belt 5 The bobbin turning part 3 is arranged on the side, and the side of the bobbin positioning part 2 away from the synchronous toothed belt 5 is provided with a feeding part 1; the feeding part 1 includes a feeding frame 11 and a pair of To the rotating roll 12, the position above the one end of the opposite rotating roll 12 on the said feeding frame 11 is equipped with a bobbin bin 13, and the position on the feeding frame 11 located at the other end of the opposing rotating roll 12 is inst...

Embodiment 2

[0064] Basic content is the same as embodiment 1, the difference is:

[0065] see Figure 1 to Figure 5 , the positioning frame 21 includes a No. 1 support 211, a No. 2 support 212, and a No. 3 support 213. The No. 1 support 211 and the No. 2 support 212 are parallel to each other, and the No. 1 support 211 is connected to the No. The No. 1 bracket 212 is connected, the No. 1 bracket 211 is perpendicular to the No. 3 bracket 213, and the No. 1 bracket 211 is connected with the No. 3 bracket 213 through the No. 1 crossbeam 215, and the No. 2 bracket 212 is mutually perpendicular to the No. 3 bracket 213. Vertical, and No. two support 212 is connected with No. three support 213 by No. two beam 216, and described No. three support 213 is installed on the frame 6; Described No. three support 213 comprises No. one vertical beam 217, No. two vertical beam 218, No. 2 longitudinal beam 219, one end of the No. 2 longitudinal beam 219 is vertically connected with the No. 1 vertical bea...

Embodiment 3

[0067] Basic content is the same as embodiment 1, the difference is:

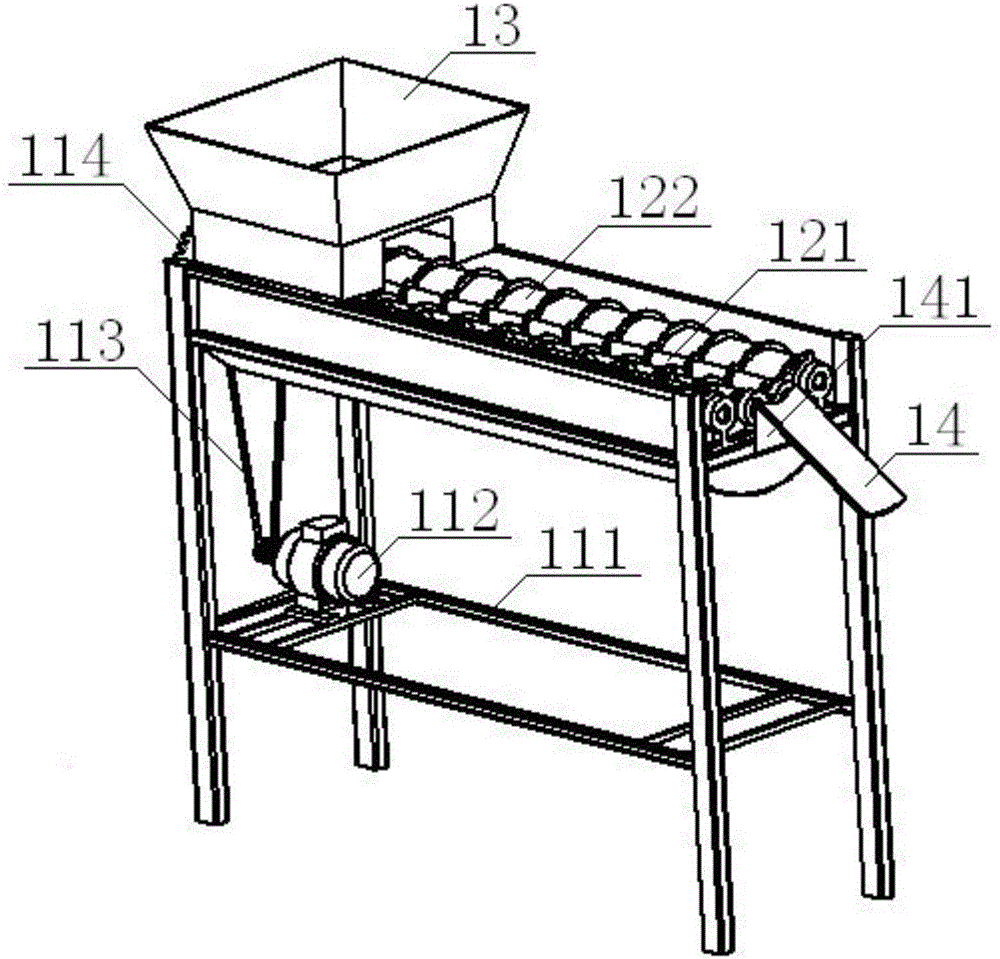

[0068] see Figure 1 to Figure 5 , the bottom of the feeding frame 11 is provided with a mounting bracket 111, and one end of the mounting bracket 111 is provided with a No. 1 motor 112, and the No. 1 motor 112 is connected with the No. 1 pulley 114 through a No. 1 belt 113. The mounting bracket The other end of 111 is provided with No. 2 motor 115; Said opposite rotating roll 12 comprises two No. 1 rotating rolls 121 that are in contact with each other, and both sides of No. 1 rotating roll 121 are provided with No. 2 rotating roll 122 that contacts with it. , the outer diameter of No. 2 rotating roll 122 is greater than the outer diameter of No. 1 rotating roll 121, and No. 1 rotating roll 121 is connected with No. 1 pulley 114; , the angle between the bobbin discharge trough 14 and the vertical plate 141 is an acute angle, the other end of the vertical plate 141 is vertically connected with the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com