Quality inspection method, device and storage medium based on laser welding

A quality inspection method and laser welding technology, applied in laser welding equipment, welding equipment, neural learning methods, etc., can solve the problems of reducing product accuracy, welding abnormality, and low probability of occurrence, and achieve the effect of improving efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

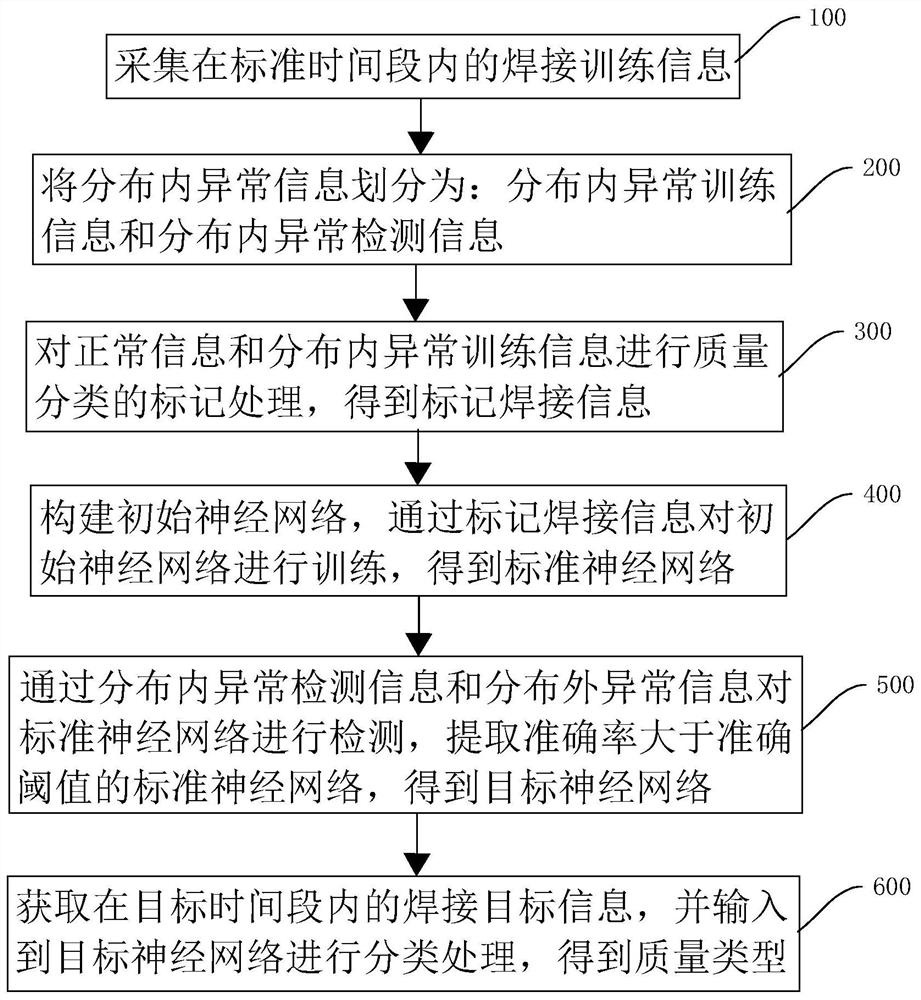

[0035] Such as figure 1 As shown, a quality detection method based on laser welding according to an embodiment of the present invention includes:

[0036] Step S100: Collect welding training information within a standard time period; the welding training information includes: normal information, abnormal information within the distribution, and abnormal information outside the distribution;

[0037] Step S200: Divide the abnormality information in the distribution into: the abnormality training information in the distribution and the abnormality detection information in the distribution;

[0038] Step S300: Perform quality classification marking processing on the normal information and abnormal training information within the distribution to obtain marked welding information;

[0039] Step S400: Construct an initial neural network, train the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com