Automatic drilling machine

A drilling machine and drilling device technology, applied in the direction of boring/drilling, automatic control devices, drilling/drilling equipment, etc., can solve the problems of low processing efficiency, low pipe consistency, low degree of automation, etc. Achieve the effect of good consistency, efficient drilling and small deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The accompanying drawings are for illustrative purposes only, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, certain components in the accompanying drawings will be omitted, enlarged or reduced, and do not represent the size of the actual product; for those skilled in the art It is understandable that some well-known structures and descriptions thereof may be omitted in the drawings. The positional relationship described in the drawings is for illustrative purposes only, and should not be construed as a limitation on this patent.

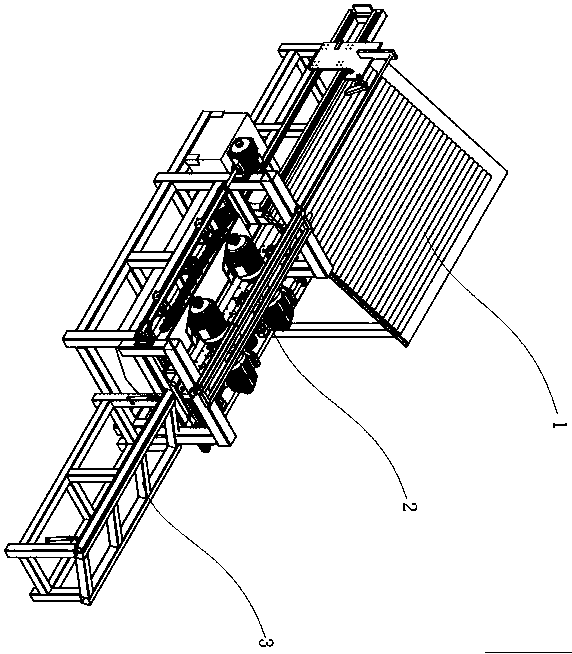

[0058] like figure 1 As shown, an automatic drilling machine includes a feeding device 1, a discharging device 3 and a drilling device 2, and the feeding device 1, the drilling device 2 and the discharging device 3 are connected in sequence.

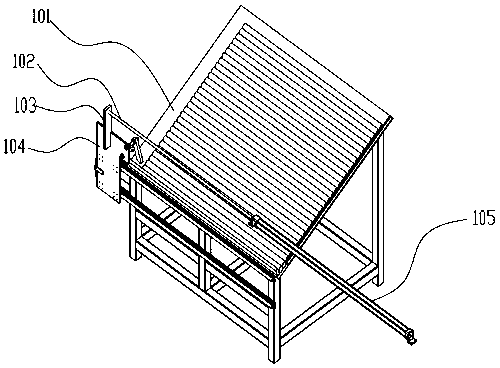

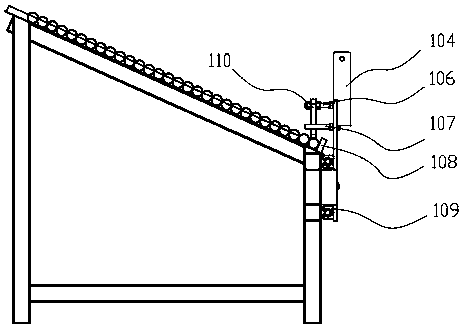

[0059] Among them, such as figure 2 , 3 As shown, the feeding device 1 includes an inclined slide table 101, a linear reciprocating mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com