Patents

Literature

49results about How to "Effective sorting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

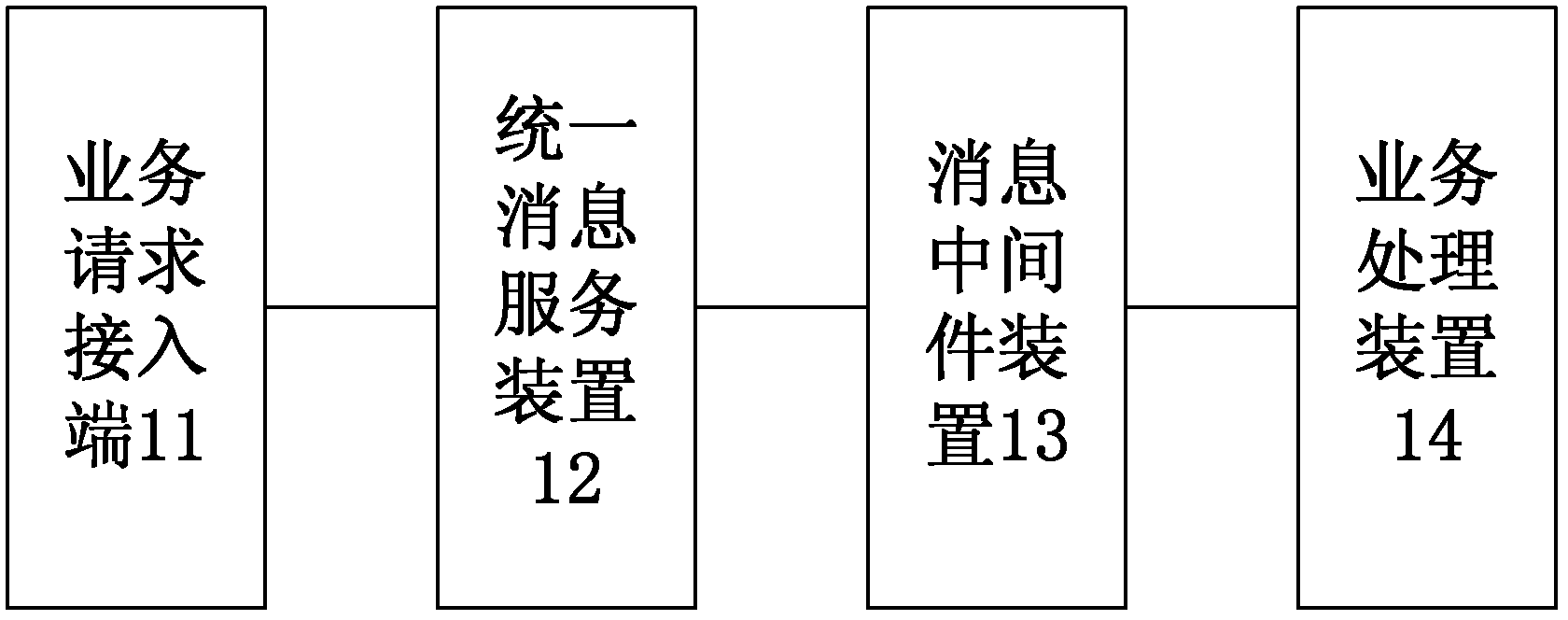

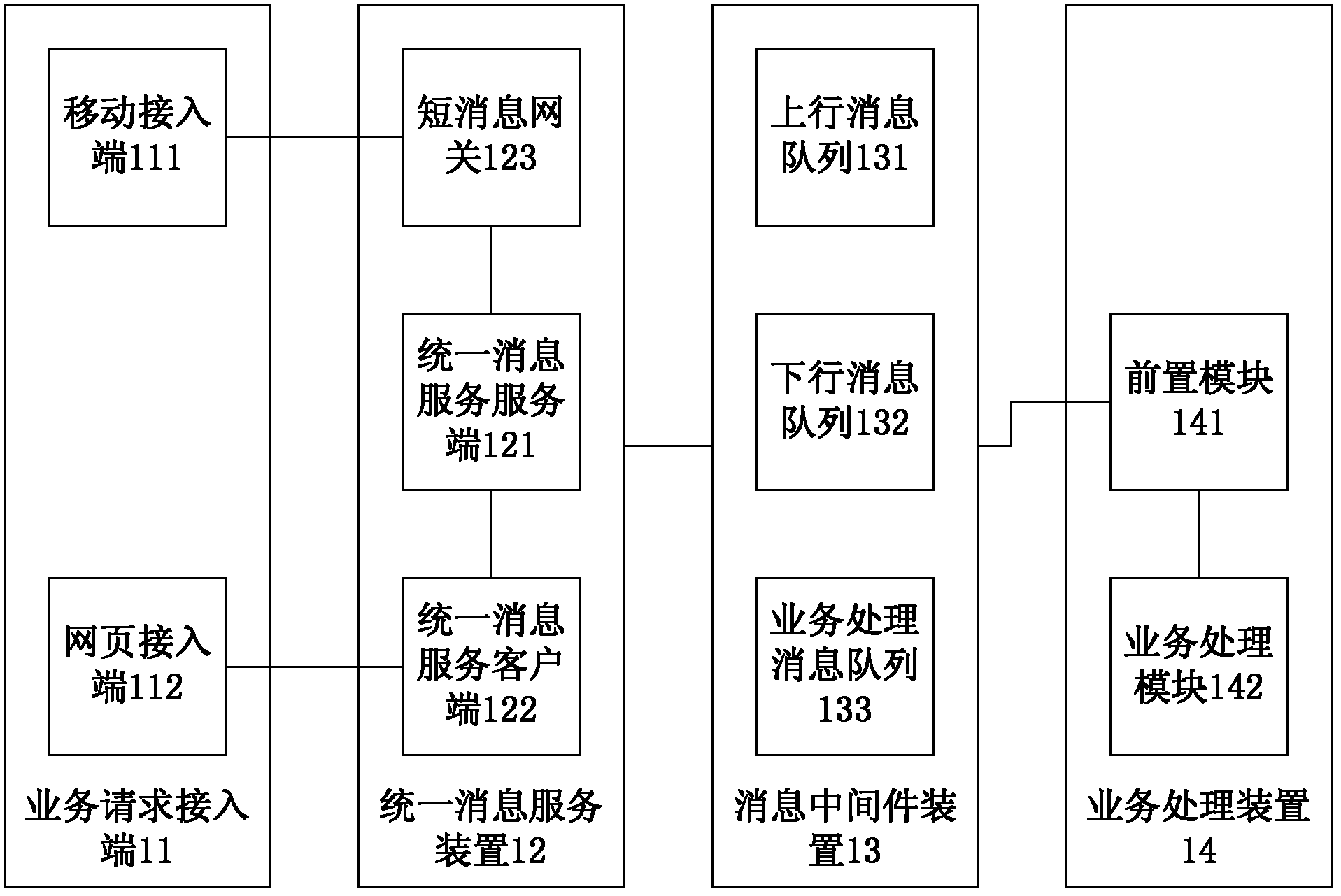

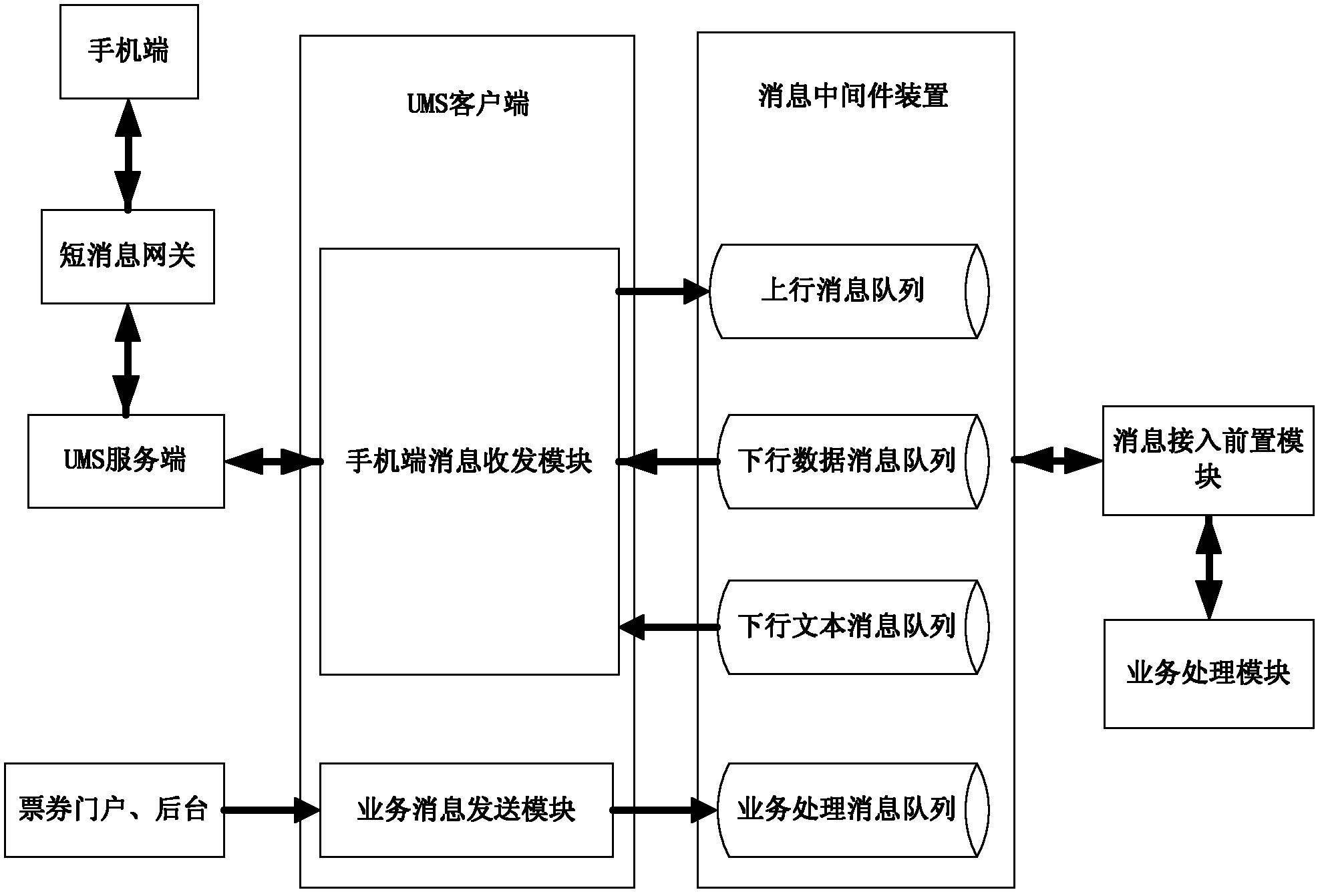

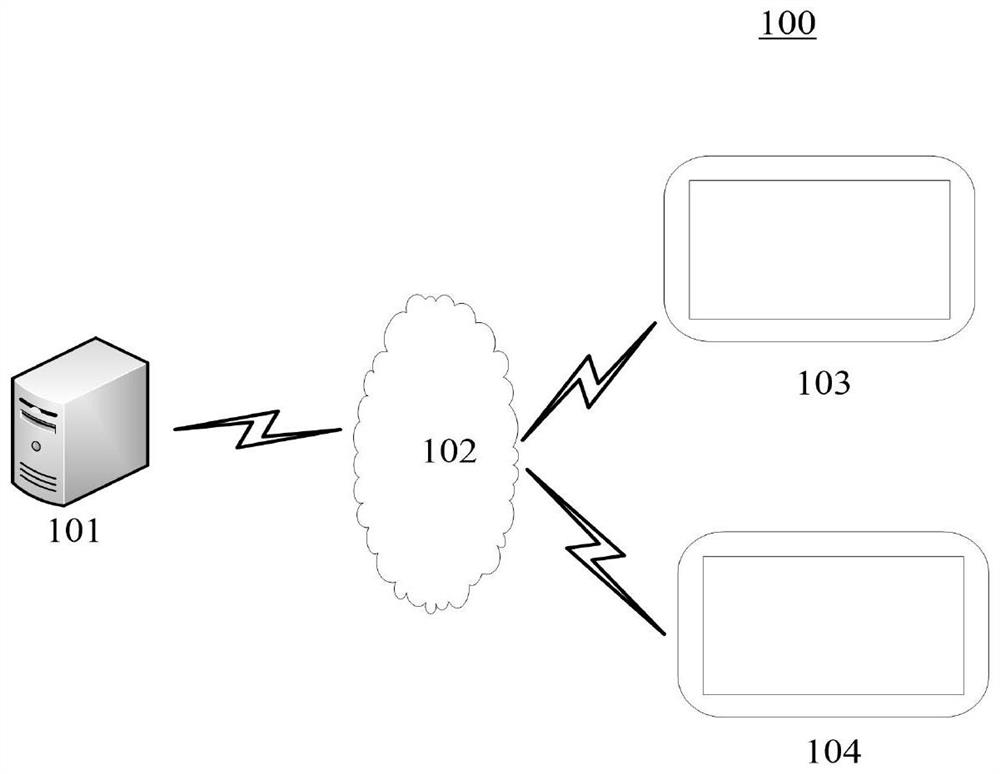

Service request processing system

ActiveCN103188140AImprove concurrent processing capabilitiesEfficient message classification processingMessaging/mailboxes/announcementsData switching networksMessage queueData messages

The invention discloses a service request processing system. Through arrangement of a message-oriented middleware, various messages generated in a service are dispatched and managed in a unified mode so as to enable the system to carry out unified processing on accessed different service requests, through the asynchronous mode, the service requests are processed and fed back, and the concurrent processing capacity of the service requests is improved. According to objects which the messages are sent to, the messages are classified into an uplink message queue, a downlink message queue and a service processing message queue, wherein the downlink message queue is further classified into a downlink data message queue and a downlink text message queue, and effective message classification processing is achieved.

Owner:NATIONZ TECH INC

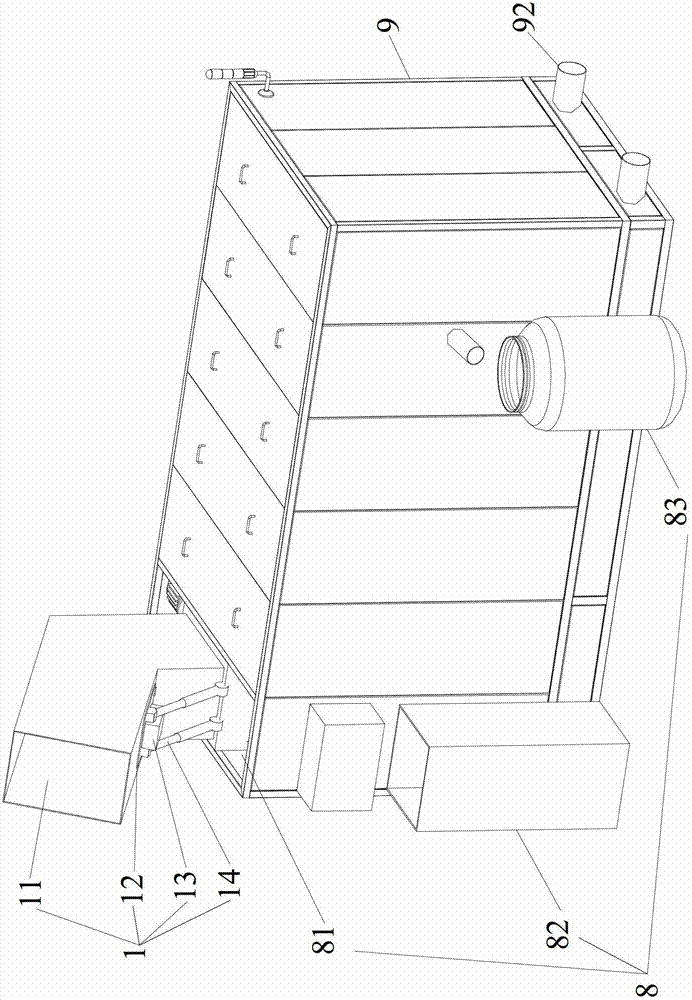

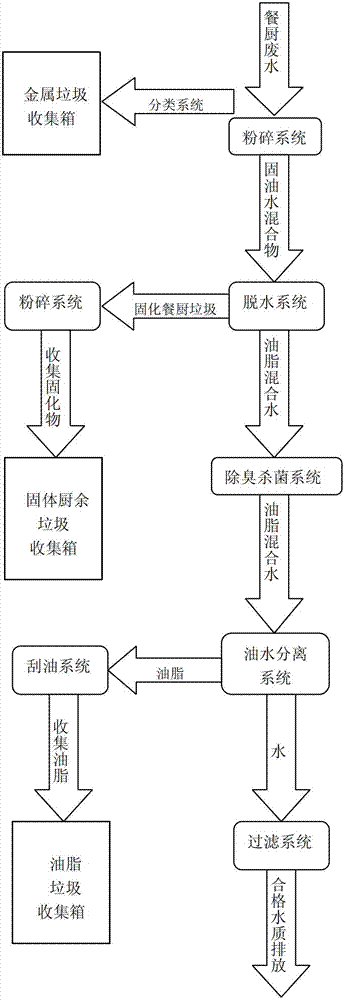

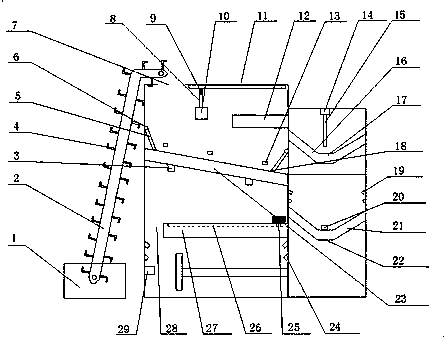

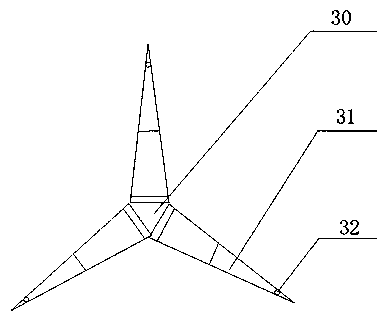

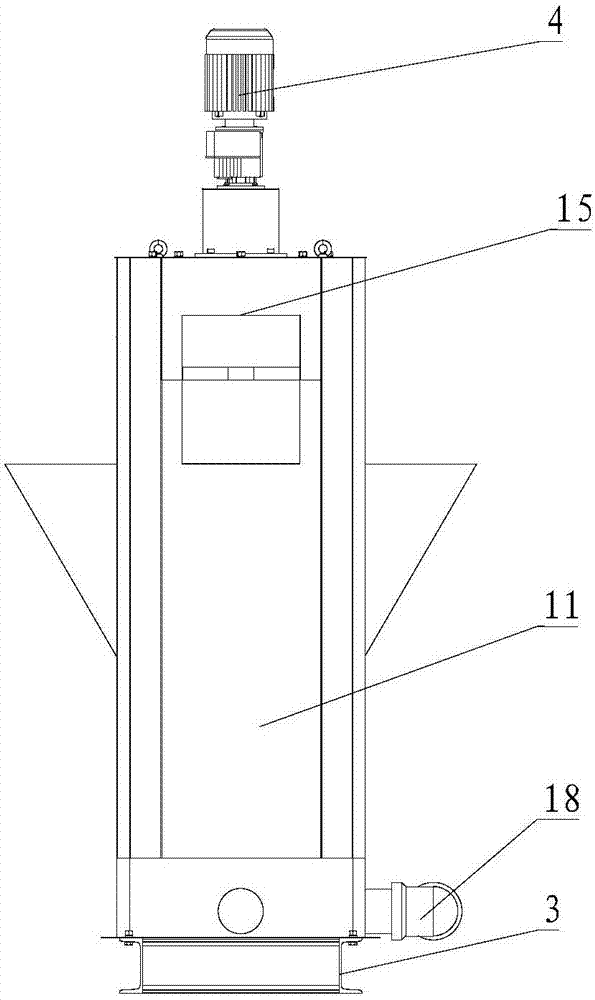

Kitchen waste and waste water treatment integrated device and method

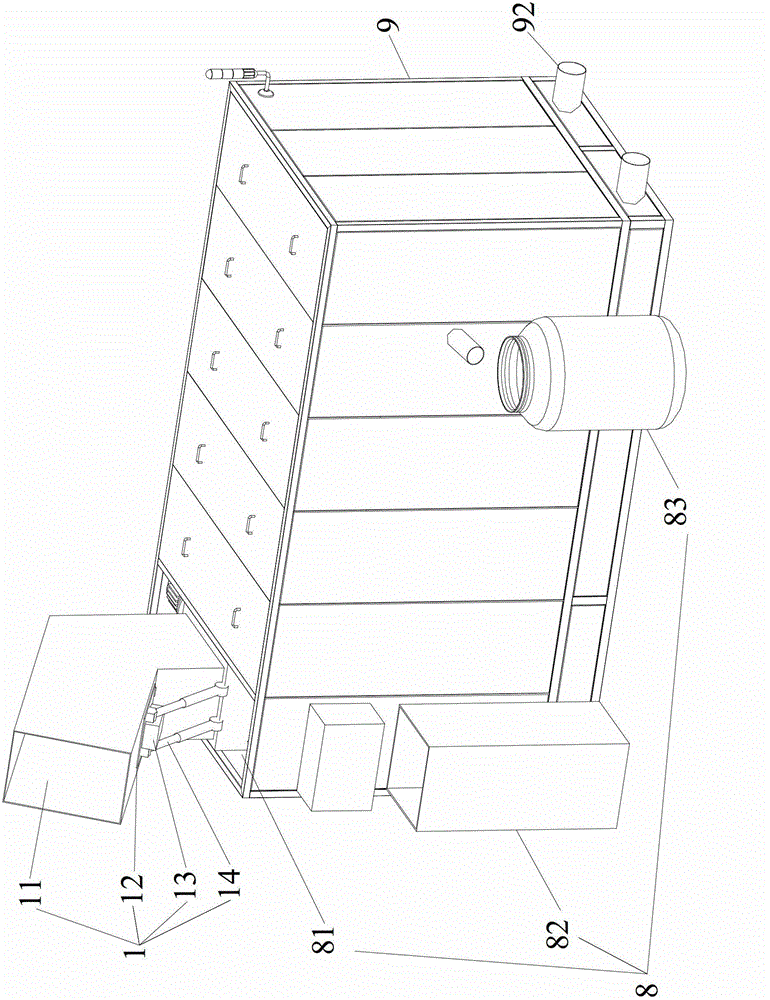

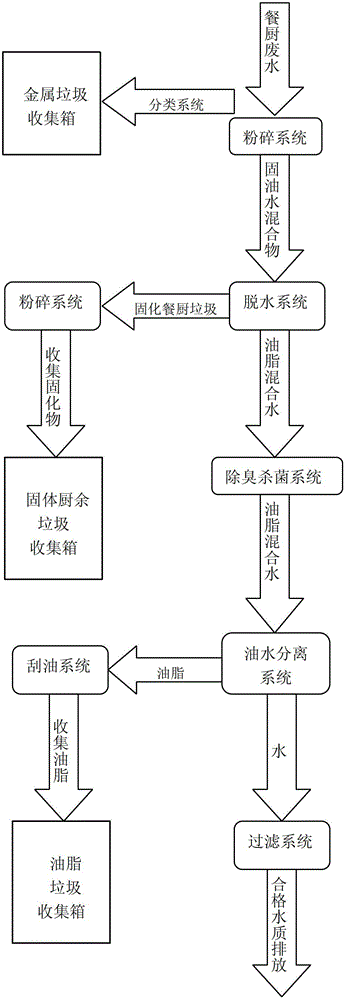

InactiveCN103159367AEffective sortingEffective physical isolation spaceMultistage water/sewage treatmentGrain treatmentsOil and greaseCollection system

The invention discloses a kitchen waste and waste water treatment integrated device and a method. The kitchen waste and waste water treatment integrated device comprises casing body which contains a water inlet and a sewage draining port, a classification system arranged at the position of the water inlet, a crushing system connected to the classification system, a dehydration system connected to the crushing system, a deodorizing and sterilization system connected to the dehydration system, an oil-water separating system connected to the deodorizing and sterilization system, an oil scraping system connected to the oil-water separating system, a filtration system connected to the oil-water separating system and a collection system; and the classification system, the crushing system and the oil scraping system are respectively connected to the collection system. The kitchen waste and waste water treatment integrated device employs the above structure, and can effectively classify and treat the metal waste, organic garbage, oil and waste water in kitchen waste water.

Owner:广州护源环境保护科技有限公司

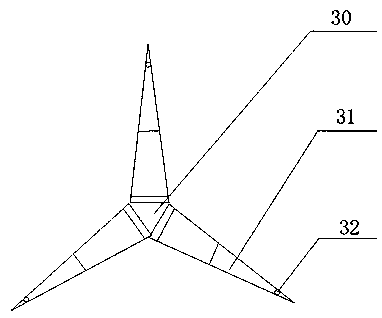

Automated construction waste sorting and recycling device

ActiveCN108772194AEffective sortingImprove resource utilizationMagnetic separationCleaning using liquidsBrickSoil treatment

The invention discloses an automated construction waste sorting and recycling device, comprising a feeding device, a sorting device and a treating device, wherein the feeding device comprises a wasteplacement box, a conveyor belt, a baffle plate and a feeding hole; the sorting device comprises an electromagnetic net, a material picker and a conveyor belt; the treating device comprises a plastic treatment chamber, a metal treatment chamber and a brick and soil treatment chamber; the brick and soil treatment chamber is internally provided with a water injection nozzle and a transverse plate; the transverse plate is provided with a groove, and a sawing plate is arranged in the groove; a drop mouth is formed at one side of the transverse plate, and a first pressure sensor is arranged under the drop mouth; a push rod is arranged under the brick and soil treatment chamber; the metal treatment chamber is provided with a flushing head and a first barrier plate; the first barrier plate is provided with a second pressure sensor and a moving opening; a heating rod is arranged above the plastic treatment chamber; a contraction device is arranged above the heating rod; a second barrier plate is arranged under the heating rod; a material collecting hole is formed in the second barrier plate. By means of arrangement of the devices, the automated construction waste sorting and recycling device realizes the sorting and recycling of construction wastes, and increases the utilization rate of resources.

Owner:福建永东南建设集团有限公司

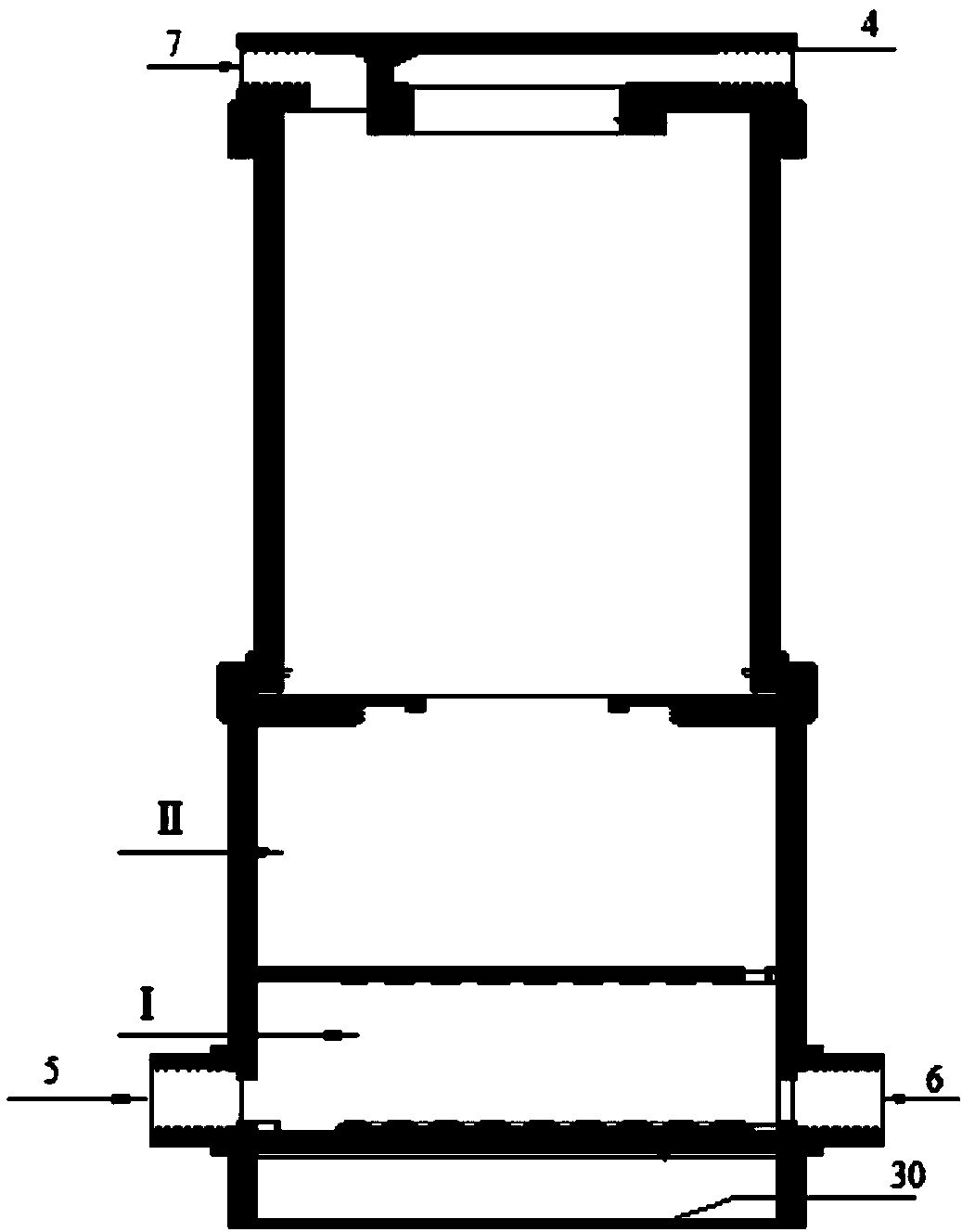

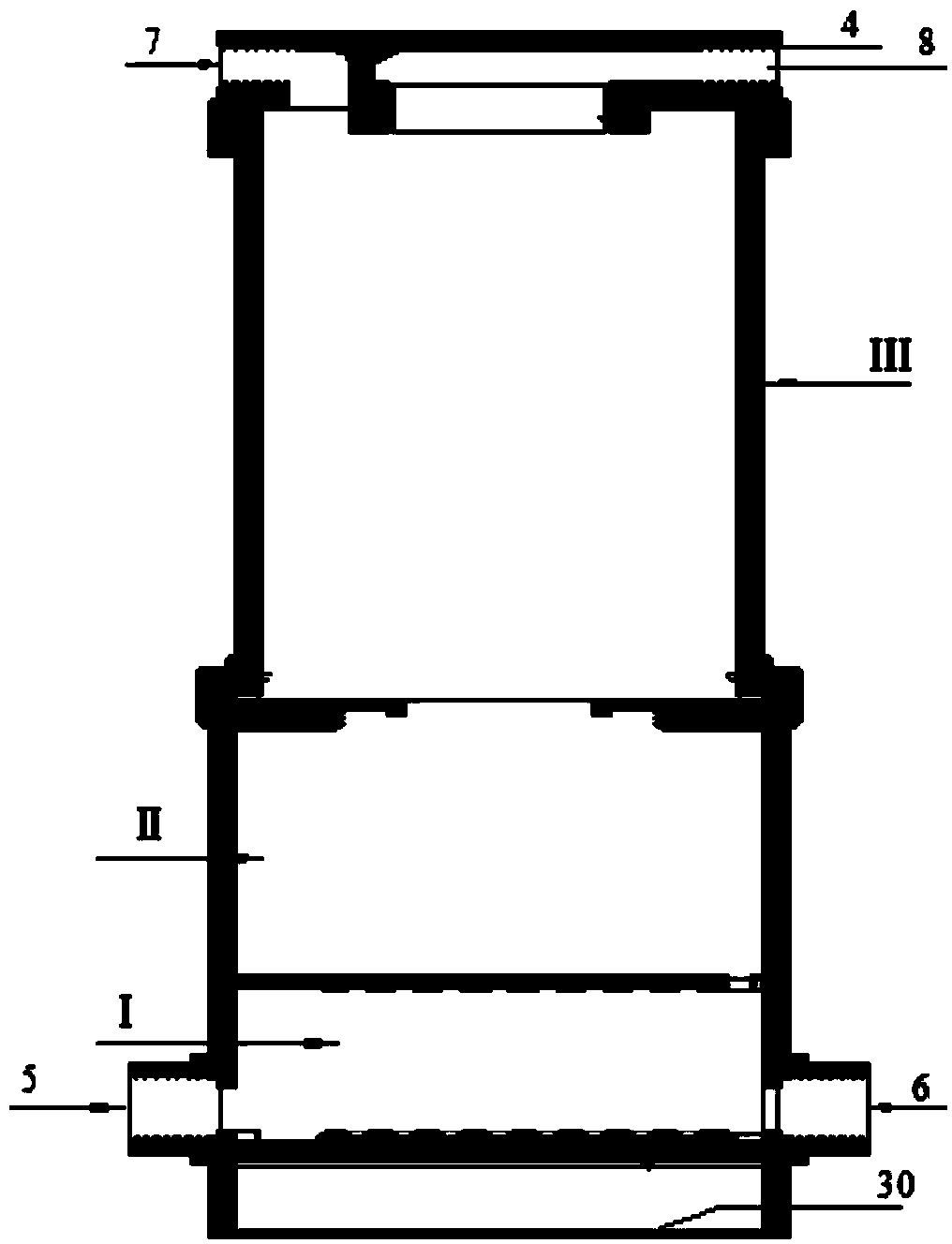

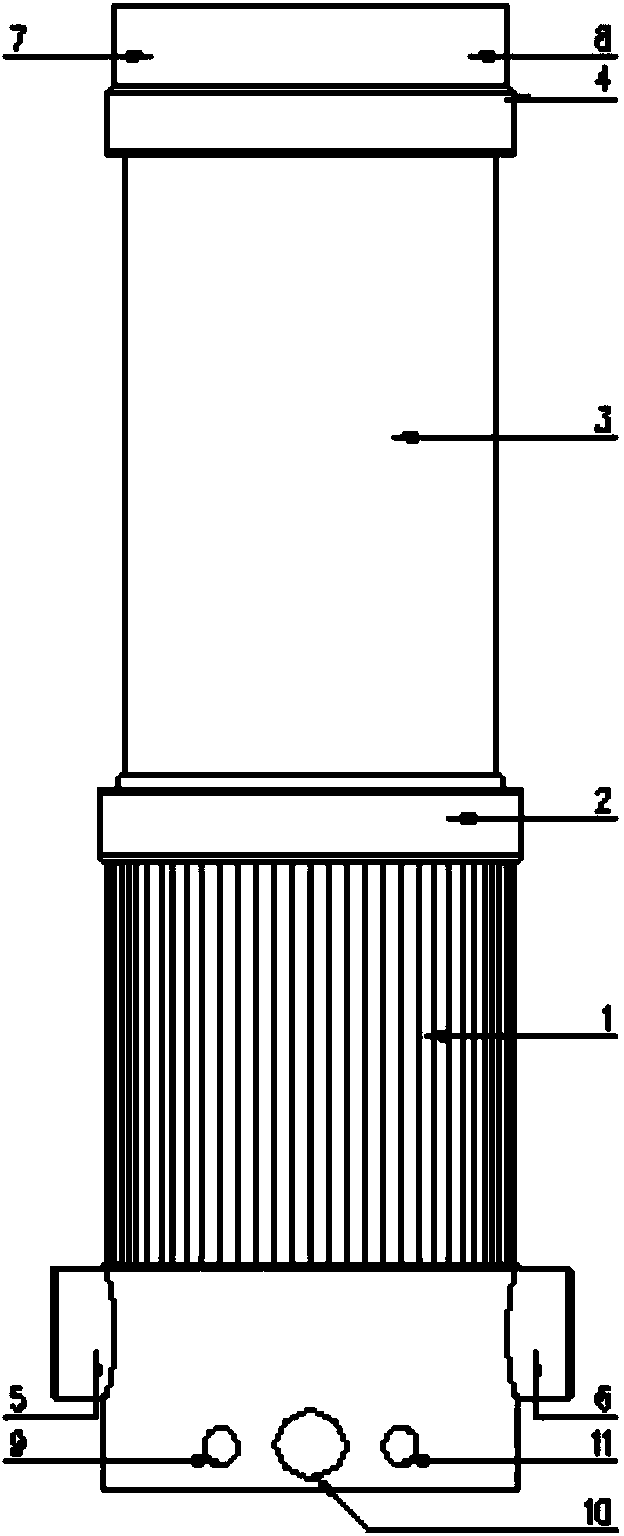

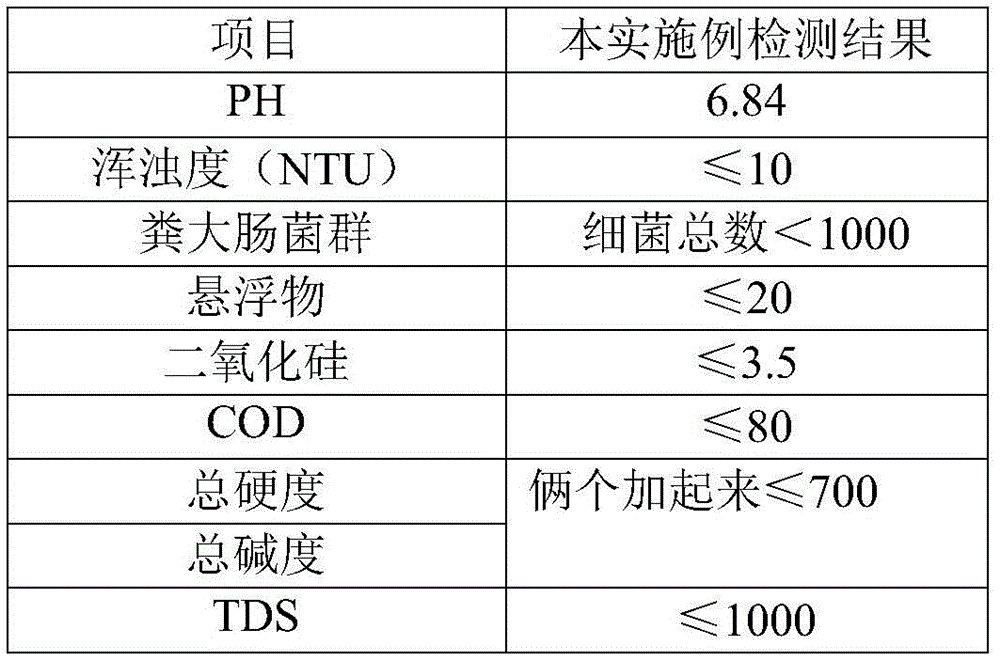

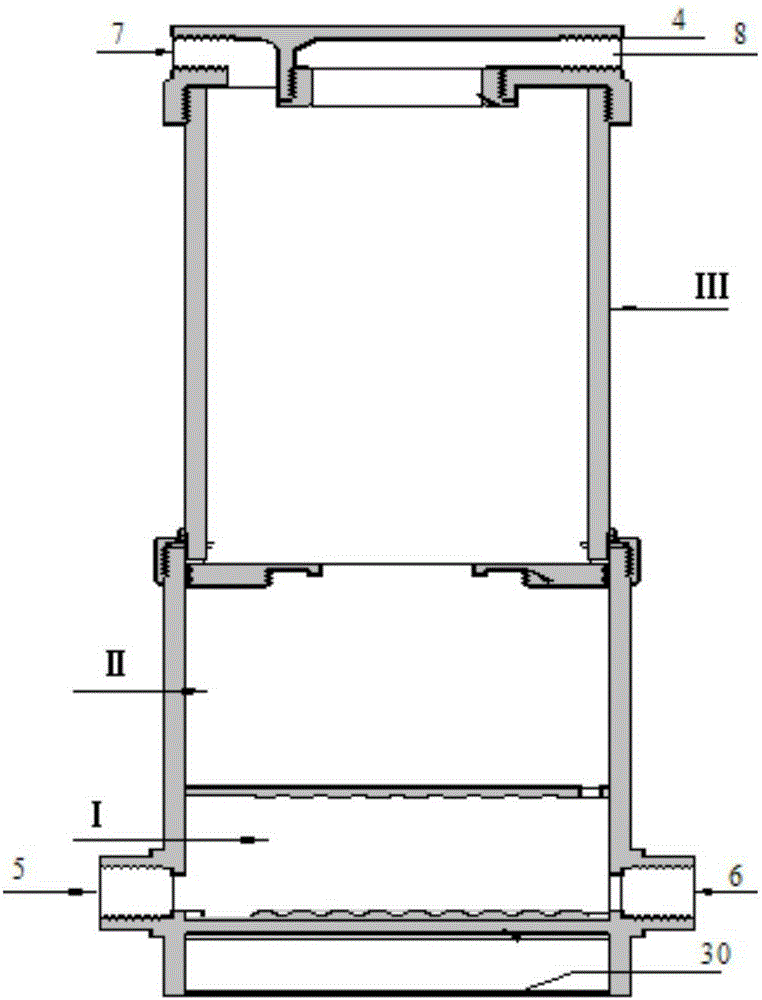

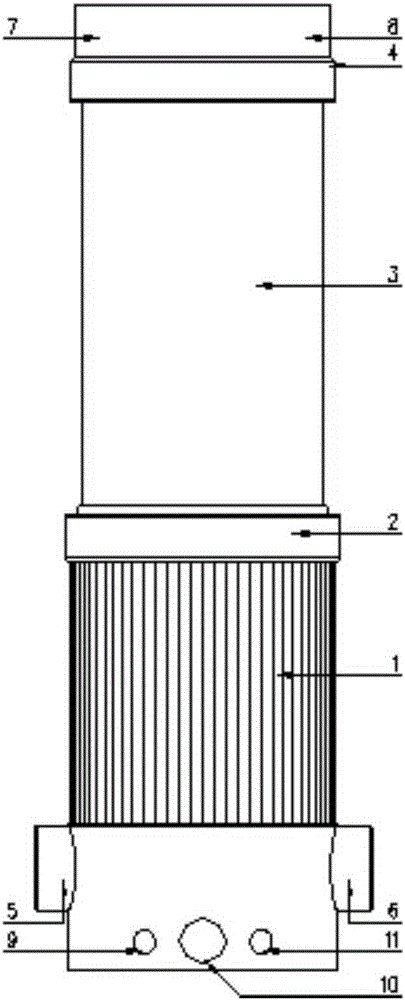

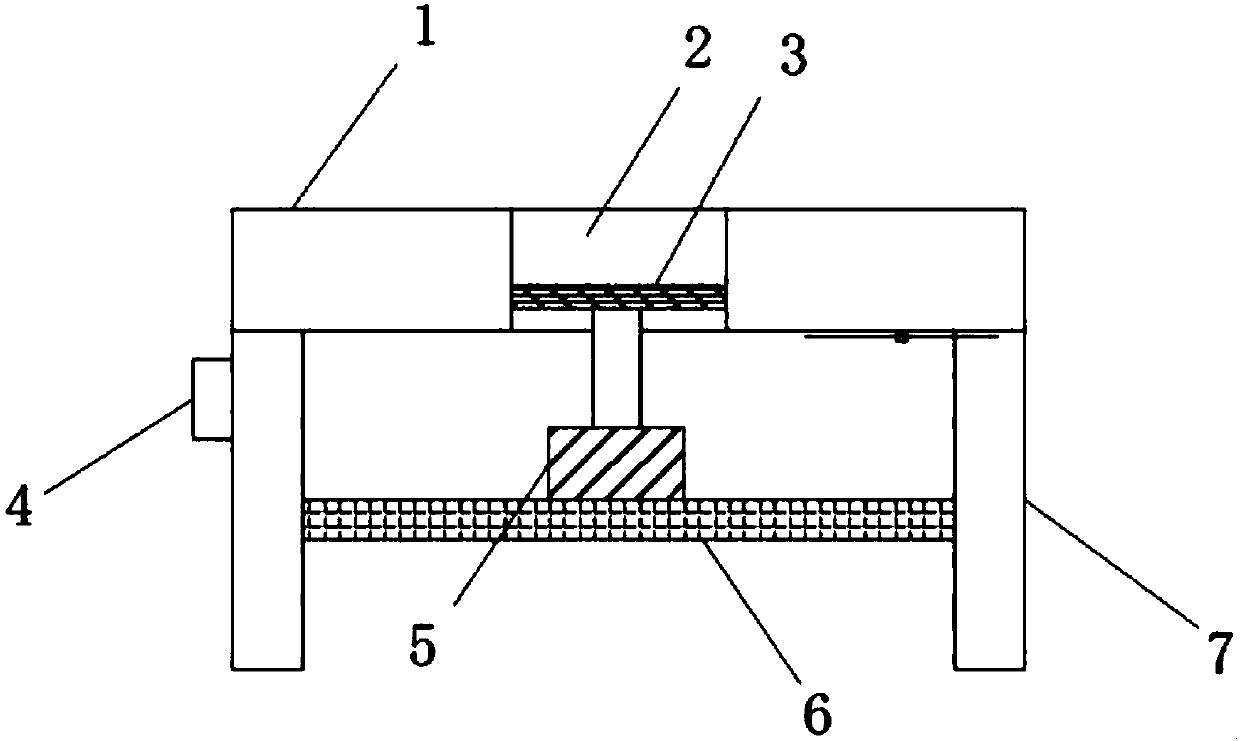

Water-purifying process and water-purifying equipment thereof

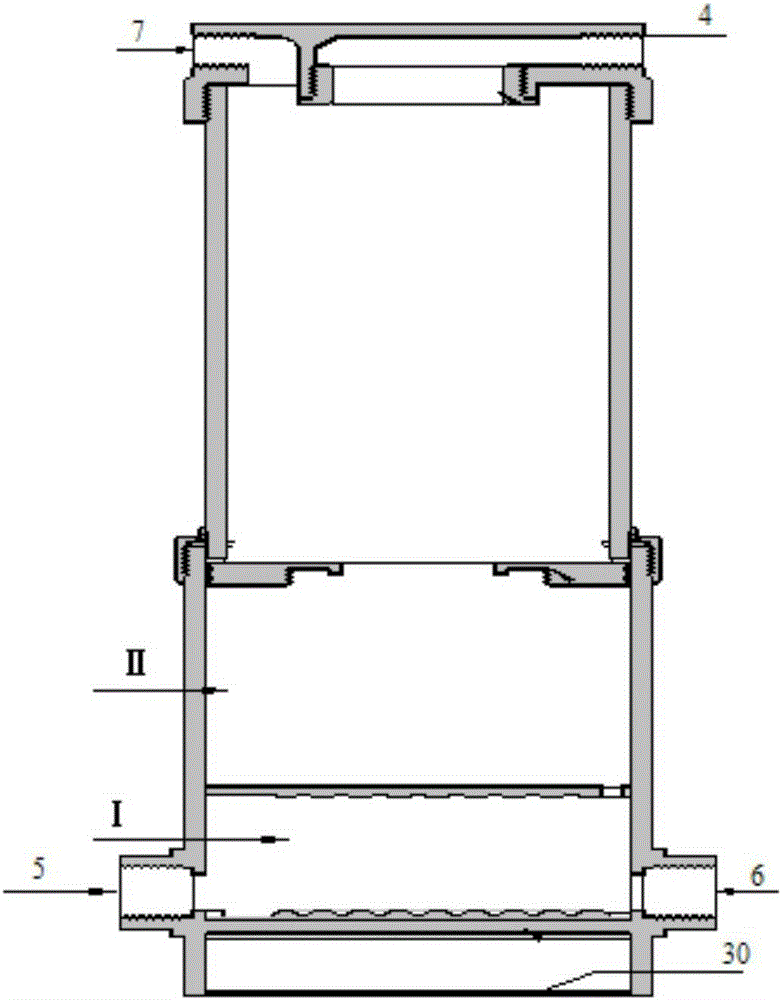

InactiveCN104098218ARealize integrated processingRealize water conservation and environmental protectionMultistage water/sewage treatmentWater savingTap water

The invention relates to a water-purifying process and water-purifying equipment thereof. Tap water is treated into flushing water, clean water and direct drinking water in a grading and classifying manner as required through a first-stage purification treatment device, a second-stage purification treatment device and a third-stage purification treatment device which are connected in sequence from bottom to top. By adopting the water-purifying process and the water-purifying equipment, water resources are utilized more optionally and reasonably, the problems of secondary pollution and the like since heavy metal pollutants in tap water cannot be removed in an efficient and environment-friendly way in the prior art are solved effectively, heavy metal ions, residual chlorine and other harmful particles in tap water are removed efficiently, bacteria are killed, the water quality is improved, sewage is disposed automatically, and the water yield and the utilization ratio of water are increased greatly; the health of a user is ensured; tap water is classified and treated effectively and is utilized in a shunting way according to the water quality, water amount and water pressure requirements of household water, and water is saved; energy is saved efficiently, space is saved, and remarkable energy-saving and environmental protection effects are achieved. The water-purifying process and the water-purifying equipment are suitable to be popularized and applied in relevant tap water treatment field.

Owner:合肥一言科技发展有限公司

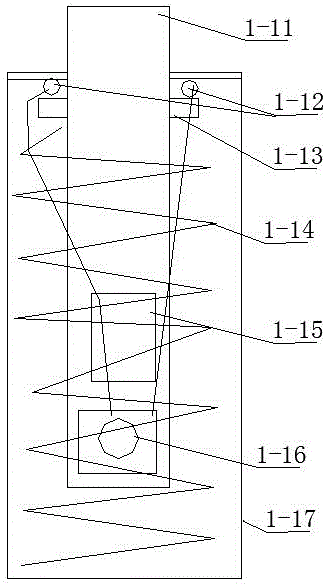

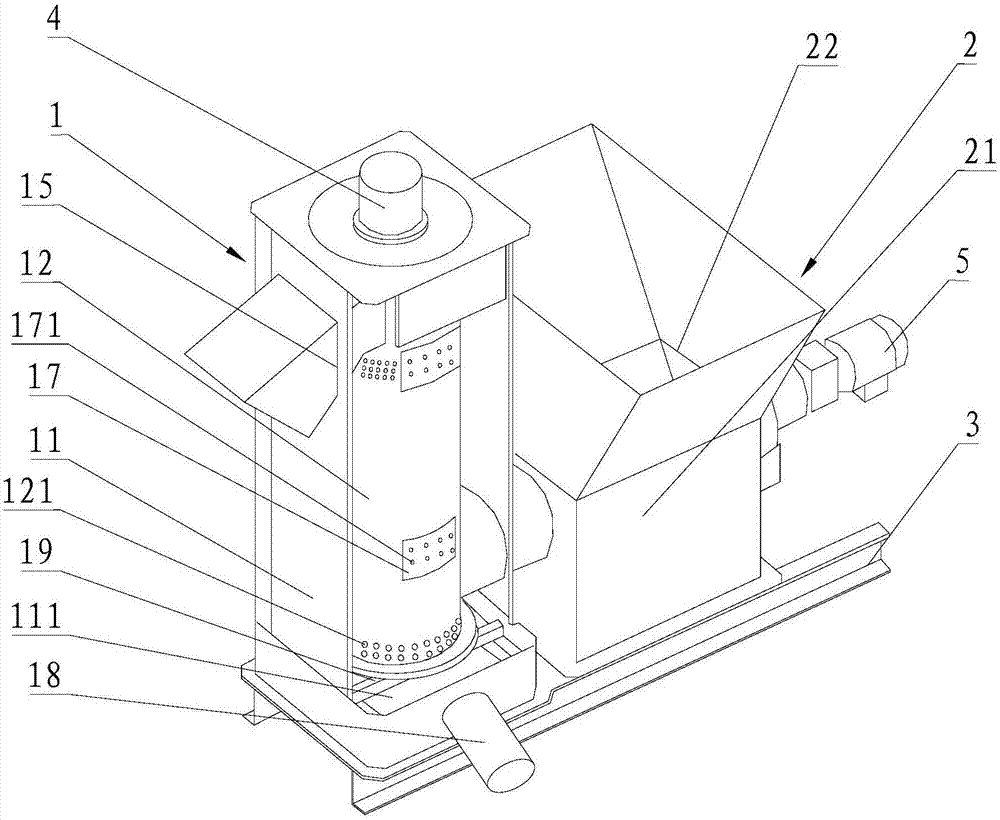

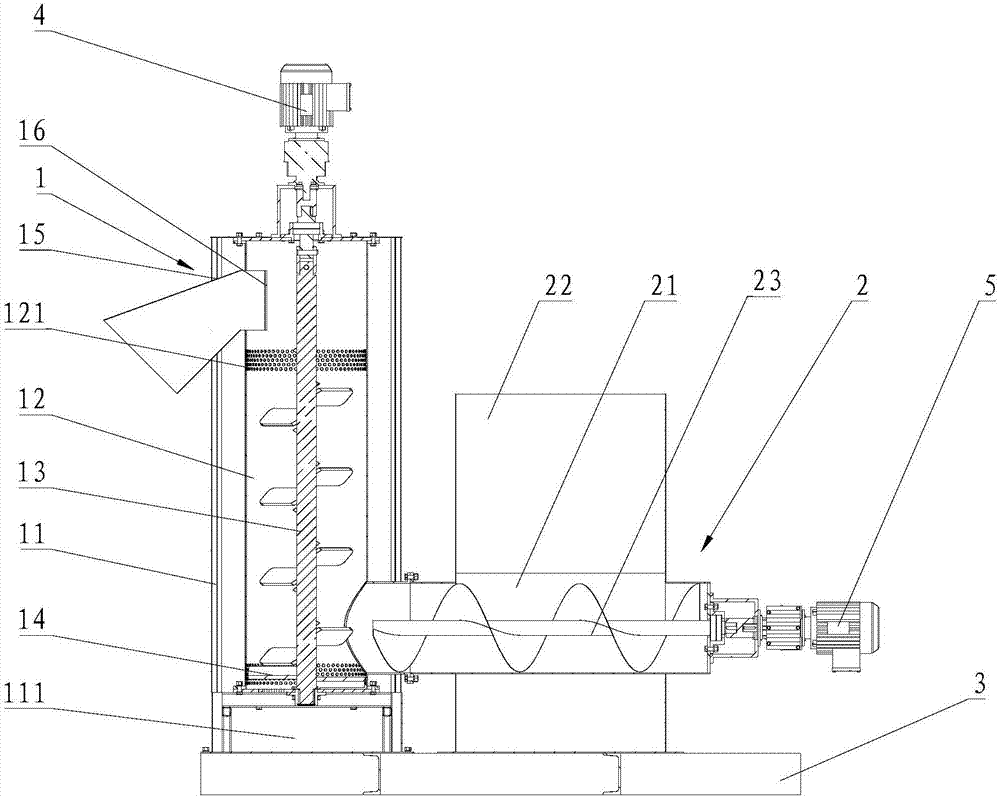

Integral kitchen waste treatment device

InactiveCN106140793AEffective sortingImprove processing efficiencyFatty/oily/floating substances removal devicesTransportation and packagingWastewaterEngineering

The invention discloses an integral kitchen waste treatment device. The integral kitchen waste treatment device comprises a feed port, a first smashing cavity, a first motor, a smashing device, a second smashing cavity, a smashing rotating plate, a fixed blade, a transverse separation plate, a rotating shaft, a motor cavity, a second motor, a first discharge pipe, a solid-liquid separator, a spiral conveyor, a third motor, a second discharge pipe, a storage box, a storage container, a first water outlet pipe, a separation tank, an oil-water separator, an oil outlet pipe, a grease storage box, a first communicating pipe, a heat exchanger, a second communicating pipe, an adjusting pool, a third communicating pipe, a heating tank, an electric heating pipe, a temperature sensor, a liquid level, a second water outlet pipe and a medicine adding device, and is characterized in that the first smashing cavity is formed in the lower end of the feed port. The integral kitchen waste treatment device adopts the structure to effectively classify metal wastes, organic garbage, grease and waste water in kitchen waste water. The integral kitchen waste treatment device has the advantages of high treatment efficiency, convenience for operation, energy conservation and environmental protection.

Owner:霍普科技(天津)股份有限公司

Method for resource utilization of food waste and slaughter-house garbage

InactiveCN102225418AEffective sortingEfficient use ofSolid waste disposalCoal waterResource utilization

The present invention relates to the technical field of treating garbage, and particularly relates to a method for resource utilization of food waste and slaughter-house garbage. The method comprises the following steps: separating garbage resources into solid state materials and liquid state materials by a solid-liquid separator; sterilizing and drying the separated solid state materials and sorting the non-organic material for crushing and packaging; sterilizing the separated liquid state materials with high temperature and adding a quantitative coal water slurry composite additive and an alkalescent desulfurizer for emulsifying; grinding coal into powders through a milling apparatus; mixing the emulsified mixed liquor in a step 6 and a powdery coal in a step 7 and then placing into a pulping apparatus for preparing oil coal water mixture. The food waste and slaughter-house garbage can be thoroughly treated according to the invention, the method is capable of treating solid garbage as well as treating oil and water in liquid state without generating secondary pollutant; the invention has the advantages of low treatment cost, good utilization efficiency, low investment, easy implementation and good process effect.

Owner:张晓群

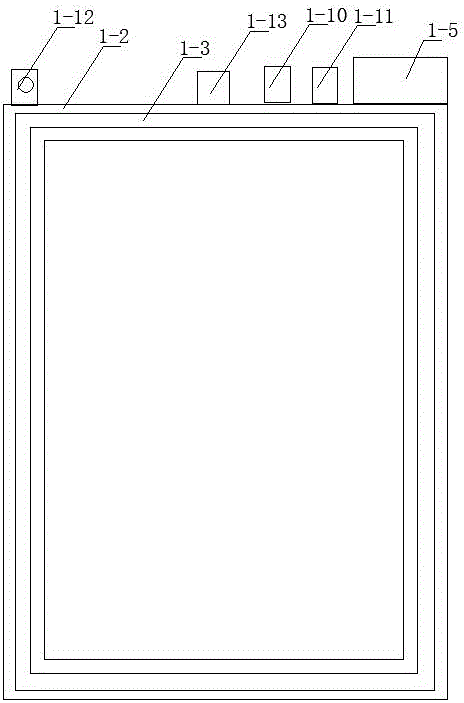

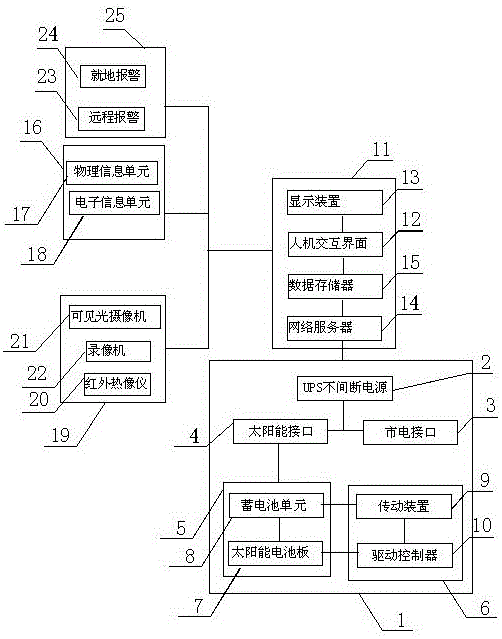

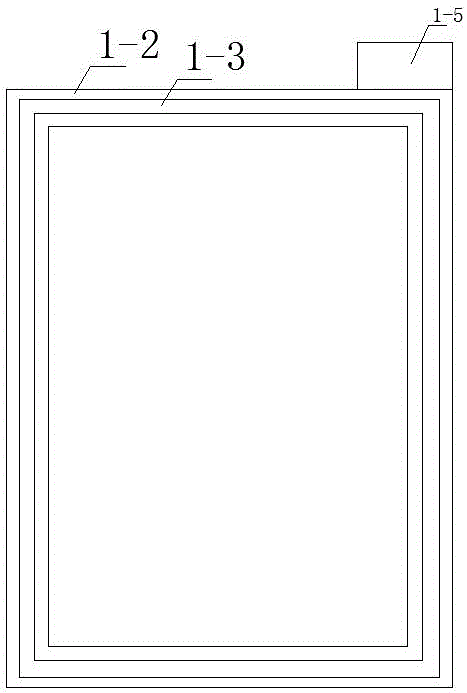

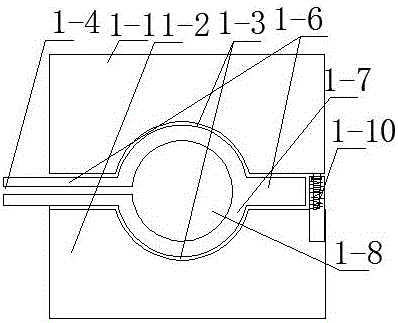

Non-outage human resource archive management cabinet

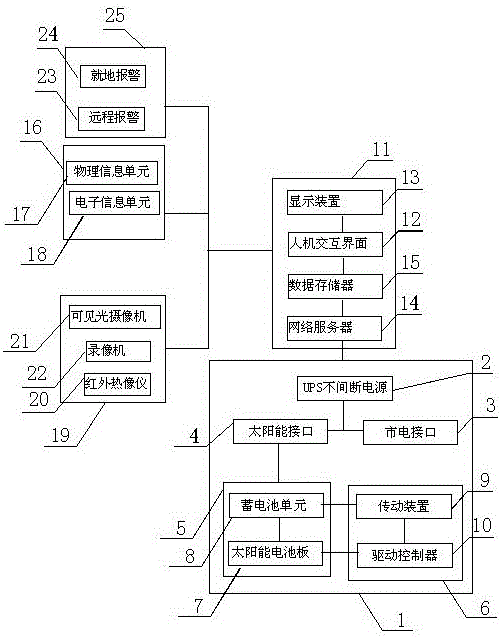

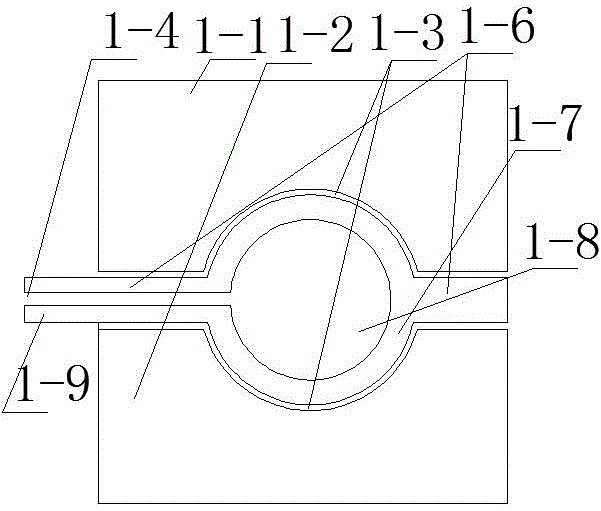

InactiveCN106388319AGuaranteed uninterrupted supplyIncrease profitBatteries circuit arrangementsBook cabinetsVideo monitoringElectronic information

The invention provides a non-outage human resource archive management cabinet. The non-outage human resource archive management cabinet comprises an archive management cabinet body, a source supply unit, an information inquiry unit, a state acquisition unit and a monitoring and alarming unit, wherein the source supply unit, the information inquiry unit, the state acquisition unit and the monitoring and alarming unit are arranged on the archive management cabinet body; the source supply unit is connected with the information inquiry unit, the state acquisition unit and the monitoring and alarming unit; the state acquisition unit comprises a physical information unit and an electronic information unit; the monitoring and alarming unit comprises a video monitoring unit and an alarm unit. The non-outage human resource archive management cabinet can guarantee archive storage safety and reliability and can also integrate multiple other service functions to achieve the purposes of optimal configuration and comprehensive service.

Owner:ZHONGZHOU UNIV

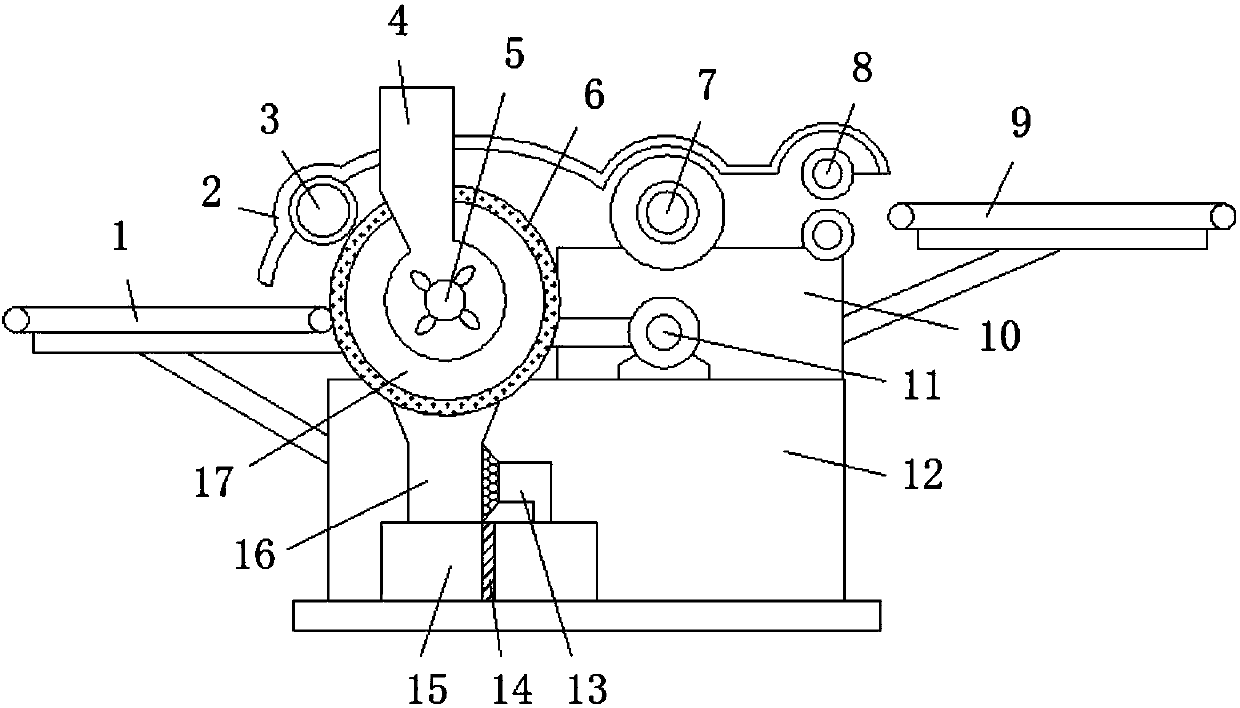

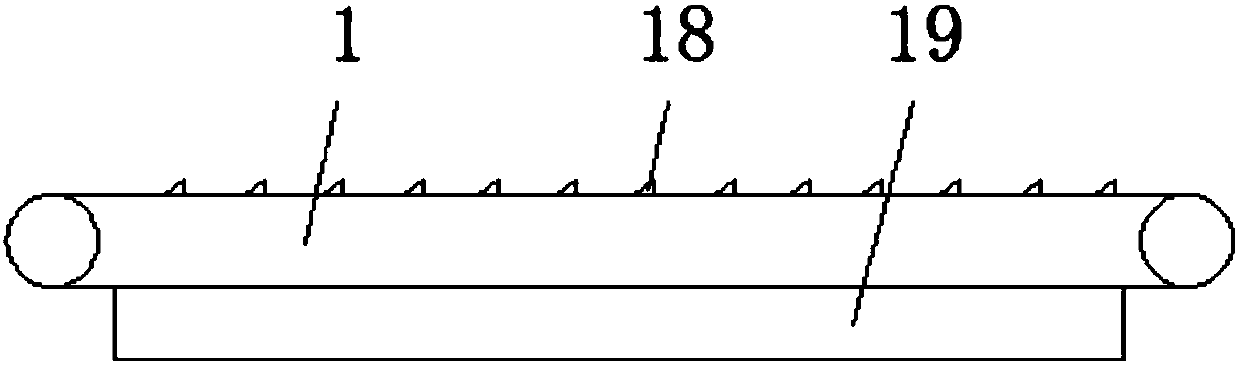

Spinning dust-removing cotton fluffer

InactiveCN107699994AEfficient popping work efficiencyPlay the role of fixing and anti-looseningCarding machinesElectric machineryEngineering

The invention discloses a spinning dust-removing cotton fluffer which comprises a cotton fluffer body. A first roller is arranged on one side of the top of the cotton fluffer body, an induced draft fan is arranged inside the first roller, a vent pipe is arranged at the top of the induced draft fan, a hollow plate is arranged on the outer surface of the first roller, a conveying belt is arranged onone side of the first roller, a drying pad is arranged at the bottom of the conveying belt, a second roller and a pressing roller are horizontally and sequentially arranged at the top of an operatingboard, the first roller is in transmission connection with a motor in the operating board through a rotating shaft, a discharging belt is welded on the outer side of the operating board, a dust outlet pipe is welded at the bottom of the first roller, a dust separating pipe is welded on one side of the dust outlet pipe, a dust collecting bin is welded at the bottom of the dust outlet pipe, and a partition plate is welded on the inner surface wall of the dust collecting bin. The cotton fluffer is simple and reasonable in integral structural design, safe and stable in running, flexible and convenient to operate and high in practicability, and has strong self-protection capacity.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

Anti-theft alarm article cabinet used in nursing department

InactiveCN106419161AGuaranteed continuityIncrease profitBook cabinetsBurglar alarm mechanical actuationElectronic informationAnti theft

The invention provides an anti-theft alarm article cabinet used in a nursing department. The anti-theft alarm article cabinet comprises an archive management cabinet body, a power supply unit, an information query unit, a state acquisition unit and a monitoring alarm unit, wherein the power supply unit, the information query unit, the state acquisition unit and the monitoring alarm unit are arranged on the archive management cabinet body; the power supply unit is connected with the information query unit, the state acquisition unit and the monitoring alarm unit respectively; the state acquisition unit comprises a physical information unit and an electronic information unit; the monitoring alarm unit comprises a video monitoring unit and an alarm unit. By adopting the anti-theft alarm article cabinet, not only is assurance of archive storage security and reliability achieved, but also multiple other service functions can be integrated, and purposes of optimal configuration and comprehensive service can be achieved.

Owner:NANYANG MEDICAL COLLEGE

Management cabinet of nursing department

InactiveCN106522739AGuaranteed uninterrupted supplyIncrease profitBook cabinetsSafesVideo monitoringElectronic information

The invention provides a management cabinet of a nursing department. The management cabinet comprises a file management cabinet body, and a source supply unit, an information inquiry unit, a state acquisition unit and a monitoring and alarming unit which are arranged on the file management cabinet body, wherein the source supply unit is connected with the information inquiry unit, the state acquisition unit and the monitoring and alarming unit; the state acquisition unit comprises a physical information unit and an electronic information unit; and the monitoring and alarming unit comprises a video monitoring unit and an alarming unit. According to the management cabinet, the safety and reliability of file storage can be guaranteed, other multiple service functions can be integrated, and the purposes of optimal allocation and comprehensive service are achieved.

Owner:NANYANG MEDICAL COLLEGE

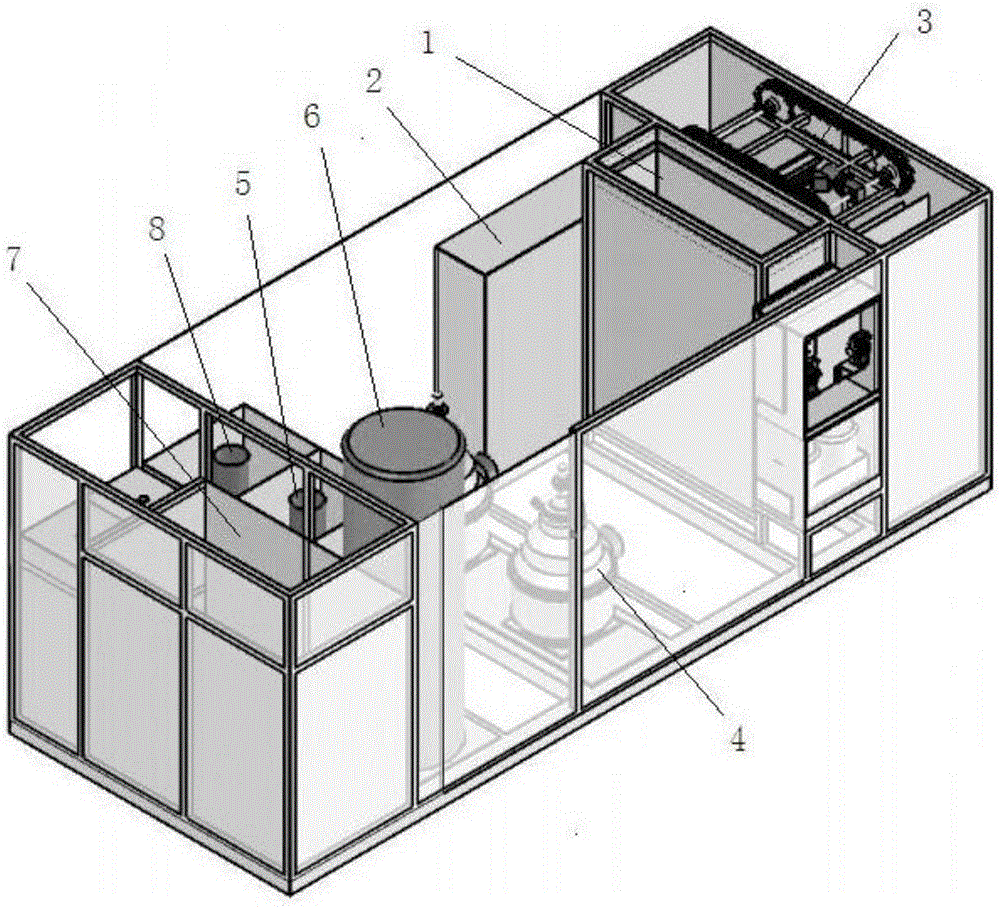

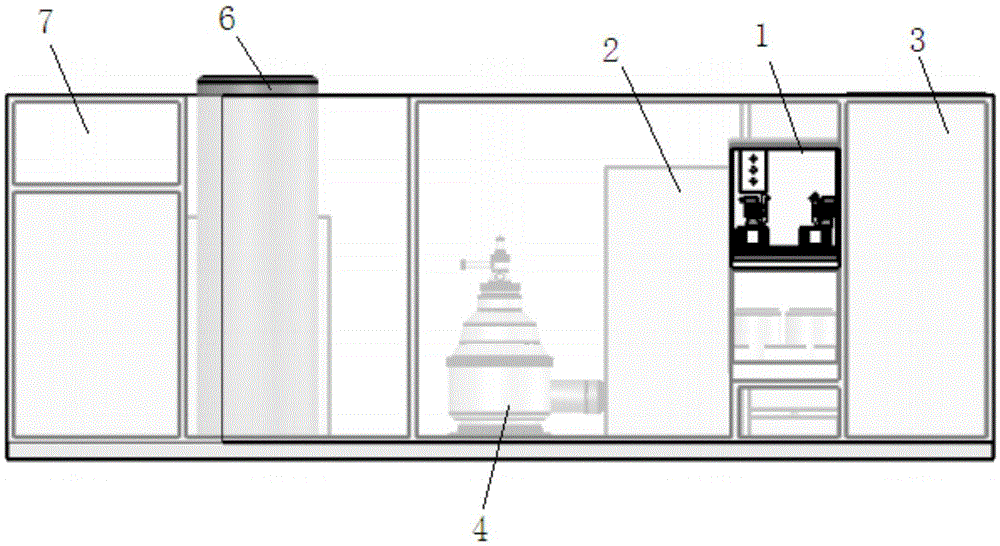

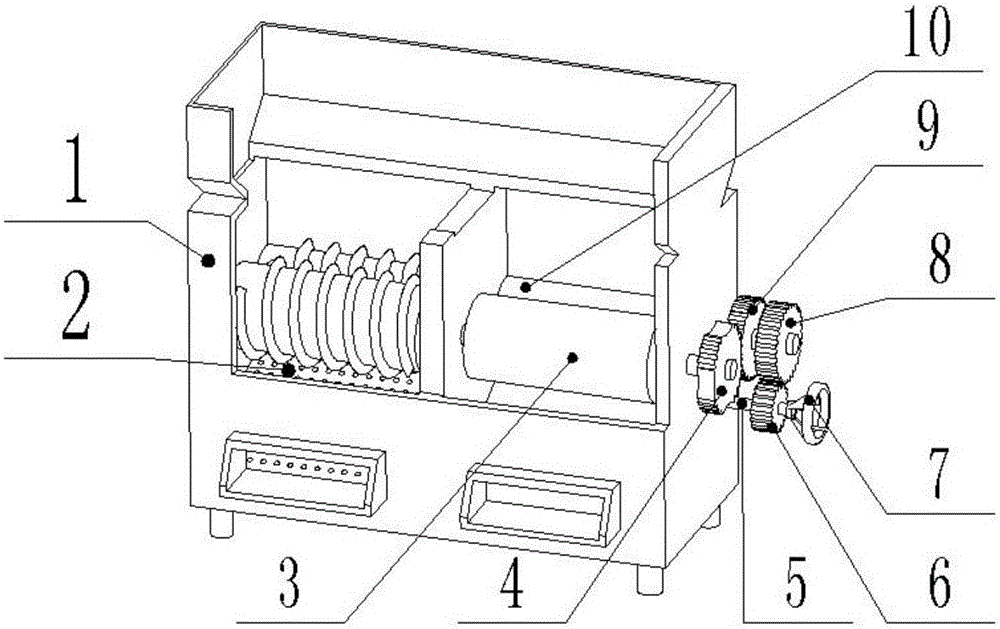

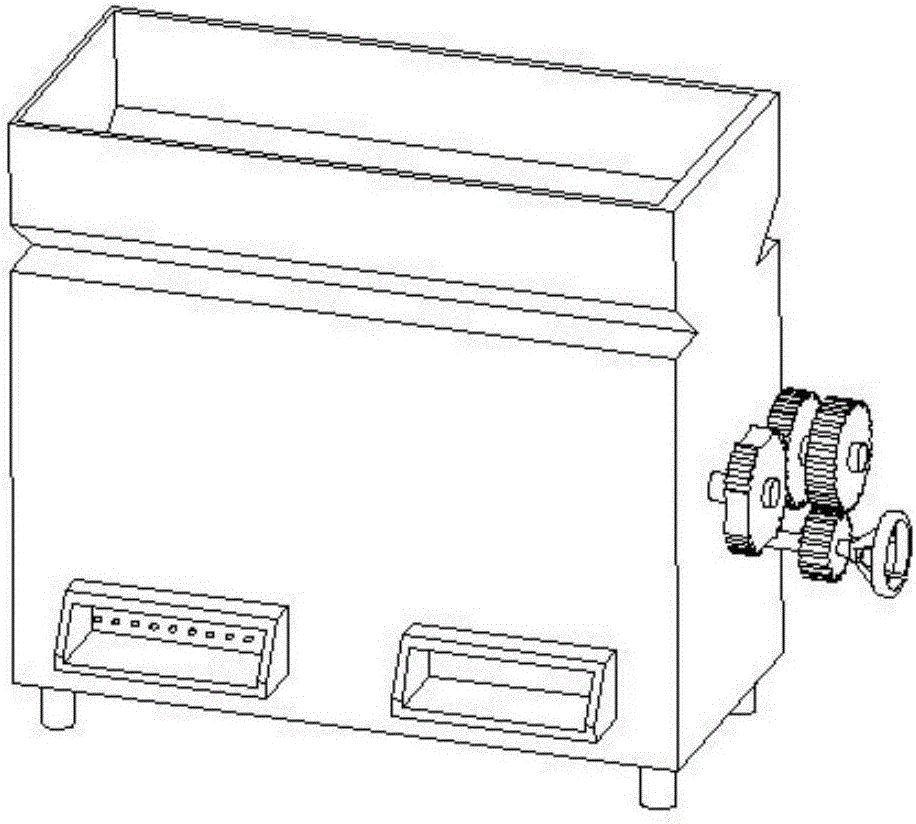

Recycling system and recycling method for die-casting waste liquid

ActiveCN105417802AEffective sortingEasy to handleWater contaminantsTreatment involving filtrationPollutionMembrane filter

The invention discloses a recycling system and a recycling method for die-casting waste liquid. The recycling system is provided with a box body, wherein a vacuum filtering system, a waste liquid centralizing pool, a control box, a scraper system, a sterilizing system, a centrifugal filtering system, a net bag filtering system, an electric flocculation system, a bag type filter and a membrane filter are arranged in the box body. The recycling system has the advantages that the processes of suction, filtering, centrifuging (customizing), sterilizing, electric flocculation, gas mixing, recovering of calcium and magnetism ions, bag type filter and membrane filtering are cooperated to use, so the energy-saving and environment-protection effects are realized, and the wealth is created; by using a PLC (programmable logic controller) to control, the high-efficiency operation of equipment is realized, the hourly treatment amount is more than fifty-thousand tons, and the land occupation area is 40 square meters; compared with building of sewage treatment plants, the time, labor and land are saved, the convenience is realized, the physical type is used for treating, the environment-friendly and recycling effects are realized, and the efficiency is high; the treated wastewater can reach the standard of reused water, the equipment is recycled, the energy-saving and emission-reduction effects for oil-containing wastewater are realized, the wastewater is utilized, the resources are protected, and the secondary pollution is prevented.

Owner:昆山辰芳环保科技有限公司

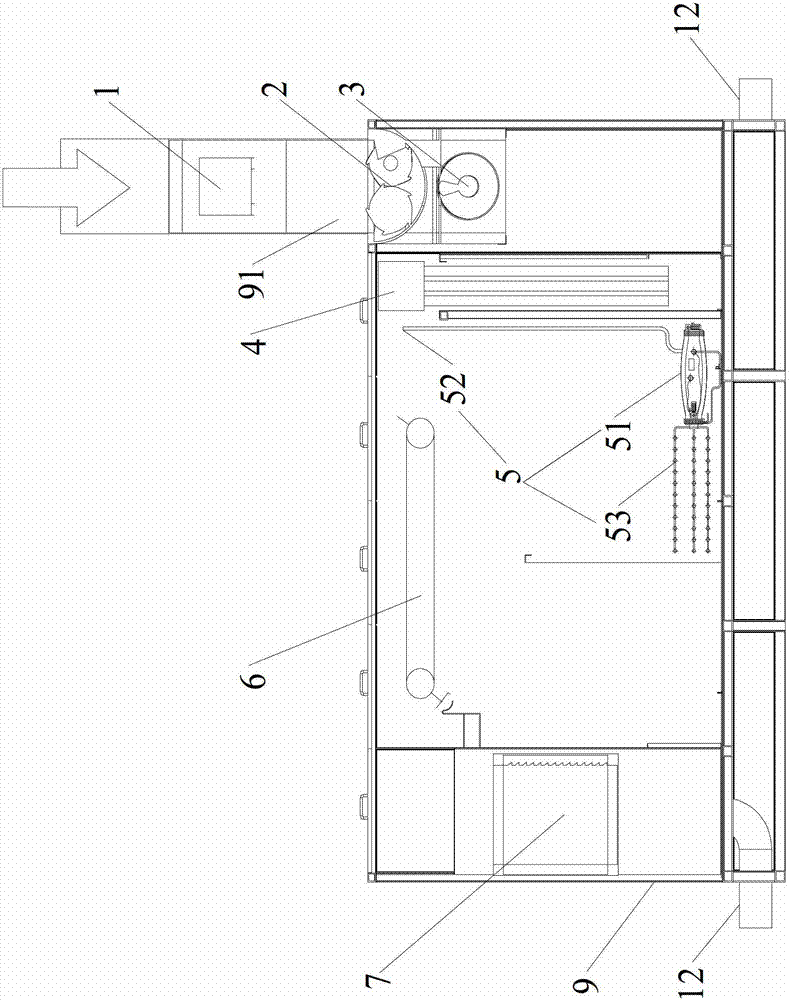

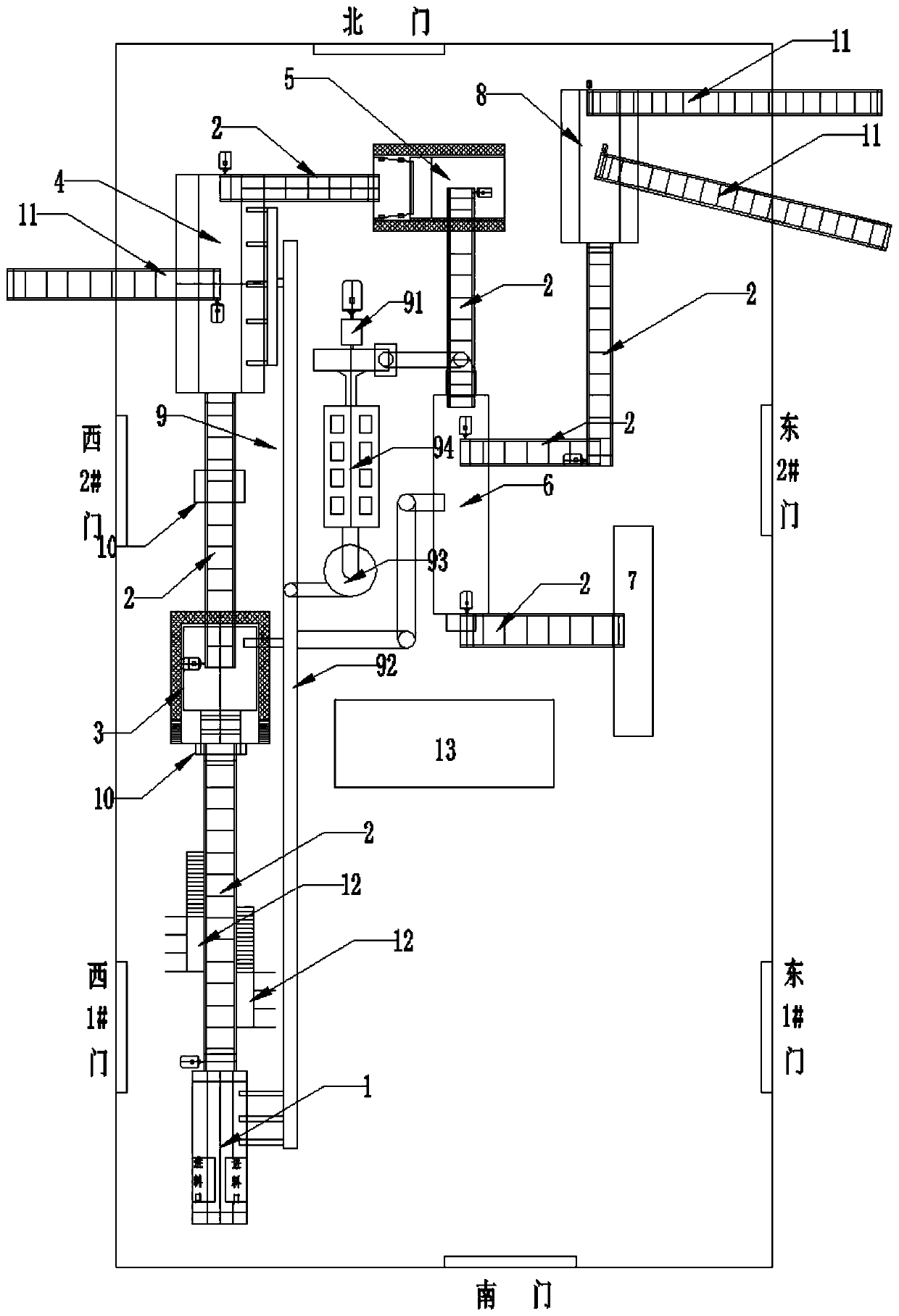

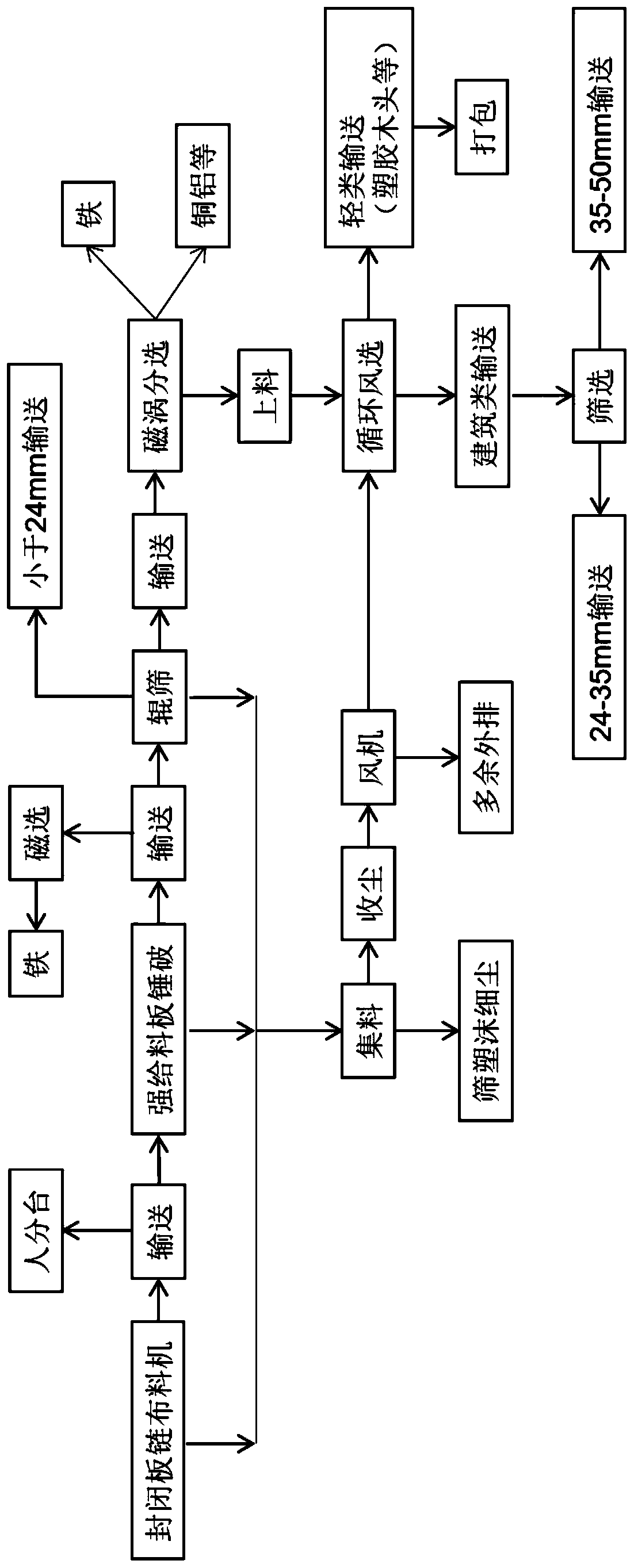

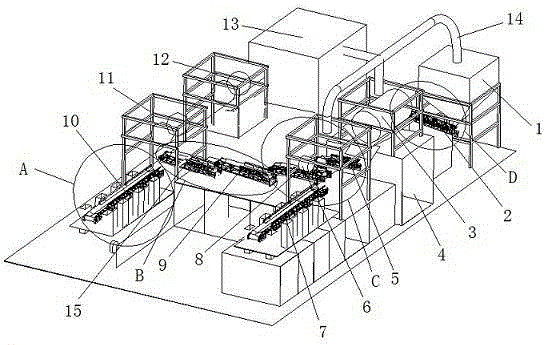

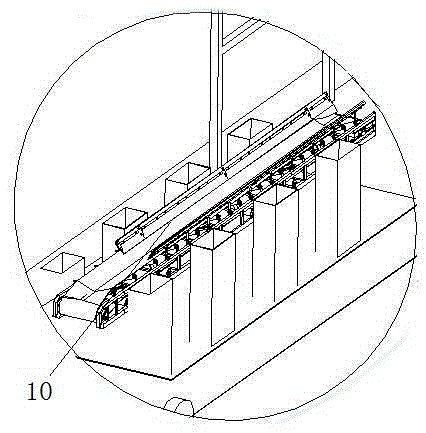

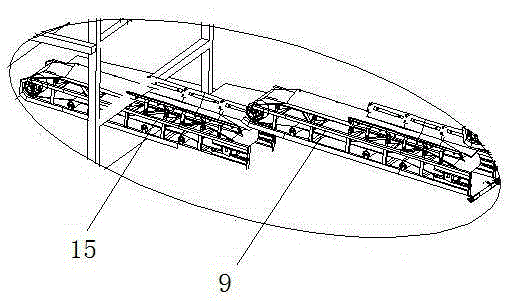

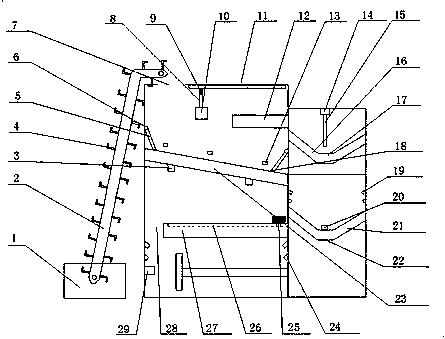

Construction waste classification treatment system and process

PendingCN110899309AAchieve recyclingEfficient collectionConstruction waste recoverySolid waste disposalMagnetic vortexDust control

The invention discloses a construction waste classification treatment system and process. The classified treatment system is characterized by comprising a closed chain plate distributing machine (1),strong feeding plate hammering equipment (3), a first roller screen (4), magnetic vortex sorting equipment (5) and circulating winnowing equipment (6) which are sequentially connected through conveying equipment (2); the circulating winnowing equipment (6) is connected with the packaging equipment (7) and a second roller screen (8) through the conveying equipment (2); the system also comprises dust removing equipment (9) which is connected with the closed chain plate distributing machine (1), the strong feeding plate hammering equipment (3), the first roller screen (4) and the circulating winnowing equipment (6) to remove dust. According to the construction waste treatment system, the processes of crushing, screening, magnetic separation, winnowing, packaging and the like can be effectively carried out on construction waste, recycling of the construction waste is achieved, and particularly dust and the like generated in the production process can be effectively collected through the dust collection system. An environment-friendly, effective and economical construction waste recycling and classifying treatment system is realized.

Owner:HUBEI XINXINLAN ENVIRONMENTAL PROTECTION TECH CO LTD

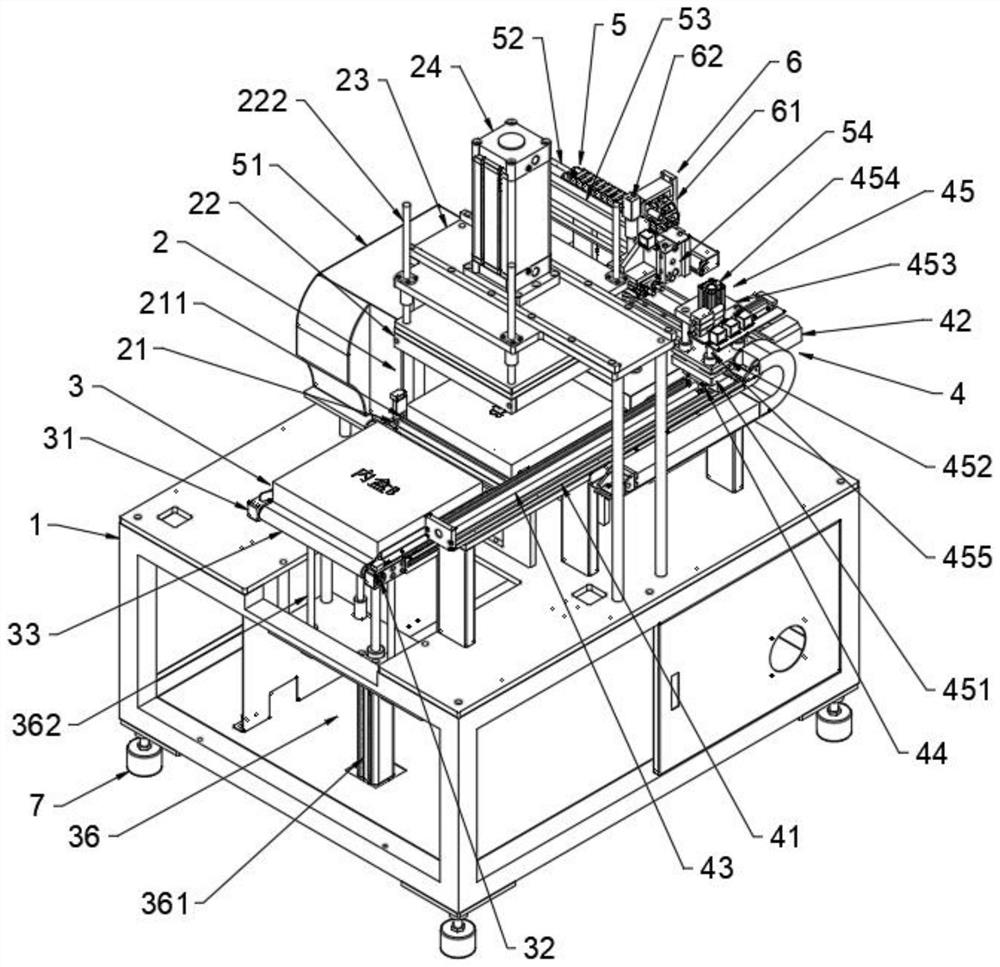

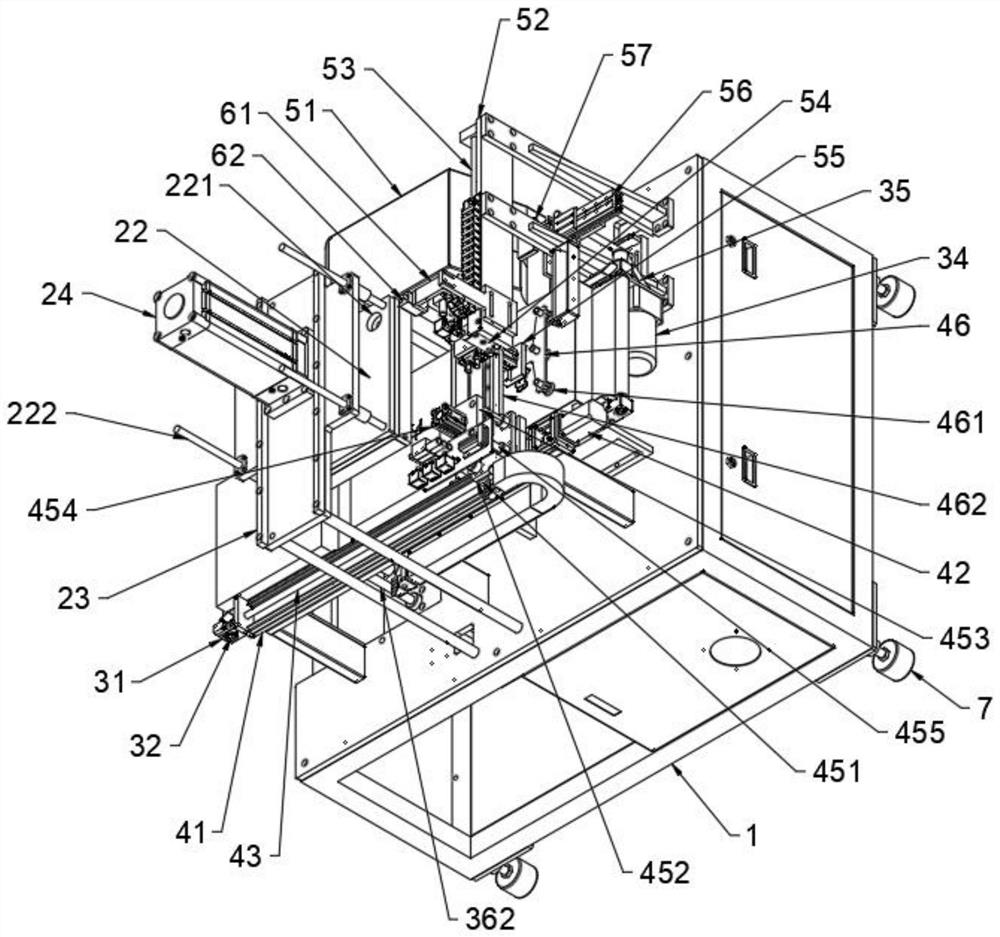

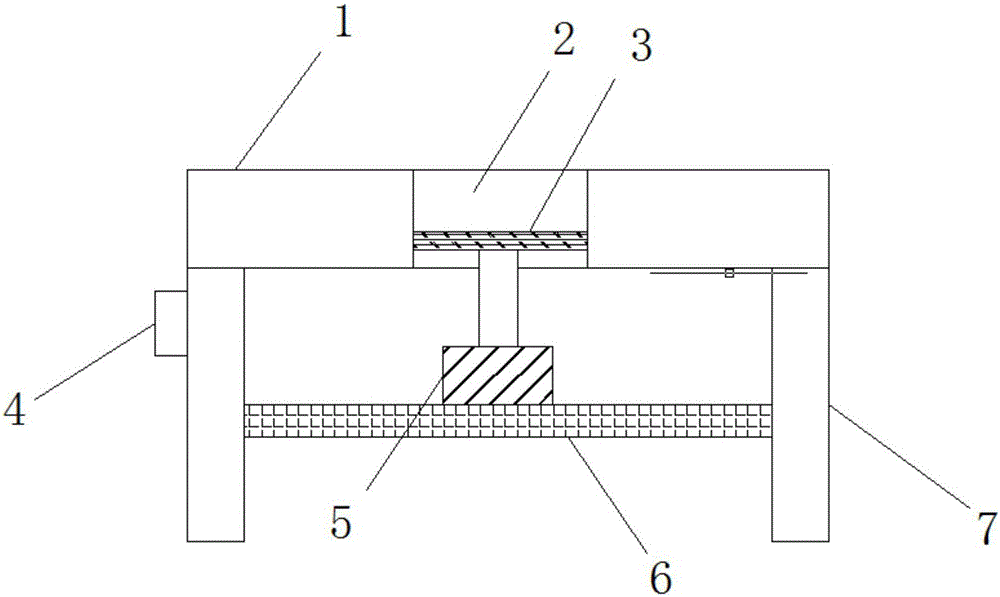

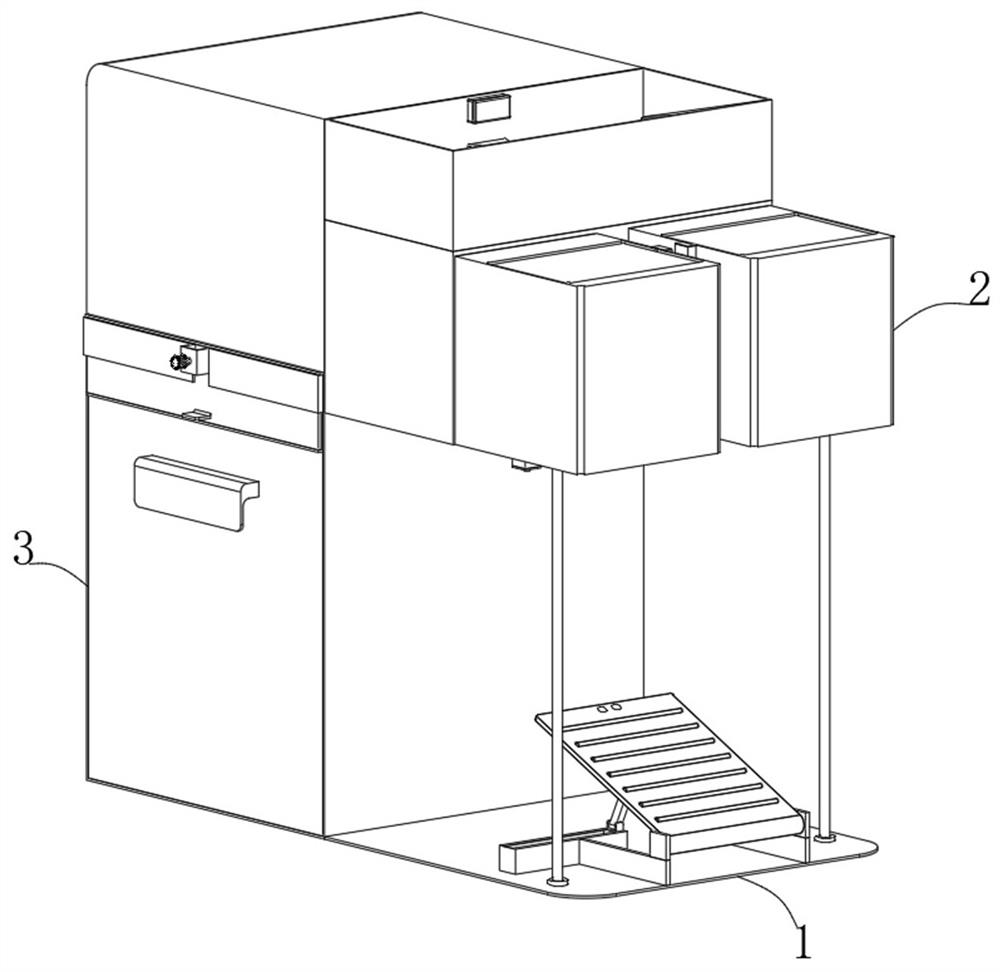

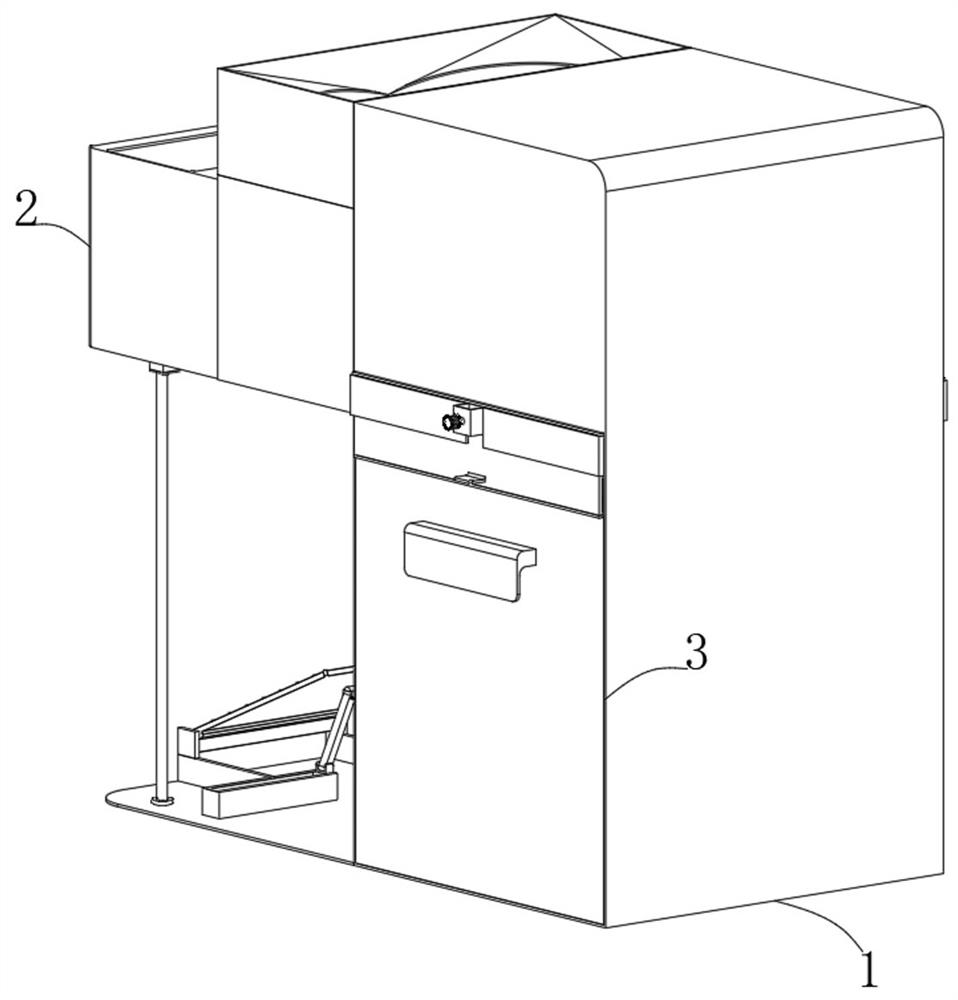

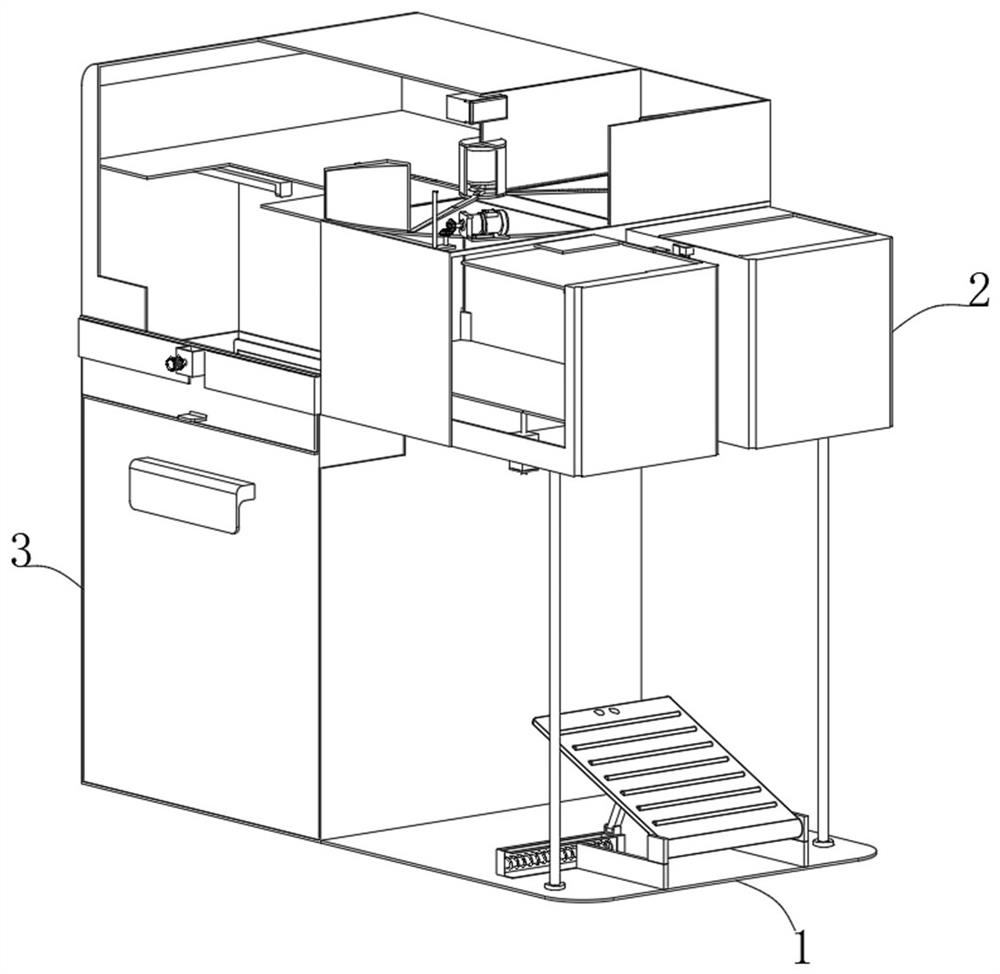

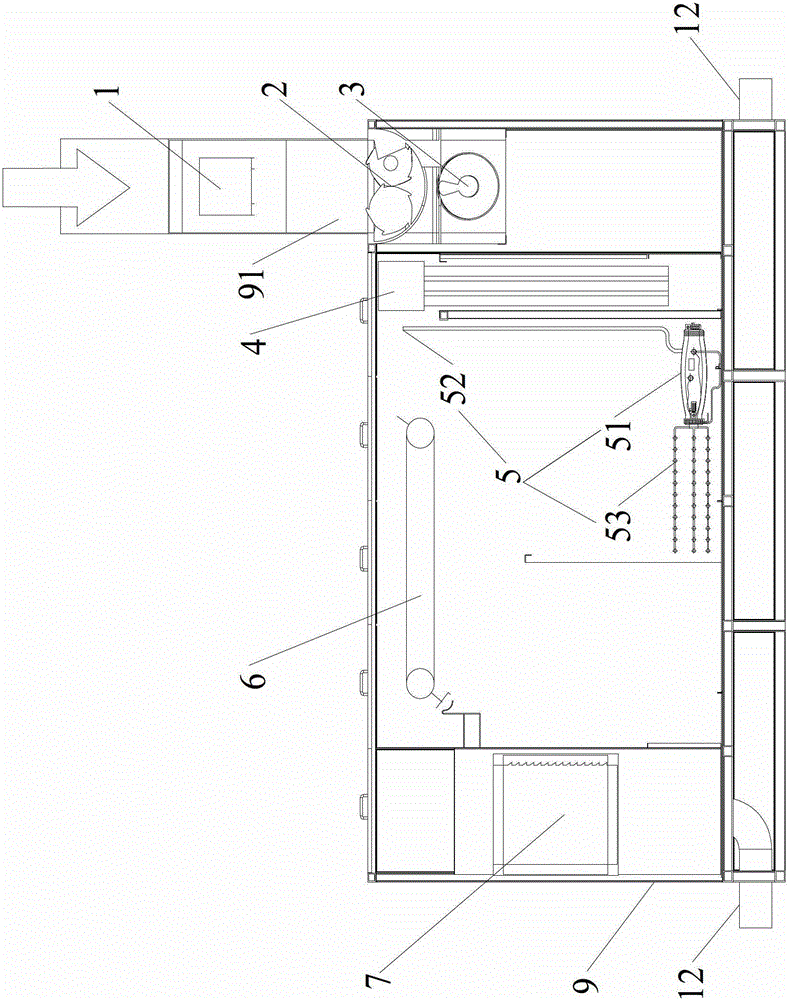

Full-automatic air tightness detection machine

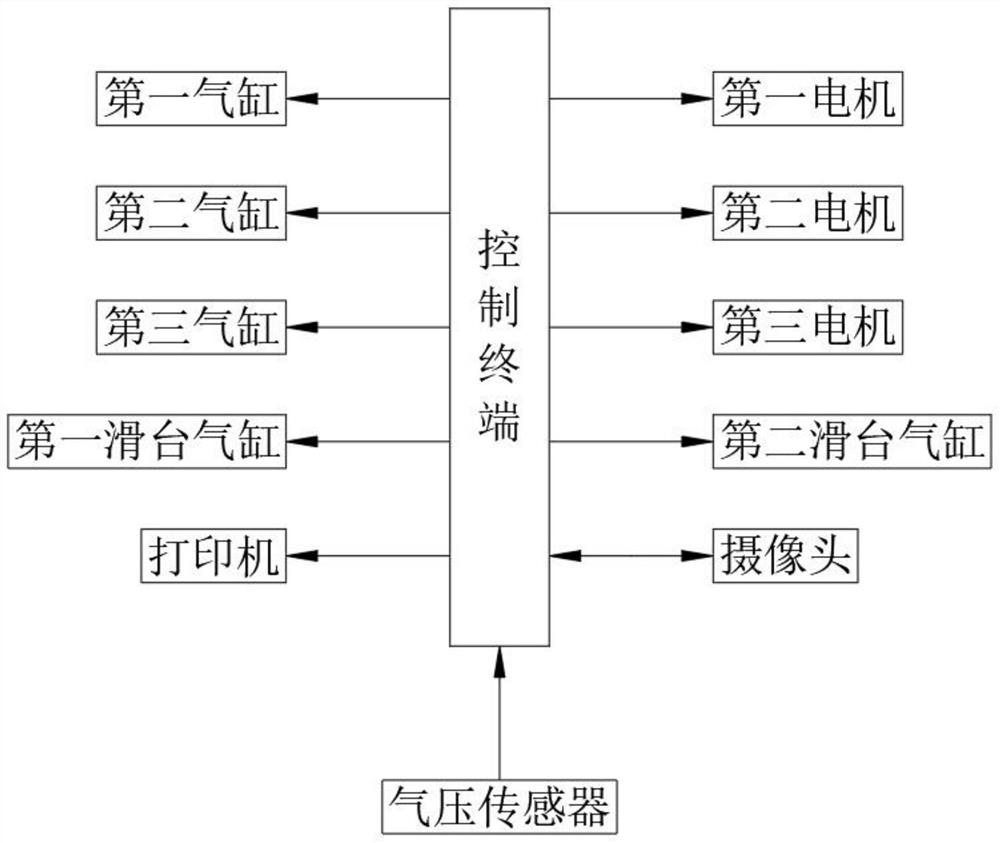

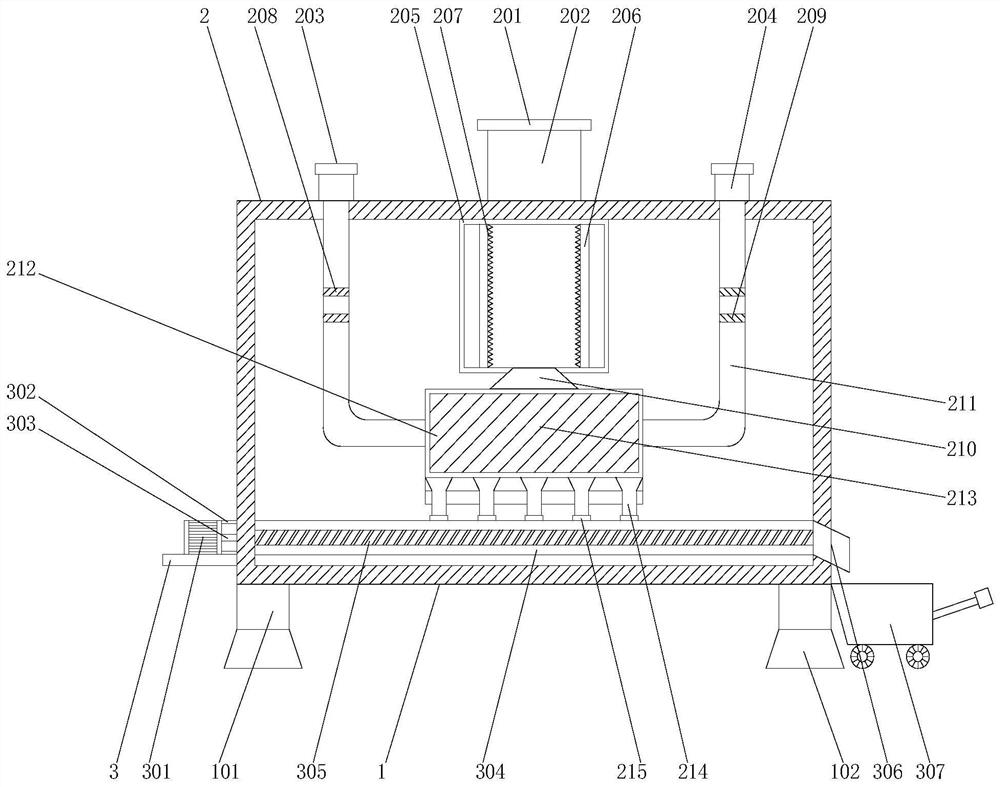

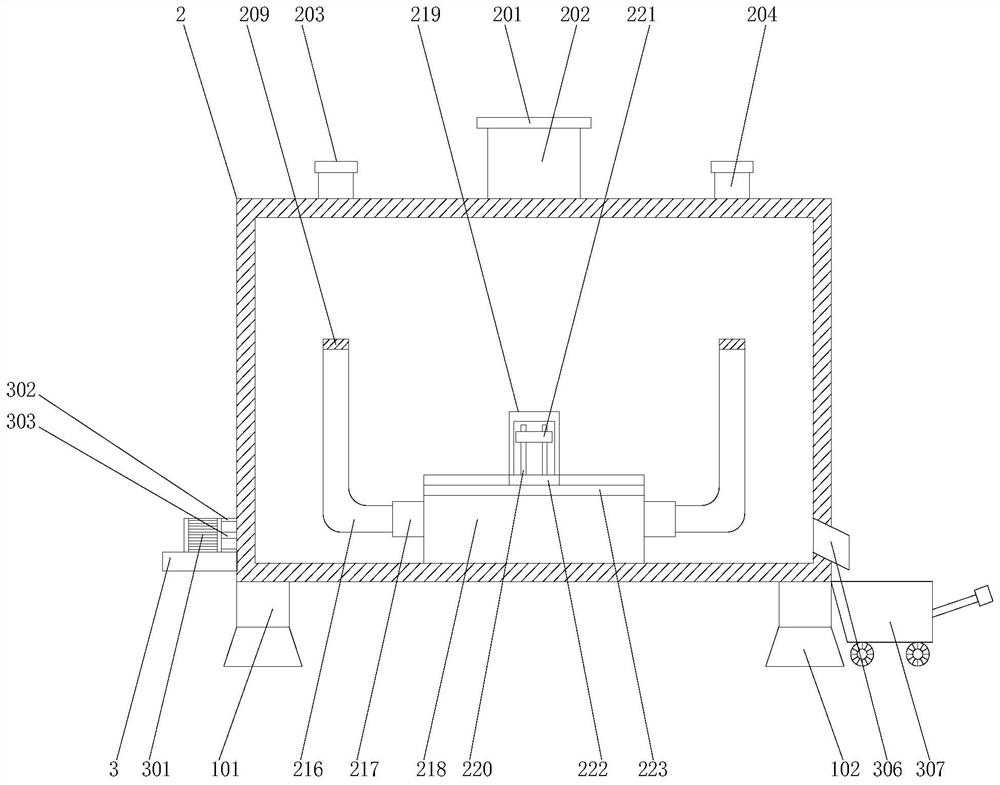

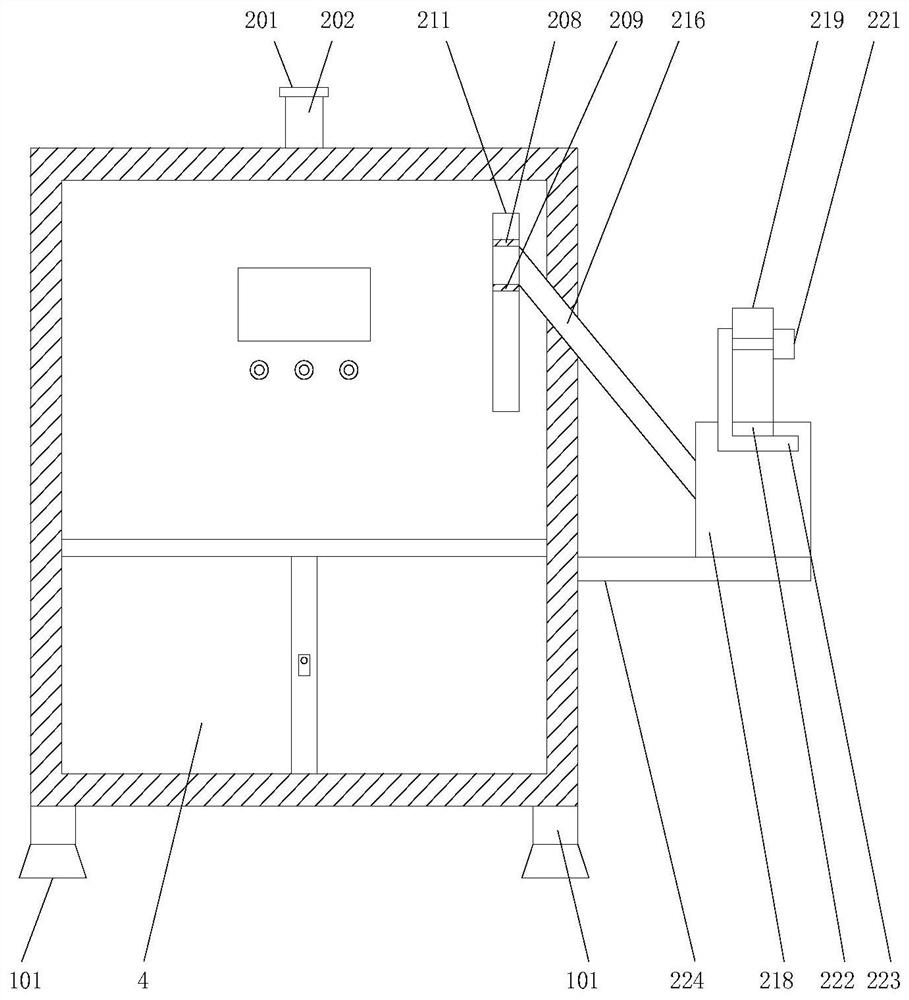

PendingCN112113724ALow running costRealize fully automatic detectionMeasurement of fluid loss/gain rateStructural engineeringCylinder block

The invention discloses a full-automatic air tightness detection machine, belonging to the field of quality inspection equipment. The full-automatic air tightness detection machine comprises a supportbody, an air tightness detection mechanism, feeding mechanisms, a material taking device, a labeling mechanism and a label calibration device, wherein the air tightness detection mechanism comprisesa lower cylinder body fixedly installed on the support body and an upper cylinder body which is located above the lower cylinder body and can move up and down to seal and cover the lower cylinder body; the upper cylinder body is provided with an air inlet which longitudinally penetrates through the upper cylinder body and is used for installing an inflation guide pipe; an air pressure sensor connected with a control terminal is fixedly mounted in the lower cylinder body or the upper cylinder body; and the number of the feeding mechanisms is two, and the two feeding mechanisms are symmetricallyinstalled on the two sides of the lower cylinder body and used for feeding or discharging. The full-automatic air tightness detection machine is simple in structure and convenient to use, intelligentcontrol is adopted, product packaging air tightness detection is achieved, and qualified products and inferior-quality products can be effectively classified; and the full-automatic air tightness detection machine is suitable for application and popularization.

Owner:上海磐云科技有限公司

Waste recovery device for refractory material installation

ActiveCN112620301AEffective sortingEfficient use ofSievingSolid waste disposalElectric machineRefractory

The invention discloses a waste recovery device for refractory material installation. The waste recovery device for refractory material installation comprises a supporting mechanism, a recovery mechanism, a conveying mechanism and a control mechanism, wherein a square groove charging port is formed in the central position of the top of the recovery mechanism, a square charging pipe is fixedly connected to the bottom of the square groove charging port, and circular groove charging ports are formed in the two ends of the outer side of the square groove charging port. According to the waste recovery device for refractory material installation, fine refractory material chippings are heated in the heating device for a certain period of time and discharged from a discharging port formed in the bottom of a discharging pipe, a discharging port consistent with the discharging port formed in the bottom of the discharging pipe is formed in the surface of the top of a sealing pipe fixedly connected with the outer surface of a threaded rod in a sleeving mode, and therefore the refractory material chippings are conveyed into the sealing pipe; and under the operation of a driving motor, a rotating shaft drives the threaded rod to rotate to convey the refractory material chippings to the right side, and finally the refractory material chippings are guided out from an inclined pipe fixedly connected to the right side of the sealing pipe to reach the conveying device, so that refractory material wastes are comprehensively treated and recycled, and the waste recycling rate is increased.

Owner:马鞍山盛平新材料科技有限公司

Solid waste treatment device and method

ActiveCN105381881AEffective sortingThe area of land resources is smallMagnetic separationWaste treatmentSmall footprint

The invention belongs to the technical field of solid waste treatment and particularly provides a solid waste treatment device. The solid waste treatment device comprises a bin, first conveying equipment, a drum screen, a magnetic separator, a vortex type magnetic separator and an electromagnetic separator, wherein the bin, the first conveying equipment, the drum screen, the magnetic separator, the vortex type magnetic separator and the electromagnetic separator are arranged in sequence. A discharge outlet of the bin is connected with a feed inlet of the drum screen through the first conveying equipment. The solid waste treatment device further comprises a wind magnetic separator, a gravity wind separator and an eddy current separator, wherein the wind magnetic separator is connected with the magnetic separator. The solid waste treatment device is reasonable in structure, small in occupied area and good in separation effect. The invention further provides a solid waste treatment method using the solid waste treatment device. By the adoption of the solid waste treatment method, the labor intensity of workers is relieved, the separation effect is good, economization and environmental friendliness are achieved, and the utilization rate of separated solid waste is high.

Owner:NANJING JIARONG RENEWABLE MATERIALS RECOVERY CO LTD

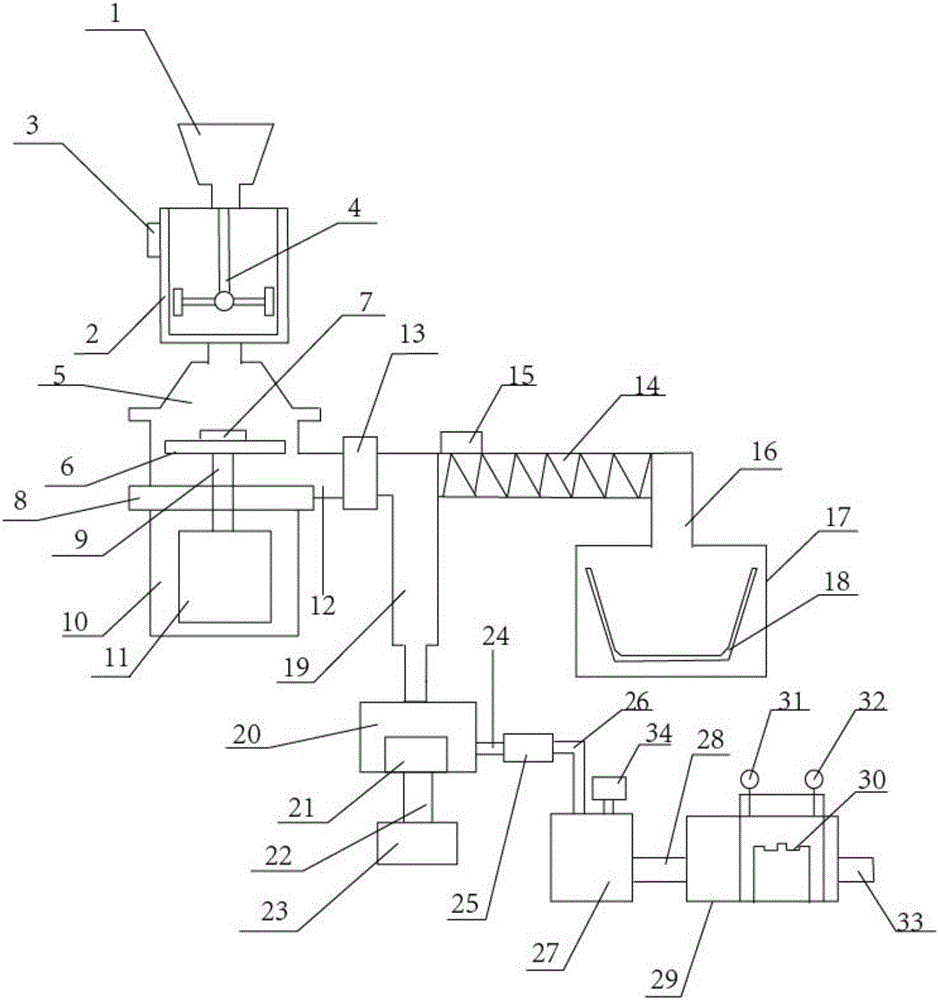

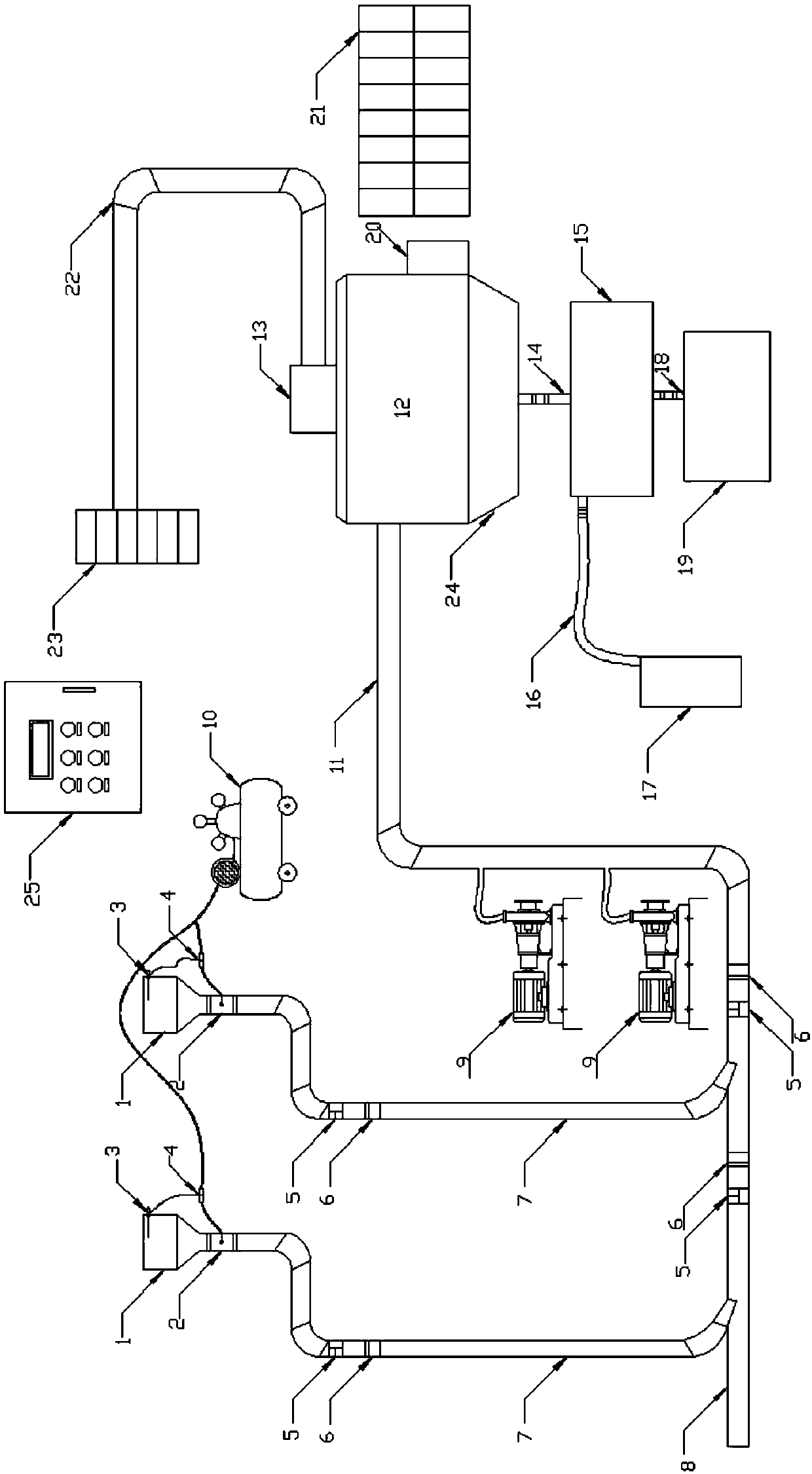

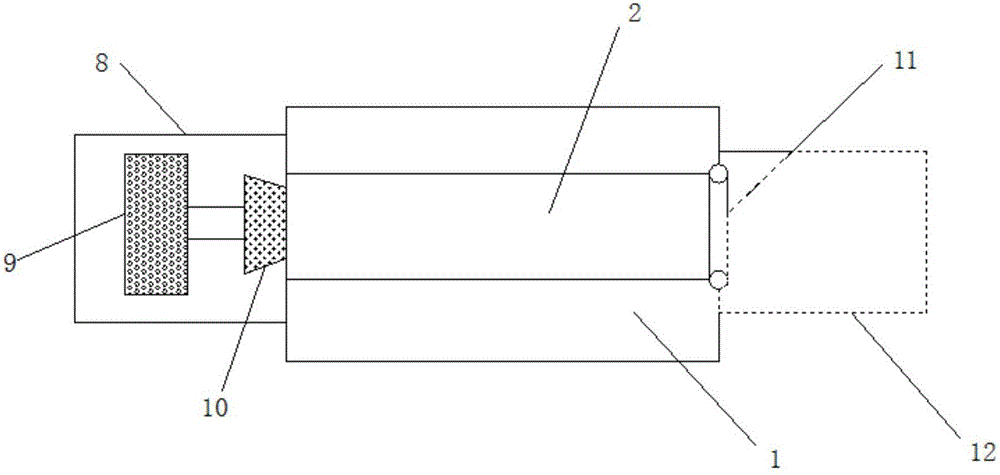

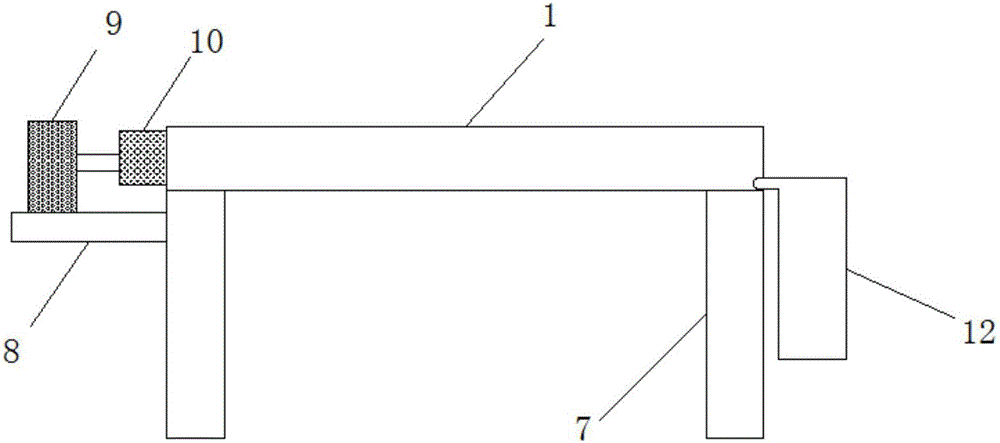

Kitchen waste vacuum collecting, crushing and classifying treatment system and method

PendingCN109570193AIncrease water pressureGuarantee a clean environmentSolid waste disposalAutomatic controlControl system

The invention discloses a kitchen waste vacuum collecting, crushing and classifying treatment system and method. The kitchen waste vacuum collecting, crushing and classifying treatment system comprises a kitchen garbage collecting tank, a flushing device, a vacuum transporting device, a kitchen waste crushing treatment device and a PLC automatic control system; power structures and movable parts of the flushing device, the vacuum transporting device and the kitchen waste crushing treatment device are all controlled by the PLC automatic control system; kitchen waste is sucked into the vacuum transporting device through a vacuum interface valve under the effects of water flow impulsion, gravity and vacuum negative pressure; and the vacuum transporting device transports the waste to the kitchen waste crushing treatment device through the negative pressure generated by the vacuum transporting device. The negative pressure is generated through the vacuum principle to suck the kitchen waste,and thus as for waste treating, the defects that waste residue is left, and the smell of the waste is not diffused for a long time can be avoided, so that a kitchen is always in a clean and fresh environment.

Owner:SHANDONG UNIV

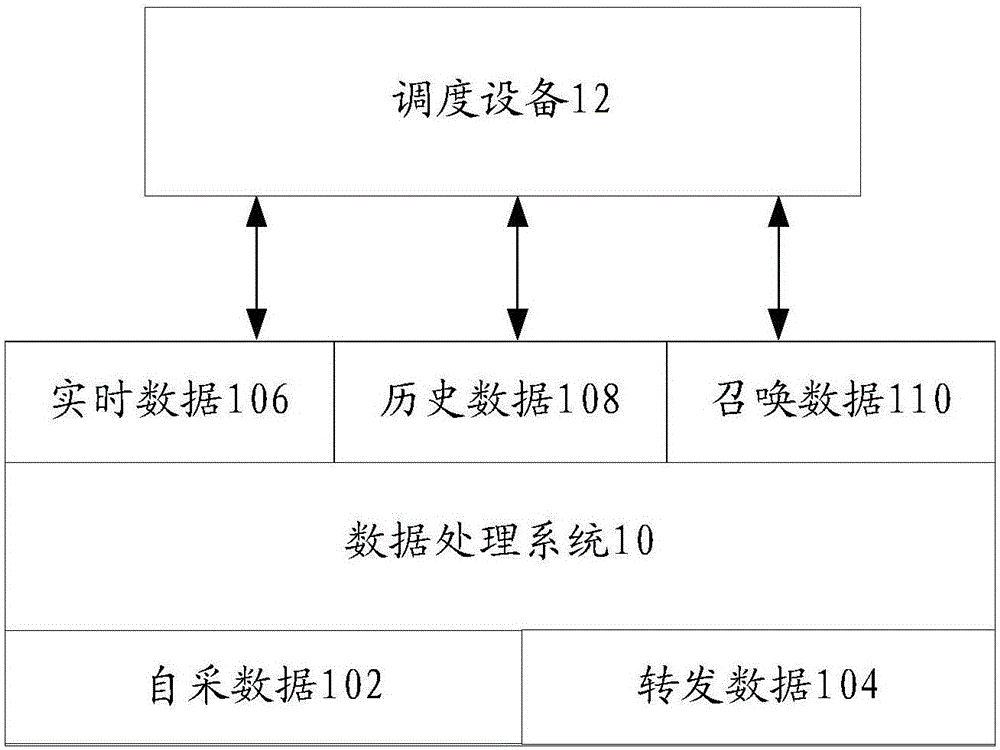

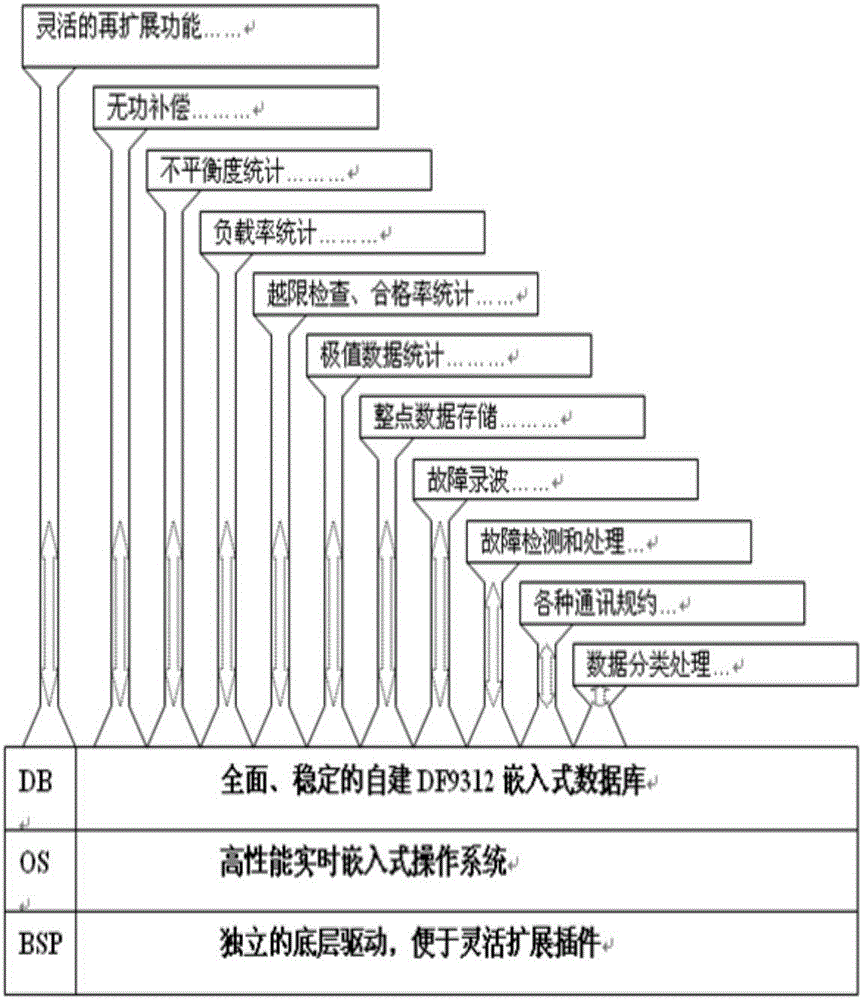

Data processing method, apparatus and system

InactiveCN106708979AImprove processing efficiencyEffective sortingRelational databasesSpecial data processing applicationsPriority schedulingData model

The invention discloses a data processing method, apparatus and system. The system comprises a data processing system and dispatching equipment. The data processing system is used for performing classification processing on at least one type of data meeting a preset condition to obtain at least one type of data model. The data processing system is further used for setting a priority of the at least one type of data model, wherein the at least one type of data at least includes one of the following data: self-acquired data and forwarded data. The dispatching equipment communicates with the data processing system and is used for dispatching the at least one type of data model according to the priority of the at least one type of data model, wherein the at least one type of data model at least comprises one of the following data: real-time data, historical data and call data. According to the data processing method, apparatus and system, the technical problem that the data cannot be effectively processed to obtain an electric data model during data dispatching in the prior art is solved.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

Water purification technology and water purification equipment

InactiveCN104098218BReasonable useEfficient removalMultistage water/sewage treatmentWater usePotable water

The invention relates to a water-purifying process and water-purifying equipment thereof. Tap water is treated into flushing water, clean water and direct drinking water in a grading and classifying manner as required through a first-stage purification treatment device, a second-stage purification treatment device and a third-stage purification treatment device which are connected in sequence from bottom to top. By adopting the water-purifying process and the water-purifying equipment, water resources are utilized more optionally and reasonably, the problems of secondary pollution and the like since heavy metal pollutants in tap water cannot be removed in an efficient and environment-friendly way in the prior art are solved effectively, heavy metal ions, residual chlorine and other harmful particles in tap water are removed efficiently, bacteria are killed, the water quality is improved, sewage is disposed automatically, and the water yield and the utilization ratio of water are increased greatly; the health of a user is ensured; tap water is classified and treated effectively and is utilized in a shunting way according to the water quality, water amount and water pressure requirements of household water, and water is saved; energy is saved efficiently, space is saved, and remarkable energy-saving and environmental protection effects are achieved. The water-purifying process and the water-purifying equipment are suitable to be popularized and applied in relevant tap water treatment field.

Owner:合肥一言科技发展有限公司

Two-bin eccentric garbage-compressing bin device

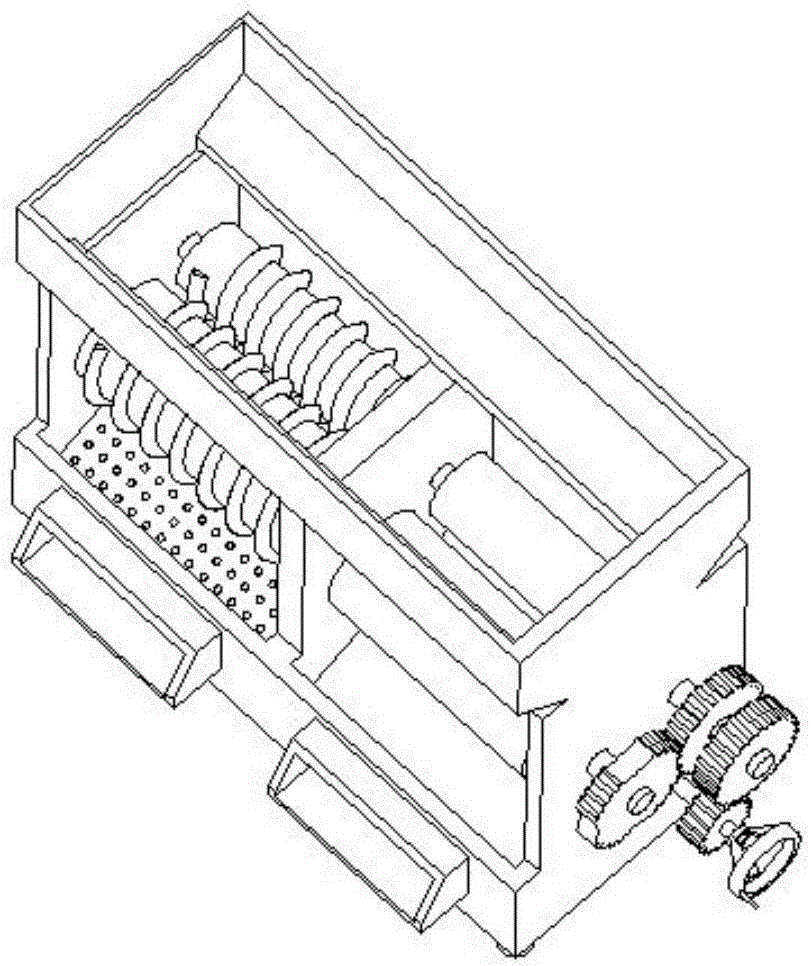

The invention discloses a two-bin eccentric garbage-compressing bin device. The two-bin eccentric garbage-compressing bin device comprises a bin body, a hydrophobic board, a large roller, an incomplete gear, an input shaft, a small gear, a hand wheel, a first large gear, a second large gear and an eccentric roller and is characterized in that the bin body is divided into two parts; a left cavity is a dewatering cavity; the hydrophobic board is mounted at the bottom of the left cavity; the large roller and the eccentric roller in the left cavity have spiral structures; a right cavity of the bin body is used for compressing water-free garbage; the incomplete gear is mounted at the tail end of the large roller; the second large gear is meshed with the incomplete gear; the input shaft is mounted on the bin body; the small gear and the hand wheel are mounted on the input shaft; the small gear is meshed with the first large gear. The two-bin eccentric garbage-compressing bin device has the beneficial effects that the garbage is compressed by two cavities; the classification treatment of garbage is effectively achieved; meanwhile, the device is capable of ensuring that the water-containing garbage and the dry garbage are separately compressed and packed; the garbage is cleaner; the hybrid mode of static grinding and rolling grinding is adopted; common characteristics of the static grinding mode and the rolling grinding mode are combined together; the efficiency is higher; the effect is better.

Owner:JIANGSU MORAL ENVIRONMENTAL PROTECTION TECH CO LTD

Workbench used for making clothes

The invention discloses a workbench used for making clothes. The workbench includes a platform. The middle of the upper end of a cross bar is provided with a first air cylinder. The upper end of the first air cylinder is connected with a first top plate through a connecting rod. The first top plate is located in an inner cavity of a channel. The middle of the upper part of a fixing plate is provided with a second air cylinder, the second air cylinder is connected with a second top plate matched with the channel through a connecting rod, and a one-way valve is arranged at an end hole of the channel. According to the workbench used for making clothes, through the arrangement of the fixing plate and the cross bar, the upper ends of the fixing plate and the cross bar are provided with the first air cylinder and the second air cylinder respectively, workbench is simple to make, the working efficiency is high, labor of workers is saved, the benefits of manufacturers are improved, the workingenvironment of the manufacturers is kept and reaches a certain standard, garbage and finished products are effectively classified for treatment, working operation is reduced, meanwhile the investmentin workers' wages is reduced, and the workbench has a certain advantage and is worth of application and popularization in the future.

Owner:浙江百先得服饰有限公司

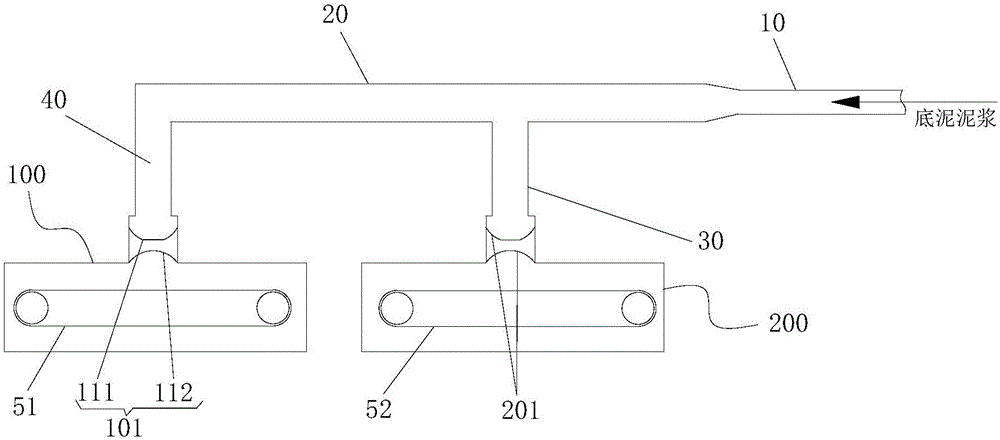

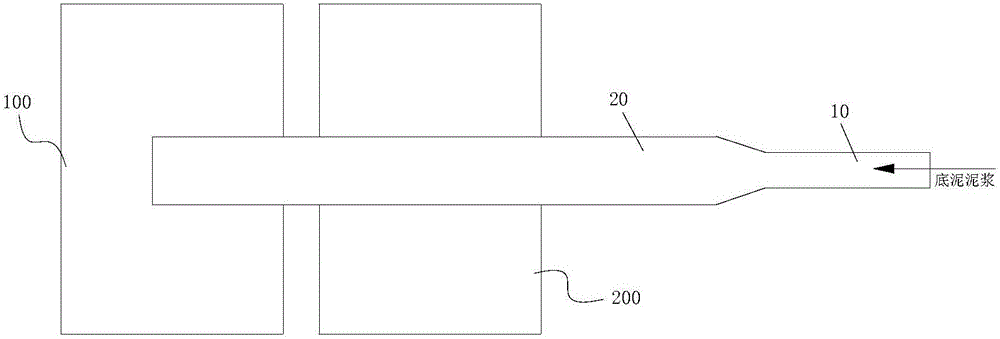

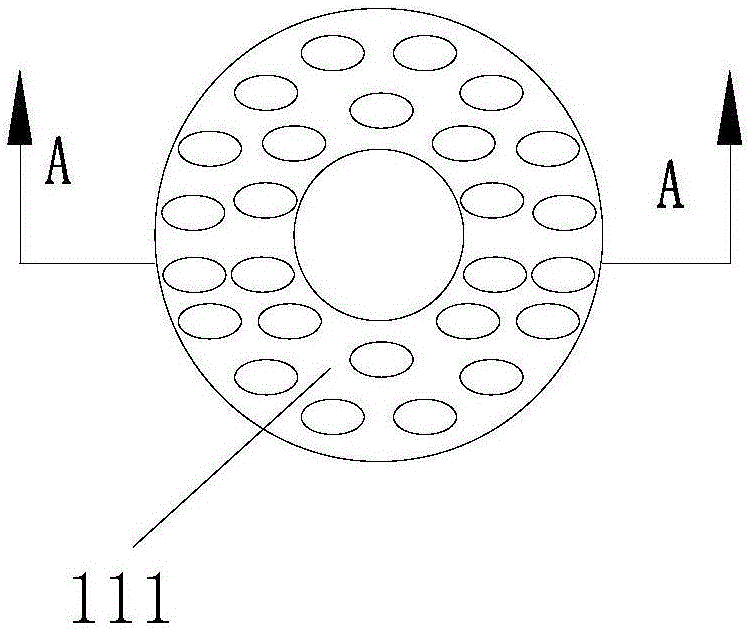

Garbage primary selection system for river and lake pollution bottom sludge treatment

ActiveCN106082573AEffective sortingSave the heavy sorting workSludge treatment by de-watering/drying/thickeningSoil-shifting machines/dredgersPollutionSelection system

The invention provides a garbage primary selection system for river and lake pollution bottom sludge treatment. The garbage primary selection system comprises a first grid machine and a second grid machine which are arranged in parallel, a bottom sludge slurry conveying main pipeline, a first bottom sludge slurry conveying branch pipeline and a second bottom sludge slurry conveying branch pipeline, wherein one end of the bottom sludge slurry conveying main pipeline is used for being communicated with a sludge conveying pipeline of dredging equipment; one end of the first bottom sludge slurry conveying branch pipeline is communicated with the other end of the bottom sludge slurry conveying main pipeline; the other end of the first bottom sludge slurry conveying branch pipeline is communicated with the first grid machine; one end of the second bottom sludge slurry conveying branch pipeline is communicated with the first bottom sludge slurry conveying branch pipeline and a connection position between the end and the first bottom sludge slurry conveying branch pipeline is located at the bottom of the first bottom sludge slurry conveying branch pipeline; the other end of the second bottom sludge slurry conveying branch pipeline is communicated with the second grid machine. By virtue of the technical scheme provided by the invention, building garbage and domestic garbage in bottom sludge slurry are sorted and then are separated.

Owner:POWERCHINA WATER ENVIRONMENT GOVERANCE

An automatic construction waste sorting and recycling device

ActiveCN108772194BEffective sortingImprove resource utilizationMagnetic separationCleaning using liquidsSoil treatmentBrick

The invention discloses an automated construction waste sorting and recycling device, comprising a feeding device, a sorting device and a treating device, wherein the feeding device comprises a wasteplacement box, a conveyor belt, a baffle plate and a feeding hole; the sorting device comprises an electromagnetic net, a material picker and a conveyor belt; the treating device comprises a plastic treatment chamber, a metal treatment chamber and a brick and soil treatment chamber; the brick and soil treatment chamber is internally provided with a water injection nozzle and a transverse plate; the transverse plate is provided with a groove, and a sawing plate is arranged in the groove; a drop mouth is formed at one side of the transverse plate, and a first pressure sensor is arranged under the drop mouth; a push rod is arranged under the brick and soil treatment chamber; the metal treatment chamber is provided with a flushing head and a first barrier plate; the first barrier plate is provided with a second pressure sensor and a moving opening; a heating rod is arranged above the plastic treatment chamber; a contraction device is arranged above the heating rod; a second barrier plate is arranged under the heating rod; a material collecting hole is formed in the second barrier plate. By means of arrangement of the devices, the automated construction waste sorting and recycling device realizes the sorting and recycling of construction wastes, and increases the utilization rate of resources.

Owner:福建永东南建设集团有限公司

Working table for garment processing

ActiveCN106360864ALabor savingImprove efficiencyClothes making applicancesWorking environmentEngineering

The invention discloses a working table for garment processing. The working table comprises a platform, a first cylinder placed in the middle of the upper end of a level bar, a first top plate connected with the upper end of the first cylinder through a connection bar, the first top plate is placed in an inner cavity of a groove path, a second cylinder is placed in the middle of the upper end of a fixing plate, and a second top plate matched with the groove path is connected with the second cylinder through a connection bar. Both ends of the groove path are provided with one-way valves. By the placement of the fixing plate and the level bar and the installation of the first cylinder and the second cylinder on the fixing plate and the level bar respectively; plus the simple manufacturing of the work table itself, boosts the work efficiency to a high level, saves labor of workers, increases the profits of manufacturers, and maintains the working environment of manufacturers at a qualified standard. The effective separation and classification of waste material from finished products and the divided treatment thereof can save a plurality of processing stages, thus save the salaries for many workers at the same time. All these factors grant the working table certain advantages, and make the working table worthy to be promoted and applied.

Owner:ZHEJIANG DAZUIYA CLOTHING CO LTD

A sorting garbage collection device and collection method thereof

ActiveCN113859806BEffective sortingLower the altitudeRefuse receptaclesRefuse cleaningEngineeringStructural engineering

The invention discloses a sorting garbage collection device and a collection method thereof, comprising: a functional mechanism, a guiding mechanism and a storage mechanism, the functional mechanism includes a bottom frame, a screening part, a connecting part and an adjusting part, and the front surface of the bottom frame is close to the edge of the bottom The bottom plate is fixedly connected, and the outer surfaces of both sides of the bottom frame are fixedly connected with sliding frames. The top of each sliding frame slides through a card plate, and the bottom of each card plate is fixedly connected with a positioning bar. The outer surface of one side of each sliding frame Positioning bolts are connected by threads, and a T-shaped support plate is fixedly connected to the inner bottom surface of the bottom frame. The invention can effectively classify domestic garbage, and can effectively prevent the breeding of more bacteria and heavy odor after the garbage is stored for a long time.

Owner:徐州芒原智能科技有限公司

Kitchen waste and waste water treatment integrated device and method

InactiveCN103159367BEffective sortingEffective physical isolation spaceMultistage water/sewage treatmentGrain treatmentsOil and greaseCollection system

The invention discloses a kitchen waste and waste water treatment integrated device and a method. The kitchen waste and waste water treatment integrated device comprises casing body which contains a water inlet and a sewage draining port, a classification system arranged at the position of the water inlet, a crushing system connected to the classification system, a dehydration system connected to the crushing system, a deodorizing and sterilization system connected to the dehydration system, an oil-water separating system connected to the deodorizing and sterilization system, an oil scraping system connected to the oil-water separating system, a filtration system connected to the oil-water separating system and a collection system; and the classification system, the crushing system and the oil scraping system are respectively connected to the collection system. The kitchen waste and waste water treatment integrated device employs the above structure, and can effectively classify and treat the metal waste, organic garbage, oil and waste water in kitchen waste water.

Owner:广州护源环境保护科技有限公司

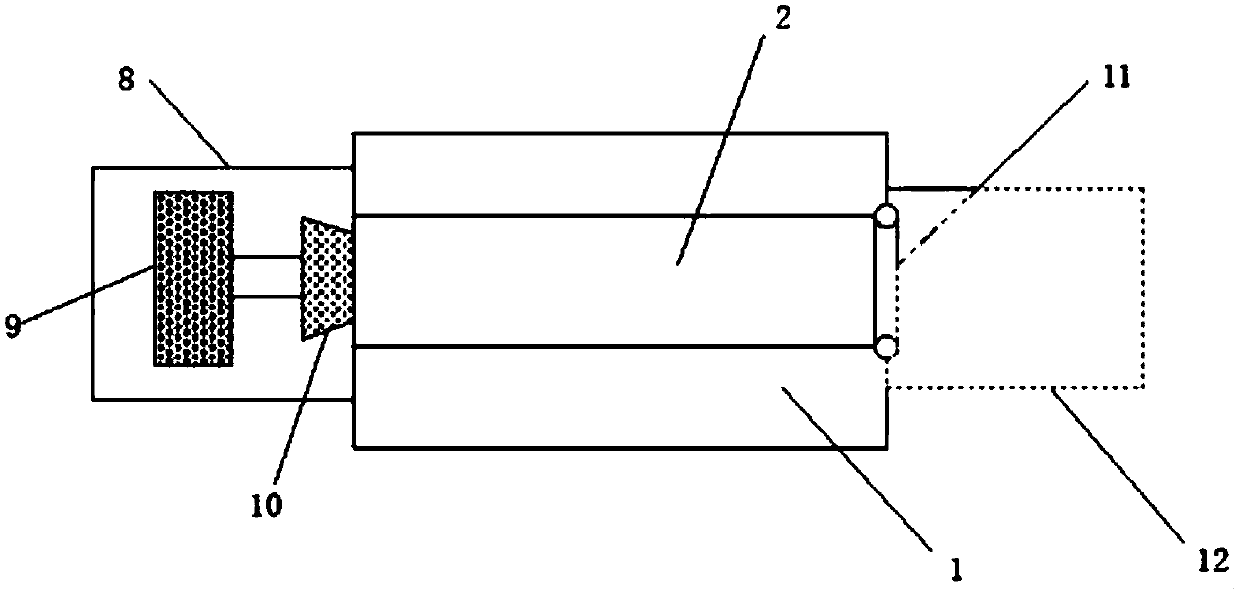

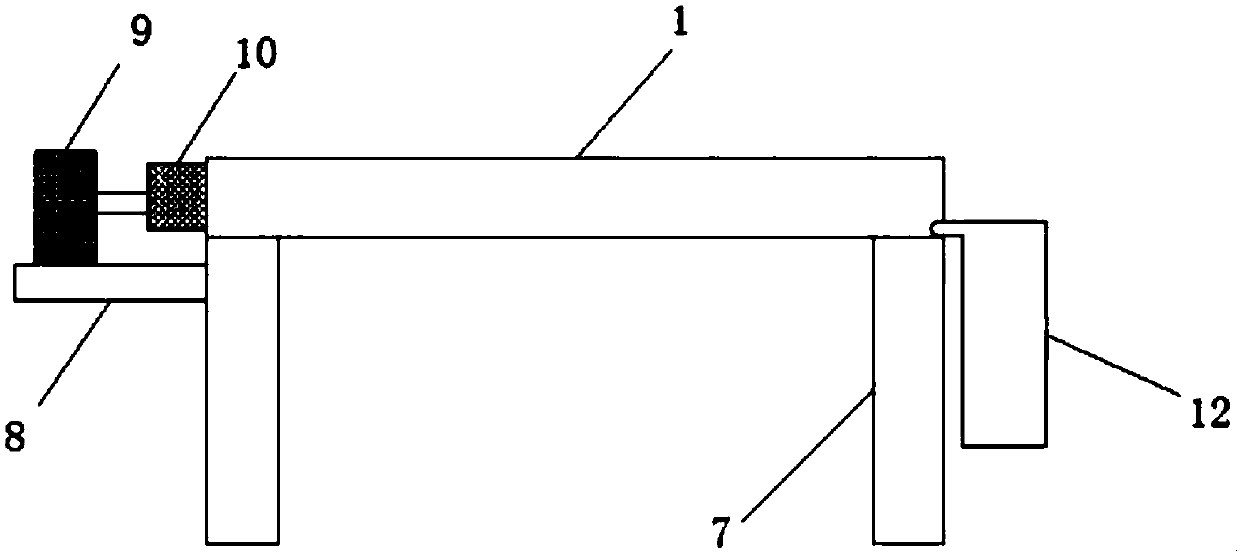

Kitchen waste pretreatment equipment

PendingCN107999225AEffectively complete the crushingEffective sortingGrain treatmentsPre treatmentWaste management

Kitchen waste pretreatment equipment comprises a treatment device and a feeding device. The treatment device comprises a discharging chamber, a separation chamber, a spiral feeding piece and a grinding piece. The discharging chamber is provided with a discharging port, and a circulation pond is arranged at the bottom of the discharging chamber. The separation chamber is arranged in the dischargingchamber and arranged above the circulation pond, and a gap is arranged between the side wall of the separation chamber and the discharging chamber. The side wall of the separation chamber is providedwith filter holes distributed in the circumferential direction of the separation chamber. The separation chamber is provided with a separable chamber outlet communicating with the discharging port. The spiral feeding piece is arranged in the separation chamber, the grinding piece is arranged at the bottom of the separation chamber, and the grinding piece can rotate around the center axis of the separation chamber. The feeding device is used for conveying kitchen waste to the bottom of the separation chamber. The separation chamber outlet is formed above the connecting position of the feedingdevice and the separation chamber. The spiral feeding piece is used for conveying kitchen waste to the separation chamber outlet. The kitchen waste pretreatment equipment can effectively conduct separation treatment on different kinds of garbage, and cost is low.

Owner:彭小冬 +1

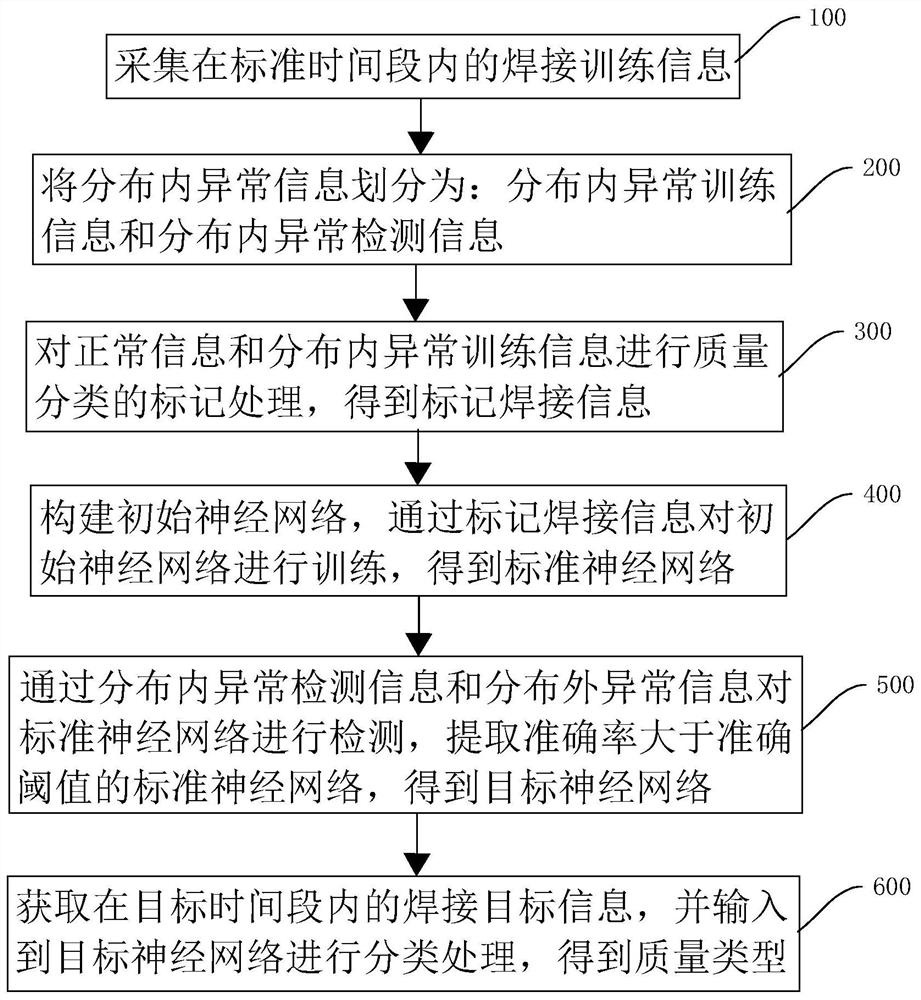

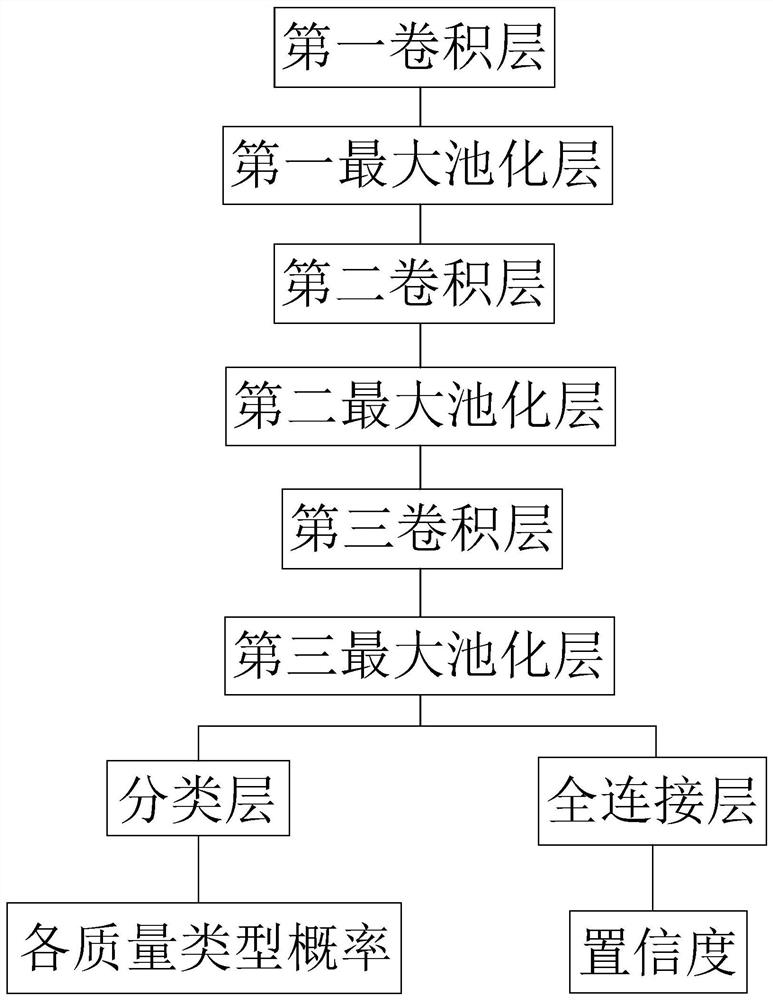

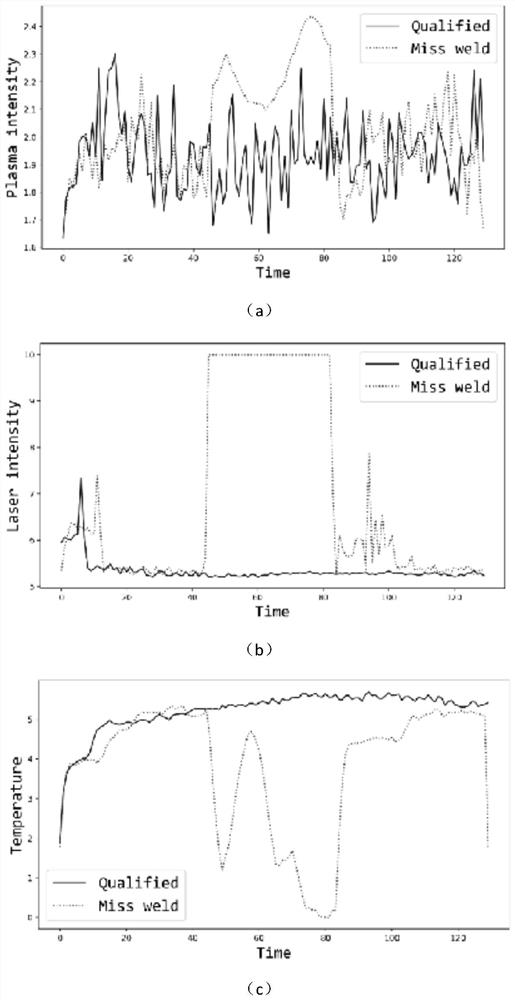

Quality inspection method, device and storage medium based on laser welding

ActiveCN112171057BEasy to trainEffective sortingCharacter and pattern recognitionNeural architecturesAnomaly detectionEngineering

Owner:WUYI UNIV

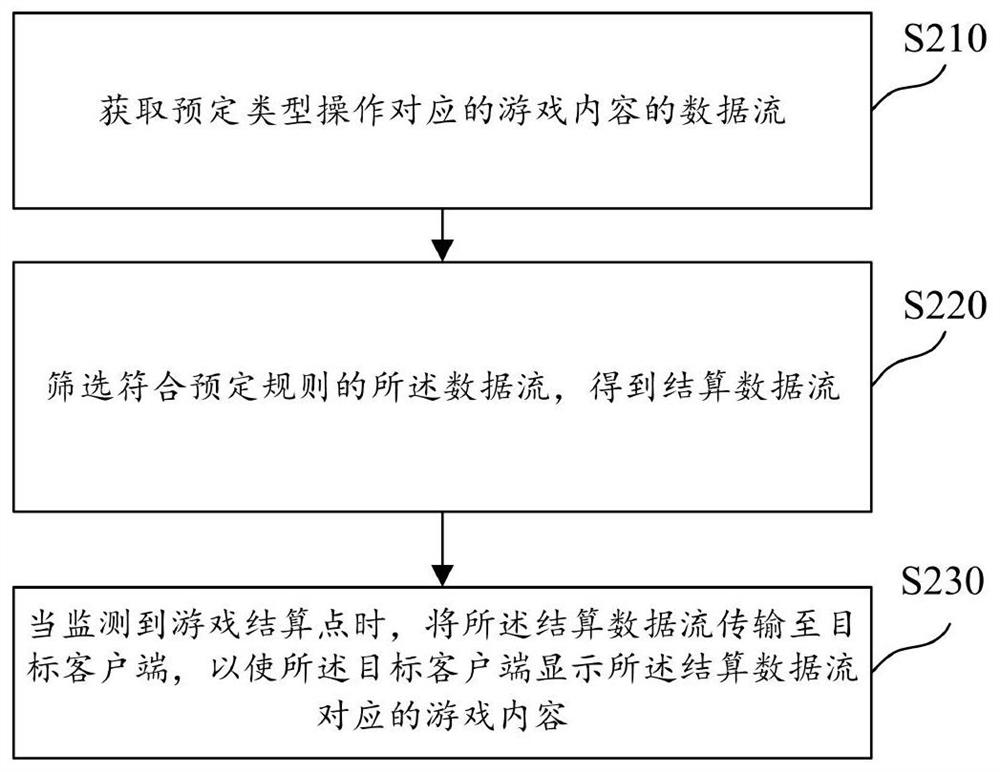

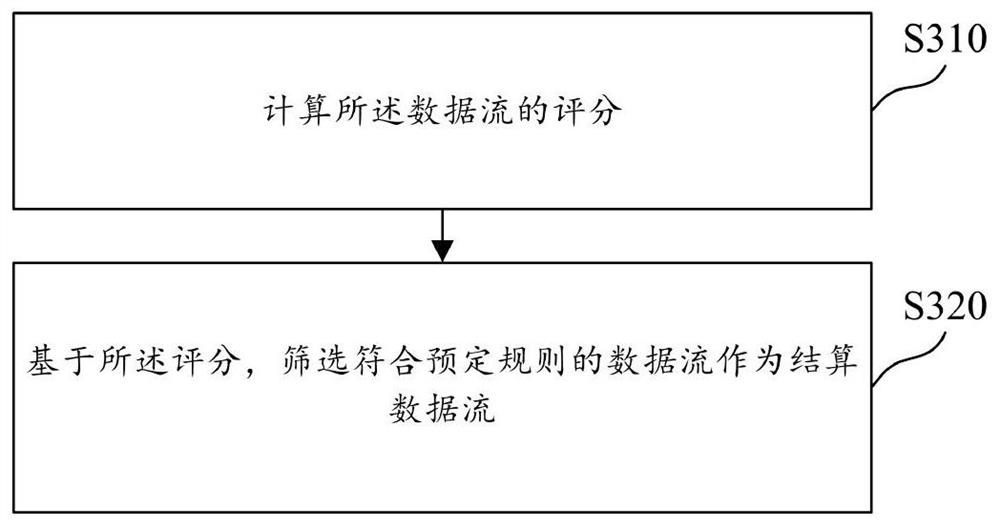

Game content data processing method and related device

The invention provides a game content data processing method and a related device, and belongs to the technical field of computers. The method comprises the following steps: acquiring a data stream of game content corresponding to a predetermined type of operation; screening the data streams conforming to a predetermined rule to obtain settlement data streams; and when a game settlement point is monitored, transmitting the settlement data stream to a target client, so that the target client displays game content corresponding to the settlement data stream. According to the embodiment, the game content data processing capacity is effectively improved, and the user game experience is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

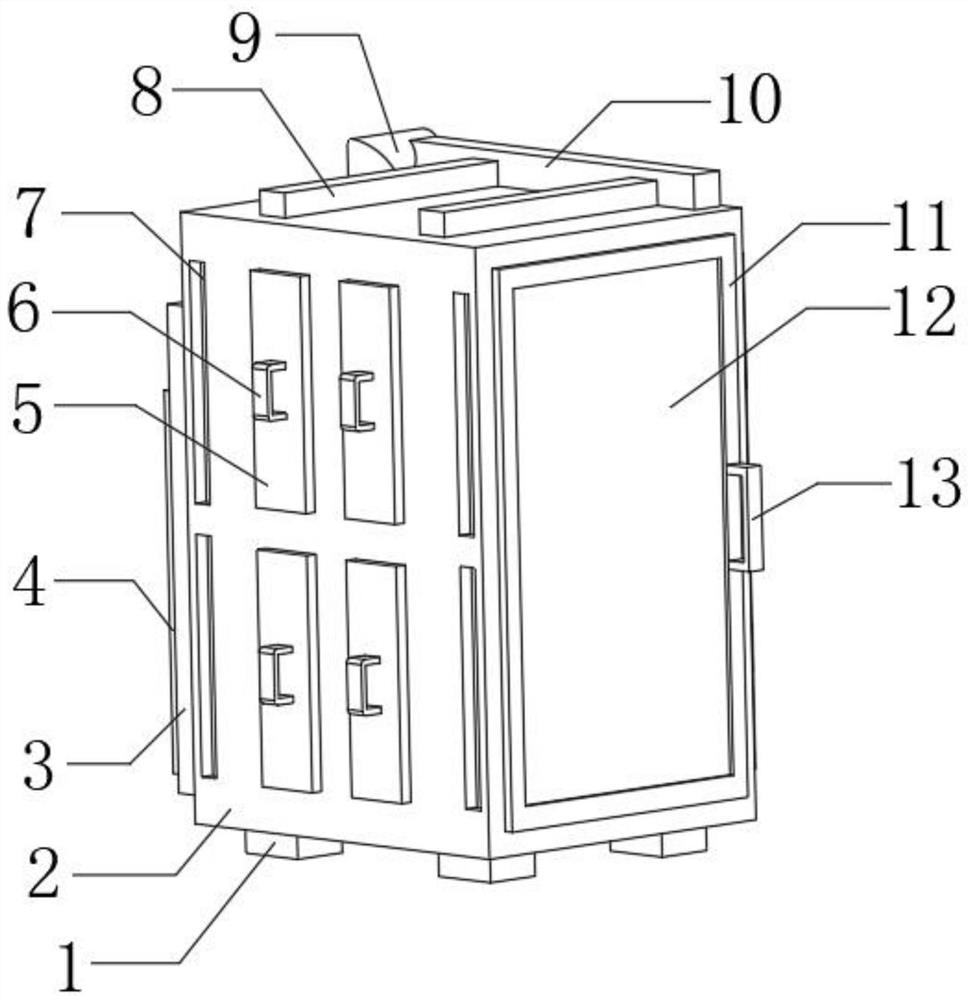

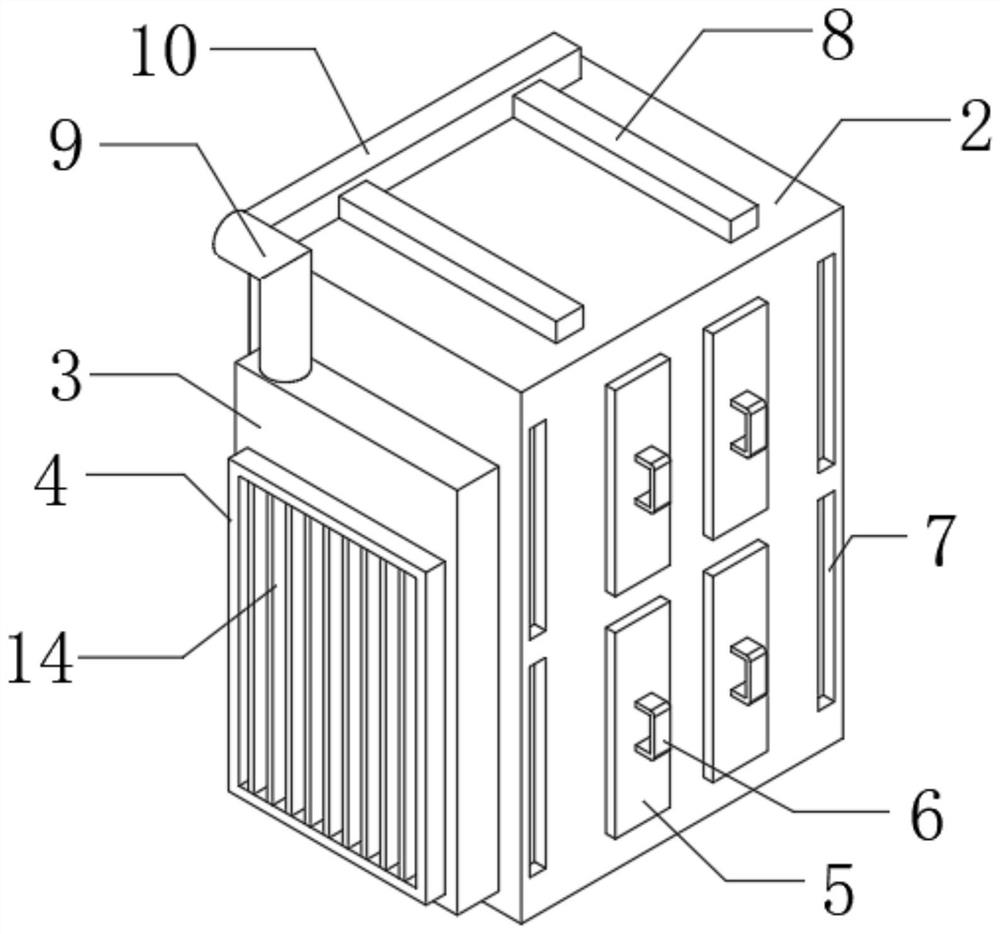

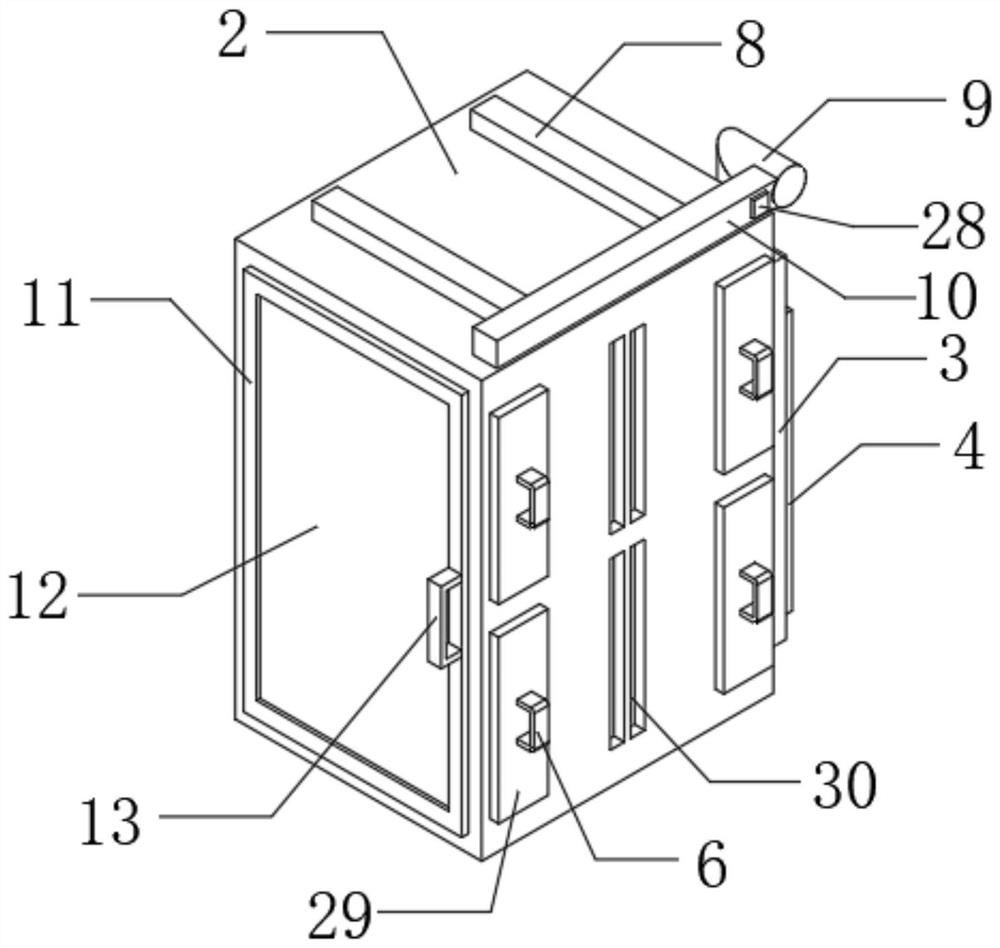

Draw-out type switch cabinet

InactiveCN111682442AFor dust protection and protectionImprove securitySwitchgear with horizontal withdrawalSubstation/switching arrangement cooling/ventilationStructural engineeringMechanics

The invention belongs to the technical field of switch cabinets, especially a draw-out switchgear, and aims at solving the problems that an existing switch cabinet is poor in use safety and inconvenient to use. The cabinet comprises a cabinet body and four supporting pads, the four supporting pads are installed on the outer walls of the four corners of the bottom of the cabinet body through boltsrespectively, four first openings distributed in a rectangular array mode are formed in the outer wall of the middle of one side of the cabinet body, first sealing plates are arranged on the outer walls of one sides of the first openings, and second openings are formed in the outer walls of the four corners of the other side of the cabinet body. In the present invention, according to the draw-outtype switch cabinet, a filter screen block is arranged, so that when air flow exchange is carried out inside and outside the cabinet body, dust filtering treatment can be carried out by the filter screen block, meanwhile, air flow pumped by an air blower can be filtered, the dustproof effect inside the cabinet body is improved, and in addition, the heat dissipation effect inside the cabinet body can be further improved through the arrangement of a heat conduction plate.

Owner:陈春艳

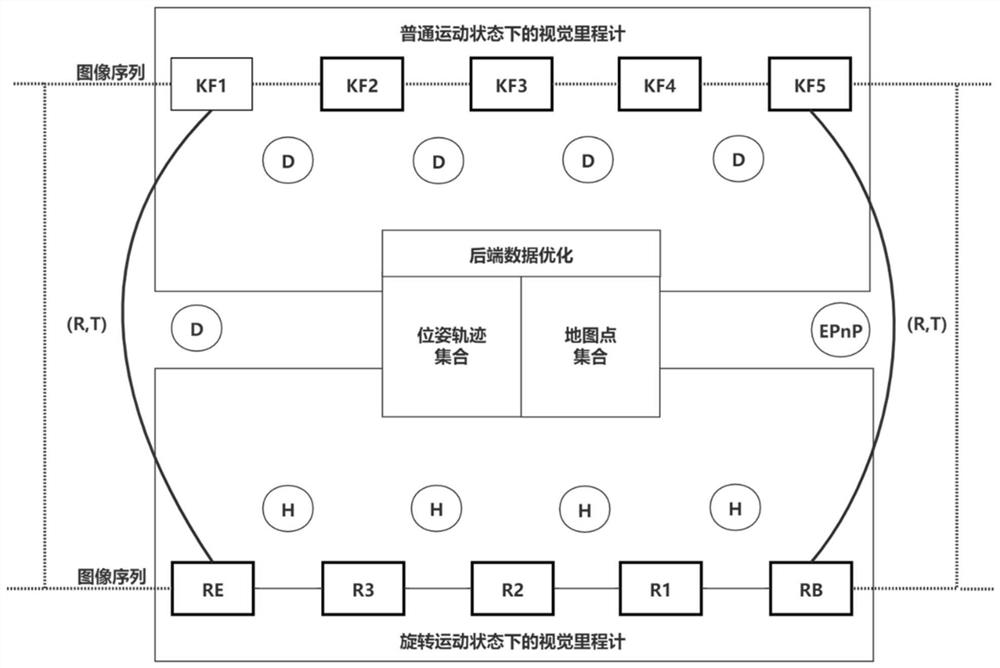

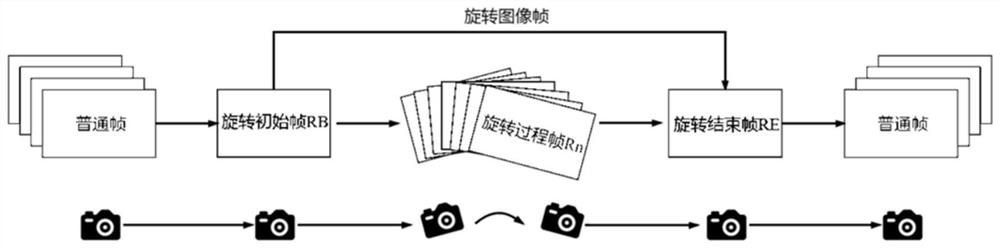

Visual odometer rotational motion processing method based on pause information supplement mechanism

PendingCN111833402AAvoid downtimeEffective sortingImage enhancementImage analysisOdometerComputer graphics (images)

The invention discloses a visual odometer rotational motion processing method based on a pause information supplement mechanism. The method comprises the following steps: step 1, monitoring an image frame and judging the motion category of the image frame; step 2, switching the flow direction of the data flow according to the judgment result in the step 1; dividing the image frames into three types: a rotation initial frame RB, rotation process frames R1, R2,..., Rn and a rotation end frame RE, wherein the rotating initial frame RB is used for inheriting current camera pose information and providing initialization for subsequent frames, the rotation process frames R1, R2,..., Rn are used for integrating the rotation images for calculation, the rotation ending frame RE is used for processing accumulated errors of each rotation and is connected to a common calculation process; step 3, carrying out image frame matching and pose calculation, and completing image processing of camera rotation; performing error optimization processing on the pose calculation result according to the number of the image frames; and step 4, optimizing back-end data.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com