Cleaning device for intermediate bulk container for liquid chemicals

A cleaning device and chemical technology, applied in the direction of chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of increased energy consumption, inconvenience, and increased amount of cleaning waste liquid in drying treatment, and achieve a reduction in tons Drum loading and unloading operations, improvement of processing efficiency, and reduction in usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

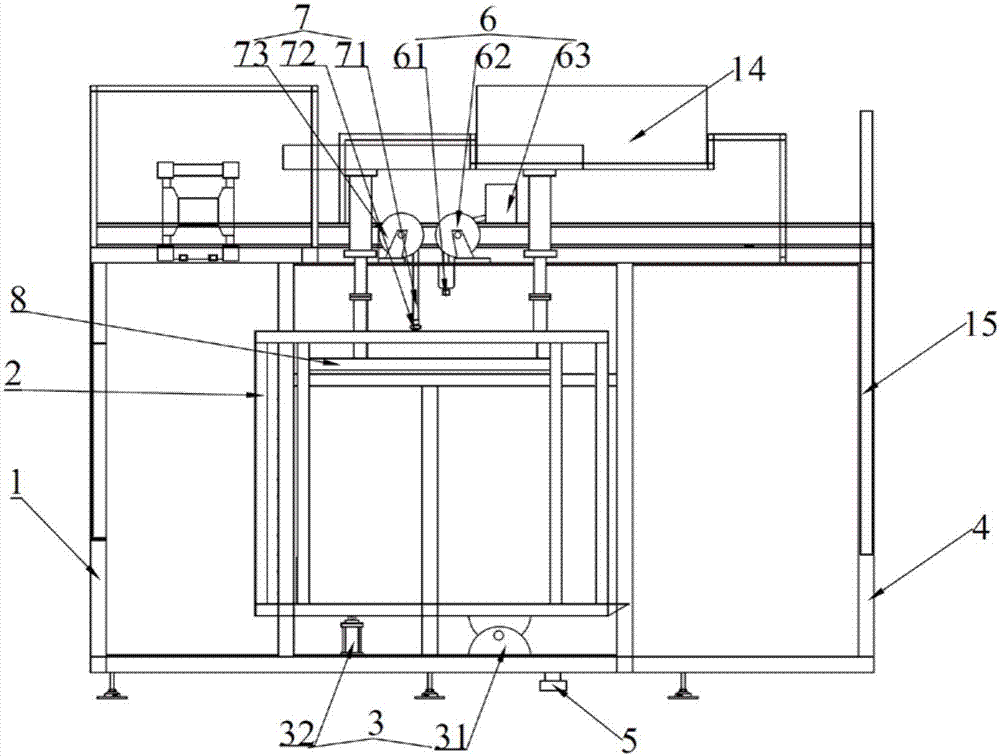

[0033] Such as figure 1 As shown, the liquid chemical ton barrel cleaning device in Example 1 includes a cleaning chamber 1, a barrel loading frame 2 and a turning mechanism 3. One side of the cleaning chamber 1 is provided with a ton barrel inlet and outlet 4, and the bottom end is provided with a cleaning waste liquid Outlet 5, the turning mechanism is used to drive the barrel frame 2 to turn over in the inner cavity of the cleaning chamber 1, and the cleaning chamber 1 is provided with a barrel pumping component 6 and a barrel inner wall cleaning component 7 matched with the barrel frame 2. The bucket frame is provided with a limit piece matched with the tote bucket.

[0034] In Embodiment 1, the overturning mechanism 3 is arranged below the barrel frame 2, and the barrel frame 2 is connected to the hinge 31 below, and an oil cylinder 32 is arranged between the bottom of the barrel frame 2 and the bottom surface of the cleaning chamber (for driving the barrel The frame rot...

Embodiment 2

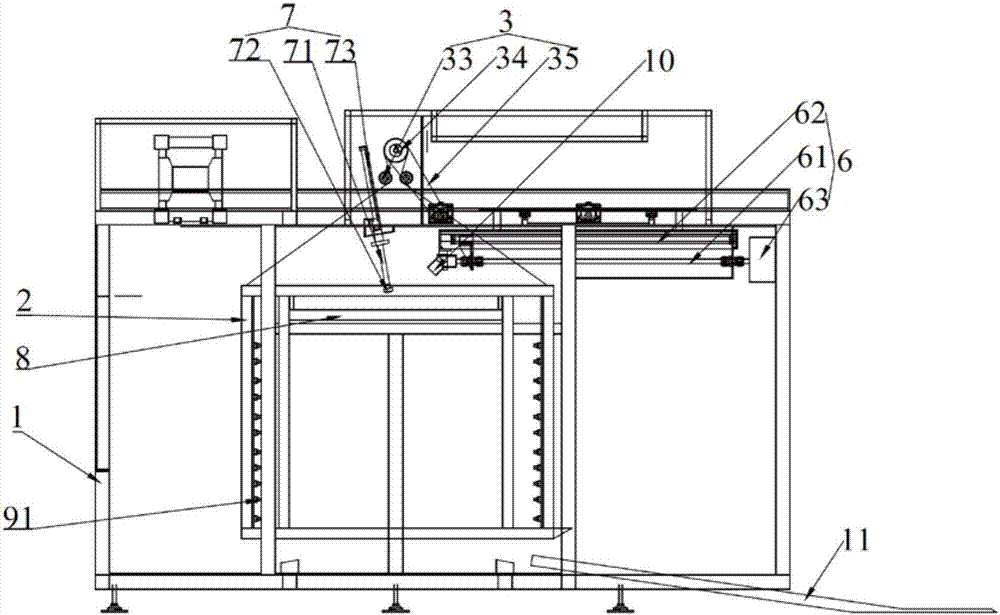

[0041] Such as figure 2 As shown, the difference between embodiment 2 and embodiment 1 is that the turning mechanism 3 includes a transmission assembly and a drive motor 34, the transmission assembly is a pulley 35 pulley 33 mechanism, and at least three Click to connect. Concrete, among the embodiment 2, PVC traction rope 35 is connected with the top four corners of bucket frame 2.

[0042] The suction pipe retractable mechanism 62 and the cleaning liquid pipe lifting mechanism 73 are all rodless cylinders.

[0043] The cleaning chamber of embodiment 2 is also provided with a barrel outer wall cleaning assembly 9, which is an outer wall spray head 91 fixedly connected to the vertical pillar of the barrel carrying frame.

[0044] The liquid suction pipe is a corrugated pipe, and the liquid suction assembly in the barrel also includes a guide ring 10, which is sleeved on the periphery of the liquid suction pipe 61, and is fixedly connected between the guide ring 10 and the l...

Embodiment 3

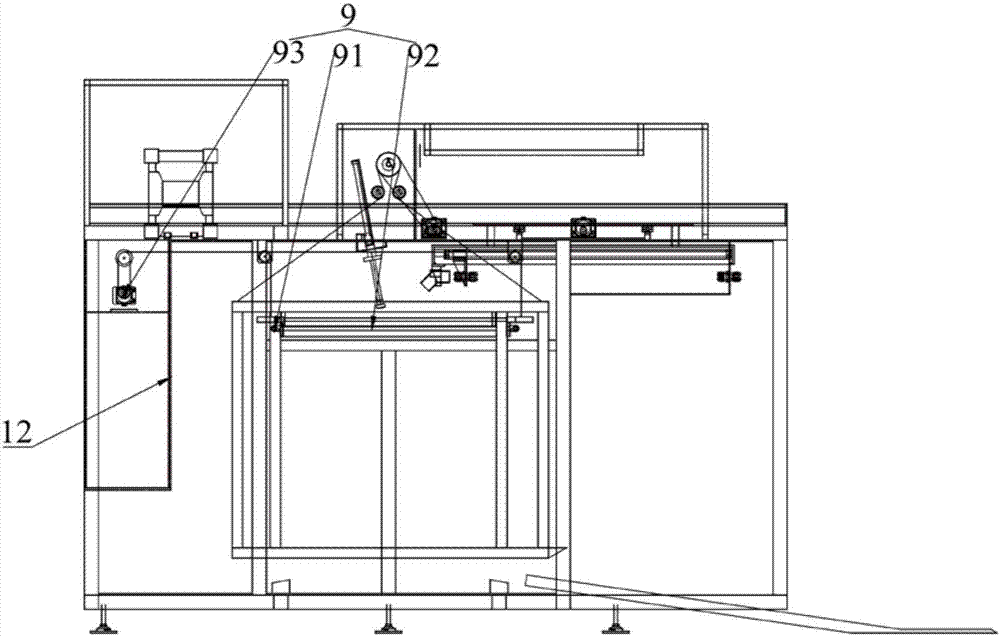

[0048] Such as Figure 3-5 As shown, the difference between embodiment 3 and embodiment 2 is that the barrel outer wall cleaning assembly includes an outer wall nozzle 91, a cage 92 and a cage lifting mechanism 93, and the outer wall nozzle 91 is fixedly arranged on the inner surface of the cage 92, and the cage 92 uses It is sleeved on the outer periphery of the tonnage and has a spray gap with the outer surface of the tonneau. Cage lifting mechanism 93 adopts the structure of PVC traction rope and motor-driven sheave equally.

[0049] A corrosion-resistant interlayer 12 is provided on the inner surface of the cleaning chamber 1 and the outer surface of the bucket frame 2 .

[0050] Three pumping units are arranged in the liquid pumping assembly in the barrel, and each liquid pumping unit includes a liquid pumping tube 61 , a liquid pumping tube retractable mechanism 62 and a liquid pumping pump 63 . The above three pumping units are respectively used for pumping hydrofluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com