Kitchen waste pretreatment equipment

A technology for kitchen waste and pretreatment, applied in the direction of grain processing, etc., can solve the problems of harsh working environment, low working efficiency, harmful to the health of workers, etc., and achieve the effect of promoting promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

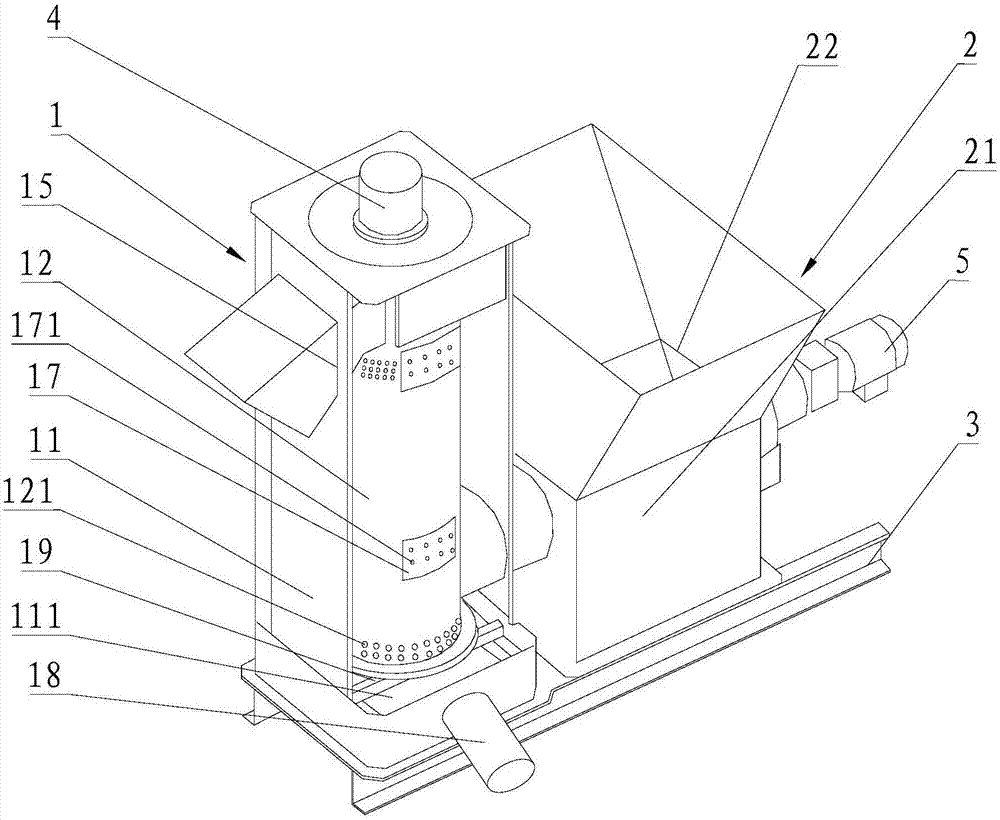

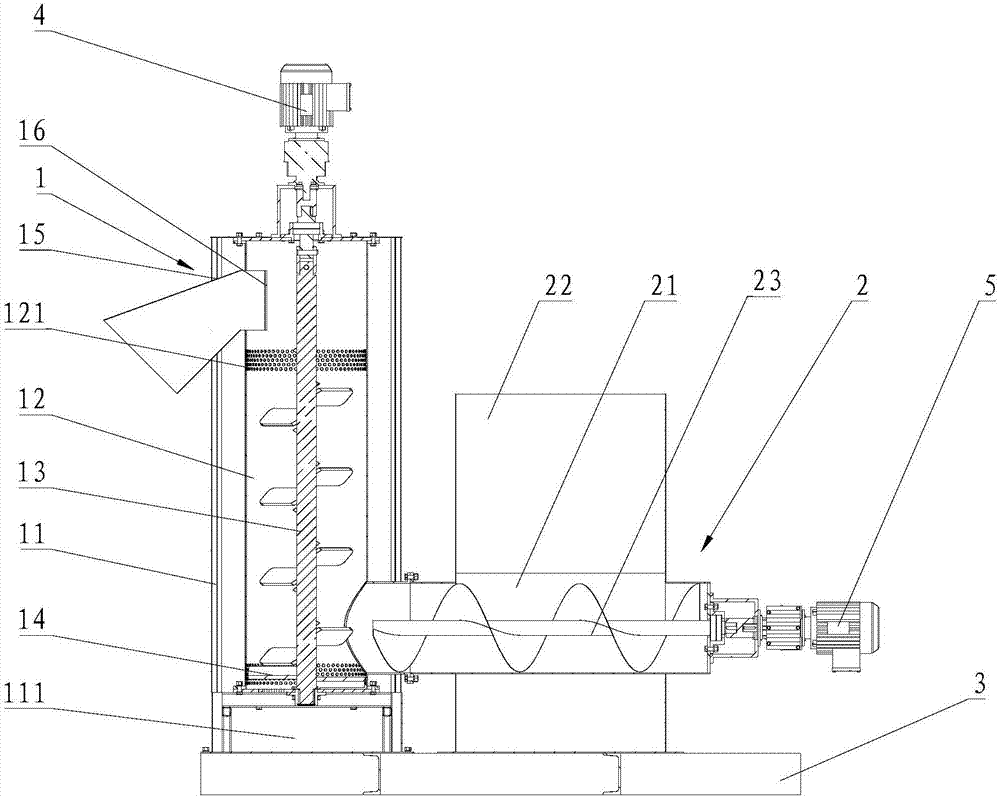

[0053] Please refer to Figure 1-4 , Embodiment 1 of the present invention is:

[0054] A food waste pretreatment equipment, comprising a processing device 1, a feeding device 2, a base 3, a first motor deceleration mechanism 4 and a second motor deceleration mechanism 5, the feeding device 2 and the processing device 1 are respectively arranged on the base 3 on.

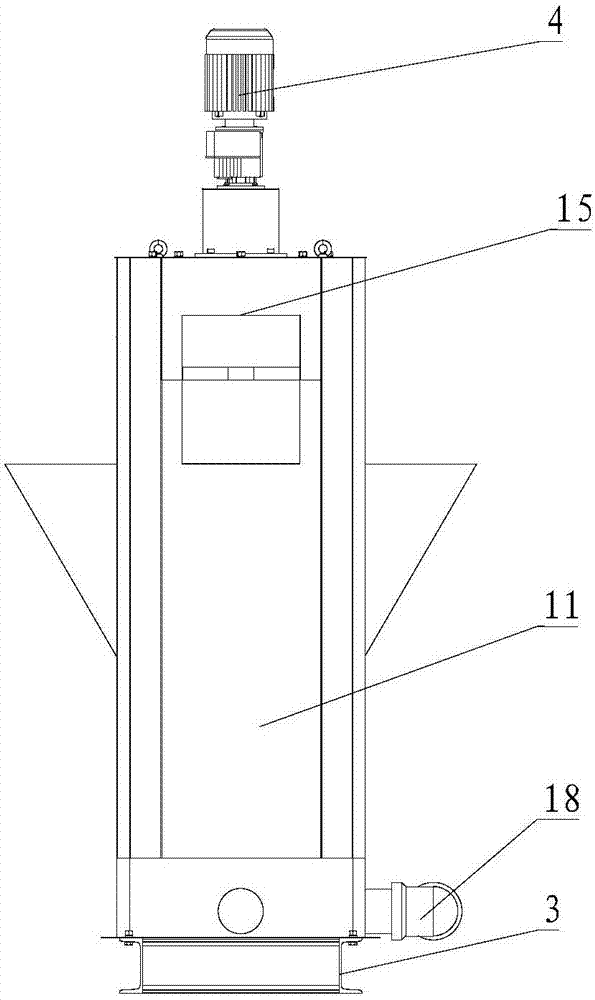

[0055] The processing device 1 comprises a discharge chamber 11, a separation chamber 12, a screw feed member 13, a grinding member 14 and a discharge pipe 18, and the discharge chamber 11 and the separation chamber 12 are columnar structures respectively;

[0056] The discharge chamber 11 is provided with a discharge port 15 , and the bottom of the discharge chamber 11 is provided with a turnover pool 111 , and the discharge pipe 18 communicates with the turnover pool 111 .

[0057] The inner wall of the discharge chamber 11 is provided with a support frame 19, the separation chamber 12 is located on the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com