Integral kitchen waste treatment device

A treatment device and a technology for kitchen waste, applied in grain treatment, multi-stage water treatment, heating water/sewage treatment, etc., can solve problems such as environmental and human health hazards, inability to realize waste reuse, non-compliance with sewage discharge requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

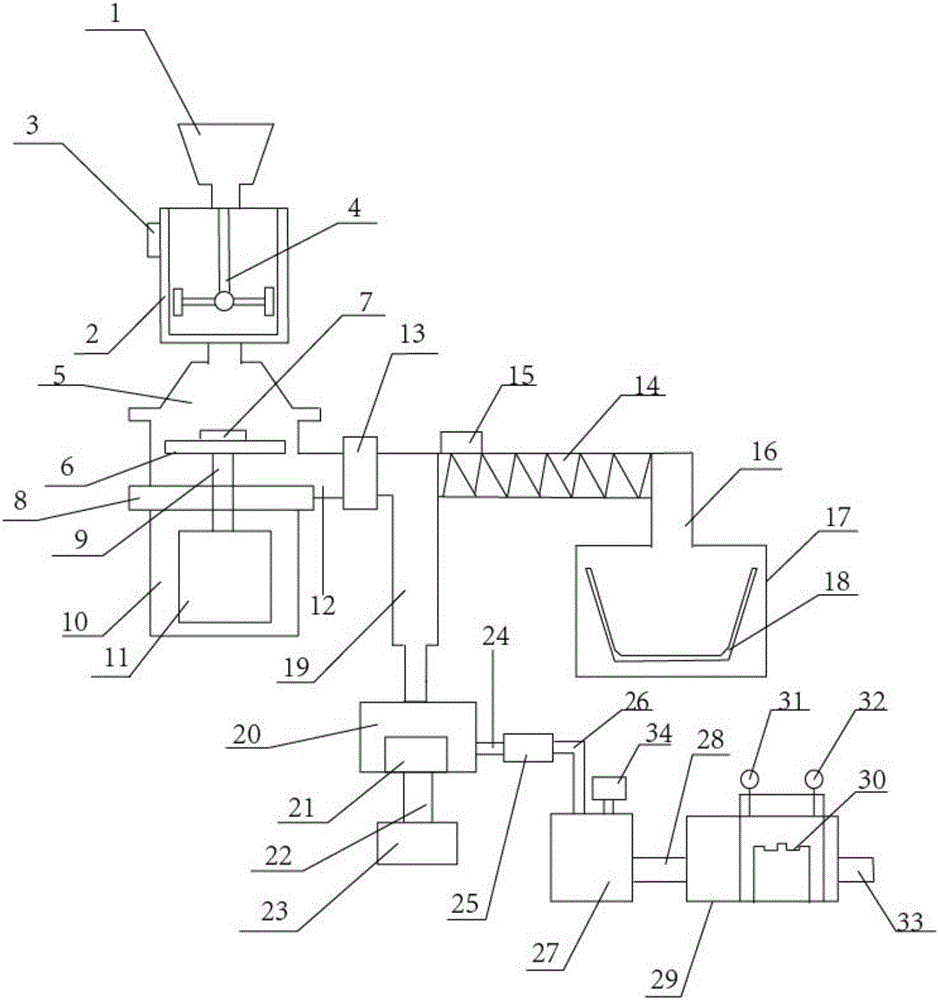

[0022] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

[0023] Such as figure 1As shown, an integrated kitchen waste treatment device includes: a feed inlet 1, a first crushing chamber 2, a first motor 3, a crushing device 4, a second crushing chamber 5, a crushing rotating plate 6, a fixed blade 7, Diaphragm 8, rotating shaft 9, motor cavity 10, second motor 11, first discharge pipe 12, solid-liquid separator 13, screw conveyor 14, third motor 15, second discharge pipe 16, storage box 17. Material storage vessel 18, first water outlet pipe 19, separation box 20, oil-water separator 21, oil outlet pipe 22, grease storage tank 23, first communication pipe 24, heat exchanger 25, second communication pipe 26, adjustment pool 27. The third connecting pipe 28, heating box 29, electric heating pipe 30, temperature sensor 31, liquid level gauge 32, second water outlet pipe 33 and dosing devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com