Wool jetting machine

A technology of hair spraying machine and top, which is applied in textiles, papermaking, yarn, etc. It can solve the problems of excessive hair loss, increased hair loss rate, and poor output, so as to ensure a clean environment, reduce manufacturing costs, and prevent hair loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

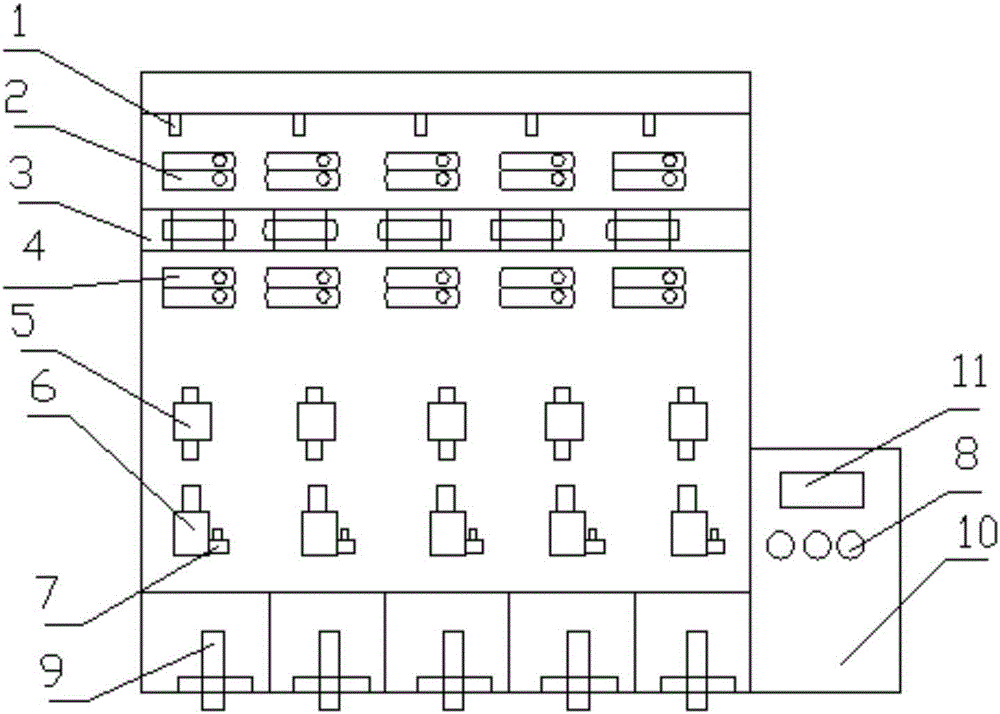

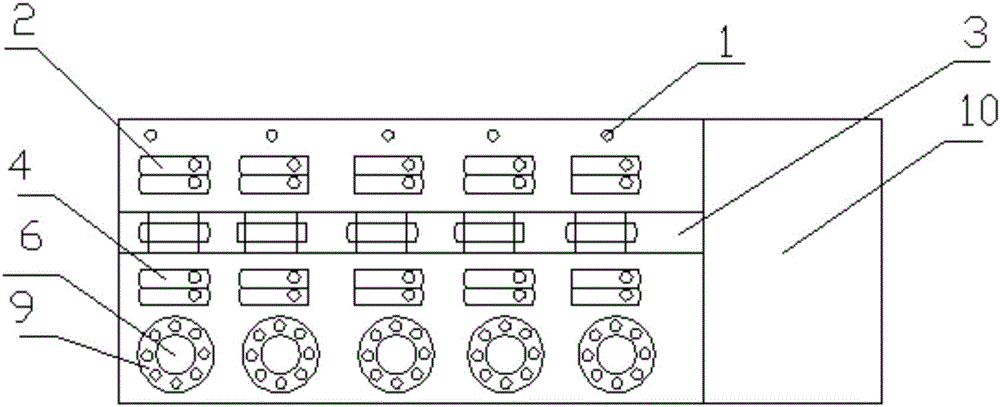

[0019] Such as figure 1 with figure 2 The hair spraying machine shown includes wool top card position 1, pressure wheel 2, air bubble pressure wheel 3, fiber sheath wheel 4, negative pressure generator 5, needle cylinder 6, motor 7, control switch 8, yarn receiving rod 9, frequency conversion The control box 10 and the display panel 11, the top clamping position 1, the pressure wheel 2, the air bubble pressure wheel 3, the fiber wheel 4, the negative pressure generator 5, the needle cylinder 6, and the yarn receiving rod 9 are arranged on the hair spraying machine from top to bottom On the frame; Motor 7 is provided with belt and is connected with syringe 6; Frequency conversion control box 10 is arranged on the frame side position of hair spraying machine;

[0020] The working process of the above hair spraying machine is as follows:

[0021] (1) Clamp the purchased wool tops on the wool top card position 1, and extend the carded wool tops to the middle of the strip feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com