Kitchen waste vacuum collecting, crushing and classifying treatment system and method

A technology of vacuum collection of food waste, which is applied in the field of vacuum collection, crushing, classification and treatment system of food waste, which can solve problems such as difficult to handle, easy to pollute the environment, and easy to leave garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

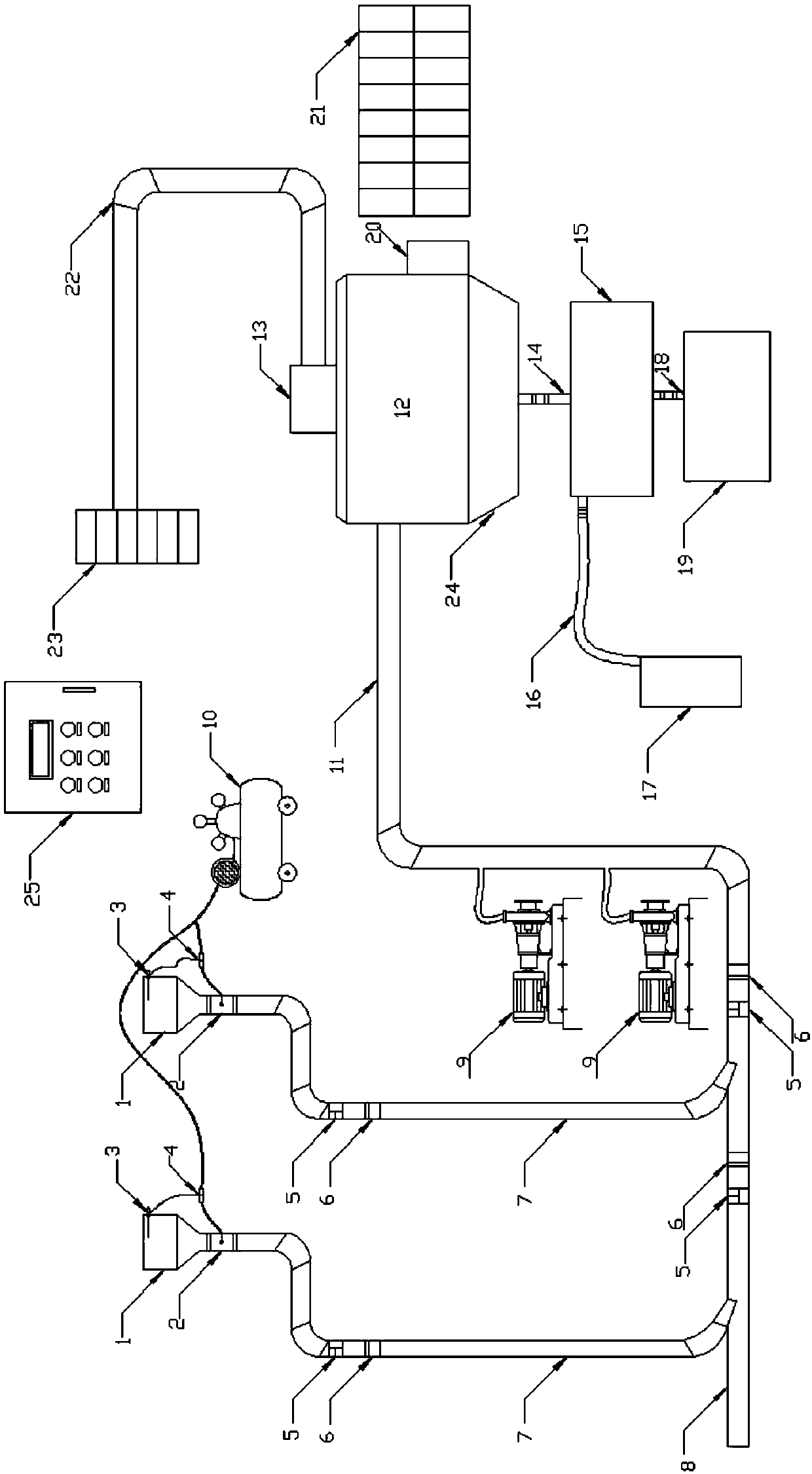

[0052] The food waste vacuum collection, crushing and classification treatment system is characterized in that it includes: a food waste collection tank, a washing device, a vacuum transportation device, a food waste crushing treatment device and a PLC automatic control system;

[0053] The power structure and moving parts of the flushing device, vacuum transport device, and food waste crushing device are all controlled by the PLC automatic control system.

[0054] A first liquid level sensor is provided in the kitchen waste collection tank, and the first liquid level sensor is connected with the PLC automatic control system.

[0055] The flushing device is arranged on the top of the kitchen waste collection tank; the flushing device includes an electromagnetic water valve and an air compressor; the flushing device is connected to the kitchen waste collection tank through the electromagnetic water valve; one end of the electromagnetic water valve is connected to the air compres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com