Water-purifying process and water-purifying equipment thereof

A technology of water purification equipment and process, applied in the field of water treatment, can solve the problems of inability to remove harmful substances such as bacteria, unfavorable rupture, easy blockage of filter elements, etc. and environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

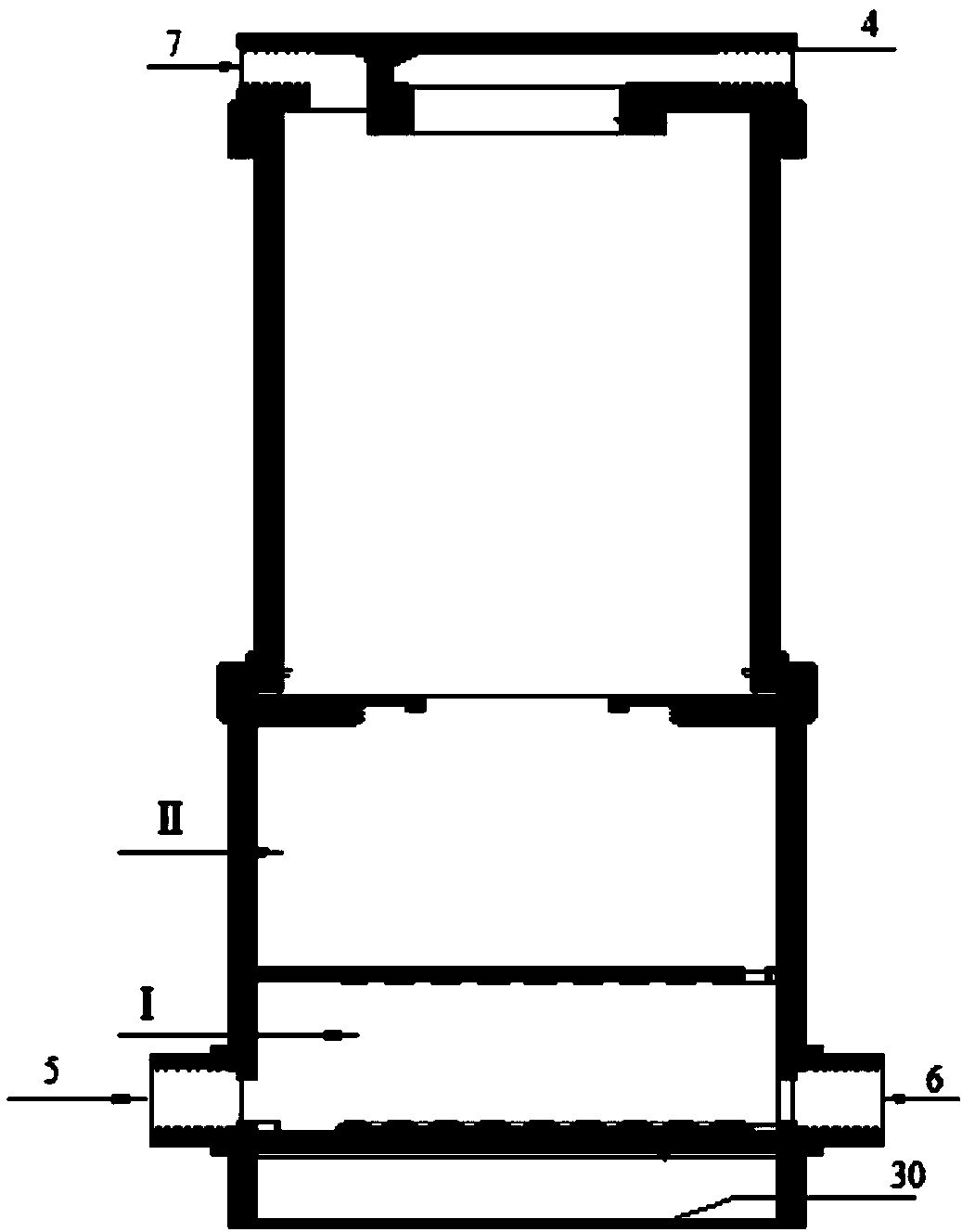

[0042] Such as figure 1 Shown, a kind of water purification process of the present invention comprises the steps:

[0043] (1) The tap water is transported from the tap water inlet 5 to the first-stage purification treatment device I for the first-stage purification treatment to obtain the first-stage purified water and the first-stage residue, and the gained first-stage purified water is carried out in step (2) ), the resulting first-level residue is discharged through the first-level water outlet 6;

[0044] (2) The first-stage purified water obtained in step (1) is transported to the second-stage purification treatment device II for the second-stage purification treatment to obtain the second-stage purified water and the second-stage residue, and the obtained second-stage purified water It is discharged through the second-stage water outlet 7, and the obtained second-stage residue is discharged through the first-stage water outlet 6;

[0045] Wherein, the water discharged...

Embodiment 2

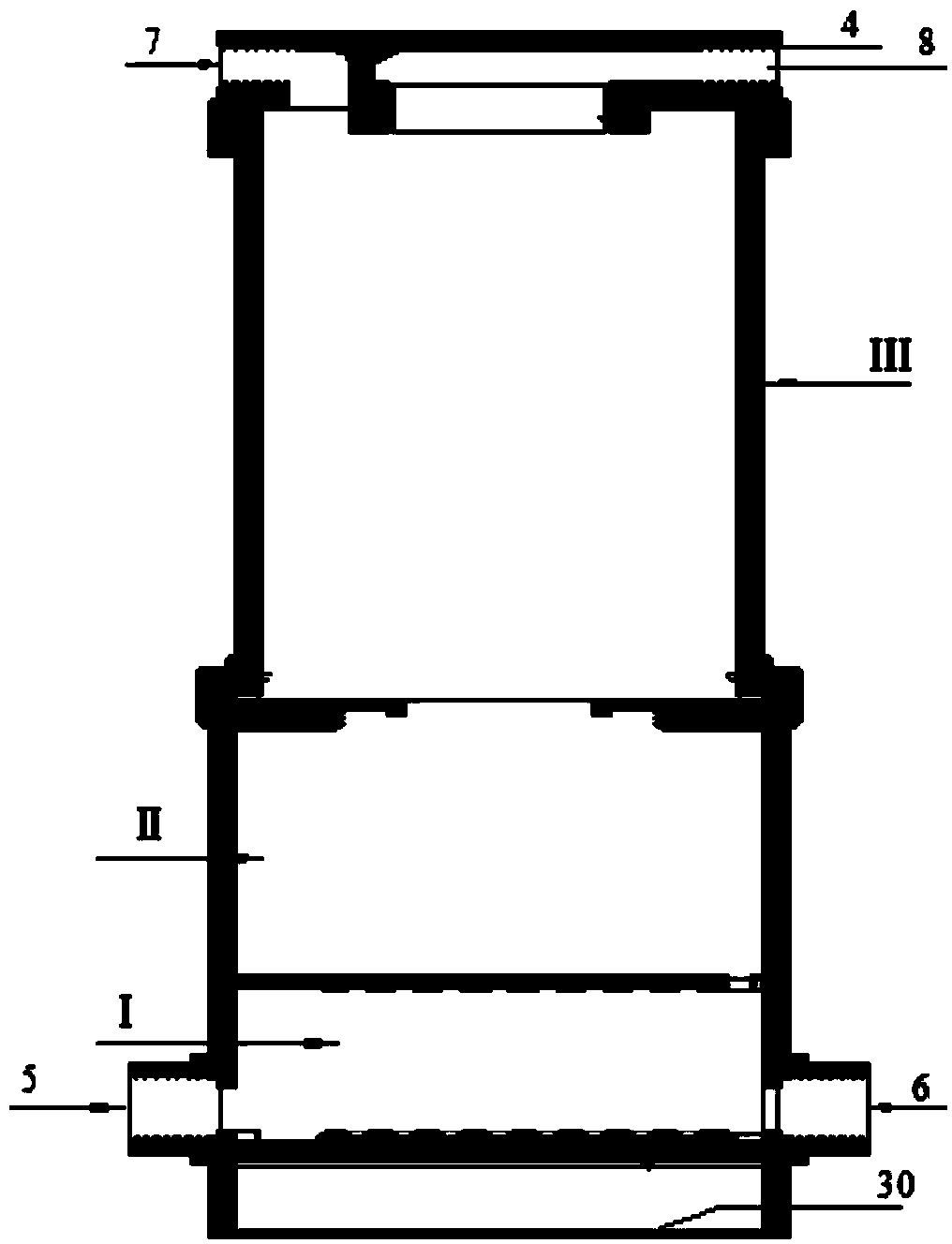

[0050] Such as figure 2 As shown, a kind of water purification process of the present invention, basic steps are the same as embodiment 1, in order to purify tap water more effectively and make it fully meet people's living needs, specifically, comprise the following steps:

[0051] (1) The tap water is transported from the tap water inlet 5 to the first-stage purification treatment device I for the first-stage purification treatment to obtain the first-stage purified water and the first-stage residue, and the gained first-stage purified water is carried out in step (2) ), the resulting first-level residue is discharged through the first-level water outlet 6;

[0052] (2) The first-stage purified water obtained in step (1) is transported to the second-stage purification treatment device II for the second-stage purification treatment to obtain the second-stage purified water and the second-stage residue, and the obtained second-stage purified water It is discharged through th...

Embodiment 3

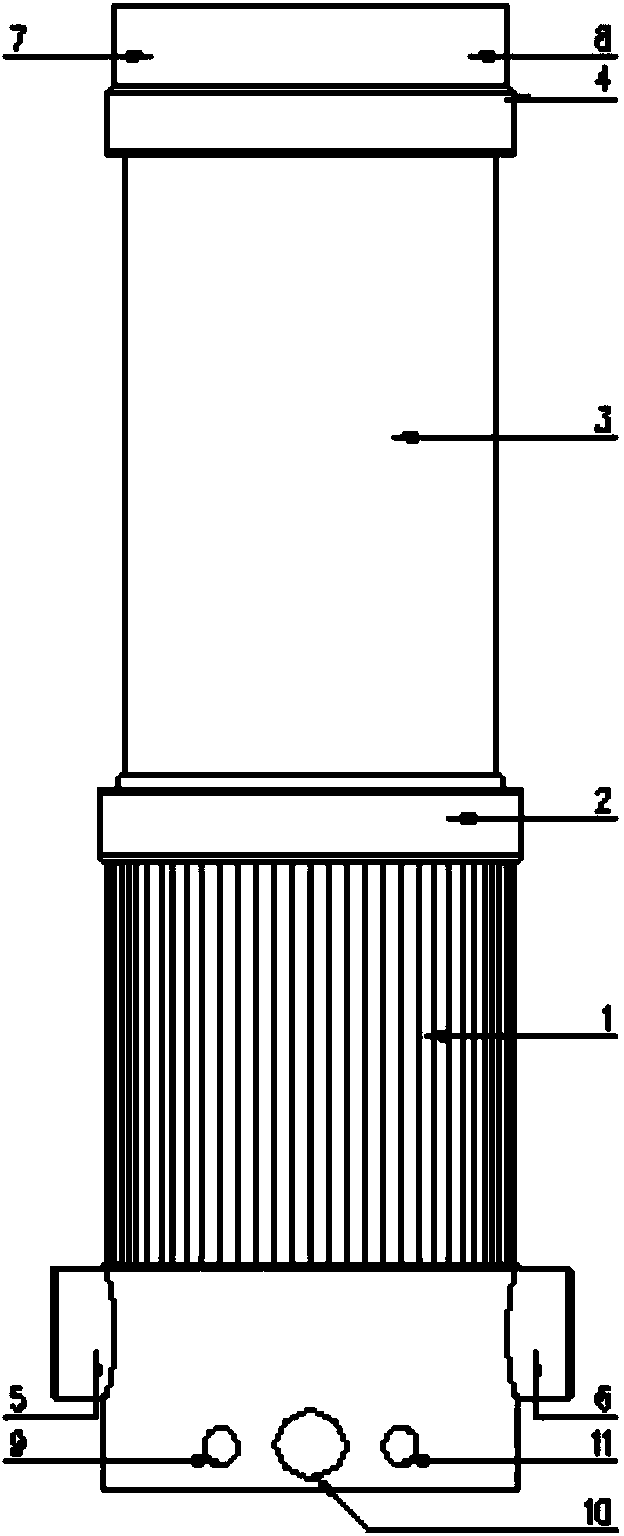

[0059] A kind of water purification process basic step of the present invention is the same as embodiment 1 or 2, specifically, as Figure 4 Shown:

[0060] In step (1), in the first-stage purification treatment process, tap water is sequentially subjected to magnetization treatment, ultraviolet sterilization treatment and slow-flow precipitation treatment to obtain first-stage purified water and first-stage residue;

[0061] In step (2), in the second-stage purification treatment process, the first-stage purified water obtained in step (1) is sequentially subjected to electro-adsorption treatment, first separation and filtration treatment, adsorbent adsorption separation and filtration treatment, second The second-stage purified water and the second-stage residue are obtained after separation and filtration treatment and nutrient improvement treatment;

[0062] In step (3), in the third-stage purification process, the second-stage purified water obtained in step (2) is subje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com